Abstract

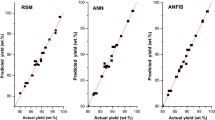

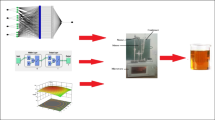

This study conducted experiments used for the development of both the regression model with uncertainty analysis and the adaptive neuro-fuzzy inference system (ANFIS) model for the prediction of the yield of biodiesel (YB) produced from castor oil in the presence of calcium oxide derived from the eggshell. Box Behnken design (BBD) was used to develop the experimental condition for five different variables while YB was the response. Uncertainty analysis was determined from Monte Carlo simulation (MCS). The model was optimized and validated before the generated data was applied in the three ANFIS modelling techniques. Root mean square error (RMSE), coefficient of correlation (R2) and average percentage error (APE) were used to determine the accuracy of the models developed. The result of this modelling shows that the optimum YB (94.29%) was achieved at a methanol to oil ratio of 11.48, catalyst loading of 3.38 wt%, reaction time of 1.84 h, the temperature of 60.2 °C, and agitation of 343.5 rpm. The prediction from BBD, ANFIS and MCS agreed that the methanol to oil ratio was the most important parameter for investigation. The considered ANFIS model technique (subtractive clustering) for the modelling of YB outperformed BBD model. The novelty of this study are the determination of the optimum condition for the transesterification of castor oil in the presence of thermally treated anthill, the establishment of the use of ANFIS in modelling YB, the prediction of the influence of variables on YB using both statistical and, AI techniques and validation of the predictions from the two methods using MCS.

Similar content being viewed by others

Change history

13 September 2022

A Correction to this paper has been published: https://doi.org/10.1007/s43393-022-00132-5

References

Arshad M, Zia MA, Shah FA. Perspectives on water usage for biofuels production. In: Arshad M (ed) An overview of biofuel. Springer International Publishing; 2018.

Romano SD, Sorichetti PA. Dielectric spectroscopy in biodiesel production and characterization. Green Energy Technol. 2011. https://doi.org/10.1007/978-1-84996-519-4.

Balat M. Potential alternatives to edible oils for biodiesel production—a review of current work. Energy Convers Manage. 2011;52(2):1479–92. https://doi.org/10.1016/j.enconman.2010.10.011.

Patel VR, Dumancas GG, Viswanath LCK, Maples R, Subong BJJ. Castor oil: properties, uses, and optimization of processing parameters in commercial production. Lipid Insights. 2016;9:1-12.https://doi.org/10.4137/LPI.S40233.TYPE.

Sánchez N, Encinar JM, Nogales S, González JF. Biodiesel production from castor oil by two-step catalytic transesterification: optimization of the process and economic assessment biodiesel production from castor oil by two-step catalytic transesterification: optimization of the process and economic. Catalysts. 2019;9:1–16. https://doi.org/10.3390/catal9100864.

Sánchez N, Sánchez R, Encinar JM, González JF, Martínez G. Complete analysis of castor oil methanolysis to obtain biodiesel. Fuel. 2015;147:95–9. https://doi.org/10.1016/j.fuel.2015.01.062.

Marwaha A, Rosha P, Kumar S, Kumar S. Biodiesel production from Terminalia bellerica using eggshell-based green catalyst: an optimization study with response surface methodology. Energy Rep. 2019;5:1580–8. https://doi.org/10.1016/j.egyr.2019.10.022.

Asri NP, Podjojono B, Fujiani R, Nuraini N. Utilization of eggshell waste as low-cost solid base catalyst for biodiesel production from used cooking oil. IOP Conf Ser Earth Environ Sci. 2017. https://doi.org/10.1088/1755-1315/67/1/012021.

Rashid IM, Atiya MA, Hameed BH. Production of biodiesel from waste cooking oil using cao-egg shell waste derived heterogeneous catalyst. IJSR. 2017;6(11):94–103. https://doi.org/10.21275/ART20177723.

Oke EO, et al. Heterogeneously catalyzed biodiesel production from Azadiricha indica oil : predictive modelling with uncertainty quantification, experimental optimization and techno-economic analysis. Bioresour Technol. 2021;332:1–11. https://doi.org/10.1016/j.biortech.2021.125141.

Obayomi KS, Bello JO, Ogundipe TA, Olawale O. Extraction of castor oil from castor seed for optimization of biodiesel production. IOP Conf Earth Environ Sci. 2020;445:1–12. https://doi.org/10.1088/1755-1315/445/1/012055.

Thirugnanasambandham K, Shine K, Agatheeshwaren A, Sivakumar V. Environmental effects biodiesel production from castor oil using potassium hydroxide as a catalyst: simulation and validation. Energy Sources Part A Recover Util Environ Eff. 2016;38(19):2898–905. https://doi.org/10.1080/15567036.2016.1179363.

Banerjee A, Varshney D, Kumar S, Chaudhary P, Gupta VK. Biodiesel production from castor oil: ANN modeling and kinetic parameter estimation. Int J Ind Chem. 2017. https://doi.org/10.1007/s40090-017-0122-3.

Banerjee A, Varshney D, Kumar S, Chaudhary P, Gupta VK. Biodiesel production from castor oil : ANN modeling and kinetic parameter estimation. Int J Ind Chem. 2017;8(3):253–62. https://doi.org/10.1007/s40090-017-0122-3.

Betiku E, Okunsolawo SS, Ajala SO, Odedele OS. Performance evaluation of arti fi cial neural network coupled with generic algorithm and response surface methodology in modeling and optimization of biodiesel production process parameters from shea tree (Vitellaria paradoxa) nut butter. Renew Energy. 2015;76:408–17. https://doi.org/10.1016/j.renene.2014.11.049.

Badday AS, Abdullah AZ, Lee K. Chemical engineering and processing: process intensification artificial neural network approach for modeling of ultrasound-assisted transesterification process of crude Jatropha oil catalyzed by heteropolyacid based catalyst. Chem Eng Process Process Intensif. 2014;75:31–7. https://doi.org/10.1016/j.cep.2013.10.008.

R. D. Pereira, A. C. Badino, and A. J. G. Cruz, “Framework Based on Arti fi cial Intelligence to Increase Industrial Bioethanol Production,” 2020, doi: https://doi.org/10.1021/acs.energyfuels.0c00033.

Hesami M, Naderi R, Tohidfar M, Yoosefzadeh-Najafabadi M. Application of adaptive neuro-fuzzy inference system-non-dominated sorting genetic algorithm-II (ANFIS-NSGAII) for modeling and optimizing somatic embryogenesis of chrysanthemum. Front Plant Sci. 2019;10(July):1–12. https://doi.org/10.3389/fpls.2019.00869.

Dzakpasu M, Scholz M, McCarthy V, Jordan S, Sani A. Adaptive neuro-fuzzy inference system for real-time monitoring of integrated-constructed wetlands. Water Sci Technol. 2015;71(1):22–30. https://doi.org/10.2166/wst.2014.461.

Tanyildizi H, Özcan F, Atis CD, Karahan O, Uncuog E. Comparison of artificial neural network and fuzzy logic models for prediction of long-term compressive strength of silica fume concrete. Adv Eng Softw. 2009;40:856–63. https://doi.org/10.1016/j.advengsoft.2009.01.005.

Alalaya MM, Al Rawashdeh HA, Alkhateb A. Combination method between fuzzy logic and neural network models to predict amman stock exchange. Open J Bus Manag. 2018;6:632–50. https://doi.org/10.4236/ojbm.2018.63048.

Mpallas L, Tzimopoulos C, Evagelides C. Comparison between neural networks and adaptive neuro-fuzzy inference system in modeling lake kerkini water level fluctuation lake management using artificial intelligence. J Environ Sci Technol. 2011;4(4):366–76.

Aransiola EF, Betiku E, Ikhuomoregbe DIO, Ojumu TV. Production of biodiesel from crude neem oil feedstock and its emissions from internal combustion engines. Afr J Biotechnol. 2012;11(22):6178–86. https://doi.org/10.5897/AJB11.2301.

Ismail S, Ahmed AS, Anr R, Hamdan S. Biodiesel production from castor oil by using calcium oxide derived from mud clam shell. J Renew Energy. 2016; Article ID 5274917.

Jeong G-T, Park D-H. Optimization of biodiesel production from castor oil using response surface methodology. Appl Biochem Biotechnol. 2009;156:431–41. https://doi.org/10.1007/s12010-008-8468-9.

Wong YC, Ang RX. Study of calcined eggshell as potential catalyst for biodiesel formation using used cooking oil what is so different about was ist so anders am neuroenhancement ? Open Chem. 2018;16:1166–75.

Yusuff AS. Characterization of alkaline modified anthill and investigation of its catalytic behaviour in transesterification of Chrysophyllum albidium seed oil. South Afr J Chem Eng. 2019;29(May):24–32. https://doi.org/10.1016/j.sajce.2019.05.001.

ASTMD445-21. Standard test method for kinematic viscosity of transparent and opaque liquids (and calculation of dynamic viscosity). 2021.

ASTM D1298-12b. Standard test method for density, relative density, or API gravity of crude petroleum and liquid petroleum products by hydrometer method. West Conshohocken: ASTM International; 2017.

ASTM D3828-16a. Standard test methods for flash point by small scale closed cup tester. 2021.

ASTM D5555-95. Standard test method for determination of free fatty acids contained in animal, marine, and vegetable fats and oils used in fat liquors and stuffing compounds. 2017.

ASTM D5558-95. Standard test method for determination of the saponification value of fats and oils. 2017.

ASTM E1252-98. Standard practice for general techniques for obtaining infrared spectra for qualitative analysis. 2021.

ASTM D3663-20. Standard test method for surface area of catalysts and catalyst carriers. 2020.

ASTM D5381-93. Standard guide for X-ray fluorescence (XRF) spectroscopy of pigments and extenders. 2021.

ASTMD97-17b, Standard test method for pour point of petroleum products. 2017.

Oke EO, et al. Techno-economic analysis and neuro-fuzzy production rate prediction of sorghum (Sorghum bicolor) leaf shealth colourant extract production. Agric Res. 2021. https://doi.org/10.1007/s40003-021-00596-2.

Ghadge SV, Raheman H. Process optimization for biodiesel production from mahua (Madhuca indica) oil using response surface methodology. Bioresour Technol. 2006;97(3):379–84. https://doi.org/10.1016/j.biortech.2005.03.014.

Panhwar T, Mahesar SA, Kandhro AA, Sheerazi ST, Kori A, Laghari ZH, Memon J. Physicochemical composition and FTIR characterization of castor seed oil. Food Technol. 2019;8(4):778–87. https://doi.org/10.24263/2304-974X-2019-8-4-9.

Awogbemi O, Inambao F, Onuh EI. Modification and characterization of chicken eggshell for possible catalytic applications. Heliyon. 2020;6(10): e05283. https://doi.org/10.1016/j.heliyon.2020.e05283.

Muhdarina N, Linggawati A, Anita S, Amri TA. Preparation and characterization of calcium oxide heterogeneous catalyst derived from anadara granosa shell for biodiesel synthesis. In: KnE EngineeringICoSE conference on instrumentation, environment and renewable energy. 2015. p. 1–8. https://doi.org/10.18502/keg.v1i1.494.

Ayodeji AA, Ojewumi ME, Rasheed B, Ayodele JM. Data on CaO and eggshell catalysts used for biodiesel production. Data Br. 2018;19:1466–73. https://doi.org/10.1016/j.dib.2018.06.028.

Hoogsteen MJJ, Lantinga EA, Bakker EJ, Tittonell PA. An evaluation of the loss-on-ignition method for determining the soil organic matter content of calcareous soils. Commun Soil Sci Plant Anal. 2018;49(13):1541–52. https://doi.org/10.1080/00103624.2018.1474475.

Ngayakamo BH, Bello A, Onwualu AP. Development of eco-friendly fired clay bricks incorporated with granite and eggshell wastes. Environ Challenges. 2020;1:100006. https://doi.org/10.1016/j.envc.2020.100006.

Mumtaz MW, et al. Response surface methodology: an emphatic tool for optimized biodiesel production using rice bran and sunflower oils. Energies. 2012;5:3307–28. https://doi.org/10.3390/en5093307.

Daniyan IA, Bello EI, Ogedengbe TI, Mogaji PB. Gas chromatography and Fourier transform infrared analysis of biodiesel from used and unused palm olein oil. Int J Eng Res Afr. 2019;42:47–64. https://doi.org/10.4028/www.scientific.net/JERA.42.47.

Elkady MF, Zaatout A, Balbaa O. Production of biodiesel from waste vegetable Oil via KM micromixer. J Chem. 2015; Article ID: 630168.

Ayoola AA, Hymore KF, Omonhinmin CA. Optimization of biodiesel production from selected waste oils using response surface methodology. Biotechnology. 2017;16:1–9. https://doi.org/10.3923/biotech.2017.1.9.

Amalia S, Khalifah SN, Baroroh H, Muiz A. Biodiesel production from castor oil using heterogeneous catalyst KOH/zeolite of natural zeolite Bandung Indonesia. AIP Conf Proc 2120. 2019;080016:3–10.

Nakarmi A, Joshi S. A study on castor oil and its conversion into biodiesel by transesterification method. Nepal J Sci Technol. 2015;15(1):45–52.

Funding

The authors declare that no funds, grants, or other support were received during the preparation of this manuscript.

Author information

Authors and Affiliations

Contributions

KAB and KKS conceived and designed the frame work of this study. Laboratory experiments were conducted by OAA, OAO-A and SOA. Data analysis was implemented by SKK and TDO. The first draft was written by KKS, KAB and TDO. All the authors read and commented on the first draft. This manuscript was approved by all the authors.

Corresponding author

Ethics declarations

Conflict of interest

The authors have no relevant financial or non-financial interests to disclose.

Additional information

The author names Olufunmilayo A. Aworanti and Olusesan A. Olu-Arotiowa were incorrectly given as Olufunmilola A. Aworanti and Olu-Olusesan A. Arotiowa respectively.

Rights and permissions

Springer Nature or its licensor holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Babatunde, K.A., Salam, K.K., Aworanti, O.A. et al. Transesterification of castor oil: neuro-fuzzy modelling, uncertainty quantification and optimization study. Syst Microbiol and Biomanuf 3, 669–680 (2023). https://doi.org/10.1007/s43393-022-00120-9

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s43393-022-00120-9