Abstract

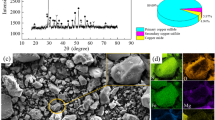

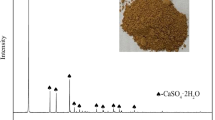

In recent years, a new process for leaching scheelite concentrates with sulfur-phosphorus mixed acid has been successfully industrialized. This process suffers from the elimination of the retarding effect of calcium sulfate, the selective extraction of tungsten from the H3PW12O40-H2SO4-H3PO4 mixture solution, and the removal of introduced phosphorus. Therefore, in this paper, we investigated the inhibition measures of a calcium sulfate-blocking membrane, the selective extraction of tungsten by ion exchange, and the removal of phosphorus by the magnesium ammonium salt method. The results showed that the addition of calcium sulfate whisker seeds and a higher H3PO4 concentration inhibited spontaneous diffuse nucleation, promoted crystal growth, and avoided the formation of a dense blocking film. About 98 wt.% of the scheelite concentrate was digested by H2SO4-H3PO4. The selective adsorption of PW12O403− was realized using D301 resin, and the extraction efficiency of tungsten exceeded 99.9%. After desorption with ammonia water, PW12O403− was depolymerized into WO42− and PO43−. 99.9 wt.% of phosphorus was removed in the form of MgNH4PO4 by the magnesium ammonium salt method, and the residual phosphorus concentration in the solution was lower than 10 mg·L−1. After purification, the highest-grade ammonium paratungstate product was prepared by evaporative crystallization.

Similar content being viewed by others

Data availability

The data generated during and/or analysed in this article are available from the corresponding author on reasonable request.

References

Richard S, James TB, Brian GC, David LA, Kyle B. Critical materials- present danger to U.S. manufacturing. Santa Monica: RAND Corporation Publisher. 2013: 5.

Johansson O, Pamidi T, Shankar V. Extraction of tungsten from scheelite using hydrodynamic and acoustic cavitation. Ultrason Sonochem. 2021;71: 105408. https://doi.org/10.1016/j.ultsonch.2020.105408.

Liu QS, Tu T, Guo H, Cheng HJ, Wang XZ. Complexation extraction of scheelite and transformation behaviour of tungsten-containing phase using H2SO4 solution with H2C2O4 as complexing agent. T Nonferr Metal Soc. 2021;31(10):3150. https://doi.org/10.1016/S1003-6326(21)65724-2.

Lassner E, Schubert WD. Tungsten: properties, chemistry, technology of the element, alloys, and chemical compounds. New York: Kluwer Academic/Plenum Publishers. 1999: 159.

Lei YT, Sun FL, Liu XH, Zhao ZW. Understanding the wet decomposition processes of tungsten ore: Phase, thermodynamics and kinetics. Hydrometallurgy. 2022;213: 105928. https://doi.org/10.1016/j.hydromet.2022.105928.

Martins JI. Leaching systems of wolframite and scheelite: a thermodynamic approach. Min Proc Ext Met Rev. 2014;35:23. https://doi.org/10.1080/08827508.2012.757095.

Martins JP. Kinetics of soda ash leaching of low-grade scheelite concentrates. Hydrometallurgy. 1996;42:221. https://doi.org/10.1016/0304-386X(95)00099-3.

Afolabi UO, Du H, Wang SN, Liu B, Lv YQ, Pan B. Cleaner production of ammonium paratungstate by membrane electrolysis-precipitation of sodium tungstate solution. Tungsten. 2023;5:145. https://doi.org/10.1007/s42864-022-00155-4.

Chen YL, Guo XY, Wang QM, Tian QH, Huang SB, Zhang JX. Tungsten and arsenic substance flow analysis of a hydrometallurgical process for tungsten extracting from wolframite. Tungsten. 2021;3:348. https://doi.org/10.1007/s42864-021-00090-w.

Zhao ZW, Li JT, Wang SB, Li HG, Liu MS, Sun PM, Li YJ. Extracting tungsten from scheelite concentrate with caustic soda by autoclaving process. Hydrometallurgy. 2011;108:152. https://doi.org/10.1016/j.hydromet.2011.03.004.

Shen LT, Li XB, Zhou QS, Peng ZH, Liu GH, Qi TG, Taskinen P. Sustainable and efficient leaching of tungsten in ammoniacal ammonium carbonate solution from the sulfuric acid converted product of scheelite. J Clean Prod. 2018;197:690. https://doi.org/10.1016/j.jclepro.2018.06.256.

Zhao ZW, Hu F, Hu YJ, Wang SB, Sun PM, Huo GS, Li HG. Adsorption behaviour of WO42− onto 201 × 7 resin in highly concentrated tungstate solutions. Int J Refract Hard Met. 2010;28:633. https://doi.org/10.1016/j.ijrmhm.2010.04.005.

Cao CF, Qiu XC, Li YH, Yang L, Pang ZS, Yuan ZZ. Study on leaching behavior of tungstates in acid solution containing phosphoric acid. Hydrometallurgy. 2020;197: 105392. https://doi.org/10.1016/j.hydromet.2020.105392.

Zhao ZW, Sun FL, Yang JH, Fang Q, Jiang WW, Liu XH, Chen XY, Li JT. Status and prospect for tungsten resources, technologies and industrial development in China. Chinese J Nonferrous Metals. 2019;29(09):1902. https://doi.org/10.19476/j.ysxb.1004.0609.2019.09.07.

Baba AA, Kayode JO, Raji MA. Low-energy feasibility for leaching an indigenous scheelite ore for industrial applications. J Sustain Metall. 2020;6(4):659. https://doi.org/10.1007/s40831-020-00301-7.

Shen LT, Li XB, Lindberg D, Taskinen P. Tungsten extractive metallurgy: a review of processes and their challenges for sustainability. Miner Eng. 2019;142: 105934. https://doi.org/10.1016/j.mineng.2019.105934.

Li JT, Cui MY, Zhao ZW, Liu XH, Chen XY, He LH, Sun FL, **ao LP, Li XK, Wang LZ. Extraction of tungsten from scheelite concentrate using a methanesulfonic acid-phosphoric acid coleaching process followed by solvent extraction with N1923. Hydrometallurgy. 2022;213: 105917. https://doi.org/10.1016/j.hydromet.2022.105917.

Gong DD, Zhang Y, Wan LS, Qiu TS, Chen YN, Ren SL. Efficient extraction of tungsten from scheelite with phosphate and fluoride. Process Saf Environ. 2022;159:708. https://doi.org/10.1016/j.psep.2022.01.029.

Li JT, Cao GX, Tang ZY, Zhao ZW. Simulation of flow field characteristics in scheelite leaching tank with H2SO4–H3PO4. Int J Chem React Eng. 2021;19(12):1. https://doi.org/10.1515/ijcre-2021-0161.

Wu PZ. Wet-process phosphoric acid. Bei**g: Chemical Industry Press. 1987: 34–60.

Jia CY, Zhang HJ. Progress on studies of crystal nucleation: coexistence of classical and non-classical nucleation in a common system. J Chin Ceramic Soc. 2023;51(7):1. https://doi.org/10.14062/j.issn.0454-5648.20221090

Marina P, Amedeo L, Dino M. Calcium sulfate dihydrate nucleation in the presence of calcium and sodium chloride salts. Ind Eng Chem Res. 2001;40:2335. https://doi.org/10.1021/ie000391q.

He L, Zhu GY, Zheng GM, Wu WF, Zhang JB, Li F, Li HQ, Chen W. Study on crystallization process and mechanism of phosphogypsum in wet process phosphoric acid system. Inorg Chem Indus. 2022;54(7):110. https://doi.org/10.19964/j.issn.1006-4990.2021-0655

Liu XH, Zai JP, Chen XY, Li JT, He LH, Sun FL, Zhao ZW. Recovery of tungsten in the process of preparation of calcium sulfate whiskers from scheelite decomposed residue. ACS Sustain Chem Eng. 2022;10(39):13194. https://doi.org/10.1021/acssuschemeng.2c04787.

Liao YL, Zhao ZW. Effects of phosphoric acid and ageing time on solvent extraction behavior of phosphotungstic acid. Hydrometallurgy. 2017;169:515. https://doi.org/10.1016/j.hydromet.2017.03.003.

Li HG. Rare metal metallurgy. Bei**g: Metallurgical Industry Press. 1990:52.

He GX, He LH, Zhao ZW, Chen XY, Gao LL, Liu XH. Thermodynamic study on phosphorus removal from tungstate solution via magnesium salt precipitation method. T Nonferr Soc. 2013;23(11):3440. https://doi.org/10.1016/S1003-6326(13)62886-1.

Mo SH. Principle and process of tungsten metallurgy. Bei**g: Light Industry Press. 1984:90.

Acknowledgements

This work was jointly supported by the National Natural Science Foundation of China (No. 51334008), the Basic Science Center of the National Natural Science Foundation of China (72088101), and the National Key Research and Development Program of China (No. 2022YFC2904505).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Li, JT., Gao, LL., Zhao, ZW. et al. Efficient recovery of tungsten from scheelite concentrates using a sulfur-phosphorus mixed acid leaching system. Tungsten (2024). https://doi.org/10.1007/s42864-024-00265-1

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s42864-024-00265-1