Abstract

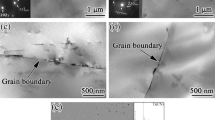

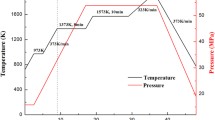

In fusion reactor or spallation neutron source environment, damage of tungsten components begins at the surface. To enhance the surface toughness, strength, and hardness of tungsten, a nano-to-microscale lamellar gradient surface layer (thickness up to ~ 50 μm) was produced on as-rolled pure tungsten using a dry-sliding surface treatment. The dry-sliding temperature and time were established by observing the grain-size evolution from room temperature to 750 ℃ and the coefficient of friction on the surface layer after sliding from 10 to 50 min. The grains changed into a slender fibrous structure at 250 °C, which is higher than the ductile–brittle transition temperature but lower than the dynamic recrystallization temperature (750 °C). The coefficient of friction of the surface layer decreased with sliding time and stabilized at approximately 50 min, indicating near-saturation of the surface refinement. After repetitive thermal loads of 10, 20, and 30 MW·m−2 on the gradient modified layer, it exhibited mainly recrystallization and grain growth. The proportion of low-angle grain boundaries (< 10°) reached 50.6, 42.2, and 17.3%, respectively, and the hardness decreased to 602, 582, and 488HV. A heat load of 30 MW·m−2 was the threshold for the fast grain growth. Compared with unmodified tungsten, the recrystallization and grain growth are relatively slow. Besides, the gradient layer could suppress the formation of pits and protrusions in the as-rolled tungsten sample.

Similar content being viewed by others

Data availability

The data that support the findings of this study are available from the corresponding author upon reasonable request.

References

Wurster S, Baluc N, Battabyal M, Crosby T, Du J, García-Rosales C, Hasegawa A, Hoffmann A, Kimura A, Kurishita H, Kurtz RJ, Li H, Noh S, Reiser J, Riesch J, Rieth M, Setyawan W, Walter M, Pippan R. Recent progress in R&D on tungsten alloys for divertor structural and plasma facing materials. J Nucl Mater. 2013;442(1–3):S181.

Rieth M, Dudarev SL, De Vicente SG, Aktaa J, Ahlgren T, Antusch S, Armstrong DEJ, Balden M, Baluco N, Barthe MF, Basuki WW, Battabyal M, Becquart CS, Blagoeva D, Boldyryeva H, Brinkmann J, Celino M, Ciupinski L, Zivelonghi A. Recent progress in research on tungsten materials for nuclear fusion applications in Europe. J Nucl Mater. 2013;432(1–3):482.

Yang L, Zhan WL. New concept for ADS spallation target: gravity-driven dense granular flow target. Sci China Technol Sci. 2015;58(10):1705.

Jiang Y, **e ZM, Yang JF, Fang QF. High-temperature tribological behavior of tungsten. Int J Refract Met H. 2019;84: 104992.

Pang L, Tai P, Shen T, Wang Z, Zhu S, Cui M, Chang HL, Zhang HP, Ma ZW, Mu ZX, Yao C. Study on collective friction and wear behavior of W–Ni–Fe alloy balls. Tribol Int. 2021;164: 107232.

Jiang Y, Hou J, Huang P, Li J, Wu EH, Xu Z, Liu QS, **e ZM, Fang QF. Tensile behavior of hybrid tungsten composites with zirconium carbide nanoparticles and tungsten fibers. Int J Refract Met H. 2020;93: 105360.

Wang MM, **e ZM, Deng HW, Liu R, Yang JF, Zhang T, Wang XP, Fang QF, Liu CS, Liu X, **ong Y. Thermal shock fatigue behaviors of various W-0.5 wt% ZrC materials under repetitive transient heat loads. J Nucl Mater. 2020;534:152152.

Liu R, **e ZM, Yang JF, Zhang T, Hao T, Wang XP, Fang QF, Liu CS. Recent progress on the R&D of W-ZrC alloys for plasma facing components in fusion devices. Nucl Mater Energy. 2018;16:191.

Deng HW, **e ZM, Wang YK, Liu R, Zhang T, Hao T, Wang XP, Fang QF, Liu CS. Mechanical properties and thermal stability of pure W and W-0.5 wt% ZrC alloy manufactured with the same technology. Mater Sci Eng A-Struct. 2018;715:117.

Wu YC, Hou QQ, Luo LM, Zan X, Zhu XY, Li P, Xu Q, Cheng JG, Luo GN, Chen JL. Preparation of ultrafine-grained/nanostructured tungsten materials: an overview. J Alloy Compd. 2019;779:926.

**e ZM, Liu R, Zhang T, Fang QF, Liu CS, Liu X, Luo GN. Achieving high strength/ductility in bulk W–Zr–Y2O3 alloy plate with hybrid microstructure. Mater Design. 2016;107:144.

Wang YK, Miao S, **e ZM, Liu R, Zhang T, Fang QF, Hao T, Wang XP, Liu CS, Liu X, Cai LH. Thermal stability and mechanical properties of HfC dispersion strengthened W alloys as plasma-facing components in fusion devices. J Nucl Mater. 2017;492:260.

**g K, Zhang C, Liu R, **e ZM, Zhang LC, Zhang LF, Liu J, Gao R, Yang JF, Wang XP, Hao T, Wu XB, Fang QF, Liang CH, Luo GN, Lian YY, Liu X, Liu CS. Mechanical properties and thermal shock resistance of tungsten alloys strengthened by laser fragmentation-processed zirconium carbide nanoparticles. Tungsten. 2020;2(4):381.

Firneis D, Wurster S, Nikolić V, Pippana R, Hohenwarter A. The beneficial effect of rolling on the fracture toughness and R-curve behavior of pure tungsten. Mater Sci Eng A-Struct. 2022;838:142756.

Zhang T, Du WY, Zhan CY, Wang MM, Deng HW, **e ZM, Li H. The high thermal stability induced by a synergistic effect of ZrC nanoparticles and Re solution in W matrix in hot rolled tungsten alloy. Nucl Eng Technol. 2022;54(8):2801.

Zhao BL, **a YP, Zhang LF, Ke JG, Cheng X, **e ZM, Liu R, Miao S, Hao T, Wu XB, Fang QF, Liu CS. Effects of rolling reduction on microstructural evolution and mechanical properties of W-0.5 wt% ZrC alloys. Mater Sci Eng A-Struct. 2022;830(7):142310.

Guo HY, **a M, Chan LC, Wang K, Zhang XX, Yan QZ, He MC, Lu J, Ge CC. Nanostructured laminar tungsten alloy with improved ductility by surface mechanical attrition treatment. Sci Rep. 2018;8(1):1.

Zhang T, Deng HW, **e ZM, Liu R, Yang JF, Liu CS, Wang XP, Fang QF, **ong Y. Recent progresses on designing and manufacturing of bulk refractory alloys with high performances based on controlling interfaces. J Mater Sci Technol. 2020;52:29.

**e ZM, Miao S, Liu R, Zeng LF, Zhang T, Fang QF, Liu CS, Wang XP, Lian YY, Liu X, Cai LH. Recrystallization and thermal shock fatigue resistance of nanoscale ZrC dispersion strengthened W alloys as plasma-facing components in fusion devices. J Nucl Mater. 2017;496:41.

Pintsuk G, Kurishita H, Linke J, Arakawa H, Matsuo S, Sakamoto T, Kobayashi S, Nakai K. Thermal shock response of fine-and ultra-fine-grained tungsten-based materials. Phys Scr. 2011;T145: 014060.

Zhang H, Gong MY. Mechanism and research progress of SMAT technology applied on surface of metallic materials. Angang Technol. 2018;6:414.

Lu K. Gradient nanostructured materials. Acta Metall Sin. 2015;51(1):1.

Li JS, Gao WD, Cao Y, Huang ZW, Gao B, Mao QZ, Li YS. Microstructures and mechanical properties of a gradient nanostructured 316L stainless steel processed by rotationally accelerated shot peening. Adv Eng Mater. 2018;20(10):1800402.

Chen X, Han Z, Li X, Lu K. Lowering coefficient of friction in Cu alloys with stable gradient nanostructures. Sci Adv. 2016;2(12): e1601942.

Chamgordani SA, Miresmaeili R, Aliofkhazraei M. Improvement in tribological behavior of commercial pure titanium (CP-Ti) by surface mechanical attrition treatment (SMAT). Tribol Int. 2018;119:744.

Wang H, **e ZM, Zhang LC, Han L, Liu R, Fang QF, Wang XP, Liu CS, Wu XB. Damage behaviors in microstructures and mechanical properties of pure tungsten induced by repetitive thermal loads. J Nucl Mater. 2022;559: 153433.

Hasan MS, Kordijazi A, Rohatgi PK, Nosonovsky M. Triboinformatics approach for friction and wear prediction of Al-Graphite composites using machine learning methods. J Tribol. 2022;144(1): 011701.

Yin CH, Liang YL, Liang Y, Li W, Yang M. Formation of a self-lubricating layer by oxidation and solid-state amorphization of nano-lamellar microstructures during dry sliding wear tests. Acta Mater. 2019;166:208.

Kommel L, Põdra P, Mikli V, Omranpour B. Gradient microstructure in tantalum formed under the wear track during dry sliding friction. Wear. 2021;466–467:203573.

Loewenhoff T, Bürger A, Linke J, Pintsuk G, Schmidt A, Singheiser L. Evolution of tungsten degradation under combined high cycle edge-localized mode and steady-state heat loads. Phys Scr. 2011;T145: 014057.

Pan Q, Lu L. Improved fatigue resistance of gradient nanograined metallic materials: Suppress strain localization and damage accumulation. Scripta Mater. 2020;187:301.

Matějíček J, Veverka J, Yin C, Vilémová M, Terentyev D, Wirtz M, Gago M, Dubinko A, Hadrab H. Spark plasma sintered tungsten–mechanical properties, irradiation effects and thermal shock performance. J Nucl Mater. 2020;542: 152518.

Zhao M, Zhou Z, Zhong M, Tan J, Lian YY, Liu X. Thermal shock behavior of fine grained W-Y2O3 materials fabricated via two different manufacturing technologies. J Nucl Mater. 2016;470:236.

Webb J, Gollapudi S, Charit I. An overview of creep in tungsten and its alloys. Int J Refract Met Hard Mater. 2019;82:69.

Acknowledgements

The authors want to appreciate Doctor Z. M. **e at Institute of Solid State Physics, Chinese Academy of Sciences, for his assistance in materials fabrication and characterization.

Funding

The National Natural Science Foundation of China (Grant no. 51601189), Panzhihua Guided Science and Technology Program (2019ZD-G-15) and the cultivation project of Panzhihua University (2020ZD003) supported this work.

Author information

Authors and Affiliations

Contributions

Data integration, PH and JH; Formal analysis: ZX, JL and EHW; Methodology and Writing: YJ and ZQJ; Funding acquisition: YJ. All authors have read and agreed to the published version of the manuscript.

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Jiang, Y., Huang, P., Jiang, ZQ. et al. Gradient nanostructured tungsten and the thermal shock response. Tungsten 5, 548–557 (2023). https://doi.org/10.1007/s42864-023-00211-7

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42864-023-00211-7