Abstract

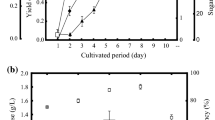

Bacterial cellulose (BC) is an exopolysaccharide produced by bacteria that has unusual structural features and is more refined than plant cellulose. BC has recently gained more attention in a variety of fields including biological and biomedical applications due to its excellent physiochemical properties including easy biodegradability, better water holding capacity, high tensile strength, high thermal stability, and high degree of polymerization. However, application of BC at industrial scale is still limited due to its high production cost and lesser yielding strains. The present study is an attempt to isolate and characterize a novel BC-producing bacterial strain. The bacterial strain S5 has resulted into maximum cellulose production of 4.76 ± 0.49 gL−1 (30°C, pH 7.0). The strain has been further identified as Stenotrophomonas sp. Derivation of nutritional and cultural conditions has resulted into 2.34-fold enhanced BC production (banana peel powder, peptone, tartaric acid, pH 7, 30°C). FTIR spectrum of BC revealed characteristic absorption bands which could be attributed to the O-H band, C-H stretching, C-O-C stretching band, O-H bending, and >CH2 bending, indicative of the β-1,4 glycosidic linkages of cellulose. Thermogravimetric analysis has also revealed stability of polysaccharide backbones and characteristic weight loss points. Employment of banana peel powder has appeared as a proficient low-cost source for large-scale economic production of BC for industrial applications.

Similar content being viewed by others

Data availability

The authors confirm that the data supporting the findings of this study are available within the article. Raw data that support the findings of this study are available from corresponding author, upon reasonable request.

Change history

20 November 2023

A Correction to this paper has been published: https://doi.org/10.1007/s42770-023-01180-2

References

Kothari N, Bhagia S, Pu Y, Yoo CG, Li M, Venketachalam S et al (2020) The effect of switchgrass plant cell wall properties on its deconstruction by thermochemical pretreatments coupled with fungal enzymatic hydrolysis or Clostridium thermocellum consolidated bioprocessing. Green Chem 22(22):7924–7945

Lahiri D, Nag M, Dutta B, Dey A, Sarkar T, Pati S et al (2021) Bacterial cellulose: production, characterization, and application as antimicrobial agent. Int J Mol Sci 22(23):12984

Souza EF, Furtado MR, Carvalho CW, Freitas-Silva O, Gottschalk LM (2020) Production and characterization of Gluconacetobacter xylinus bacterial cellulose using cashew apple juice and soybean molasses. Int J Biol Macromol 146:285–289

Almeida AP, Saraiva JN, Cavaco G, Portela RP, Leal CR, Sobral RG, Almeida PL (2022) Crosslinked bacterial cellulose hydrogels for biomedical applications. Eur Polym J 177:111438

** YH, Lee T, Kim JR, Choi YE, Park C (2019) Improved production of bacterial cellulose from waste glycerol through investigation of inhibitory effects of crude glycerol-derived compounds by Gluconacetobacter xylinus. J Ind Eng Chem 75:158–163

Martínez-Sanz M, Mikkelsen D, Flanagan B, Gidley MJ, Gilbert EP (2016) Multi-scale model for the hierarchical architecture of native cellulose hydrogels. Carbohydr Polym 147:542–555

Rahman SSA, Vaishnavi T, Vidyasri GS, Sathya K, Priyanka P, Venkatachalam P, Karuppiah S (2021) Production of bacterial cellulose using Gluconacetobacter kombuchae immobilized on Luffa aegyptiaca support. Sci Rep 11(1):1–15

Dubey S, Sharma RK, Agarwal P, Singh J, Sinha N, Singh RP (2017) From rotten grapes to industrial exploitation: Komagataeibacter europaeus SGP37, a micro-factory for macroscale production of bacterial nanocellulose. Int J Biol Macromol 96:52–60

Gallegos AMA, Carrera SH, Parra R, Keshavarz T, Iqbal HM (2016) Bacterial cellulose: a sustainable source to develop value-added products–a review. BioResources 11(2):5641–5655

Wang J, Tavakoli J, Tang Y (2019) Bacterial cellulose production, properties and applications with different culture methods–a review. Carbohydr Polym 219:63–76

Abdelraof M, Hasanin MS, El-Saied H (2019) Ecofriendly green conversion of potato peel wastes to high productivity bacterial cellulose. Carbohydr Polym 211:75–83

Vazquez A, Foresti ML, Cerrutti P, Galvagno M (2013) Bacterial cellulose from simple and low cost production media by Gluconacetobacter xylinus. J Polym Environ 21(2):545–554

Cerrutti P, Roldán P, García RM, Galvagno MA, Vázquez A, Foresti ML (2016) Production of bacterial nanocellulose from wine industry residues: importance of fermentation time on pellicle characteristics. J Appl Polym Sci 133(14):1–9

Verma M, Mishra V (2023) Bioelectricity generation by microbial degradation of banana peel waste biomass in a dual-chamber S. cerevisiae-based microbial fuel cell. Biomass Bioenergy 168:106677

Zaini HM, Roslan J, Saallah S, Munsu E, Sulaiman NS, Pindi W (2022) Banana peels as a bioactive ingredient and its potential application in the food industry. J Funct Foods 92:105054

Ewing-Chow D (2022) Banana Peel Cuisine Is The Latest Plant Based Trend. Forbes. pp 1–4. https://www.forbes.com/sites/daphneewingchow/2022/03/31/banana-peels-have-found-mass-a-peel-in-food-and-drink/?sh=17768bfa5b55

Singh R, Saati AA, Faidah H, Bantun F, Jalal NA, Haque S et al (2022) Prospects of microbial cellulase production using banana peels wastes for antimicrobial applications. Int J Food Microbiol 388:110069

Schramm M, Hestrin S (1954) Factors affecting production of cellulose at the air/liquid interface of a culture of Acetobacter xylinum. Microbiology 11(1):123–129

Ausubel FM, Brent R, Kingston RE, Moore DD, Seidman JG, Smith JA, Struhl K (1992) Short protocols in molecular biology. N Y 275:28764–28773

Lane, D. J. (1991). 16S/23S rRNA sequencing. Nucleic acid techniques in bacterial systematics. pp 115–175

Tamura K, Stecher G, Peterson D, Filipski A, Kumar S (2013) MEGA6: molecular evolutionary genetics analysis version 6.0. Mol Biol Evol 30(12):2725–2729

Verma A, Patnaik SK, Suryawanshi P (2023) Stenotrophomonas maltophilia sepsis in preterm neonates. Med J Armed Forces India

Kashyap P, Shirkot P, Das R, Pandey H, Singh D (2023) Biosynthesis and characterization of copper nanoparticles from Stenotrophomonas maltophilia and its effect on plant pathogens and pesticide degradation. J Agric Food Res 100654:1–11

Ercole TG, Kava VM, Aluizio R, Pauletti V, Hungria M, Galli-Terasawa LV (2023) Co-inoculation of Bacillus velezensis and Stenotrophomonas maltophilia strains improves growth and salinity tolerance in maize (Zea mays L.). Rhizosphere 27:100752

Hu Z, Zhou Z, Zhou Y, Zheng L, Guo J, Liu Y et al (2023) Synergy of surface adsorption and intracellular accumulation for removal of uranium with Stenotrophomonas sp.: performance and mechanisms. Environ Res 220:115093

Yang X, Kim DS, Choi HS, Kim CK, Thapa LP, Park C, Kim SW (2017) Repeated batch production of 1, 3-propanediol from biodiesel derived waste glycerol by Klebsiella pneumoniae. Chem Eng J 314:660–669

Jahan F, Kumar V, Saxena RK (2018) Distillery effluent as a potential medium for bacterial cellulose production: a biopolymer of great commercial importance. Bioresour Technol 250:922–926

Silva SMF, Ribeiro HL, Mattos ALA, Borges MDF, Rosa MDF, de Azeredo HMC (2021) Films from cashew byproducts: cashew gum and bacterial cellulose from cashew apple juice. J Food Sci Technol 58:1979–1986

Kang SW, Lee H, Kim D, Lee D, Kim S, Chun GT et al (2010) Strain development and medium optimization for fumaric acid production. Biotechnol Bioprocess Eng 15(5):761–769

Jung YR, Shin HY, Song YS, Kim SB, Kim SW (2012) Enhancement of immobilized enzyme activity by pretreatment of β-glucosidase with cellobiose and glucose. J Ind Eng Chem 18(2):702–706

Shuler ML, Kargi F (2002) Recovery and purification of products. In: Bioprocess Engineering. Basic Concepts. Prentice Hall, Upper Saddle River, NJ, pp 329–384

Waites MJ, Morgan NL, Rockey JS, Higton G (2009) Industrial microbiology: an introduction. John Wiley & Sons

Biebl H, Zeng AP, Menzel K, Deckwer WD (1998) Fermentation of glycerol to 1, 3-propanediol and 2, 3-butanediol by Klebsiella pneumoniae. Appl Microbiol Biotechnol 50(1):24–29

Zhao H, **a J, Wang J, Yan X, Wang C, Lei T et al (2018) Production of bacterial cellulose using polysaccharide fermentation wastewater as inexpensive nutrient sources. Biotechnol Biotechnol Equip 32(2):350–356

Gayathri G, Srinikethan G (2019) Bacterial Cellulose production by K. saccharivorans BC1 strain using crude distillery effluent as cheap and cost-effective nutrient medium. Int J Biol Macromol 138:950–957

Coates J (2006) Interpretation of infrared spectra, a practical approach. Encycl Anal Chem 12(10):815–810

El-Gendi H, Salama A, El-Fakharany EM, Saleh AK (2023) Optimization of bacterial cellulose production from prickly pear peels and its ex situ impregnation with fruit byproducts for antimicrobial and strawberry packaging applications. Carbohydr Polym 302:120383

Thorat MN, Dastager SG (2018) High yield production of cellulose by a Komagataeibacter rhaeticus PG2 strain isolated from pomegranate as a new host. RSC Adv 8(52):29797–29805

Barud HS, de Araújo Júnior AM, Santos DB, de Assunção RM, Meireles CS, Cerqueira DA et al (2008) Thermal behavior of cellulose acetate produced from homogeneous acetylation of bacterial cellulose. Thermochim Acta 471(1-2):61–69

Funding

The work was financially supported by the Science and Engineering Research Board (SPG/2021/003648), Government of India, India.

Author information

Authors and Affiliations

Contributions

RK and MS conceived and performed the experiments, analyzed the data, and wrote the article. MK contributed in the analysis and writing. VV edited the article. NP supervised, conceptualized, wrote, and edited the article.

Corresponding author

Ethics declarations

Consent for publication

All the authors agreed for the publication of the manuscript in the Environmental Science and Pollution Research.

Competing interests

The authors declare no competing interests

Additional information

Responsible Editor: Julio Santos

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rajni Kumari and Mesevilhou Sakhrie are equal contributing authors.

The original online version of this article was revised: In this article the author name Mesevilhou Sakhrie was incorrectly written as Mesevilhou Sakhire.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Kumari, R., Sakhrie, M., Kumar, M. et al. Enhanced production of bacterial cellulose employing banana peel as a cost-effective nutrient resource. Braz J Microbiol 54, 2745–2753 (2023). https://doi.org/10.1007/s42770-023-01151-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42770-023-01151-7