Abstract

Background

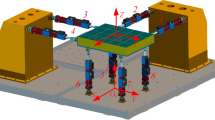

Electro-hydraulic shake table, also known as vibration simulator, is a kind of important rig for reliability tests. However, the realization of continuous swept-sine vibration signal with electro-hydraulic shake table is still imperfect due to nonlinearities, uncertainties of the electro-hydraulic servo system, time-varying dynamics and unexpected disturbance.

Purpose

An online controller combining inverse model compensation and ultra-local model principle-based adaptive sliding mode control is proposed to improve the swept-sine vibration realization accuracy of the electro-hydraulic shake table in this paper.

Methods

The swept-sine vibration controller is established based on the classical three variable controller as the inner servo controller. Then H1 system identification method-based inverse model compensator is designed. To further enhance the performance of the swept-sine vibration controller, the ultra-local model principle-based adaptive sliding controller is adopted.

Results

Comparative experiments are performed following theoretical analysis of the proposed controller on an electro-hydraulic shake table with linear and logarithmic swept-sine vibration realization.

Conclusion

The experimental results validate the feasibility of the proposed swept-sine vibration realization control method.

Similar content being viewed by others

References

Laborde S, Calvi A (2012) Spacecraft base-sine vibration test data uncertainties investigation based on stochastic scatter approach. Mech Syst Signal Process 32:69–78

Cooper SB, Tiels K, Titurus B, Di Maio D (2020) Polynomial nonlinear state space identification of an aero-engine structure. Comput Struct 238:106299

Bosworth R, Burton D, Williams R (2018) In: Combining test and analysis to troubleshoot steering system vibration problems in an automobile. Routledge, pp 224–237

Murphy HP, Petersen SM, Coats TW, Riley MR (2017) Standardized laboratory test requirements for hardening equipment to withstand wave impact shock in small high speed craft. NAVSEA Carderock Virginia Beach United States

Palmieri M, Cianetti F, Zucca G, Morettini G, Braccesi C (2021) Spectral analysis of sine-sweep vibration: a fatigue damage estimation method. Mech Syst Signal Process 157:107698

Chandra NH, Sekhar A (2014) Swept sine testing of rotor-bearing system for dam** estimation. J Sound Vib 333(2):604–620

Musella U, Waimer S, Peeters B, Marulo F, Guillaume P (2019) Development of a steepest-descent control solution for multi-input multi-output swept sine testing in a virtual shaker environment. J Phys Conf Ser 1264:012002

Zhang B, Chen H, He X (2015) New control method for MIMO swept-sine test. J Vib Shock 34(8):198–202

Wei W, Liu X, Kong J, Huang W, Han J (2018) Flow nonlinear compensation control for electro-hydraulic servo shaking table. J South China Univ Technol (Nat Sci) 46(9):24–29 ((72))

Righettini P, Strada R, Valilou S, KhademOlama E (2018) Nonlinear model of a servo-hydraulic shaking table with dynamic model of effective bulk modulus. Mech Syst Signal Process 110:248–259

Liu J, Qiao B, Zhang X, Yan R, Chen X (2019) Adaptive vibration control on electrohydraulic shaking table system with an expanded frequency range: theory analysis and experimental study. Mech Syst Signal Process 132:122–137

Shen G, Li G, Zang W, Li X, Tang Y (2019) Modal space feedforward control for electro-hydraulic parallel mechanism. IEEE Access 7:39751–39761

Plummer A (2016) Model-based motion control for multi-axis servohydraulic shaking tables. Control Eng Pract 53:109–122

Yao J, Di D, Jiang G, Gao S, Yan H (2013) Identification of acceleration harmonic for an electro-hydraulic servo shaking table based on Kalman filter. Trans Inst Meas Control 35(8):986–996

Nowak RF, Kusner DA, Larson RL, Thoen BK (2000) Utilizing modern digital signal processing for improvement of large scale shaking table performance 2035:1–8

Tagawa Y, Kajiwara K (2007) Controller development for the E-Defense shaking table. Proc Inst Mech Eng Part I J Syst Control Eng 221(2):171–181

Yang Z (2009) Research on control technologies of simulation of vibration environment using hydraulic vibration table

Gang S et al (2013) Adaptive feed-forward compensation for hybrid control with acceleration time waveform replication on electro-hydraulic shaking table. Control Eng Pract 21(8):1128–1142

Yao J (2018) Model-based nonlinear control of hydraulic servo systems: challenges, developments and perspectives. Front Mech Eng 13(2):179–210

Chen C, Ricles JM (2009) Improving the inverse compensation method for real-time hybrid simulation through a dual compensation scheme. Earthq Eng Struct Dyn 38(10):1237–1255

Lee KH et al (2019) Feedforward model-inverse position control of three-stage servo-valve using zero magnitude error tracking control. Proc Inst Mech Eng Part C J Mech Eng Sci 233(7):2340–2348

Shen G et al (2018) Acceleration waveform replication on six-degree-of-freedom redundant electro-hydraulic shaking tables using an inverse model controller with a modelling error. Trans Inst Meas Control 40(3):968–986

Tang Y, Zhu Z-C, Shen G, Li X (2016) Improved feedforward inverse control with adaptive refinement for acceleration tracking of electro-hydraulic shake table. J Vib Control 22(19):3945–3964

Ya J et al (2019) Resonance suppression for hydraulic servo shaking table based on adaptive notch filter. Shock Vib 2019

Li G, Shen G, Zhu Z-C, Li X, Zang W-S (2018) Sine phase compensation combining an amplitude phase controller and a discrete feed-forward compensator for electro-hydraulic shaking tables. Trans Inst Meas Control 40(11):3377–3389

Baek SG, Ji S, Koo JC (2018) Experimental study of electro-hydraulic actuator with payload for precision motion control. Microsyst Technol 24(3):1347–1357

Cornelis B, Toso A, Verpoest W, Peeters B (2013) Adaptive modelling for improved control in durability test rigs 507–516

Rana K (2011) Fuzzy control of an electrodynamic shaker for automotive and aerospace vibration testing. Expert Syst Appl 38(9):11335–11346

Della Flora L, Gründling H (2008) Time domain sinusoidal acceleration controller for an electrodynamic shaker. IET Control Theory Appl 2(12):1044–1053

Zhang B, Wang D, Zhou K, Wang Y (2008) Linear phase lead compensation repetitive control of a CVCF PWM inverter. IEEE Trans Ind Electron 55(4):1595–1602

Cao Y, Zhao Q, Ye Y, **ong Y (2019) ADRC-based current control for grid-tied inverters: design, analysis, and verification. IEEE Trans Ind Electron 67(10):8428–8437

Yin L, Zhang L, Cong D, Han J (2013) Sine swept vibration control based on offline iteration technique (IEEE), vol 1, pp 456–461

Zhipeng Y, Lutao Y (2014) System identification and online equalization technique based swept sine vibration testing control (IEEE, Hangzhou, China), pp 372–375. https://ieeexplore.ieee.org/document/6911522

**g C, Xu H, Song X, Lu B (2018) Adaptive extended state observer-based flatness nonlinear output control for torque tracking of electrohydraulic loading system. Trans Inst Meas Control 40(10):2999–3009

Yao Z et al (2020) Model reference adaptive tracking control for hydraulic servo systems with nonlinear neural-networks. ISA Trans 100:396–404

Borges FAP, Perondi EA, Cunha MAB, Sobczyk MR (2021) A neural network-based inversion method of a feedback linearization controller applied to a hydraulic actuator. J Braz Soc Mech Sci Eng 43(5):1–19

Cai Y et al (2021) Sliding-mode control of ship-mounted Stewart platforms for wave compensation using velocity feedforward. Ocean Eng 236:109477

Guan C, Pan S (2008) Adaptive sliding mode control of electro-hydraulic system with nonlinear unknown parameters. Control Eng Pract 16(11):1275–1284

Strano S, Terzo M (2014) A multi-purpose seismic test rig control via a sliding mode approach. Struct Control Health Monit 21(8):1193–1207

Soleymani M, Khalatabari-S A, Ghanbari-S B (2019) Fuzzy-sliding-mode supervisory control of a seismic shake table with variable payload for robust and precise acceleration tracking. J Earthq Eng 23(4):539–556

Rajabi N, Abolmasoumi AH, Soleymani M (2018) Sliding mode trajectory tracking control of a ball-screw-driven shake table based on online state estimations using EKF/UKF. Struct Control Health Monit 25(4):e2133

Fliess M, Join C (2013) Model-free control. Int J Control 86(12):2228–2252

Precup R-E, Radac M-B, Roman R-C, Petriu EM (2017) Model-free sliding mode control of nonlinear systems: algorithms and experiments. Inf Sci 381:176–192

Han S, Wang H, Tian Y (2018) Model-free based adaptive nonsingular fast terminal sliding mode control with time-delay estimation for a 12 DOF multi-functional lower limb exoskeleton. Adv Eng Softw 119:38–47

Wang Z, Wang J (2020) Ultra-local model predictive control: a model-free approach and its application on automated vehicle trajectory tracking. Control Eng Pract 101:104482

Plummer AR (2008) A detailed dynamic model of a six-axis shaking table. J Earthq Eng 12(4):631–662

Manring ND, Fales RC (2019) Hydraulic control systems. Wiley, New York

Yang C, Huang Q, Jiang H, Peter OO, Han J (2010) PD control with gravity compensation for hydraulic 6-DOF parallel manipulator. Mech Mach theory 45(4):666–677

Gloth G, Sinapius M (2004) Analysis of swept-sine runs during modal identification. Mech Syst Signal Process 18(6):1421–1441

Qiao L, Zhang W (2019) Trajectory tracking control of AUVs via adaptive fast nonsingular integral terminal sliding mode control. IEEE Trans Ind Inform 16(2):1248–1258

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Yang, H., Cong, D., Yang, Z. et al. Continuous Swept-Sine Vibration Realization Combining Adaptive Sliding Mode Control and Inverse Model Compensation for Electro-hydraulic Shake Table. J. Vib. Eng. Technol. 10, 1007–1019 (2022). https://doi.org/10.1007/s42417-021-00425-4

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42417-021-00425-4