Abstract

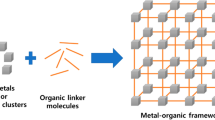

The importance of inorganic membranes for gas separation and purification is analyzed. Although the cost of inorganic membranes is higher than that for polymeric membranes, they have higher permeance, selectivity and better resistance to higher pressure and temperature. The main materials used for porous inorganic membranes are alumina (Al2O3), silica (SiO2), zirconia (ZrO2), zeolite and carbon. Ceramics are compounds of metallic and non-metallic elements. They generally have a macroporous support, an intermediate layer and a small porous top layer. Because the Knudsen gas separation regime has a very low selectivity, various membrane surface modification techniques have started to be experimented with at a number of laboratories. The research focuses on materials that exhibit molecular sieving properties, such as silica, zeolites, MOFs (metal-organic frameworks), graphene and carbon. Finally, gas transport mechanisms through porous membranes are summarized.

Similar content being viewed by others

Abbreviations

- MOFs:

-

metal organic framework

- SEM:

-

scanning electron microscope

- CVD:

-

chemical vapor deposition

- CVI:

-

chemical vapor infiltration

- a AB :

-

separation factor of a component A over component B

- Pvisc:

-

viscous permeance (mol m−2 s−1 Pa−1)

- ε:

-

porosity

- μ:

-

viscosity [Pa s]

- η:

-

shape factor

- r:

-

pore radius [m]

- p av :

-

mean pressure [Pa]

- L:

-

thickness of the membrane (m)

- PKn:

-

Knudsen permeance [mol m−2 s−1 Pa−1]

- v:

-

molecular velocity [m s−1]

- M:

-

molecular weight of the diffusing gas (kg mol−1)

- R:

-

the gas constant (8.31445 J mol−1 K−1)

- T:

-

temperature [K]

- F:

-

permeation molar flux [mol s−1]

- P e :

-

permeability coefficient, [mol m−1 s−1 Pa−1]

- A:

-

permeation area [m2]

- P 1 :

-

upstream gas partial pressure [Pa]

- P 2 :

-

downstream gas partial pressure [Pa]

- GTR:

-

gas transmission rate

- λ:

-

mean free path

- K n :

-

Knudsen number

- K b :

-

the Boltzmann constant

- p:

-

pressure [Pa]

- d g :

-

gas molecule diameter [m]

References

Baker, R.W.: Future directions of membrane gas separation technology. Ind. & Eng. Chem. Res. 41 (2000) 1393–1411

Chen, X.Y.: Membrane gas separation technologies for biogas upgrading. RSC Advances 5 (2015) [31] 24399–24448, DOI: 10:1039/c5ra00666j

**elley, C.N.: Membranes for gas separation, PhD thesis, University of Bath, November (2015)

Mulder, M.: Basic principles of membrane technology. Kluwer Academic Publishers, Netherlands, (1996)

Abedini, R. et al.: Application of membrane in gas separation processes: Its suitability and mechanisms. Petroleum & Coal 52 (2010) 69–80

Keizer, K., Verweij, H.: Progress in inorganic membranes. Chemtech (1996) 37

Lin, Y.S.: Inorganic membranes for gas separation and purification. Membrane 3 (2006) 170–173

Zhang, W.: Experimental investigation on gas separation using porous membranes. Master Thesis, Technische Universität Berlin (2011)

Bhattacharyya, R.: Inorganic membranes for hydrogen isotope-helium separation in fusion energy research. Chem. Technol. 9 (2014) [6] 234–241, ISSN: 0974 - 7443

Cardoso, S.P. et al.: Inorganic membranes for hydrogen separation. Separation & Purification Rev. DOI: 10.1080/15422119.2017.1383917

Gitis, V., Rothenberg, G.: Ceramic membranes: New opportunities and practical applications. 1th edition, Wiley-VCH (2016), ISBN: 978-3-527-33493-3

Amin, S.K. et al.: An overview of production and development of ceramic membranes. Inter. J. Appl. Eng. Res. 11 (2016) [12] 7708–7721, ISSN 0973-4562

Meinema, H.A. et al.,: Ceramic membranes for gas separation — recent developments and state of the art. Interceram 54 (2005) [2] 86–91

Lundin, S.T., Way, J.D. et al.: Dense inorganic membranes for hydrogen separation. In: Membranes for Gas Separation. Editor: M.A. Carreon (2017) World Scientific, Singapore, ISBN: 978-981-3207-70-7

Ebrahimi, M., Ehlen, F. et al.: Innovative ceramic hollow fiber membranes for recycling/reuse of oilfield produced water. Desalination and Water Treatment (2014), DOI: 10.1080/19443994.2014.947780

Li, K.: Ceramic membranes for separation and reaction. Wiley (2007), ISBN: 978-0-470-01440-0

Soleimany, A. et al.: Recent progress in developments of membrane materials and modification techniques for high performance helium separation and recovery: A review. Chem. Eng. & Proc.: Process Intensification 122 (2017) 296–318, DOI: 10.1016/j.cep.2017.06.001

Sunarso, J. et al.: Membranes for helium recovery: An overview of the context, materials and future directions. Separation & Purification Technol. 176 (2017) 335–383, DOI: 10.1016/j.seppur.2016.12.020

Isobe, T. et al.: Preparation and gas permeability of the surface-modified porous Al2O3 ceramic filter for CO2 gas separation, J. Asian Ceram. Soc. 1 (2013) 65–70

Koutsonikolas, D.E. et al.: Pore size reduction and performance upgrade of silica membranes with an ambient temperature C-ALD post treatment method. DOI: 10:1080/01496395.2011.560919

Barboiu, C. et al.: Development of new microporous silica membranes for gas separation. Proc. WHEC 16, 13–16 June (2006) Lyon, France

Ahn, S.J. et al.: Permeation properties of silica-zirconia composite membranes supported on porous alumina substrates. J. Membrane Sci. 526 (2017) 409–416, DOI: 10.1016/j.memsci.2016.12.023

Khatib, S.J.: Silica membranes for hydrogen separation prepared by chemical vapor deposition (CVD). Separation & Purification Technol. 111 (2013) 20–42

Aoki, K. et al.: Separation of gases with an A-type zeolite membrane. Ind. & Eng. Chem. Res. 39 (2000) 2245–2251

Korelskiy, D. et al.: Efficient ceramic zeolite membranes for CO2/H2 separation. J. Mater. Chem. A 3 (2015) 12500–12506

Kosinov, N.: Recent developments in zeolite membranes for gas separation. J. Membrane Sci. 499 (2016) 65–79

de Vos, R.M. et al.: Improved performance of silica membranes for gas separation. J. Membrane Sci. 143 (1998) 37–51

Koutsonikolas, D.E. et al.: Characterization of commercial and hybrid membranes using gas permeation and permporometry test. J. Membrane Sci. Res. 1 (2015) 130–134

Wall, Y. et al.: Gas transport through ceramic membranes under super-critical conditions. Desalination 250 (2010) 1056–1059

Oyama, S.T. et al.: Review on mechanisms of gas permeation through inorganic membranes. J. Japan Petroleum Inst. 54 (2011) [5] 298–309

Hamm, J.B.S. et al.: Recent advances in the development of supported carbon membranes for gas separation. Int. J. Hydrogen Energy 42 (2017) 24830–24845

Sanyal, O. et al.: Next generation membranes — using tailored carbon-.127 (2018) 688–698

Hägg, M.B., Lie., J.A., Lindbråthen, A.: Carbon molecular sieve membranes: A promising alternative for selected industrial applications. Ann. N.Y. Acad. Sci. 984 (2003) 329–345

Zhao, Z. et al.: Gas separation properties of metal organic framework (MOF-5) membranes. Ind. Eng. Chem. Res. 52 (2013) 1102–1108, DOI.org/10.1021/ie202777q

Xu, Q.: Graphene and graphene oxide: Advanced membranes for gas separation and water purification. Inorganic Chem. Front. 2 (2015) 417–424, DOI: 10.1039/c4qi00230j

Yoo, B.M. et al.: Graphene and graphene oxide membranes for gas separation applications, Current Opinion in Chemical Engineering 16 (2017) 39–47

Kast, W. et al.: Mass transfer within the gas-phase of porous media. Int. J. Heat & Mass Transfer 43 (2000) 807–823

Lu, G.Q.: Inorganic membranes for hydrogen production and purification: A critical review and perspective. J. Colloid and Interface Sci. 314 (2007) 589–603

Turel, T.: Gas transmission trough microporous membranes. Dissertation, submitted to the Graduate Faculty of Auburn University, Alabama (USA), (2008)

van den Berg, G.B.: Diffusional phenomena in membrane separation processes. J. Membrane Sci. 73 (1992) 103–118

Acknowledgment

The authors thank all their colleagues for their help and support. In particular, D. De Meis expresses his sincere gratitude to Prof. Ted Oyama for his suggestions.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

De Meis, D., Richetta, M. & Serra, E. Microporous Inorganic Membranes for Gas Separation and Purification. Interceram. - Int. Ceram. Rev. 67, 16–21 (2018). https://doi.org/10.1007/s42411-018-0023-2

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42411-018-0023-2