Abstract

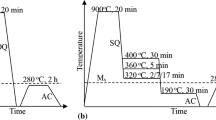

The effect of the amount of isothermal martensite and bainite on the microstructure and properties in a medium-carbon quenching and partitioning (Q&P) steel was investigated by designing the different Q&P treatment parameters. The results show that the amount of isothermal martensite increased gradually with the increase in quenching time. The increase in isothermal martensite amount improved the product of strength and elongation (PSE) of Q&P steels. In addition, the increase in carbides amount and the recovery in prior martensite with longer partitioning time led to an increase in PSE first and then, a decrease. It implies that a higher PSE could be obtained by the selection of a suitable partitioning time. Furthermore, the effect of bainite transformation during partitioning on PSE was investigated by designing the different partitioning temperatures, including 300, 400 (below bainite starting temperature, Bs) and 480 °C (above Bs). The results show that compared with the samples partitioned at temperature above Bs, the bainite transformation was only detected when the samples were partitioned at temperature below Bs. The bainite transformation amount increased with the decreasing partitioning temperature, leading to the inhibition of carbides precipitation and more stable RA and thus, resulting in the highest PSE.

Similar content being viewed by others

References

J.G. Speer, D.V. Edmonds, F.C. Rizzo, D.K. Matlock, Curr. Opin. Solid State Mater. Sci. 8 (2004) 219–237.

J.G. Speer, E. De Moor, K.O. Findley, D.K. Matlock, B.C. De Cooman, D.V. Edmonds, Metall. Mater. Trans. A 42 (2011) 3591–3601.

Y.J. Liu, X.L. Gan, W. Liang, G. Xu, J.H. Qi, M. Liu, Materials 16 (2023) 3575.

M. Liu, J.H. Hu, M. Kern, B. Lederhaas, G. Xu, C. Bernhard, Trans. Indian Inst. Met. 74 (2021) 3265–3272.

M. Liu, J. Wang, Q. Zhang, H. Hu, G. Xu, Met. Mater. Int. 27 (2021) 2473–2480.

A. Zinsaz-Borujerdi, A. Zarei-Hanzaki, H.R. Abedi, M. Karam-Abian, H. Ding, D. Han, N. Kheradmand, Mater. Sci. Eng. A 725 (2018) 341–349.

J. Speer, D.K. Matlock, B.C. De Cooman, J.G. Schroth, Acta Mater. 51 (2003) 2611–2622.

J. Tian, G. Xu, Z. Jiang, H. Hu, M. Zhou, Met. Mater. Int. 24 (2018) 1202–1212.

G. Xu, F. Liu, L. Wang, H. Hu, Scripta Mater. 68 (2013) 833–836.

S. Golchin, B. Avishan, S. Yazdani, Mater. Sci. Eng. A 656 (2016) 94–101.

Q. Li, X. Huang, W. Huang, Mater. Sci. Eng. A 662 (2016) 129–135.

Y. Toji, G. Miyamoto, D. Raabe, Acta Mater. 86 (2015) 137–147.

M.C. Somani, D.A. Porter, L.P. Karjalainen, R.D.K. Misra, Metall. Mater. Trans. A 45 (2014) 1247–1257.

D.H. Kim, J.G. Speer, H.S. Kim, B.C. De Cooman, Metall. Mater. Trans. A 40 (2009) 2048–2060.

J. Guan, M. Liu, J. Tian, Z. Chen, G. Xu, Trans. Indian Inst. Met. 74 (2021) 3265–3272.

J. Tian, G. Xu, Z. Jiang, H. Hu, Q. Yuan, X. Wan, Met. Mater. Int. 26 (2020) 961–972.

I. Miettunen, S. Ghosh, M.C. Somani, S. Pallaspuro, J. Kömi, J. Mater. Res. Technol. 11 (2021) 1045–1060.

M.J. Santofimia, L. Zhao, R. Petrov, C. Kwakernaak, W.G. Sloof, J. Sietsma, Acta Mater. 59 (2011) 6059–6068.

F. HajyAkbary, J. Sietsma, G. Miyamoto, T. Furuhara, M.J. Santofimia, Acta Mater. 104 (2016) 72–83.

H.Y. Li, X.W. Lu, X.C. Wu, Y.A. Min, X.J. **, Mater. Sci. Eng. A 527 (2010) 6255–6259.

S. Yan, X. Liu, W.J. Liu, H. Lan, H. Wu, Mater. Sci. Eng. A 640 (2015) 137–146.

M. Mohammadi Zahrani, M. Ketabchi, E. Ranjbarnodeh, J. Mater. Res. Technol. 22 (2023) 2806–2818.

S. Pashangeh, M. Somani, S.S. Ghasemi Banadkouki, ISIJ Int. 61 (2021) 442–451.

Q.G. Li, Y.N. Zhang, W.D. Li, X.F. Huang, W.G. Huang, J. Mater. Eng. Perform. 29 (2020) 32–41.

C.Y. Wang, J. Shi, W.Q. Cao, H. Dong, Mater. Sci. Eng. A 527 (2010) 3442–3449.

M. Zhou, G. Xu, L. Wang, B. He, Trans. Indian Inst. Met. 70 (2017) 1447–1453.

Y. Liu, X. Gan, S. Wang, H. Yang, Y. Li, G. Xu, Steel Res. Int. 94 (2023) 2200840.

F.G. Caballero, M.J. Santofimia, C. García-Mateo, J. Chao, C. García de Andrés, Mater. Des. 30 (2009) 2077–2083.

H.K.D.H. Bhadeshia, S.A. David, J.M. Vitek, R.W. Reed, Mats. Sci. Tech. 7 (1991) 686–698.

A. Lindström, Austempered high silicon steel: investigation of wear resistance in a carbide free microstructure, Luleå University of Technology, Luleå, Sweden, 2006.

J. Tian, G. Xu, L. Wang, M. Zhou, H. Hu, Trans. Indian Inst. Met. 71 (2018) 185–194.

M. Liu, G. Xu, J.Y. Tian, Q. Yuan, X. Chen, Int. J. Miner. Metall. Mater. 27 (2020) 340–346.

J. Tian, G. Xu, H. Hu, X. Wang, H. Zurob, J. Mater. Res. Technol. 9 (2020) 13594–13606.

A. Navarro-López, J. Hidalgo, J. Sietsma, M.J. Santofimia, Mater. Sci. Eng. A 735 (2018) 343–353.

M. Saeglitz, G. Krauss, Metall. Mater. Trans. A 28 (1997) 377–387.

H. Kong, Q. Chao, M.H. Cai, E.J. Pavlina, B. Rolfe, P.D. Hodgson, H. Beladi, Mater. Sci. Eng. A 707 (2017) 538–547.

X. Tan, Y. Xu, X. Yang, D. Wu, Mater. Sci. Eng. A 589 (2014) 101–111.

S. Samanta, P. Biswas, S. Giri, S.B. Singh, S. Kundu, Acta Mater. 105 (2016) 390–403.

N.N. Thadhani, M.A. Meyers, Prog. Mater. Sci. 30 (1986) 0079642586900022.

E.P. Da Silva, D. De Knijf, W. Xu, C. Föjer, Y. Houbaert, J. Sietsma, R. Petrov, Mater. Sci. Technol. 31 (2015) 808–816.

S.M.C. van Bohemen, M.J. Santofimia, J. Sietsma, Scripta Mater. 58 (2008) 488–491.

S. Samanta, P. Biswas, S.B. Singh, Scripta Mater. 136 (2017) 132–135.

G.A. Thomas, J.G. Speer, D.K. Matlock, Iron Steel Technol. 5 (2008) 227–236.

T. Swarr, G. Krauss, Metall. Trans. A 7 (1976) 41–48.

D.E. Kaputkin, L.M. Kaputkina, S.D. Prokoshkin, J. Phys. IV France 112 (2003) 275–278.

H.Y. Li, X.W. Lu, W.J. Li, X.J. **, Metall. Mater. Trans. A 41 (2010) 1284–1300.

S. Kumar, S.B. Singh, Mater. Charact. 196 (2023) 112561.

G. Larzabal, N. Isasti, J.M. Rodriguez-Ibabe, P. Uranga, Metall. Mater. Trans. A 49 (2018) 946–961.

T. Kang, Z. Zhao, J. Liang, J. Guo, Y. Zhao, Mater. Sci. Eng. A 771 (2020) 138584.

N. Isasti, D. Jorge-Badiola, M.L. Taheri, P. Uranga, Met. Mater. Int. 20 (2014) 807–817.

H.R. Ghazvinloo, A. Honarbakhsh-Raouf, A.R.K. Rashid, Metallurgist 59 (2015) 90–96.

G. Chen, G. Xu, H.S. Zurob, H. Hu, X. Wan, Metall. Mater. Trans. A 50 (2019) 573–580.

Y. Wang, K. Zhang, Z. Guo, N. Chen, Y. Rong, Mater. Sci. Eng. A 552 (2012) 288–294.

X.C. **ong, B. Chen, M.X. Huang, J.F. Wang, L. Wang, Scripta Mater. 68 (2013) 321–324.

K. Zhang, M. Zhang, Z. Guo, N. Chen, Y. Rong, Mater. Sci. Eng. A 528 (2011) 8486–8491.

J. Tian, W. Wang, G. Xu, X. Wang, M. Zhou, H. Zurob, Met. Mater. Int. 29 (2023) 1298–1310.

Acknowledgements

The authors gratefully acknowledge the financial supports from the National Natural Science Foundation of China (No. 52104381) and the China Postdoctoral Science Foundation (No. 2023M732721) and also the help on microstructure analysis from Dr. Zhen Wang at the Analytical and Testing Center of Wuhan University of Science and Technology.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors have no competing interests or conflicts of interest to declare that are relevant to the contents of this article.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Liu, Yj., Tian, Jy., Liu, M. et al. Effect of isothermal martensite and bainite transformation on microstructure and properties in a medium-carbon high-strength Q&P steel. J. Iron Steel Res. Int. (2024). https://doi.org/10.1007/s42243-024-01216-3

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s42243-024-01216-3