Abstract

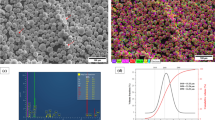

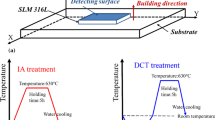

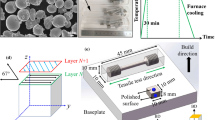

PH13-8Mo stainless steel powder with high sphericity and well fluidity was prepared by the plasma rotating electrode process. The formed parts with ultra-high purity were manufactured by selective laser melting. The tensile and impact mechanical properties of the printed parts under three heat treatment regimes were compared to those without heat treatment. The microstructure, grain orientation and phase composition were characterized by electron-backscatter diffraction, X-ray diffraction and transmission electron microscopy. The characterization results reveal that the addition of heat treatment makes the grains enlarge, and after different heat treatments, the average grain size from 1.51 µm in the printed state increases to 2.78, 3.09 and 2.06 μm, respectively. The formed parts are mainly composed of martensite and retained austenite. Moreover, the NiAl and M23C6 precipitates form, which are the major strengthening phases of PH13-8Mo stainless steel. The optimal heat treatment process is 925 °C × 1 h water cooling (WC) + 0 °C × 2 h air cooling (AC) + 540 °C × 4 h AC. Using this heat treatment process, PH13-8Mo formed parts have the optimal comprehensive mechanical properties: the tensile strength, yield strength and impact energy KU2 are 1492 MPa, 1432 MPa and 63 J, respectively. The strengthening and toughening via heat treatment are mainly attributed to dislocation strengthening, the formation of NiAl and M23C6 precipitates and the change of volume fraction of the retained austenite.

Similar content being viewed by others

References

Z. Guo, W. Sha, D. Vaumousse, Acta Mater. 51 (2003) 101–116.

H. Leitner, R. Schnitzer, M. Schober, S. Zinner, Acta Mater. 59 (2011) 5012–5022.

P. Munn, B. Andersson, Corrosion 46 (1990) 286–295.

J. Fan, L. Zhang, S. Wei, Z. Zhang, S.K. Choi, B. Song, Y. Shi, Mater. Today 50 (2021) 303–328.

J.P. Kruth, L. Froyen, J. Van Vaerenbergh, P. Mercelis, M. Rombouts, B. Lauwers, J. Mater. Process. Technol. 149 (2004) 616–622.

D. Gu, X. Shi, R. Poprawe, D.L. Bourell, R. Setchi, J. Zhu, Science 372 (2021) 1487.

G. Chen, S.Y. Zhao, P. Tan, J. Wang, C.S. **ang, H.P. Tang, Powder Technol. 333 (2018) 38–46.

S. Yin, C. Chen, X. Yan, X. Feng, R. Jenkins, P. O'Reilly, M. Liu, H. Li, R. Lupoi, Addit. Manuf. 22 (2018) 592–600.

S. Sarkar, C.S. Kumar, A.K. Nath, Mater. Sci. Eng. A 755 (2019) 235–245.

Y. Bai, Y. Yang, D. Wang, M. Zhang, Mater. Sci. Eng. A 703 (2017) 116–123.

S. Pasebani, M. Ghayoor, S. Badwe, H. Irrinki, S.V. Atre, Addit. Manuf. 22 (2018) 127–137.

V. Vignal, S. Ringeval, S. Thiébaut, K. Tabalaiev, C. Dessolin, O. Heintz, F. Herbst, R. Chassagnon, Corros. Sci. 85 (2014) 42–51.

S.Y. Lu, K.F. Yao, Y.B. Chen, M.H. Wang, N. Chen, X.Y. Ge, Corros. Sci. 103 (2016) 95–104.

H. Duan, B. Liu, A. Fu, J. He, T. Yang, C.T. Liu, Y. Liu, J. Mater. Sci. Technol. 99 (2022) 207–214.

X. Teng, G. Zhang, J. Liang, H. Li, Q. Liu, Y. Cui, T. Cui, L. Jiang, Mater. Res. Express 6 (2019) 086592.

L. Couturier, F. De Geuser, M. Descoins, A. Deschamps, Mater. Des. 107 (2016) 416–425.

Y. Liu, J. Zhang, Z. Pang, Opt. Laser Technol. 98 (2018) 23–32.

C. Liu, K. Zhu, W. Ding, Y. Liu, G. Chen, X. Qu, Powder Metall. 65 (2022) 413–425.

L.E. Murr, E. Martinez, J. Hernandez, S. Collins, K.N. Amato, S.M. Gaytan, P.W. Shindo, J. Mater. Res. Technol. 1 (2012) 167–177.

F. Pan, J. Zhang, H.L. Chen, Y.H. Su, C.L. Kuo, Y.H. Su, S.H. Chen, K.J. Lin, P.H. Hsieh, W.S. Hwang, Materials 9 (2016) 417.

Z. Dong, H. Kang, Y. **e, C. Chi, X. Peng, Mater. Lett. 236 (2019) 214–217.

X. Lou, P.L. Andresen, R.B. Rebak, J. Nucl. Mater. 499 (2018) 182–190.

L. Proville, B. Bakó, Acta Mater. 58 (2010) 5565–5571.

I. Nikitin, A. Fedoseeva, R. Kaibyshev, J. Mater. Sci. 55 (2020) 7530–7545.

Z. Shi, S. Liu, Y. Zhou, X. **ng, X. Ren, Q. Yang, J. Alloy. Compd. 773 (2019) 264–276.

C. Köse, J. Mater. Eng. Perform. 30 (2021) 7417–7448.

K.L. Dahm, P.A. Dearnley, Proc. Insitut. Mech. Eng. Part L J. Mater. Des. Appl. 214 (2000) 181–199.

Y. Zou, Y.B. Xu, Z.P. Hu, X.L. Gu, F. Peng, X.D. Tan, S.Q. Chen, D.T. Han, R.D.K. Misra, G.D. Wang, Mater. Sci. Eng. A 675 (2016) 153–163.

T. Koseki, J. Inoue, S. Nambu, Mater. Trans. 55 (2014) 227–237.

S.D. Erlach, H. Leitner, M. Bischof, H. Clemens, F. Danoix, D. Lemarchand, I. Siller, Mater. Sci. Eng. A 429 (2006) 96–106.

S. Wu, D. Wang, X. Di, C. Li, Z. Zhang, Z. Zhou, X. Liu, Mater. Sci. Eng. A 755 (2019) 57–65.

Acknowledgements

This work was supported by the National Key Research & Development Program of China (No. 2021YFB3702501) and the Innovation Fund of China Steel Research Technology Group Co., Ltd. (No. KNJT05-JT0M-21001).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

We declare that we have no financial and personal relationships with other people or organizations that can inappropriately influence our work; there is no professional or other personal interest of any nature or kind in any product, service and/or company that could be construed as influencing the position presented in, or the review of, the manuscript entitled.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Zhang, Y., Liu, X., Wang, Cj. et al. Effect of heat treatment on microstructure and mechanical properties of selective laser-melted PH13-8Mo stainless steel. J. Iron Steel Res. Int. 31, 945–955 (2024). https://doi.org/10.1007/s42243-023-00969-7

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42243-023-00969-7