Abstract

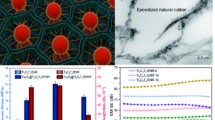

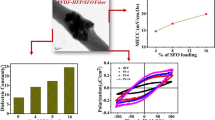

The limited electronic applications of magnetorheological elastomers (MREs), polymer composites with carbonyl iron powder (CIP), are addressed in this study with a groundbreaking methodology. By utilizing a noncontact AC electric field, CIP manipulation at low concentrations (0.5–5 vol%) leads to the formation of conductive pathways within MREs. The resulting H-shaped structure exhibits columnar conductive pathways along the film’s thickness and interconnected pathways throughout the matrix, effectively reducing both volume and surface resistivity. Insights into the formation process are gained through real-time observations and numerical simulations. Experimental measurements reveal a remarkable reduction in volume and surface resistivity, achieving three and two orders of magnitude reduction, respectively, in 5 vol% H-shaped structure MREs. Remarkably, the H-shaped structure MREs display exceptional magneto-resistive and magneto-rheological behavior. Variations in surface resistance and resonant frequency occur with changing magnetic fields, with surface resistance decreasing by up to 89.6% (510 mT) and resonant frequency decreasing by up to 49.05% (300 mT). The efficacy of electric field-treated H-shaped structure MRE films is confirmed for practical applications in self-sensing tunable vibration absorbers. This research presents an innovative approach to enhance MRE conductivity, introducing a significant advancement in electronic functionality that opens doors to cutting-edge applications.

Similar content being viewed by others

Data availability

The authors declare that the data supporting the findings of this study are available within the paper and its Supplementary Information files.

References

Bahl S, Nagar H, Singh I, Sehgal S (2020) Smart materials types, properties and applications: a review. In: Materials Today: Proceedings. Elsevier Ltd. pp 1302–1306

Surmenev RA, Chernozem RV, Pariy IO, Surmeneva MA (2021) A review on piezo- and pyroelectric responses of flexible nano- and micropatterned polymer surfaces for biomedical sensing and energy harvesting applications. Nano Energy 79:105442

Wei H, Gu J, Ren F, Zhang L, Xu G, Wang B, Song S, Zhao J, Dou S, Li Y (2021) Smart materials for dynamic thermal radiation regulation. Small 17(35):2100446

Alagha AN, Hussain S, Zaki W (2021) Additive manufacturing of shape memory alloys: a review with emphasis on powder bed systems. Mater Des 204:109654

Bastola AK, Hossain M (2021) The shape-morphing performance of magnetoactive soft materials performance. Mater Des 211:110172

Díez AG, Tubio CR, Etxebarria JG, Lanceros-Mendez S (2021) Magnetorheological elastomer-based materials and devices: state of the art and future perspectives. Adv Eng Mater 23(6):2100240

Khayam SU, Usman M, Umer MA, Rafique A (2020) Development and characterization of a novel hybrid magnetorheological elastomer incorporating micro and nano size iron fillers. Mater Des 192. https://doi.org/10.1016/j.matdes.2020.108748

Bastola AK, Hossain M (2020) A review on magneto-mechanical characterizations of magnetorheological elastomers. Compos Part B Eng 200:108348

Ginde JM, Nichols ME, Eliea LD, Tardiff’ IL (1999) Magnetorheological elastomers: properties and applications. Smart structures and materials 1999: smart materials technologies, vol 3675. SPIE, pp 131–138

Vatandoost H, Hemmatian M, Sedaghati R, Rakheja S (2020) Dynamic characterization of isotropic and anisotropic magnetorheological elastomers in the oscillatory squeeze mode superimposed on large static pre-strain. Compos B Eng 182. https://doi.org/10.1016/j.compositesb.2019.107648

Leng D, Wang X, Sun L, Gordaninejad F (2017) Shock attenuation mechanisms of magnetorheological elastomers absorbers: a theoretical analysis. J Compos Mater 51:721–730. https://doi.org/10.1177/0021998316649252

Testa P, Style RW, Cui J, Donnelly C, Borisova E, Derlet PM, Dufresne ER, Heyderman LJ (2019) Magnetically addressable shape-memory and stiffening in a composite elastomer. Adv Mater 31. https://doi.org/10.1002/adma.201900561

Yao J, Gao Y, Fan J, Scarpa F, Li Y (2022) Design and verification of a magnetorheological elastomer-based actuator to reduce rotor vibration. Int J Mech Mater Des 18:701–718. https://doi.org/10.1007/s10999-022-09599-5

Sedlacik M, Mrlik M, Babayan V, Pavlinek V (2016) Magnetorheological elastomers with efficient electromagnetic shielding. Compos Struct 135:199–204. https://doi.org/10.1016/j.compstruct.2015.09.037

Cvek M, Kutalkova E, Moucka R, Urbanek P, Sedlacik M (2020) Lightweight, transparent piezoresistive sensors conceptualized as anisotropic magnetorheological elastomers: a durability study. Int J Mech Sci 183. https://doi.org/10.1016/j.ijmecsci.2020.105816

Hu T, Xuan S, Ding L, Gong X (2018) Stretchable and magneto-sensitive strain sensor based on silver nanowire-polyurethane sponge enhanced magnetorheological elastomer. Mater Des 156:528–537. https://doi.org/10.1016/j.matdes.2018.07.024

Wang Y, Lu S, He W, Gong S, Zhang Y, Zhao X, Fu Y, Zhu Z (2022) Modeling and characterization of the electrical conductivity on metal nanoparticles/carbon nanotube/polymer composites. Sci Rep 12. https://doi.org/10.1038/s41598-022-14596-x

Kuang T, Zhang M, Chen F, Fei Y, Yang J, Zhong M, Wu B, Liu T (2023) Creating poly(lactic acid)/carbon nanotubes/carbon black nanocomposites with high electrical conductivity and good mechanical properties by constructing a segregated double network with a low content of hybrid nanofiller. Adv Compos Hybrid Mater 6. https://doi.org/10.1007/s42114-022-00622-z

Moučka R, Sedlačík M, Kutálková E (2018) Magnetorheological elastomers: electric properties versus microstructure. In: AIP Conference Proceedings. American Institute of Physics Inc

Aziz SAA, Mazlan SA, Ubaidillah U, Shabdin MK, Yunus NA, Nordin NA, Choi SB, Rosnan RM (2019) Enhancement of viscoelastic and electrical properties of magnetorheological elastomers with nanosized Ni-Mg cobalt-ferrites as fillers. Materials 12. https://doi.org/10.3390/ma12213531

Puente-Córdova JG, Reyes-Melo ME, Palacios-Pineda LM, Martínez-Perales IA, Martínez-Romero O, Elías-Zúñiga A (2018) Fabrication and characterization of isotropic and anisotropic magnetorheological elastomers, based on silicone rubber and carbonyl iron microparticles. Polymers (Basel) 10. https://doi.org/10.3390/polym10121343

Agirre-Olabide I, Kuzhir P, Elejabarrieta MJ (2018) Linear magneto-viscoelastic model based on magnetic permeability components for anisotropic magnetorheological elastomers. J Magn Magn Mater 446:155–161. https://doi.org/10.1016/j.jmmm.2017.09.017

Lee TW, Lee SE, Jeong YG (2016) Highly effective electromagnetic interference shielding materials based on silver nanowire/cellulose papers. ACS Appl Mater Interfaces 8:13123–13132. https://doi.org/10.1021/acsami.6b02218

Zhang W, Lin L, Zhang L, Wang Y, Zhuang Y, Choi Y, Cho Y, Chen T, Yao H, Piao Y (2022) 3D nanoconductive network based on the microstructure of latex foam for superior performance piezoresistive sensors. ACS Appl Polym Mater 4:54–63. https://doi.org/10.1021/acsapm.1c00834

Onishi G, Trung NNC, Matsutani N, Nakayama T, Suzuki T, Suematsu H, Niihara K (2018) Demonstration of motion control of ZrO2 microparticles in uniform/non-uniform electric field. Jpn J Appl Phys 57(2S2):02CB11

Huynh MTT, Cho HB, Suzuki T, Suematsu H, Nguyen ST, Niihara K, Nakayama T (2018) Electrical property enhancement by controlled percolation structure of carbon black in polymer-based nanocomposites via nanosecond pulsed electric field. Compos Sci Technol 154:165–174. https://doi.org/10.1016/j.compscitech.2017.09.019

Osazuwa O, Vasileiou AA, Kontopoulou M, Docoslis A (2017) Electric-field induced filler association dynamics and resulting improvements in the electrical conductivity of polyester/multiwall carbon nanotube composites. Polym Compos 38:1571–1578. https://doi.org/10.1002/pc.23724

Guo Y, Chen Y, Wang E, Cakmak M (2017) Roll-to-roll continuous manufacturing multifunctional nanocomposites by electric-field-assisted “z” direction alignment of graphite flakes in poly(dimethylsiloxane). ACS Appl Mater Interfaces 9:919–929. https://doi.org/10.1021/acsami.6b13207

Chen Y, Liu Y, **a Y, Liu X, Qiang Z, Yang J, Zhang B, Hu Z, Wang Q, Wu W, Duan Y, Fu KK, Zhang J (2020) Electric field-induced assembly and alignment of silver-coated cellulose for polymer composite films with enhanced dielectric permittivity and anisotropic light transmission. ACS Appl Mater Interfaces 12:24242–24249. https://doi.org/10.1021/acsami.0c03086

Park KR, Cho HB, Lim M, Jang BK, Lee J, Jeon BS, Choa YH (2021) Through-plane high thermal conducting networks via incorporation of graphene nanoplatelets in nanocomposite film under electric field and avoiding breakdown voltage. Appl Surf Sci 551. https://doi.org/10.1016/j.apsusc.2021.149201

Zhang H, Cadusch J, Kinnear C, James T, Roberts A, Mulvaney P (2018) Direct assembly of large area nanoparticle arrays. ACS Nano 12:7529–7537. https://doi.org/10.1021/acsnano.8b02932

Bishop KJM, Drews AM, Cartier CA, Pandey S, Dou Y (2018) Contact charge electrophoresis: fundamentals and microfluidic applications. Langmuir 34:6315–6327. https://doi.org/10.1021/acs.langmuir.7b02946

Knutson CR, Edmond KV, Tuominen MT, Dinsmore AD (2007) Shuttling of charge by a metallic sphere in viscous oil. J Appl Phys 101. https://doi.org/10.1063/1.2403242

Dutta S, Singh AK, Gooh Pattader PS, Bandyopadhyay D (2021) Genesis of electric field assisted microparticle assemblage in a dielectric fluid. J Fluid Mech 915. https://doi.org/10.1017/jfm.2021.22

Colla T, Mohanty PS, Nöjd S, Bialik E, Riede A, Schurtenberger P, Likos CN (2018) Self-assembly of ionic microgels driven by an alternating electric field: theory, simulations, and experiments. ACS Nano 12:4321–4337. https://doi.org/10.1021/acsnano.7b08843

Shen ZH, Wang JJ, Lin Y, Nan CW, Chen LQ, Shen Y (2018) High-throughput phase-field design of high-energy-density polymer nanocomposites. Adv Mater 30. https://doi.org/10.1002/adma.201704380

Li R, Gou X, Zhou M, Yang PA, Li P, Shou M, Liao C, Wang X (2022) Modeling and validation of multifield coupled self-sensing characteristics of magnetorheological elastomer for vibration isolators. Mater Des 217. https://doi.org/10.1016/j.matdes.2022.110636

Fu Y, Li S, Liu J, Zhao B (2021) Design and experimentation of a self-sensing actuator for active vibration isolation system with adjustable anti-resonance frequency controller. Sensors 21:1–13. https://doi.org/10.3390/s21061941

Li R, Zhou M, Wang M, Yang PA (2018) Study on a new self-sensing magnetorheological elastomer bearing. AIP Adv 8. https://doi.org/10.1063/1.5025384

Kwon H, Song Y, Park JE, Kim YK (2021) A standalone tunable vibration absorber with self-sensing magnetorheological elastomer. Smart Mater Struct 30. https://doi.org/10.1088/1361-665X/ac26e7

Li R, Zhou M, Wang M, Chen S, Yang P (2019) The influence of force and magnetic field on the self-sensing characteristics of magneto-rheological elastomer bearing. Proceedings - 2018 Prognostics and System Health Management Conference, PHM-Chongqing 2018. Institute of Electrical and Electronics Engineers Inc, pp 758–763

Davis LC (1999) Model of magnetorheological elastomers. J Appl Phys 85:3348–3351. https://doi.org/10.1063/1.369682

Zhang J, Pang H, Wang Y, Gong X (2020) The magneto-mechanical properties of off-axis anisotropic magnetorheological elastomers. Compos Sci Technol 191. https://doi.org/10.1016/j.compscitech.2020.108079

Cantera MA, Behrooz M, Gibson RF, Gordaninejad F (2017) Modeling of magneto-mechanical response of magnetorheological elastomers (MRE) and MRE-based systems: a review. Smart Mater Struc 26(2):023001

ASTM Standard E756-05 (2005) Standard Test Method for Measuring Vibration-Dam** Properties of Materials. ASTM International, West Conshohocken, PA, 2005. https://doi.org/10.1520/E0756-05R17, https://www.astm.org

Cortés F, Elejabarrieta MJ (2007) Viscoelastic materials characterisation using the seismic response. Mater Des 28:2054–2062. https://doi.org/10.1016/j.matdes.2006.05.032

Sulatchaneenopdon N, Shen Z, Son HW, Khantachawana A, Garcia-Barruetabena J, Elejabarrieta MJ, Takahashi T, Nakayama T, Niihara K (2022) Analyzing the influence of the core pre-structure on the dynamic response of a magnetorheological elastomer sandwich structure. Smart Mater Struct 31. https://doi.org/10.1088/1361-665X/ac775b

Author information

Authors and Affiliations

Contributions

Zhiming Shen: Methodology, Writing-original draft, Data curation. Narongdet Sulatchaneenopdon: Methodology. Hideto Furuno: Reviewing & editing. Takeshi Fujihara: Reviewing & editing. Hong-Baek Cho: Reviewing & editing. Tadachika Nakayama: Project administration, Resources, Supervision. Koichi Niihara: Supervision.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Shen, Z., Sulatchaneenopdon, N., Furuno, H. et al. Fabrication of H-shaped structure magnetorheological elastomer film for enhancing electrical properties by AC electric field. Adv Compos Hybrid Mater 6, 225 (2023). https://doi.org/10.1007/s42114-023-00803-4

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s42114-023-00803-4