Abstract

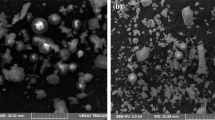

This paper attempts to examine the influence of slag content on the fly ash geopolymer concrete exposed to the marine environment and to analyse their interrelationship between the mechanical and durability properties towards the microstructural parameters. The dosage of the slag content is varied with a 10% increment up to 40% based on the literature and preliminary trial mixes. Sodium-based alkaline activator with hydroxide to silicate ratio of 2 is considered and the molarity is fixed as 8M. Several experimental tests to access the mechanical, durability and microstructural parameters are performed. 28-day ambient cured specimens were subjected to a marine environment for various exposure durations and their corresponding mechanical and durability results are obtained which are then interrelated upon microstructural parameters. Irrespective of the dosage of slag, all the specimens show 40–50% deterioration in mechanical properties after 150 days of exposure to the marine environment. 30% dosage of slag which showed higher mechanical performance in unexposed conditions showed a high rate of deterioration after marine exposure, around 50% in mechanical and durability properties, whereas 40% slag mix which showed lesser efficiency before exposure, showed good resistance to strength loss and external agent ingress. SEM images revealed that the weathering action of NaCl salts deteriorates the surface and the size of pores and flaws largely influence the mechanical and durability performances of the exposed specimens. EDAX test confirms the unexpected chemical reactions with respect to intensity and reactions between specimens and marine exposure.

Similar content being viewed by others

Data availability

Not applicable.

References

Ahmad, J., Kontoleon, K. J., Majdi, A., Naqash, M. T., Deifalla, A. F., Ben Kahla, N., Isleem, H. F., & Qaidi, S. M. (2022). A comprehensive review on the ground granulated blast furnace slag (GGBS) in concrete production. Sustainability, 14(14), 8783.

Alexander, M., & Beushausen, H. (2019). Durability, service life prediction, and modelling for reinforced concrete structures—Review and critique. Cement and Concrete Research, 122, 17–29.

Amran, M., Huang, S. S., Debbarma, S., & Rashid, R. S. (2022). Fire resistance of geopolymer concrete: A critical review. Construction and Building Materials, 324, 126722.

ASTM C 348-02. (1999). Standard test method for flexural strength of hydraulic-cement mortars. Document Number: ASTM C0348-02. ASTM International.

ASTM C1202. (2000). Electrical indication of concrete’s ability to resist chloride ion penetration. Annual Book of American Society for Testing Materials Standards (vol. C04.02).

ASTM C1585. (2013). Standard test method for measurement of the rate of absorption of water by hydraulic-cement concretes; ASTM C1585. ASTM International.

ASTM C618. (2003). Standard specification for coal fly ash and raw or calcined natural pozzolan for use in concrete. American society for testing and materials. ASTM International.

Babu, G. K., Rao, K. V., Dey, S., & Veerendra, G. T. N. (2023). Performance studies on quaternary blended geopolymer concrete. Hybrid Advances, 2, 100019.

Davidovits, J. (Ed.). (2005). Geopolymer, green chemistry and sustainable development solutions: Proaeedings of the world congreass geopolymer. Geopolymer Institute.

Endale, S. A., Taffese, W. Z., Vo, D. H., & Yehualaw, M. D. (2022). Rice husk ash in concrete. Sustainability, 15(1), 137.

Ferron, J. M., & Hess, M. R. (2007). Estimation in SEM: A concrete example.

Hardjito, D., Wallah, S. E., Sumajouw, D. M., & Rangan, B. V. (2005). Fly ash-based geopolymer concrete. Australian Journal of Structural Engineering, 6(1), 77–86.

Hassan, A., Arif, M., & Shariq, M. (2020). Influence of microstructure of geopolymer concrete on its mechanical properties—A review. Advances in Sustainable Construction Materials and Geotechnical Engineering: Select Proceedings of TRACE, 2018, 119–129.

Haynes, R. J. (2009). Reclamation and revegetation of fly ash disposal sites—Challenges and research needs. Journal of Environmental Management, 90(1), 43–53.

Hu, C. (2014). Microstructure and mechanical properties of fly ash blended cement pastes. Construction and Building Materials, 73, 618–625.

IS: 4031-6. (1988). Methods of physical tests for hydraulic cement—Determination of compressive strength of Hydraulic cement. Bureau of Indian Standards.

IS: 16714:2018. (2018). Ground granulated blast furnace slag for use of cement, mortar and concrete specification. Bureau of Indian Standards.

IS: 383-2016. (2016). Coarse and fine aggregate for concrete—Specification. Bureau of Indian Standards.

IS: 5816-1999. (1999). Method of test splitting tensile strength of concrete—Specification. Bureau of Indian Standards.

John, S. K., Nadir, Y., & Girija, K. (2021). Effect of source materials, additives on the mechanical properties and durability of fly ash and fly ash-slag geopolymer mortar: A review. Construction and Building Materials, 280, 122443.

Juenger, M. C., & Siddique, R. (2015). Recent advances in understanding the role of supplementary cementitious materials in concrete. Cement and Concrete Research, 78, 71–80.

Jumaa, N. H., Ali, I. M., Nasr, M. S., & Falah, M. W. (2022). Strength and microstructural properties of binary and ternary blends in fly ash-based geopolymer concrete. Case Studies in Construction Materials, 17, e01317.

Khatri, R. P., & Sirivivatnanon, V. (2004). Characteristic service life for concrete exposed to marine environments. Cement and Concrete Research, 34(5), 745–752.

Khedr, S. A., & Abou-Zeid, M. N. (1994). Characteristics of silica-fume concrete. Journal of Materials in Civil Engineering, 6(3), 357–375.

Lothenbach, B., Scrivener, K., & Hooton, R. D. (2011). Supplementary cementitious materials. Cement and Concrete Research, 41(12), 1244–1256.

Malhotra, V. M. (2002). High-performance high-volume fly ash concrete. Concrete International, 24(7), 30–34.

Marvila, M. T., Azevedo, A. R. G., & Vieira, C. M. (2021a). F, Reaction mechanisms of alkali-activated materials. IBRACON Structures and Material Journal, 14(3), e14309.

Marvila, M. T., de Azevedo, A. R. G., de Matos, P. R., Monteiro, S. N., & Vieira, C. M. F. (2021b). Materials for production of high and ultra-high performance concrete: Review and perspective of possible novel materials. Materials, 14(15), 4304.

Mehta, P. K., & Monteiro, P. J. (2014). Concrete: Microstructure, properties, and materials. McGraw-Hill Education.

Nematollahi, B., & Sanjayan, J. (2014). Effect of different superplasticizers and activator combinations on workability and strength of fly ash based geopolymer. Materials & Design, 57, 667–672.

Noushini, A., & Castel, A. (2018). Performance-based criteria to assess the suitability of geopolymer concrete in marine environments using modified ASTM C1202 and ASTM C1556 methods. Materials and Structures, 51(6), 146.

Oner, A. D. N. A. N., Akyuz, S., & Yildiz, R. (2005). An experimental study on strength development of concrete containing fly ash and optimum usage of fly ash in concrete. Cement and Concrete Research, 35(6), 1165–1171.

Parathi, S., Nagarajan, P., & Pallikkara, S. A. (2021). Ecofriendly geopolymer concrete: A comprehensive review. Clean Technologies and Environmental Policy, 23, 1701–1713.

Pillay, D. L., Olalusi, O. B., Kiliswa, M. W., Awoyera, P. O., Kolawole, J. T., & Babafemi, A. J. (2022). Engineering performance of metakaolin based concrete. Cleaner Engineering and Technology, 6, 100383.

Qu, F., Li, W., Dong, W., Tam, V. W., & Yu, T. (2021). Durability deterioration of concrete under marine environment from material to structure: A critical review. Journal of Building Engineering, 35, 102074.

Reddy, D. V., Edouard, J. B., & Sobhan, K. (2013). Durability of fly ash–based geopolymer structural concrete in the marine environment. Journal of Materials in Civil Engineering, 25(6), 781–787.

Saeed, A., Najm, H. M., Hassan, A., Sabri, M. M. S., Qaidi, S., Mashaan, N. S., & Ansari, K. (2022). Properties and applications of geopolymer composites: A review study of mechanical and microstructural properties. Materials, 15(22), 8250.

Shilar, F. A., Ganachari, S. V., Patil, V. B., Javed, S., Khan, T. Y., & Baig, R. U. (2022). Assessment of destructive and nondestructive analysis for GGBS based geopolymer concrete and its statistical analysis. Polymers, 14(15), 3132.

Taylor, H. F. (1997). Cement chemistry (Vol. 2, p. 459). Thomas Telford.

Thomas, B. S., Yang, J., Bahurudeen, A., Abdalla, J. A., Hawileh, R. A., Hamada, H. M., & Ashish, D. K. (2021). Sugarcane bagasse ash as supplementary cementitious material in concrete—A review. Materials Today Sustainability, 15, 100086.

Van Oss, H. G., & Padovani, A. C. (2003). Cement manufacture and the environment part II: Environmental challenges and opportunities. Journal of Industrial Ecology, 7(1), 93–126.

Wasim, M., Ngo, T. D., & Law, D. (2021). A state-of-the-art review on the durability of geopolymer concrete for sustainable structures and infrastructure. Construction and Building Materials, 291, 123381.

Wesche, K. (Ed.). (1991). Fly ash in concrete: Properties and performance. CRC Press.

Wong, L. S. (2022). Durability performance of geopolymer concrete: A review. Polymers, 14(5), 868.

Yaswanth, K. K., Revathy, J., & Gajalakshmi, P. (2022a). Influence of copper slag on Mechanical, durability and microstructural properties of GGBS and RHA blended strain hardening geopolymer composites. Construction and Building Materials, 342, 128042.

Yaswanth, K. K., Revathy, J., & Gajalakshmi, P. (2022b). Strength, durability and micro-structural assessment of slag-agro blended based alkali activated engineered geopolymer composites. Case Studies in Construction Materials, 16, e00920.

Zhang, P., Gao, Z., Wang, J., Guo, J., Hu, S., & Ling, Y. (2020). Properties of fresh and hardened fly ash/slag based geopolymer concrete: A review. Journal of Cleaner Production, 270, 122389.

Acknowledgements

The project staff at VFSTR, Guntur, India, contributed greatly to the execution of the experiments, which the authors gratefully acknowledge.

Funding

The authors have not disclosed any funding.

Author information

Authors and Affiliations

Contributions

CRG: Manuscript writing, draft, methodology, investigation, result analysis. DSC: Reviewing, supervising, drafting

Corresponding author

Ethics declarations

Conflict of interest

The authors of this paper declaring that no conflict of interest in the publishing of this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Gadikota, C.R., Chandra, D.S. Influence of slag content on mechanical, durability and microstructural performance and their correlations in fly ash geopolymers exposed to marine environment. Asian J Civ Eng 25, 2091–2108 (2024). https://doi.org/10.1007/s42107-023-00896-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42107-023-00896-8