Abstract

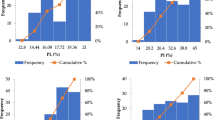

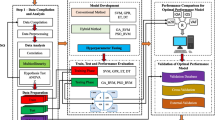

The present research introduces the best architecture approach and model for predicting the unconfined compressive strength (UCS) of cohesive virgin soil by comparing the multivariable regression analysis (MRA), gaussian process regression (GPR), and gene expression programming (GEP) approaches. The present research reveals the effect of the quality & quantity of the training database and the impact of the multicollinearity on the performance and overfitting of the MRA, GPR, and GEP models. The performance of the soft computing models has been measured by root mean square error (RMSE), mean absolute error (MAE), mean absolute percentage error (MAPE), weighted mean absolute percentage error (WMAPE), coefficient of determination (R2), correlation coefficient (r), variance accounted for (VAF), Nash–Sutcliffe efficiency (NS), normalized mean bias error (NMBE), Legate McCabe's Index (LMI), root mean square error to observations’ standard deviation ratio (RSR), a20-index, index of agreement (IOA), and index of scatter (IOS) statistical tools. The performance comparison of MRA, GPR, and GEP shows that GPR model MD11 has predicted UCS of soil with high performance (R = 0.9959, VAF = 99.18, NS = 0.9909, LMI = 0.1026, RSR = 0.0952, a20-index = 100.00, IOA = 0.9487 & IOS = 0.0531) and the least prediction error (RMSE = 2.4482 N/cm2, MAE = 1.8840 N/cm2, MAPE = 5.0849 N/cm2, WMAPE = 0.0408 N/cm2, NMBE = 0.1299 N/cm2). In the validation, model MD11 has achieved RMSE = 3.4849 N/cm2, MAE = 3.1845 N/cm2, R = 0.9040, R2 = 0.8172, confidence interval of ± 5.0% by predicting UCS of lab-tested twelve soil samples, which is acceptable. This study shows that the GPR approach predicts better UCS in the presence of multicollinearity and using a small database. The sensitivity analysis illustrates that the UCS prediction of cohesive virgin soil is very highly influenced by fine content, dry unit weight, porosity, void ratio, degree of saturation, and specific gravity of soil.

Similar content being viewed by others

Data availability

The data would remain confidential and shared by the corresponding author at the request. Software support: MATLAB R2020a: for employing soft computing models, analysis, evaluation, prediction. Origin Lab 2022b: for graphical presentations and analysis.

Abbreviations

- \(C^{\prime}\) :

-

Cohesion (N/mm2)

- \(CBR_{10}\) :

-

CBR of soil compacted with 10 blows (%)

- \(CBR_{30}\) :

-

CBR of soil compacted with 30 blows (%)

- \(CBR_{65}\) :

-

CBR of soil compacted with 65 blows (%)

- \(C^{C}\) :

-

Cement condition

- \(C_{{\text{C}}}\) :

-

Coefficient of curvature

- \(C^{{\text{T}}}\) :

-

Curing period (days)

- \(C_{{\text{U}}}\) :

-

Coefficient of uniformity

- \(C^{{{\text{cc}}}}\) :

-

Curing condition

- \(L^{{\text{C}}}\) :

-

Lime content (%)

- \(L_{{\text{S}}}\) :

-

Linear shrinkage (%)

- \(M^{{\text{O}}}\) :

-

Molar concentration of alkali solution

- \(M^{{\text{S}}}\) :

-

Micro silica (%)

- \(V_{{\text{p}}}\) :

-

Primary ultrasonic wave velocity (m/s)

- \(\gamma_{{\text{w}}}\) :

-

Wet density (g/cc)

- A/B:

-

Amount of alkali to binder

- AI:

-

Artificial intelligence

- ANFIS:

-

Adaptive neuro-fuzzy inference system

- ANN:

-

Artificial neural networks

- ASTM:

-

American standard for testing and materials

- BFS:

-

Blast furnace slag (%)

- BUW:

-

Bulk unit weight (g/cc)

- C:

-

Clay content (%)

- CBR:

-

California bearing ratio (%)

- CC:

-

Correlation coefficient

- CI:

-

Compressibility index

- COD:

-

Coefficient of determination

- CSO:

-

Cuckoo search optimization

- D:

-

Sampling depth

- DCPI:

-

Dynamic cone penetration index

- DE:

-

Differential equation

- DS:

-

Degree of saturation (%)

- DT:

-

Decision tree

- DUW:

-

Dry unit weight (gm/cc)

- EPR:

-

Evolutionary polynomial regression

- FA:

-

Fly ash (%)

- FC:

-

Fine content (%)

- GA:

-

Genetic algorithm

- GB:

-

Gradient boosting

- GGBS:

-

Ground granulated blast-furnace slag

- GMDH:

-

Group method of data handling

- K :

-

Permeability (m/s)

- LI:

-

Liquidity index

- LL:

-

Liquid limit (%)

- MC:

-

Moisture content (%)

- MDD:

-

Maximum dry density (gm/cc)

- MRA:

-

Multiple regression Analysis

- MVR:

-

Multi-variable regression

- Na/Al:

-

Atomic proportion of Na to Al

- NF:

-

Neuro fuzzy

- NMC:

-

Natural moisture content (%)

- NWC:

-

Natural water content (%)

- OMC:

-

Optimum moisture content (%)

- ɸ :

-

Diameter (m)

- P :

-

Porosity (%)

- PA:

-

Pond ash (%)

- pH:

-

Potential of hydrogen

- PL:

-

Plastic limit (%)

- PSO:

-

Particle swarm optimization

- RA:

-

Regression analysis

- RBF:

-

Radial bias function

- RF:

-

Random forest

- RHA:

-

Rice husk ask (%)

- RVM:

-

Relevance vector machine

- S :

-

Sand content

- SG:

-

Specific gravity

- Si/Al:

-

Atomic proportion of Si to Al

- SLR:

-

Simple linear regression

- SUW:

-

Saturated unit weight (gm/cc)

- SVM:

-

Support vector machine

- UCS:

-

Unconfined compressive strength (N/cm2)

- Vp:

-

Primary ultrasonic wave velocity

- VR:

-

Void ratio

- W/c ratio:

-

Water/cement ratio

- γ :

-

Density (gm/cc)

- ϕ :

-

Internal friction angle (degree)

References

Adroja PB, Solanki RV, Shah YU (2017) Development of correlation between different engineering properties of subgrade soil. J Emer Technologies Innov Res 4(5):177–180

Ahmad M, Ahmad F, Wróblewski P, Al-Mansob RA, Olczak P, Kamiński P, Safdar M, Rai P (2021) Prediction of ultimate bearing capacity of shallow foundations on cohesionless soils: a gaussian process regression approach. Appl Sci 11(21):10317. https://doi.org/10.3390/app112110317

Ali G, Hasanzadehshooiili H (2018) Prediction of UCS and CBR of microsilica-lime stabilized sulfate silty sand using ANN and EPR models; application to the deep soil mixing. Soils Found 58:34–49. https://doi.org/10.1016/j.sandf.2017.11.002

Aliyu MK, Abd Karim AT, Chan CM (2016) The relationship between unconfined compressive strength and leachate concentration of stabilised contaminated sediment. IOP Conf Series: Mater Sci Eng 160(1):012054. https://doi.org/10.1088/1757-899X/160/1/012054. (IOP Publishing)

Amin MR, Laskar AI (2015) Prediction of unconfined compressive strength of geoplymer stabilized clayey soil using artificial neural network. Computer Geotech 69:291–300. https://doi.org/10.1016/j.compgeo.2015.05.021

Ardakani A, Kordnaeij A (2019) Soil compaction parameters prediction using GMDH-type neural network and genetic algorithm. Eur J Environ Civ Eng 23(4):449–462. https://doi.org/10.1080/19648189.2017.1304269

Arumugam Ran**i AP, Rashid ASA, Yaacob H, Md Noor N (2013) Correlation between liquidity index (LI) & unconfined compressive strength of stabilized silty clay. Australian J Basic Appl Sci 7(10):450–454

Ataee O.M.O.L.B.A.N.I.N., Moghaddas NH, Lashkaripour GR, Nooghabi MJ (2018) Predicting shear wave velocity of soil using multiple linear regression analysis and artificial neural networks. Scientia Iranica. Trans A, Civil Eng, 25(4): 1943–1955

Chen W, Hasanipanah M, Nikafshan Rad H, Jahed Armaghani D, Tahir MM (2021) A new design of evolutionary hybrid optimization of SVR model in predicting the blast-induced ground vibration. Eng Computers 37(2):1455–1471. https://doi.org/10.1007/s00366-019-00895-x

Dirriba A (2017) Develo** correlation between dynamic cone penetration index (DCPI) and unconfined compressive strength (UCS) of the soils in Alem Gena Town. MTech Thesis Addis Ababa University, School of Graduate Studies, Addis Ababa

Eduard RC, Williams CKI (2006) Gaussian processes for machine learning. MIT Press, Cambridge

Egbe JG, Ewa DE, Ubi SE, Ikwa GB, Tumenayo OO (2017) Application of multilinear regression analysis in modeling of soil properties for geotechnical civil engineering works in Calabar South. Niger J Technol 36(4):1059–1065. https://doi.org/10.4314/njt.v36i4.10

Ekrem K, Akbulut S, Tortum A, Celik S (2009) Prediction of the unconfined compressive strength of compacted granular soils by using inference systems. Environ Geol 58:1429–1440. https://doi.org/10.1007/s00254-008-1645-x

Elaoud A, Hassen HB, Salah NB, Masmoudi A, Chehaibi S (2017) Modeling of soil penetration resistance using multiple linear regression (MLR). Arab J Geosci 10(20):1–8. https://doi.org/10.1007/s12517-017-3235-2

Essien U, Udoh N, Kennedy C (2014) Composite stabilization and model prediction of CBR and UCS parameters of Unyeghe Residual soils, Akwaibom State, Nigeria. Int J Eng Innov Res 3(6):854–862

Fakhri D, Khodayari A, Mahmoodzadeh A, Hosseini M, Ibrahim HH, Mohammed AH (2022) Prediction of mixed-mode I and II effective fracture toughness of several types of concrete using the extreme gradient boosting method and metaheuristic optimization algorithms. Eng Fract Mech 276:108916. https://doi.org/10.1016/j.engfracmech.2022.108916

Faradonbeh RS, Taheri A, Karakus M (2022) The propensity of the over-stressed rock masses to different failure mechanisms based on a hybrid probabilistic approach. Tunn Undergr Space Technol 119:104214. https://doi.org/10.1016/j.tust.2021.104214

Ghani S, Kumari S, Bardhan A (2021) A novel liquefaction study for fine-grained soil using PCA-based hybrid soft computing models. Sādhanā 46(3):1–17. https://doi.org/10.1007/s12046-021-01640-1

Ghani S, Kumari S, Ahmad S (2022) Prediction of the seismic effect on liquefaction behavior of fine-grained soils using artificial intelligence-based hybridized modeling. Arab J Sci Eng 47(4):5411–5441. https://doi.org/10.1007/s13369-022-06697-6

Gul N, Mir BA (2022) Parametric study of glass fiber reinforced fine-grained soil with emphasis on microstructural analysis. Int J Geotech Eng 16(6):1–13. https://doi.org/10.1080/19386362.2022.2049524

Güllü H (2014) Function finding via genetic expression programming for strength and elastic properties of clay treated with bottom ash. Eng Appl Artif Intell 35:143–157. https://doi.org/10.1016/j.engappai.2014.06.020

Gunaydin O, Gokoglu A, Fener M (2010) Prediction of artificial soil’s unconfined compressive strength test using statistical analyses and artificial neural networks. Adv Eng Softw 41:1115–1123. https://doi.org/10.1016/j.advengsoft.2010.06.008

Haghshenas SS, Faradonbeh RS, Mikaeil R, Haghshenas SS, Taheri A, Saghatforoush A, Dormishi A (2019) A new conventional criterion for the performance evaluation of gang saw machines. Measurement 146:159–170. https://doi.org/10.1016/j.measurement.2019.06.031

Hair J Jr, Wolfnibarger MC, Ortinau DJ, Bush RP (2013) Essentials of marketing. McGraw Hill, New York

Hajihassani M, Abdullah SS, Asteris PG, Armaghani DJ (2019) A gene expression programming model for predicting tunnel convergence. Appl Sci 9(21):4650. https://doi.org/10.3390/app9214650

Hamed J, Lee S (2018) Evaluating unconfined compressive strength of cohesive soils stabilized with geopolymer: a computational intelligence approach. Eng Computers 35:191–199. https://doi.org/10.1007/s00366-018-0592-8

Janjua ZS, Chand J (2016) Correlation of CBR with index properties of soil. Int J Civil Eng Technol 7(5):57–62

Javier G, Saldaña M, Arzúa J (2019) Analytical model for predicting the UCS from P-wave velocity, density, and porosity on saturated limestone. Appl Sci 9(23):5265. https://doi.org/10.3390/app9235265

Khatti J, Grover KS (2021) Computation of permeability of soil using artificial intelligence approaches. Int J Eng Adv Technol 11(1):257–266. https://doi.org/10.35940/ijeat.A3220.1011121

Khatti J, Grover KS (2022) Prediction of soaked CBR of fine-grained soils using soft computing techniques. Multiscale Multidisciplinary Modeling, Exp Design. https://doi.org/10.1007/s41939-022-00131-y

Kormu S, Sorsa A, Amena S (2022) Correlation of unconfined compressive strength (UCS) with compaction characteristics of soils in Burayu Town. Adv Mater Sci Eng. https://doi.org/10.1155/2022/1548272

Kumar M, Kumar V, Biswas R, Samui P, Kaloop MR, Alzara M, Yosri AM (2022) Hybrid ELM and MARS-based prediction model for bearing capacity of shallow foundation. Processes 10(5):1013. https://doi.org/10.3390/pr10051013

Le HA, Nguyen TA, Nguyen DD, Prakash I (2020) Prediction of soil unconfined compressive strength using artificial neural network model. Vietnam J Earth Sci 42(3):255–264. https://doi.org/10.15625/0866-7187/42/3/15342

Li D, Shirani Faradonbeh R, Lv A, Wang X, Roshan H (2022) A data-driven field-scale approach to estimate the permeability of fractured rocks. Int J Mining, Reclam Env. https://doi.org/10.1080/17480930.2022.2086769

Liu M, Huang C, Wang L, Zhang Y, Luo X (2020) Short-term soil moisture forecasting via gaussian process regression with sample selection. Water 12(11):3085. https://doi.org/10.3390/w12113085

Mahasakti M, Suman S, Anand A, Das SK (2015) Prediction of UCS and CBR values of cement stabilized mine overburden and fly ash mixture. Procedia Earth Planetary Sci 11:294–302. https://doi.org/10.1016/j.proeps.2015.06.064

Mahmoodzadeh A, Nejati HR, Ibrahim H-H, Ali HFH, Mohammed AH, Rashidi S, Majeed MK (2022a) Several models for tunnel boring machine performance prediction based on machine learning. Geomech Eng 30(1):75–91. https://doi.org/10.12989/GAE.2022a.30.1.075

Mahmoodzadeh A, Nejati HR, Mohammadi M, Ibrahim HH, Rashidi S, Mohammed AH (2022b) Meta-heuristic optimization algorithms for prediction of fly-rock in the blasting operation of open-pit mines. Geomech Eng 30(6):489–502. https://doi.org/10.12989/GAE.2022b.30.6.489

Mahmoodzadeh A, Nejati HR, Mohammadi M, Ibrahim HH, Khishe M, Rashidi S, Mohammed AH (2022c) Develo** six hybrid machine learning models based on gaussian process regression and meta-heuristic optimization algorithms for prediction of duration and cost of road tunnels construction. Tunn Undergr Space Technol 130:104759. https://doi.org/10.1016/j.tust.2022c.104759

Mahmoodzadeh A, Mohammadi M, Abdulhamid SN, Ibrahim HH, Ali HFH, Nejati HR, Rashidi S (2022d) Prediction of duration and construction cost of road tunnels using gaussian process regression. Geomech Eng 28(1):65–75. https://doi.org/10.12989/gae.2022d.28.1.065

Mahmoodzadeh A, Mohammadi M, Abdulhamid SN, Ali HFH, Ibrahim HH, Rashidi S (2022e) Forecasting tunnel path geology using gaussian process regression. Geomech Eng 28(4):359–374. https://doi.org/10.1298/gae.2022e.28.4.359

Mentaschi L, Besio G, Cassola F, Mazzino A (2013) Problems in RMSE-based wave model validations. Ocean Model 72:53–58. https://doi.org/10.1016/j.ocemod.2013.08.003

Mirzaeiabdolyousefi M, Mahmoodzadeh A, Ibrahim HH, Rashidi S, Majeed MK, Mohammed AH (2022) Prediction of squeezing phenomenon in tunneling projects: application of gaussian process regression. Geomech Eng 30(1):11–26. https://doi.org/10.12989/GAE.2022.30.1.011

Mohammadzadeh SD, Kazemi SF, Mosavi A, Nasseralshariati E, Tah JH (2019a) Prediction of compression index of fine-grained soils using a gene expression programming model. Infrastructures 4(2):26. https://doi.org/10.3390/infrastructures4020026

Mohammadzadeh D, Kazemi SF, Mosavi A (2019b) Evolutionary prediction model for fine-grained soils compression index using gene-expression programming. https://doi.org/10.20944/preprints2019b03.0049.v1

Motamedi S, Song K-I, Hashim R (2013) Prediction of unconfined compressive strength of pulverized fuel ash-cement-sand mixture. Mater Struct 48(4):1–13. https://doi.org/10.1617/s11527-013-0215-1

Nair SJ, Kishoshahina KS, Brightson PC (2019) Geotechnical investigation of different soil samples using regression analysis. Int Res J Eng Technol 5(4):1572–1577

Ngo HTT, Pham TA, Vu HLT, Giap LV (2021) Application of artificial intelligence to determined unconfined compressive strength of cement-stabilized soil in vietnam. Appl Sci 11(4):1949. https://doi.org/10.3390/app11041949

Oljira SA, Tsige D, Quezon ET (2021) Modeling unconfined compressive strength of fine grained soils: application of dynamic cone penetration to predict foundation soil strength. Appl J Env Eng Sci 7(4):7–4. https://doi.org/10.48422/IMIST.PRSM/ajees-v7i4.28114

Onyelowe KC, Jalal FE, Onyia ME, Onuoha IC, Alaneme GU (2021) Application of gene expression programming to evaluate strength characteristics of hydrated-lime-activated rice husk ash-treated expansive soil. Appl Computational Intell Soft Computing. https://doi.org/10.1155/2021/6686347

Patle GT, Sikar TT, Rawat KS, Singh SK (2019) Estimation of infiltration rate from soil properties using regression model for cultivated land. Geol, Ecol, Landsc 3(1):1–13. https://doi.org/10.1080/24749508.2018.1481633

Premarathne RPPK, Sawangsuriya A (2021) Prediction of unconfined compressive strength of cement stabilized pavement materials. Int Conf Road Airfield Pavement Technol 2019, IOP conference series: Mater Sci Eng, 1075, 012008, https://doi.org/10.1088/1757-899X/1075/1/01200

Priyadarshee A, Chandra S, Gupta D, Kumar V (2020) Neural models for unconfined compressive strength of Kaolin clay mixed with pond ash, rice husk ash and cement. J Soft Computing Civil Eng 4(2):85–102. https://doi.org/10.22115/scce.2020.223774.1189

Raja MNA, Shukla SK, Khan MUA (2022) An intelligent approach for predicting the strength of geosynthetic-reinforced subgrade soil. Int J Pavement Eng 23(10):3505–3521. https://doi.org/10.1080/10298436.2021.1904237

Reddy S, Ruchita N, Sharma P, Satyanarayana SV (2019) Prediction of California bearing ratio through empirical correlations of index properties for tropical indian soils. Int J Innov Eng Technol 15(1):67–77

Ris RC, Holthuijsen LH, Booij N (1999) A third-generation wave model for coastal regions: 2 verification. J Geophys Res: Oceans 104(C4):7667–7681. https://doi.org/10.1029/1998JC900123

Salahudeen AB, Sadeeq JA, Badamasi A, Onyelowe KC (2020) Prediction of unconfined compressive strength of treated expansive clay using back-propagation artificial neural networks. Nigerian J Eng, Faculty Eng, Ahmadu Bello, Univ 27(1):45–58

Saputra NA, Putra R (2020) The correlation between CBR (California bearing ratio) and UCS (unconfined compressive strength) Laterite soils in Palangka Raya as Heap Material. Int Conf Env Technol 10–11 August 2018 469:012093. https://doi.org/10.1088/1755-1315/469/1/012093. (Universitas Lancang Kuning, Indonesia)

Senoon Abdel-Aziz AA, Hussein Mohammd MA (2019), Correlation between unconfined compressive strength (UCS) and index properties of soil in Assiut Governorate, Egypt, 15th International Conference on Structural and Geotechnical Engineering, Faculty of Engineering, Ain Shams University

Sharma LK, Singh TN (2017) Regression-based models for the prediction of unconfined compressive strength of artificially structures soil. Eng Computers 34:175–186. https://doi.org/10.1007/s00366-017-0528-8

Shelema A, Tsige D, Quezon ET, Eng P (2021) Modeling unconfined compressive strength of fine-grained soils: application of dynamic cone penetration to predict foundation soil strength. Appl J Env Eng Sci 7(4):348–359

Shirani Faradonbeh R, Jahed Armaghani D, Abd Majid MZ, Md Tahir M, Ramesh Murlidhar B, Monjezi M, Wong HM (2016) Prediction of ground vibration due to quarry blasting based on gene expression programming: a new model for peak particle velocity prediction. Int J Environ Sci Technol 13(6):1453–1464. https://doi.org/10.1007/s13762-016-0979-2

Siddiqui FI, Osman SBABS (2013) Simple and multiple regression models for relationship between electrical resistivity and various soil properties for soil characterization. Env Earth Sci 70(1):259–267. https://doi.org/10.1007/s12665-012-2122-0

Sihag P, Tiwari NK, Ranjan S (2017) Modelling of infiltration of sandy soil using gaussian process regression. Modeling Earth Syst Env 3(3):1091–1100. https://doi.org/10.1007/s40808-017-0357-1

Sihag P, Kumar M, Singh B (2021) Assessment of infiltration models developed using soft computing techniques. Geol, Ecol, Landsc 5(4):241–251. https://doi.org/10.1080/24749508.2020.1720475

Sivrikaya O, Kayadelen C, Cecen E (2013) Prediction of the compaction parameters for coarse-grained soils with fines content by MLA and GEP. Acta Geotechnica Slovenica 10(2):29–41

Smith GN (1986) Probability and statistics in civil engineering–an introduction. Collins, London

Tabarsa A, Latifi N, Osouli A, Bagheri Y (2021) Unconfined compressive strength prediction of soils stabilized using artificial neural networks and support vector machines. Front Struct Civ Eng 15:520–536. https://doi.org/10.1007/s11709-021-0689-9

Tenpe AR, Patel A (2020) Utilization of support vector models and gene expression programming for soil strength modeling. Arab J Sci Eng 45(5):4301–4319. https://doi.org/10.1007/s13369-020-04441-6

Udeala RC, Onyelowe KC, Uranta JDC, Keke EO, Alaneme GU (2021) ANFIS model of the UCS of modified soil for construction purposes, West Africa Built Environment Research (WABER) Conference, 9–11 August 2021, Accra, Ghana, pp. 163–176

Usama K, Zia-ur-Rehman KF, Mujtaba H (2015) Prediction of unconfined compressive strength from index properties of soil. Sci Int 27(5):4071–4075

Wang HL, Yin ZY (2020) High performance prediction of soil compaction parameters using multi expression programming. Eng Geol 276:105758. https://doi.org/10.1016/j.enggeo.2020.105758

Willmott CJ, Robeson SM, Matsuura K (2012) A refined index of model performance. Int J Climatol 32(13):2088–2094. https://doi.org/10.1002/joc.2419

Yildirim E, Avic E, Tanbay NA (2021) Prediction of unconfined compressive strength of microfine cement injected sands using fuzzy logic method. Res Square. https://doi.org/10.21203/rs.3.rs-232296/v1

Yousef B (2019) Gaussian process regression models for predicting water retention curves: application of machine learning techniques for modelling uncertainty in hydraulic curves

Zarei C, Rahimi L (2021) Prediction of undrained shear strength of crushed tire mixture with fine-grained soil by using machine learning approaches. https://doi.org/10.21203/rs.3.rs-820067/v1

Zhong J, Feng L, Ong YS (2017) Gene expression programming: a survey. IEEE Comput Intell Mag 12(3):54–72. https://doi.org/10.1109/MCI.2017.2708618

Funding

No funding was received in assisting the preparation of this manuscript.

Author information

Authors and Affiliations

Contributions

JK: Main author, conceptualization, literature review, manuscript preparation, application of AI models, methodological development, statistical analysis, detailing, and overall analysis; KSG: Conceptualization, overall analysis, manuscript finalization, detailed review, and editing.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that there is no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Appendix

Appendix

Sample ID | FC (%) | DUW (gm/cc) | P (%) | VR | DS (%) | SG | Actual UCS | MD11 |

|---|---|---|---|---|---|---|---|---|

1 | 93.64 | 1.72 | 20.11 | 3.57 | 103.16 | 2.53 | 33.85 | 29.91 |

2 | 87.00 | 1.77 | 13.74 | 3.17 | 94.09 | 2.41 | 42.11 | 38.38 |

3 | 85.33 | 1.75 | 18.99 | 3.43 | 103.31 | 2.55 | 36.77 | 32.10 |

4 | 76.00 | 1.64 | 17.62 | 3.83 | 108.99 | 2.44 | 40.55 | 37.60 |

5 | 80.64 | 1.69 | 14.76 | 3.43 | 101.26 | 2.37 | 30.97 | 26.22 |

6 | 78.94 | 1.71 | 13.30 | 3.27 | 93.65 | 2.33 | 37.20 | 40.78 |

7 | 73.20 | 1.77 | 14.08 | 3.18 | 96.69 | 2.41 | 32.32 | 37.22 |

8 | 80.23 | 1.77 | 13.30 | 3.11 | 97.93 | 2.40 | 17.97 | 17.30 |

9 | 81.41 | 1.85 | 16.29 | 2.96 | 83.30 | 2.51 | 40.93 | 36.92 |

10 | 75.08 | 1.80 | 7.41 | 2.86 | 100.21 | 2.28 | 20.03 | 22.58 |

11 | 80.08 | 1.76 | 23.68 | 3.57 | 98.50 | 2.70 | 36.43 | 34.83 |

12 | 86.87 | 1.65 | 23.17 | 4.01 | 103.43 | 2.59 | 27.46 | 26.60 |

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Khatti, J., Grover, K.S. Prediction of UCS of fine-grained soil based on machine learning part 1: multivariable regression analysis, gaussian process regression, and gene expression programming. Multiscale and Multidiscip. Model. Exp. and Des. 6, 199–222 (2023). https://doi.org/10.1007/s41939-022-00137-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s41939-022-00137-6