Abstract

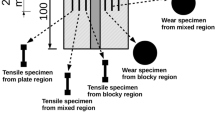

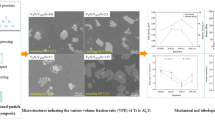

The emerging oscillatory pressure sintering technology is used to prepare high-performance Al2O3-Ti(C,N) ceramic tools for high-speed cutting. By recording the displacement during sintering, the sintering shrinkage rate of the Al2O3-Ti(C,N) composite was calculated, and the stress exponent n and sintering activation energy Q were calculated according to creep theory to determine the densification mechanism. In addition, the evolution of phases, microstructure and hardness of the composite was also observed. Results show that during oscillatory pressure sintering process at 1400 °C and 1300 °C, the stress exponent of Al2O3-Ti(C,N) composite is around 2.2 and the sintering activation energy is 486 kJ mol−1, indicating that the densification mechanism is a diffusion-controlled grain boundary sliding of Al2O3 phase. Additionally, as the oscillatory pressure increases, the average grain size of the Al2O3 decreases and the Vickers hardness increases. Hardness achieves the highest 22.7 GPa when the median oscillatory pressure is 70 MPa at 1400 °C, which is 1 GPa higher than that of static pressure of 70 MPa.

Similar content being viewed by others

Data availability

Data will be made available on request.

References

Yu, W., Ming, W., An, Q., Chen, M.: Cutting performance and wear mechanism of honeycomb ceramic tools in interrupted cutting of nickel-based superalloys. Ceram. Int. 47, 18075–18083 (2021). https://doi.org/10.1016/j.ceramint.2021.03.123

Zhang, M., Li, X., Zhang, M., **u, Z., Li, J.-G., Li, J., Sun, X.: Fabrication of a novel Al2O3-Ti(C0.7N0.3)-cBN composite with excellent performance in the turning of difficult-to-machine stellite alloys. Ceram. Int. 44, 12815–12824 (2018). https://doi.org/10.1016/j.ceramint.2018.04.088

Kıvak, T., Sarıkaya, M., Yıldırım, Ç.V., Şirin, Ş: Study on turning performance of PVD TiN coated Al2O3+TiCN ceramic tool under cutting fluid reinforced by nano-sized solid particles. J. Manuf. Process. 56, 522–539 (2020). https://doi.org/10.1016/j.jmapro.2020.05.017

Cui, E., Zhao, J., Wang, X., Song, S.: Cutting performance, failure mechanisms and tribological properties of GNPs reinforced Al2O3/Ti(C, N) ceramic tool in high speed turning of Inconel 718. Ceram. Int. 46, 18859–18867 (2020). https://doi.org/10.1016/j.ceramint.2020.04.206

Feng, X.M., Lian, X.Q., Jiang, M.X., He, Y.N.: Microstructure and mechanical properties of in situ Al2O3- Ti(C, N) composites. Adv. Mater. Res. 239–242, 1243–1247 (2011). https://doi.org/10.4028/www.scientific.net/AMR.239-242.1243

Yang, H., Shang, F., Gao, L.: Microstructure and mechanical properties of gas pressure sintered Al2O3/TiCN composite. Ceram. Int. 33, 1521–1524 (2007). https://doi.org/10.1016/j.ceramint.2006.07.001

Cheng, M., Liu, H., Zhao, B., Huang, C., Yao, P., Wang, B.: Mechanical properties of two types of Al2O3/TiC ceramic cutting tool material at room and elevated temperatures. Ceram. Int. 43, 13869–13874 (2017). https://doi.org/10.1016/j.ceramint.2017.07.110

Bertolete, M., Barbosa, P.A., de Rossi, W., Fredericci, C., Machado, I.F.: Mechanical characterisation and machining evaluation of ceramic cutting tools functionally graded with six layers. Ceram. Int. 46, 15137–15145 (2020). https://doi.org/10.1016/j.ceramint.2020.03.048

Cheng, Y., Zhang, Y., Wan, T., Yin, Z., Wang, J.: Mechanical properties and toughening mechanisms of graphene platelets reinforced Al2O3/TiC composite ceramic tool materials by microwave sintering. Mater. Sci. Eng. A 680, 190–196 (2017). https://doi.org/10.1016/j.msea.2016.10.100

**e, Z., Li, S., An, L., Franks, G.: A novel oscillatory pressure-assisted hot pressing for preparation of high-performance ceramics. J. Am. Ceram. Soc. 97, 1012–1015 (2014). https://doi.org/10.1111/jace.12869

Han, Y., Li, S., Zhu, T., **e, Z.: An oscillatory pressure sintering of zirconia powder: rapid densification with limited grain growth. J. Am. Ceram. Soc. 100, 2774–2780 (2017). https://doi.org/10.1111/jace.14953

Li, S., **e, Z., Xue, W., Luo, X., An, L., Franks, G.: Sintering of high-performance silicon nitride ceramics under vibratory pressure. J. Am. Ceram. Soc. 98, 698–701 (2015). https://doi.org/10.1111/jace.13486

Zhu, T., **e, Z., Han, Y., Li, S., Li, Y., An, D., Luo, X.: A novel approach to improve flexural strength of Al2O3-20wt% ZrO2 composites by oscillatory pressure sintering. J. Am. Ceram. Soc. 101, 1397–1401 (2018). https://doi.org/10.1111/jace.15341

Gao, K., Xu, Y., Tang, G., Fan, L., Zhang, R., An, L.: Oscillating pressure sintering of W-Ni–Fe refractory alloy. J. Alloy. Compd. 805, 789–793 (2019). https://doi.org/10.1016/j.jallcom.2019.07.141

Li, S., **e, Z., An, D., Wei, C., Wang, P., Zhou, L.: Zirconia ceramics consolidated by oscillatory pressure sintering and subsequent carburization. Ceram. Int. 45, 9038–9042 (2019). https://doi.org/10.1016/j.ceramint.2019.01.239

Fan, J., Yuan, Y., Li, J., Liu, J., Zhao, K., Liu, D., An, L.: Densification and grain growth in oscillatory pressure sintering of alumina toughened zirconia ceramic composites. J. Alloys Compd. 845, 155644 (2020). https://doi.org/10.1016/j.jallcom.2020.155644

Feng, B., Wang, Z., Fan, Y., Gu, J., Zhang, Y.: Creep deformation behavior during densification of ZrB2-SiBCN ceramics with ZrO2 additive. J. Adv. Ceram. 9, 544–557 (2020). https://doi.org/10.1007/s40145-020-0393-6

Ting, C.-J., Lu, H.-Y.: Hot-pressing of magnesium aluminate spinel—I. Kinetics and densification mechanism. Acta Mater. 47, 817–830 (1999)

Ting, C.-J., Lu, H.-Y.: Hot-pressing of magnesium aluminate spinel—II. Microstructure development. Acta Mater. 47, 831–840 (1999)

Bernard-Granger, G., Guizard, C.: Spark plasma sintering of a commercially available granulated zirconia powder: I. Sintering path and hypotheses about the mechanism(s) controlling densification. Acta Mater. 55, 3493–3504 (2007). https://doi.org/10.1016/j.actamat.2007.01.048

Bernard-Granger, G., Guizard, C., Surblé, S., Baldinozzi, G., Addad, A.: Spark plasma sintering of a commercially available granulated zirconia powder—II. Microstructure after sintering and ionic conductivity. Acta Mater. 56, 4658–4672 (2008). https://doi.org/10.1016/j.actamat.2008.05.031

Bernard-Granger, G., Addad, A., Fantozzi, G., Bonnefont, G., Guizard, C., Vernat, D.: Spark plasma sintering of a commercially available granulated zirconia powder: comparison with hot-pressing. Acta Mater. 58, 3390–3399 (2010). https://doi.org/10.1016/j.actamat.2010.02.013

Zhang, Y., Song, A., Ma, D., Zhang, X., Ma, M., Liu, R.: Sintering characteristics and grain growth behavior of MgO nanopowders by spark plasma sintering. J. Alloy. Compd. 608, 304–310 (2014). https://doi.org/10.1016/j.jallcom.2014.04.148

Gendre, M., Maître, A., Trolliard, G.: A study of the densification mechanisms during spark plasma sintering of zirconium (oxy-)carbide powders. Acta Mater. 58, 2598–2609 (2010). https://doi.org/10.1016/j.actamat.2009.12.046

Santanach, J.G., Weibel, A., Estournès, C., Yang, Q., Laurent, C., Peigney, A.: Spark plasma sintering of alumina: study of parameters, formal sintering analysis and hypotheses on the mechanism(s) involved in densification and grain growth. Acta Mater. 59, 1400–1408 (2011). https://doi.org/10.1016/j.actamat.2010.11.002

Liu, G., Li, R., Yuan, T., Zhang, M., Zeng, F.: Spark plasma sintering of pure TiCN: densification mechanism, grain growth and mechanical properties. Int. J. Refract. Metal Hard Mater. 66, 68–75 (2017). https://doi.org/10.1016/j.ijrmhm.2017.02.008

Vieira, J.M., Brook, R.J.: Hot-pressing of high-purity magnesium oxide. J. Am. Ceram. Soc. 67, 450–454 (1984). https://doi.org/10.1111/j.1151-2916.1984.tb19632.x

Antou, G., Guyot, P., Pradeilles, N., Vandenhende, M., Maître, A.: Identification of densification mechanisms of pressure-assisted sintering: application to hot pressing and spark plasma sintering of alumina. J. Mater. Sci. 50, 2327–2336 (2015). https://doi.org/10.1007/s10853-014-8804-0

Vakifahmetoglu, C., Karacasulu, L.: Cold sintering of ceramics and glasses: a review. Curr. Opin. Solid State Mater. Sci. 24, 100807 (2020). https://doi.org/10.1016/j.cossms.2020.100807

Galotta, A., Sglavo, V.M.: The cold sintering process: a review on processing features, densification mechanisms and perspectives. J. Eur. Ceram. Soc. 41, 1–17 (2021). https://doi.org/10.1016/j.jeurceramsoc.2021.09.024

Zhang, X., Zabihi, F., **ong, H., Eslamian, M., Hou, C., Zhu, M., Wang, H., Zhang, H.: Highly efficient flexible perovskite solar cells made via ultrasonic vibration assisted room temperature cold sintering. Chem. Eng. J. 394, 124887 (2020). https://doi.org/10.1016/j.cej.2020.124887

Kang, S., Zhao, X., Guo, J., Liang, J., Sun, J., Yang, Y., Yang, L., Liao, R., Randall, C.: Thermal-assisted cold sintering study of Al2O3 ceramics: enabled with a soluble γ-Al2O3 intermediate phase. J. Eur. Ceram. Soc. 43, 478–485 (2023). https://doi.org/10.1016/j.jeurceramsoc.2022.10.039

Lai, Q., Chen, J., Chang, F., Pei, J., Liang, Y., Chen, X., Feng, Q., Cen, Z., Luo, N.: Cold sintering process assisted sintering for 8YSZ ceramic: a way of achieving high density and electrical conductivity at a reduced sintering temperature. Ceram. Int. 49, 14744–14749 (2023). https://doi.org/10.1016/j.ceramint.2023.01.070

Zhang, J., Zhu, T., Cheng, Y., Sang, S., Li, Y., An, D., **e, Z.: Fabrication and mechanical properties of ZrO2-Al2O3-SiC(w) composites by oscillatory pressure sintering. Ceram. Int. 46, 25719–25725 (2020). https://doi.org/10.1016/j.ceramint.2020.07.048

Li, J., Fan, J., Yuan, Y., Liu, J., Zhao, K., Liu, D., **e, Z., An, L.: Effect of oscillatory pressure on the sintering behavior of ZrO2 ceramic. Ceram. Int. 46, 13240–13243 (2020). https://doi.org/10.1016/j.ceramint.2020.02.100

Funding

This work was supported by the Science and Technology Department of Henan Province, China [grant numbers 212102210578, 222102230057, 232102230135].

Author information

Authors and Affiliations

Contributions

Conceptualization: [Mengwen Zhang]; Methodology: [BinYang Jiang], [Lutong Yang], [Na Cao], [Zhaosheng Li]; Formal analysis and investigation: [BinYang Jiang], [Lutong Yang], [Na Cao] [Zhaosheng Li]; Writing—original draft preparation: [BinYang Jiang], [Lutong Yang]; Writing-review and editing: [Mengwen Zhang], [Lei Fan], [Shoulei Yang]; funding acquisition: [Mengwen Zhang]; Resources: [Lei Fan], [Shoulei Yang]; Supervision: [Mengwen Zhang], [Lei Fan].

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Zhang, M., Jiang, B., Yang, L. et al. Densification mechanism and mechanical properties of oscillatory pressure sintered Al2O3-Ti(C,N) composite. J Aust Ceram Soc 59, 1231–1239 (2023). https://doi.org/10.1007/s41779-023-00903-w

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s41779-023-00903-w