Abstract

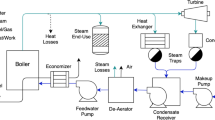

The increasing energy consumption of the industrial sector necessitates the adoption of sustainable energy practices, and steam pipeline networks provide an opportunity to improve energy efficiency while reducing environmental impact. This study evaluates the performance of branch and looped steam pipeline networks and investigates the impact of adding pipelines to branch networks, forming looped networks. A practical branch medium-pressure steam pipeline network in an operating oil refinery plant is examined, considering 16 steam users (U1–U16) and 3 boilers (S1–S3). The modified Hardy Cross model accurately simulates temperature and pressure distribution, and condensate rate and flow rate within the network. This research considers both normal and boiler maintenance conditions, enhancing the system’s robustness. Considering the limitations of modifying the existing onsite system, this research proposes various feasible design scenarios that do not rely on typical optimization algorithms. Four loop designs are proposed to mitigate temperature and pressure drops during boiler 1 (S1) maintenance, with the extended U8+50 m loop design proving the most effective in controlling the pressure and temperature distribution without condensation. Similarly, for the boiler 3 (S3) maintenance case, three loop designs are proposed, with the U12+U16 loop design identified as optimal for maintaining pressure and temperature without condensation. The findings demonstrate that loop designs reduce pressure drop, minimizing energy loss and promoting optimal and sustainable steam transport practices.

Similar content being viewed by others

Data Availability

Most relevant data have been shown on the flowsheets of those steam networks. Further information is available upon request.

Abbreviations

- Ap :

-

the surface area of the pipe (m2)

- As :

-

the surface area of pipe segments (m2)

- D:

-

pipe diameter (m)

- \(\overline{\textrm{f}}\) :

-

average pipe friction factor (-)

- H:

-

specific enthalpy of steam (J/kg)

- Hc :

-

specific enthalpy of condensate (J/kg)

- Hin :

-

specific enthalpy of steam flowing into a pipe (J/kg)

- Hout :

-

specific enthalpy of steam flowing out from a pipe (J/kg)

- L:

-

pipe length (m)

- m:

-

the mass flow rate of steam (kg/s or t/h)

- mc :

-

the mass flow rate of condensate (kg/s or t/h)

- min :

-

the mass flow rate of steam flowing into a pipe (kg/s or t/h)

- mout :

-

the mass flow rate of steam flowing out a pipe (kg/s or t/h)

- \(\overline{T}\) :

-

the average temperature of steam in a pipe (K)

- Te :

-

ambient temperature (K)

- Up :

-

overall heat transfer coefficient of pipe (W/m2K)

- Us :

-

overall heat transfer coefficient of pipe segments (W/m2K)

- ∆mc :

-

condensate mass flow rate correction (kg/s or t/h)

- ∆m:

-

mass flow rate correction (kg/s or t/h)

- ∆T:

-

temperature correction (K)

- ∆P:

-

pressure correction (bar)

- \(\overline{\rho}\) :

-

average steam density (kg/m3)

- ξ:

-

pressure drop coefficient of pipe segments (-)

References

Administration USEI (2023) Annual energy outlook 2023. Administration USEI

Alhamad K, Alkhezi Y, Alhajri M (2023) Nonlinear integer programming for solving preventive maintenance scheduling problem for cogeneration plants with production. Sustainability 15(1):239

Białecki RA, Kruczek T (1996) Frictional, diathermal flow of steam in a pipeline. Chem Eng Sci 51(19):4369–4378

Brkić D (2011) Iterative methods for looped network pipeline calculation. Water Resour Manag 25:2951–2987

Cao L, You S, Zhang H, Zhang H (2011) Modelling and simulation of steam pipeline network. In: Presented at 2011 International Conference on Remote Sensing, Environment and Transportation Engineering. IEEE, Nan**g

Chang CY, Wang SH, Huang YC, Chen CL (2017) Transient response analysis of high pressure steam distribution networks in a refinery. In: Presented at 2017 6th International Symposium on Advanced Control of Industrial Processes (AdCONIP). IEEE, Taipei, Taiwan

Chen C-L, Chen H-C (2014) A mathematical approach for retrofit and optimization of total site steam distribution networks. Process Saf Environ Prot 92(6):532–544

Chen J, Zhou S, Liu Z, Liu H, Zhan X (2022) A novel steady-state simulation approach for a combined electric and steam system considering steam condensate loss. Processes 10(8):1436

Chen L, Wang C, Zhong R, Li Z, Zhao Z, Zhou Z (2023) Prediction of Main parameters of steam in waste incinerators based on BAS-SVM. Sustainability 15(2):1132

Coetzee SW, Majozi T (2008) Steam system network synthesis using process integration. Ind Eng Chem Res 47(13):4405–4413

Cross H. (1936). “Analysis of flow in networks of conduits or conductors.” University of Illinois. Engineering Experiment Station. Bulletin; 286.

Cui Z, Lin H, Wu Y, Wang Y, Feng X (2021) Optimization of pipeline network layout for multiple heat sources distributed energy systems considering reliability evaluation. Processes 9(8):1308

Einstein D, Worrell E, Khrushch M (2001) Steam systems in industry: energy use and energy efficiency improvement potentials. Lawrence Berkeley National Laboratory

García-Gutiérrez A, Hernández A, Martínez J, Ceceñas M, Ovando R, Canchola I (2015) Hydraulic model and steam flow numerical simulation of the Cerro Prieto geothermal field, Mexico, pipeline network. Appl Therm Eng 75:1229–1243

Hanus K, Variny M, Illés P (2020) Assessment and prediction of complex industrial steam network operation by combined thermo-hydrodynamic modeling. Processes 8(5):622

Ioannou I, Galán-Martín Á, Pérez-Ramírez J, Guillén-Gosálbez G (2023) Trade-offs between Sustainable Development Goals in carbon capture and utilisation. Energy Environ Sci 16:113–124

Kiss AA (2019) Rethinking energy use for a sustainable chemical industry. Chem Eng 76:13–18. https://doi.org/10.3303/CET1976003

Kiss AA, Smith R (2020) Rethinking energy use in distillation processes for a more sustainable chemical industry. Energy 203:117788

Li Y, Liu J, Huang G (2022) Pressure drop optimization of the main steam and reheat steam system of a 1000 MW secondary reheat unit. Energies 15(9):3279

Ma Y, Zhang H, ** Y, Xu D, Xu X (2022) Impact of superheated steam on the moisture transfer, structural characteristics and rheological properties of wheat starch. Food Hydrocoll 122:107089

Mukeru BM, Patel B (2023) Conceptual design and process simulation of methanol synthesis from glycerol. Process Integr Optim Sustain 7(1):51–72

Nikoomaram H, Amidpour M, Panahi M, Farhang SA (2022) Develo** an integrated hybrid polygeneration system combined with utility steam network. Int J Sustain Energy 41(6):646–674

Salmasi F, Khatibi R, Ghorbani MA (2012) A study of friction factor formulation in pipes using artificial intelligence techniques and explicit equations. Turkish J Eng Environ Sci 36(2):121–138

Saygin D, Patel MK, Worrell E, Tam C, Gielen DJ (2011) Potential of best practice technology to improve energy efficiency in the global chemical and petrochemical sector. Energy 36(9):5779–5790

Tapia JFD, Promentilla MAB, Smarandache F (2023) Addressing Uncertainties in planning sustainable systems through multi-criteria decision analysis (MCDA). Process Integr Optim Sustain:1–2

Wang H, Wang H, Zhu T, Deng W (2017) A novel model for steam transportation considering drainage loss in pipeline networks. Appl energy 188:178–189

Wang P, Si F, Cao Y, Shao Z, Ren S (2022) Prediction of superheated steam temperature for thermal power plants using a novel integrated method based on the hybrid model and attention mechanism. Appl Therm Eng 203:117899

Wang S-H, Wang W-J, Chang C-Y, Chen C-L (2015) Analysis of a looped high pressure steam pipeline network in a large-scale refinery. Ind Eng Chem Res 54(37):9222–9229

Wu Y, Wang Y, Feng X (2016) A heuristic approach for petrochemical plant layout considering steam pipeline length. Chin J Chem Eng 24(8):1032–1037

**anxi L, Shubo L, Menghua X, Ying H (2016) Modeling and simulation of steam pipeline network with multiple supply sources in iron& steel plants. In: Presented at 2016 Chinese Control and Decision Conference (CCDC). IEEE, Yinchuan, China

Yang W, Huang Y, Zhao D (2023) A coupled hydraulic–thermal dynamic model for the steam network in a heat–electricity integrated energy system. Energy 263:125800

Zhac L, Ning C, You F (2019) Industrial steam systems optimization under uncertainty using data-driven adaptive robust optimization. In: Presented at 2019 American Control Conference (ACC). IEEE, Philadelphia, PA, USA

Zhao L, Zhong W, Du W (2019) Data-driven robust optimization for steam systems in ethylene plants under uncertainty. Processes 7(10):744

Acknowledgements

The authors thank the National Science and Technology Council, Taiwan (previously Ministry of Science and Technology, Taiwan), for supporting this research under grant numbers MOST 110-2221-E-002-022 and MOST 111-2221-E-002-001.This work is also financially supported by the “Advanced Research Center for Green Materials Science and Technology” from The Featured Area Research Center Program within the framework of the Higher Education Sprout Project by the Ministry of Education, Taiwan (112L9006).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of Interest

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Ong, C.W., Chen, SC., Cheng, HH. et al. Modeling and Performance Evaluation of Branch and Looped Steam Pipeline Networks. Process Integr Optim Sustain 8, 423–438 (2024). https://doi.org/10.1007/s41660-023-00354-7

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s41660-023-00354-7