Abstract

Polyurethane foams are obtained during the reaction of compounds with hydroxyl groups and compounds containing isocyanate groups and are widely used in the packaging, construction, transportation and electrical energy industries. To bring benefits to its properties, several types of reinforcement are added to polyurethane foams, such as improvements in the thermal, mechanical, fire resistance and thermal insulation of the PUF. Thus, this article presents a systematic review of graphene-modified polyurethane foam composites for acoustic and structural applications with a focus on the last five years. The investigation followed the PRISMA protocol which provides a meticulous summary of all available research in response to a research question. After the inclusion/exclusion of the steps, thirty one studies were included in the review. The results were presented with a focus on PU foam fabrication techniques, polyol types, carbon structured reinforcements and techniques for fabrication of filled graphene PUFs and sound properties. In short, this methodology helped to identify the main knowledge gaps in this area.

Similar content being viewed by others

References

Ghasemi S, Nima E, Mehdi A (2020) Flexible polyurethane foams reinforced with organic and inorganic nanofillers. J Appl Polym Sci 138:49983. https://doi.org/10.1002/app.49983

Leng W (2019) Evaluation and potential application of novel cellulose nanofibril and lignin-based-graphite functionalized flexible polyurethane foam. Cell 26:8685–8697. https://doi.org/10.1007/s10570-019-02700-w

Akindoyo JO, Beg MDH, Ghazali S, Islam MR, Jeyaratnam N, Yuvaraj AR (2016) Polyurethane types, synthesis and applications–a review. RSC Adv 6:114453–114482. https://doi.org/10.1039/c6ra14525f

Gurgel D, Bresolin D, Sayer C, Cardozo Filho L, Hermes de Araújo PH (2021) Flexible polyurethane foams produced from industrial residues and castor oil. Ind Crops Prod 164:113377. https://doi.org/10.1016/j.indcrop.2021.113377

Peyrton J, Avérous L (2021) Structure-properties relationships of cellular materials from biobased polyurethane foams. Mater Sci Eng R 145:100608. https://doi.org/10.1016/j.mser.2021.100608

An T, Hai P, Tessman M, Neelakantan N, Samoylov AA, Ito Y, Rajput BS, Pourahmady N, Burkart MD (2021) Renewable polyurethanes from sustainable biological precursors. Biomacromol 22:1770–1794. https://doi.org/10.1021/acs.biomac.0c01610

Agrawal A, Kaur R, Walia RS (2017) PU Foam derived from renewable sources: perspective on properties enhancement: an overview. Eur Polym J 95:255–274. https://doi.org/10.1016/j.eurpolymj.2017.08.022

Kerche EF, Bock DN, de Avila DR, Magalhães WLE, Amico SC (2021) Micro fibrillated cellulose reinforced bio-based rigid high-density polyurethane foams. Cell 28:4313–4326. https://doi.org/10.1007/s10570-021-03801-1

Zhou X, Sain MM, Oksman K (2016) Semi-rigid biopolyurethane foams based on palm-oil polyol and reinforced with cellulose nanocrystals. Compos Part A Appl Sci Manuf 83:56–62. https://doi.org/10.1016/j.compositesa.2015.06.008

Carriço CS, Fraga T, Pasa VMD (2016) Production and characterization of polyurethane foams from a simple mixture of castor oil, crude glycerol and untreated lignin as bio-based polyols. Eur Polym J 85:53–61. https://doi.org/10.1016/j.eurpolymj.2016.10.012

Ribeiro Da Silva V, Mosiewicki MA, Yoshida MI, Coelho Da Silva M, Stefani PM, Marcovich NE (2013) Polyurethane foams based on modified tung oil and reinforced with rice husk ash i: synthesis and physical chemical characterization. Polym Test 32:438–445. https://doi.org/10.1016/j.polymertesting.2013.01.002

Ghasemlou M, Daver F, Ivanova EP, Adhikari B (2019) Industrial crops and products polyurethanes from seed oil-based polyols: a review of synthesis, mechanical and thermal properties. Ind Crops Prod 142:111841. https://doi.org/10.1016/j.indcrop.2019.111841

Mohammadpour R, Sadeghi GMM (2021) Evaluation of microstructure, thermal, and mechanical properties of the green lignin-based polyurethane/hydrophobic silica nanocomposite foam. J Appl Polym Sci 138:1–14. https://doi.org/10.1002/app.49864

Liu X, Qin S, Li H, Sun J, Gu X, Zhang S, Grunlan JC (2019) Combination intumescent and kaolin-filled multilayer nanocoatings that reduce polyurethane flammability. Macromol Mater Eng 304:1–7. https://doi.org/10.1002/mame.201800531

Li Y, Tian H, Zhang J, Zou W, Wang H, Du Z, Zhang C (2020) Fabrication and properties of rigid polyurethane nanocomposite foams with functional isocyanate modified graphene oxide. Polym Compos 41:5126–5134. https://doi.org/10.1002/PC.25780

Oh J, Rae H, Umrao S, June Y, Oh I (2019) Self-aligned and hierarchically porous graphene-polyurethane foams for acoustic wave absorption. Carbon 147:510–518. https://doi.org/10.1016/j.carbon.2019.03.025

Fenner BR, Zimmermann MVG, da Silva MP, Zattera AJ (2018) Comparative analysis among coating methods of flexible polyurethane foams with graphene oxide. J Mol Liq 271:74–79. https://doi.org/10.1016/j.molliq.2018.08.113

Gedam SS, Chaudhary AK, Vijayakumar RP, Goswami AK, Bajad GS, Pal D (2019) Thermal, mechanical and morphological study of carbon nanotubes-graphene oxide and silver nanoparticles based polyurethane composites. Mater Res Express 6:085308. https://doi.org/10.1088/2053-1591/ab1db4

Pinto SC, Marques PAAP, Vicente R, Godinho L, Duarte I (2020) Hybrid structures made of polyurethane/graphene nanocomposite foams embedded within aluminum. Metals 10:768. https://doi.org/10.3390/met10060768

Jia P, Ma C, Lu J, Yang W, Jiang X, Jiang G, Yin Z, Qiu Y, Qian L, Yu X, Hu Y, Hu W, Wang B (2022) Design of copper salt@ graphene nanohybrids to accomplish excellent resilience and superior fire safety for flexible polyurethane foam. J Colloid Interface Sci 606:1205–1218. https://doi.org/10.1016/j.jcis.2021.08.139

Hoseinabadi M, Naderi M, Najafi M, Motahari S (2017) A study of rigid polyurethane foams: the effect of synthesized polyols and nanoporous graphene. J Appl Polym Sci 45001:1–6. https://doi.org/10.1002/app.45001

Piszczyk Ł, Kosmela P, Strankowski M (2017) Elastic polyurethane foams containing graphene nanoplatelets. Adv Polym Technol 34:1625–1634. https://doi.org/10.1002/adv.21819

Li C, Hui B, Ye L (2018) Construction of polyurethane-imide/graphene oxide nano-composite foam with gradient structure and its thermal mechanical stability. Ind Eng Chem Res 57:13742–13752. https://doi.org/10.1021/acs.iecr.8b02911

Santiago-Calvo M, Blasco V, Ruiz C, París R, Villafañe F, Angel M (2019) Improvement of thermal and mechanical properties by control of formulations in rigid polyurethane foams from polyols functionalized with graphene oxide. J Appl Polym Sci 47474:1–10. https://doi.org/10.1002/app.47474

Acuña P, Zhang J, Yin G, Liu X, Wang D (2021) Bio-based rigid polyurethane foam from castor oil with excellent flame retardancy and high insulation capacity via cooperation with carbon-based materials. J Mater Sci 56:2684–2701. https://doi.org/10.1007/s10853-020-05125-0

Wu Q, Zhang J, Wang S, Chen B, Feng Y, Pei Y, Yan Y (2021) Exceptionally flame-retardant flexible polyurethane foam composites: synergistic effect of the silicone resin/graphene oxide coating. Front Chem Sci Eng 15:969–983. https://doi.org/10.1007/s11705-020-1988-8

Navidfar A, Trabzon L (2019) Graphene type dependence of carbon nanotubes / graphene nanoplatelets polyurethane hybrid nanocomposites: micromechanical modeling and mechanical properties. Compos B 176:107337. https://doi.org/10.1016/j.compositesb.2019.107337

Oh JH, Kim JS, Nguyen VH, Oh IK (2020) Auxetic graphene oxide-porous foam for acoustic wave and shock energy dissipation. Compos B Eng 186:107817. https://doi.org/10.1016/J.COMPOSITESB.2020.107817

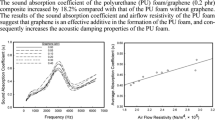

Kim JM, Kim DH, Kim J, Lee JW, Kim WN (2017) Effect of graphene on the sound dam** properties of flexible polyurethane foams. Macromol Res 25:190–196. https://doi.org/10.1007/s13233-017-5017-9

Zhang C, Chen Y, Li H, Xue W, Tian R, Dugnani R, Liu H (2018) Facile fabrication of polyurethane-based graphene foam/lead zirconate titanate/polydimethylsiloxane composites with good dam** performance. RSC Adv 8:7916–7923. https://doi.org/10.1039/c8ra00266e

Hou Y, Duan L, Gui Z, Hu Y (2017) An infiltration method to synthesize thermoplastic polyurethane composites based on size-controlled graphene foams. Compos A 97:67–75. https://doi.org/10.1016/j.compositesa.2017.02.023

Hui B, Ye L, Zhao X (2018) In situ preparation of polyurethane-imide/graphene oxide nano-composite foam: intercalation structure and thermal mechanical stability. J Polym Res 25:267. https://doi.org/10.1007/s10965-018-1660-x

Yu YY, Bai XJ, Kung MC, Xue Y, Huang Y, Keane DT, Kung HH (2017) Electromechanical properties of reduced graphene oxide thin film on 3D elastomeric substrate. Carbon 115:380–387. https://doi.org/10.1016/J.CARBON.2017.01.006

Lee J, Jung I (2019) Tuning sound absorbing properties of open cell polyurethane foam by impregnating graphene oxide. App Acoust 151:10–21. https://doi.org/10.1016/j.apacoust.2019.02.029

Gama N, Costa LC, Amaral V, Ferreira A, Barros-Timmons A (2017) Insights into the physical properties of biobased polyurethane/expanded graphite composite foams. Compos Sci Technol 138:24–31. https://doi.org/10.1016/j.compscitech.2016.11.007

Saadiya H, Zitouni A, Ahmed S, Yves M, Amina G, Houssém O (2021) Fire behavior of flame-retardant polyurethane semi-rigid foam in presence of nickel (II) oxide and graphene nanoplatelets additives. J Polym Res 28:87. https://doi.org/10.1007/s10965-021-02450-z

Mondal T, Basak S, Bhowmick AK (2017) Ionic liquid modification of graphene oxide and its role towards controlling the porosity, and mechanical robustness of polyurethane foam. Polymer 127:106–118. https://doi.org/10.1016/j.polymer.2017.08.054

Jia P, Cheng W, Lu J, Yin Z, Xu Z, Cheng L, Qiu Y, Qian L, Hu Y, Hu W, Wang B (2021) Applications of GO/OA-POSS layer-by-layer self-assembly nanocoating on flame retardancy and smoke suppression of flexible polyurethane foam. Polym Adv Technol 32:4516–4530. https://doi.org/10.1002/PAT.5453

Pietras D, Linul E, Sadowski T, Rusinek A (2020) Out-of-plane crushing response of aluminum honeycombs in-situ filled with graphene-reinforced polyurethane foam. Compos Struct 249:112548. https://doi.org/10.1016/j.compstruct.2020.112548

Kim J, Kim J, Ahn J, Kim J, Park S, Park KH, Lee J (2017) Synthesis of nanoparticle-enhanced polyurethane foams and evaluation of mechanical characteristics. Compos B 136:28–38. https://doi.org/10.1016/j.compositesb.2017.10.025

Lu W, Qin F, Zhang Q, Remillat C, Wang H, Scarpa F, Peng HX (2020) Engineering foam skeletons with multilayered graphene oxide coatings for enhanced energy dissipation. Compos Part A Appl Sci Manuf 137:106035. https://doi.org/10.1016/J.COMPOSITESA.2020.106035

Pastore Carbone MG, Beaugendre M, Koral C, Manikas AC, Koutroumanis N, Papari GP, Andreone A, Di Maio E, Galiotis C (2020) Thermoplastic polyurethane-graphene nanoplatelets microcellular foams for electromagnetic interference shielding. Graphene Technol 5:33–39. https://doi.org/10.1007/S41127-020-00034-0

Oh J, Kim J, Lee H, Kang Y, Oh I (2018) Directionally antagonistic graphene oxide-polyurethane hybrid aerogel as a sound absorber. ACS Appl Mater Interface 10:22650–22660. https://doi.org/10.1021/acsami.8b06361

Shin S, Lee D (2022) Nanocomposites of rigid polyurethane foam and graphene nanoplates obtained by exfoliation of natural graphite in polymeric 4,4’-Diphenylmethane Diisocyanate. Nanomaterials 12:685. https://doi.org/10.3390/nano12040685

Nar M, Webber C III, D’Souza NA (2015) Rigid polyurethane and kenaf core composite foams. Polym Eng Sci 55:132–144. https://doi.org/10.1002/pen

Kerche EF, da Cruz JÁ, Amico SC (2022) The influence of density on the mechanical response of reinforced high-density polyurethane foams; a statistical approach. J Res Updates Polym Sci 11:31–35. https://doi.org/10.6000/1929-5995.2022.11.05

Neves RM, Lopes KS, Zimmermann MVG, Poletto M, Zattera AJ (2019) Characterization of polystyrene nanocomposites and expanded nanocomposites reinforced with cellulose nanofibers and nanocrystals. Cell 26:4417–4429. https://doi.org/10.1007/s10570-019-02392-2

Singh SN (2002) Blowing Agents for Polyurethane Foams. iSmithers Rapra, United Kingdom

Trovati G, Natali Suman MV, Sanches EA, Campelo PH, Neto RB, Neto SC, Trovati LR (2018) Production and characterization of polyurethane castor oil (ricinus communis) foam for nautical fender. Polym Test 73:87–93. https://doi.org/10.1016/j.polymertesting.2018.11.010

Kairyte A, Kremensas A, Vaitkus S, Czlonka S, Strakowska A (2020) Fire suppression and thermal behavior of biobased rigid polyurethane foam filled with biomass incineration waste ash. Polymers 12:683. https://doi.org/10.3390/polym12030683

Delucis RA, Magalhaes WLE, Petzhold CL, Amico SC (2018) Forest-based resources as fillers in biobased polyurethane foams. J Appl Polym Sci 135:45684–45691. https://doi.org/10.1002/app.45684

Li O, Tamrakar S, Iyigundogdu Z, Mielewski D, Wyss K, Tour JM, Kiziltas A (2022) Flexible polyurethane foams reinforced with graphene and boron nitride nanofillers. Polym Comp 44:1494–1511. https://doi.org/10.1002/pc.27183

Dimiev AM, Eigler S (eds) (2016) Graphene Oxide: Fundamentals and Application. Wiley, New York

Liu D, Zou L, Chang Q, **ao T (2021) Preparation and properties of rigid polyurethane foams added with graphene oxide-hollow glass microspheres hybrid. Des Monomers Polym 24:208–215. https://doi.org/10.1080/15685551.2021.1954340

Gao M, Li J, Zhou X (2019) A flame retardant rigid polyurethane foam system including functionalized graphene oxide. Polym Compos 40:E1274–E1282. https://doi.org/10.1002/PC.24965

Meng D, Liu X, Wang S, Sun J, Li H, Wang Z, Gu X, Zhang S (2021) Self-healing polyelectrolyte complex coating for flame retardant flexible polyurethane foam with enhanced mechanical property. Compos B Eng 219:108886. https://doi.org/10.1016/J.COMPOSITESB.2021.108886

Wang L, Pan B, Gao J, Huang S, **e M, Li C, Luo D, Liu J, Wang H (2020) Tribological behaviors of porous 3D graphene lubricant reinforced monomer casting polyamide 6 composite. Adv Eng Mater 22:2070020. https://doi.org/10.1002/ADEM.202070020

Wu Q, Liu C, Tang L, Yan Y, Qiu H, Pei Y, Sailor MJ, Wu L (2021) Stable electrically conductive, highly flame-retardant foam composites generated from reduced graphene oxide and silicone resin coatings. Soft Matter 17:68–82. https://doi.org/10.1039/D0SM01540G

Verdejo R, Stämpfli R, Alvarez-Lainez M, Mourad S, Rodriguez-Perez MA, Brühwiler PA (2008) Enhanced acoustic dam** in flexible polyurethane foams filled with carbon nanotubes. Compos Sci Technol 69:1564–1569. https://doi.org/10.1016/j.compscitech.2008.07.003

Lee J, Kim G, Ha C (2012) Sound absorption properties of polyurethane/nano-silica nanocomposite foams. J Appl Polym Sci 123:2384–2390. https://doi.org/10.1002/app

Author information

Authors and Affiliations

Contributions

Eduardo and Lídia Wrote the main manuscript All authors reviewed the manuscript

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflicts of interest.

Financial support

The authors did not receive any financial support from any organization for the submitted world.

Ethical approval

The authors do not contain any studies involving human participants or animals performed by any of the authors.

Informed consent

None.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Kerche, E.F., Lazzari, L.K., de Bortoli, B.F. et al. A systematic review of enhanced polyurethane foam composites modified with graphene for automotive industry. Graphene and 2D mater 9, 27–46 (2024). https://doi.org/10.1007/s41127-024-00073-x

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s41127-024-00073-x