Abstract

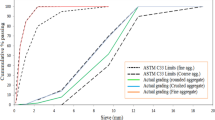

Most investigations in the literature concerning cement replacement with supplementary cementitious materials (SCMs) have predominantly focused on the utilization of fly ash and slag, which are not universally available. Laterite soil presents itself as a potential alternative to these commonly used SCMs, particularly where availability is an issue. Commonly found in tropical and subtropical regions, laterite soils have been extensively employed in building construction. Therefore, the present study aims to explore the incorporation of laterite soil calcined at 600 °C as a substitute for Portland cement (PC) in mortars, with the objective of producing sustainable construction materials. The effect of calcined laterite (CL) passing 75 μm sieves as 10, 30 and 50% replacement of Portland cement (PC) on the fresh and hardened properties of mortars was investigated. Mortars were cured at room temperature, and subjected to setting time, flowability, ASR, mechanical strength, porosity, water absorption, bulk density test along with scanning electron microscopy analysis at 28 days. The obtained result revealed the reduction in mechanical properties with the incorporation of CL up to 50 wt% compared to the reference sample only used OPC. As incorporation rates of calcined increased, the flow and setting times (initial and final) values decreased from 197 to 138 mm and 156 to 24 min and 341 to 77 min, respectively.

Similar content being viewed by others

Abbreviations

- PC:

-

Portland cement

- CL:

-

Calcined laterite

- SCMs:

-

Supplementary cementitious materials

- ASR:

-

Alkali-silica reaction

- CEM0:

-

Mortar mixtures with CL as 0% replacement of cement

- CEM10:

-

Mortar mixtures with CL as 10% replacement of cement

- CEM30:

-

Mortar mixtures with CL as 30% replacement of cement

- CEM50:

-

Mortar mixtures with CL as 50% replacement of cement

- CH:

-

Calcium hydroxide

- CSH:

-

Calcium silicate hydrate

- SEM:

-

Scanning Electron Microscopy

- XRD:

-

X-ray diffraction

References

Thomas BS (2018) Green concrete partially comprised of rice husk ash as a supplementary cementitious material – a comprehensive review. Renew Sustain Energy Rev 82:3913–3923

Pimraksa K, Hanjitsuwan S, Chindaprasirt P (2009) Synthesis of belite cement from lignite fly ash. Ceram Int 35(6):2415–2425

KLEE H (2009) Cement Sustainability Initiative: Cement Industry Energy and CO 2 Performance Getting the Numbers Right. Washington, United States, WBCSD

Kolawole JT et al (2021) Blended cement binders containing bamboo leaf ash and ground clay brick waste for sustainable concrete. Materialia 15:101045

Ogunbode E, Apeh J (2012) Waste to wealth: A study of laterite bricks produced using blended incinerated corn cob ash cement. in Proc. 4th West Africa Built Environment Research (WABER) Conference, Abuja

Bougara A, Lynsdale C, Milestone NB (2018) The influence of slag properties, mix parameters and curing temperature on hydration and strength development of slag/cement blends. Constr Build Mater 187:339–347

Bukhari SA et al (2013) Performance of cement containing laterite as supplementary cementing material. 62(3):65–70

Şimşek O, Sefidehkhan HP, Gökçe HS (2022) Performance of fly ash-blended Portland cement concrete developed by using fine or coarse recycled concrete aggregate. Constr Build Mater 357:129431

Ebert BAR et al (2021) Impact of electrodialytic remediation of MSWI fly ash on hydration and mechanical properties of blends with Portland cement. Constr Build Mater 309:125193

Wang Q et al (2022) Effects of silica fume on the abrasion resistance of low-heat Portland cement concrete. Constr Build Mater 329:127165

Zhang Y et al (2022) Effect of dosage of silica fume on the macro-performance and micro/nanostructure of seawater Portland cement pastes prepared with an ultra-low water-to-binder ratio. Cem Concr Compos 133:104700

Silva LHP et al (2021) Bamboo leaf ash for use as mineral addition with Portland cement. J Building Eng 42:102769

Pandey A, Kumar B (2022) Utilization of agricultural and industrial waste as replacement of cement in pavement quality concrete: a review. Environ Sci Pollut Res 29(17):24504–24546

Pandey A, Kumar B (2019) Effects of rice straw ash and micro silica on mechanical properties of pavement quality concrete. J Building Eng 26:100889

Singh R et al (2022) Effects of recycled fine aggregates on properties of concrete containing natural or recycled coarse aggregates: a comparative study. J Building Eng 45:103442

Adesanya DA (1996) Evaluation of blended cement mortar, concrete and stabilized earth made from ordinary Portland cement and corn cob ash. Constr Build Mater 10(6):451–456

Joel M, Edeh E, Joseph (2015) Comparative analysis of cement and lime modification of Ikpayongo laterite for effective and economic stabilization. J Emerg Trends Eng Appl Sci 6(1):49–56

Lemougna P.N.A.U.M.U.F.C.K.E.T.A.B.T.I.L.B.S.P.f.S.B.A.i.T.C.R. and C (2011) Prospects Case Sustain 3:293–305. https://doi.org/10.3390/su3010293

O OA, Chukwunonye E, O UO (2019) Performance analysis of cement-stabilised laterite for road construction in the tropics. 6(8):555–561

Osula DOA (1991) Lime modification of problem laterite. Eng Geol 30(2):141–154

Boum BE (2022) R., Thermal behavior of acidic and alkali activated laterite based geopolymer: a comparative study. Geosystem Eng, : p. 1–14

Kaze RC et al (2017) The corrosion of kaolinite by iron minerals and the effects on geopolymerization. Appl Clay Sci 138:48–62

Komnitsas K et al (2021) Factors affecting Alkali activation of Laterite Acid leaching residues. Environments 8. https://doi.org/10.3390/environments8010004

Awoyera PO, Akinmusuru JO, Ndambuki JM (2016) Green concrete production with ceramic wastes and laterite. Constr Build Mater 117:29–36

Komnitsas K, Petrakis E, Bartzas G (2023) A novel and greener sequential column leaching approach for the treatment of two different Greek laterites. Sci Total Environ 854:158748

Komnitsas K et al (2019) Column leaching of low-grade saprolitic laterites and valorization of leaching residues. Sci Total Environ 665:347–357

Komnitsas K, Zaharaki D (2007) Geopolymerisation: a review and prospects for the minerals industry. Miner Eng 20(14):1261–1277

Joel M, Agbede Isaac O (2011) Mechanical-cement stabilization of Laterite for Use as Flexible Pavement Material. J Mater Civ Eng 23(2):146–152

Awoyera PO et al (2018) Microstructural characteristics, porosity and strength development in ceramic-laterized concrete. Cem Concr Compos 86:224–237

Chindaprasirt P et al (2023) Effects of sulfate attack under wet and dry cycles on strength and durability of cement-stablized laterite. Constr Build Mater 365:129968

Lasisi F, Osunade JA, Adewale AO (1990) Short-term studies on the durability of laterized concrete and laterite-cement mortars. Build Environ 25(1):77–83

Musbau KD et al (2021) Comparative performance of limestone calcined clay and limestone calcined laterite blended cement concrete. Clean Eng Technol 4:100264

Pera TMJ, Ambroise J (1992) Action of some aggressive solutions on Portland and calcined laterite blended cement concretes. Special Publication 132:763–780

ASTM-C109 C109/C109M‐13 Standard Test Method for Compressive Strength of Hydraulic Cement Mortars (Using 2‐in. or [50‐mm] Cube Specimens)

ASTM C (2012) Standard test method for slump of hydraulic-cement concrete

ASTM CJC (2013) Standard test method for density, absorption, and voids in hardened concrete

Farooq S, Yokota H (2022) Residual mechanical properties of steel fiber reinforced concrete damaged by alkali silica reaction and subsequent sodium chloride exposure. Ceram Int 48(17):24850–24858

Naghizadeh A, Ekolu SO (2022) Activator-related effects of sodium hydroxide storage solution in standard testing of fly ash geopolymer mortars for alkali–silica reaction. Mater Struct 55(1):22

Naghizadeh A, Ekolu SO (2019) Behaviour of fly ash geopolymer binders under exposure to alkaline media. Asian J Civil Eng 20(6):785–798

Wei J, Meyer C (2014) Sisal fiber-reinforced cement composite with Portland cement substitution by a combination of metakaolin and nanoclay. J Mater Sci 49(21):7604–7619

Thomas M (2011) The effect of supplementary cementing materials on alkali-silica reaction: a review. Cem Concr Res 41(12):1224–1231

Zhou Y et al (2022) Influence of metakaolin and calcined montmorillonite on the hydration of calcium sulphoaluminate cement. Case Stud Constr Mater 16:e01104

Kim YJ, Choi YW (2012) Utilization of waste concrete powder as a substitution material for cement. Constr Build Mater 30:500–504

Senthamarai RM, Devadas P, Manoharan (2005) Concrete with ceramic waste aggregate. Cem Concr Compos 27(9):910–913

Leklou N, Nguyen V-H, Mounanga P (2017) The effect of the partial cement substitution with fly ash on delayed ettringite formation in heat-cured mortars. KSCE J Civ Eng 21:1359–1366

Chopperla KST, Smith JA, Ideker JH (2022) The efficacy of portland-limestone cements with supplementary cementitious materials to prevent alkali-silica reaction. Cement 8:100031

Kasaniya M, Thomas MDA (2022) Role of the alkalis of supplementary cementing materials in controlling pore solution chemistry and alkali-silica reaction. Cem Concr Res 162:107007

Shehata MH, Thomas MDA, Bleszynski RF (1999) The effects of fly ash composition on the chemistry of pore solution in hydrated cement pastes. Cem Concr Res 29(12):1915–1920

Shehata MH, Thomas MDA (2002) Use of ternary blends containing silica fume and fly ash to suppress expansion due to alkali–silica reaction in concrete. Cem Concr Res 32(3):341–349

Napia C et al (2012) Leaching of heavy metals from solidified waste using Portland cement and zeolite as a binder. Waste Manag 32(7):1459–1467

Zhou Y et al (2022) Effect of ultrafine slag on hydration heat and rheology properties of Portland cement paste. Powder Technol 405:117549

Collins F, Sanjayan JG (1998) Early Age Strength and Workability of Slag pastes activated by NaOH and Na2CO3. Cem Concr Res 28(5):655–664

Saha AK, Sarker PK (2016) Expansion due to alkali-silica reaction of ferronickel slag fine aggregate in OPC and blended cement mortars. Constr Build Mater 123:135–142

Wei J et al (2019) Mitigating alkali-silica reaction induced concrete degradation through cement substitution by metakaolin and bentonite. Appl Clay Sci 182:105257

Leemann A et al (2015) ASR prevention — effect of aluminum and lithium ions on the reaction products. Cem Concr Res 76:192–201

Acknowledgements

The Royal Society and the African Academy of Science through the funding FLAIR to Dr. Elie Kamseu. Grant; FLR\R1\201402. The present project also received a contribution of the European Union through financial contribution No. PRICNAC-EEPER: MD2022.

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Kaze, R.C., Bikoko, T.G.L.J., Adesina, A. et al. Influence of calcined laterite on the physico-mechanical, durability and microstructure characteristics of portland cement mortar. Innov. Infrastruct. Solut. 9, 248 (2024). https://doi.org/10.1007/s41062-024-01564-9

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s41062-024-01564-9