Abstract

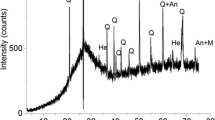

Novel, high-performance fire-retardant mortar formulations are produced involving in situ alkali activated, inorganic polymer binder (AAIPB) concept, similar to popular Geopolymers. The formulated mortar after mixing with water will cure under prevailing, ambient conditions. The proposed process of making mortar is relatively simple, economical, only involves dry blending of raw materials, and no CO2 emissions as it does not involve heating. This makes the process greener and lower energy consumption than a cement industry. It makes use of cheap by-products fly ash and other waste products. The finished product is a single pack, dry powder mix, eliminating all handling, storage and corrosion-related problems associated with commonly used two pack, aqueous paste products. The testing was carried out by directly exposing the precast mortar blocks, with embedded steel rod to fire for 4 h continuously at temperatures above 1050 °C. It is established in this experimental finding that formulated mortars have excellent heat stability, minimum mass loss, and excellent thermal shock resistance even upon prolonged heating. Characterization tests like Raman Spectroscopy, X-ray Diffraction (XRD), Fourier-Transform Infrared spectroscopy (FTIR), Scanning Electron Microscopic Images and Thermogravimetric Analysis are carried out to study the chemical changes taking place in the internal structure of material, which provides excellent fire resisting characteristics. One of the results demonstrates the superiority of using potassium silicate/potassium hydroxide as combination alkaline binder/activator instead of traditional combination of sodium silicate/sodium hydroxide. The other results obtained are presented and discussed.

Similar content being viewed by others

References

CruzJuarez RI, Finnegan S (2021) The environmental impact of cement production in Europe: a holistic review of existing EPDs. Clean Environ Syst 3:100053. https://doi.org/10.1016/j.cesys.2021.100053

Luukkonen T, Abdollahnejad Z, Yliniemi J, Kinnunen P, Illikainen M (2018) One-part alkali-activated materials: a review. Cem Concr Res 103:21–34. https://doi.org/10.1016/j.cemconres.2017.10.001

Hardjito D, Tsen M (2008) Strength and thermal stability of fly ash-based geopolymer mortar. In: The 3rd international conference-ACF/VCA 144–150

Damilola OM (2013) Syntheses, characterization and binding strength of geopolymers: a review. Int J Mater Sci Appl 2:185. https://doi.org/10.11648/j.ijmsa.20130206.14

Hameed AM, Rawdhan RR, Al-Mishhadani SA (2017) Effect of various factors on the manufacturing of geopolymer mortar. Arch Sci 1:1000111

Okoye FN (2017) Geopolymer binder: a veritable alternative to Portland cement. Mater Today Proc 4:5599–5604. https://doi.org/10.1016/j.matpr.2017.06.017

Saxena SK, Kumar M, Singh NB (2017) Fire resistant properties of alumino silicate geopolymer cement mortars. Mater Today Proc 4:5605–5612. https://doi.org/10.1016/j.matpr.2017.06.018

Weerdt KD (2011) Geopolymers - State of the art: FA 1 Environmentally friendly concrete: SP 1.1 Low carbon-footprint binder systems. In: COIN Project report 37. http://hdl.handle.net/11250/2379051

Provis JL (2014) Geopolymers and other alkali activated materials: Why, how, and what? Mater Struct. https://doi.org/10.1617/s11527-013-0211-5

Elzeadani M, Bompa DV, Elghazouli AY (2022) One-part alkali activated materials: a state-of-the-art review. J Build Eng 57:104871. https://doi.org/10.1016/j.jobe.2022.104871

Provis JL, van Deventer J (2013) Alkali activated materials: state-of-the-art report, RILEM TC 224-AAM. Springer. https://doi.org/10.1007/978-94-007-7672-2

Cong P, Cheng Y (2021) Advances in geopolymer materials: a comprehensive review. J Traffic Transp Eng (Engl Edn) 8:283–314. https://doi.org/10.1016/j.jtte.2021.03.004

Criado M, Ke X, Provis JL, Bernal SA (2017) Alternative inorganic binders based on alkali-activated metallurgical slags. Sustain Nonconvent Constr Mater Inorganic Bonded Fiber Comp. https://doi.org/10.1016/b978-0-08-102001-2.00008-5

Komljenović M, Tanasijević G, Džunuzović N, Provis JL (2020) Immobilization of cesium with alkali-activated blast furnace slag. J Hazard Mater 388:121765. https://doi.org/10.1016/j.jhazmat.2019.121765

Musil S (2014) Novel, inorganic composites using porous, alkali-activated, aluminosilicate binders, Ph.D. Dissertation. In: University of Illinois at Urbana-Champaign. https://www.ideals.illinois.edu/items/50847

Cao Y (2017) Fire-resistant geopolymer concrete and its application in concrete filled steel tubes, Dissertation, Western Sydney University. https://researchdirect.westernsydney.edu.au/islandora/object/uws%3A46752

Komnitsas K, Zaharaki D (2007) Geopolymerisation: a review and prospects for the minerals industry. Miner Eng 20:1261–1277. https://doi.org/10.1016/j.mineng.2007.07.011

Yusslee E, Beskhyroun S (2022) The potential of one-part alkali-activated materials (AAMs) as a concrete patch mortar. Sci Rep 12:15902. https://doi.org/10.1038/s41598-022-19830-0

Gonçalves M, Vilarinho IS, Capela M, Caetano A, Novais RM, Labrincha JA, Seabra MP (2021) Waste-based one-part alkali activated. Mater Mater 14:2911. https://doi.org/10.3390/ma14112911

Mehta P (2004) High-performance, high-volume fly ash concrete for sustainable development. In: Wang K (ed) Proceedings of the International Workshop on Sustainable Development and Concrete Technology, Bei**g, China May 20–21, 2004

Saridemir M, Celikten S (2017) The strength properties of alkali-activated silica fume mortars. Compute Concrete 19:153–159. https://doi.org/10.1298/cac.2017.19.2.153

Çelikten S (2021) Mechanical and microstructural properties of waste andesite dust-based geopolymer mortars. Adv Powder Technol 32:1–9. https://doi.org/10.1016/j.apt.2020.10.011

Çelikten S, Erdoğan G (2022) Effects of perlite/fly ash ratio and the curing conditions on the mechanical and microstructural properties of geopolymers subjected to elevated temperatures. Ceram Int 48:27870–27877. https://doi.org/10.1016/j.ceramint.2022.06.089

Thomas A (2013) Waterborne silicates in coatings and construction chemicals. In: Francis RA (ed) Inorganic zinc coatings: history. A Compilation of Papers Published in Australia and New Zealand, Chemistry, Properties, Applications and Alternatives, pp 227–259

(2004) Soluble Silicates, SIDS Initial Assessment for SIAM 18, OECD, UNEP Publications. https://hpvchemicals.oecd.org/UI/handler.axd?id=3cb4f34b-2afa-4004-b447-521188909235

Hager I, Sitarz M (2017) Properties of Alkali Activated Fly Ash Mortars Effect of NaOH Concentration in Activator Solution and Curing Time. Sixth International Conference on Advances in Civil, Structural and Environmental Engineering - ACSEE 2017. https://doi.org/10.15224/978-1-63248-139-9-24

Singh N (2018) Fly ash-based geopolymer binder: a future construction material. Minerals 8:299. https://doi.org/10.3390/min8070299

Thapa VB, Waldmann D (2018) A short review on alkali-activated binders and geopolymer binders, Contribution to collective works. https://orbilu.uni.lu/handle/10993/35284

11.2. Steel Exposed to Fire | American Institute of Steel Construction. https://www.aisc.org/steel-solutions-center/engineering-faqs/11.2.-steel-exposed-to-fire/. Accessed 1 Dec 2021

Fire Resistance of Steel Structures - Effect of Fire on Steel. https://clmfireproofing.com/how-does-fire-affect-structural-steel/. Accessed 2 Nov 2021

Marvila MT, de Azevedo ARG, Vieira CMF (2021) Reaction mechanisms of alkali-activated materials. Revista IBRACON de Estruturas e Materiais. https://doi.org/10.1590/s1983-41952021000300009

Duxson P, Fernández-Jiménez A, Provis JL, Lukey GC, Palomo A, van Deventer JSJ (2006) Geopolymer technology: the current state of the art. J Mater Sci 42:2917–2933. https://doi.org/10.1007/s10853-006-0637-z

Petermann JC, Saeed A, Michael I. H (2010) Alkali-Activated Geopolymers: A Literature Review. In: Defence Technical Information Center - DTIC. https://apps.dtic.mil/sti/citations/ADA559113. Accessed 12 Nov 2021

El-Hassan H, Ismail N, Al Hinaii S, Alshehhi A, Al Ashkar N (2017) Effect of GGBS and curing temperature on microstructure characteristics of lightweight geopolymer concrete. MATEC Web Conf 120:03004. https://doi.org/10.1051/matecconf/201712003004

Williams R, van Riessen A (2016) The first 20 hours of geopolymerization: an in situ waxs study of flyash-based geopolymers. Materials 9:552. https://doi.org/10.3390/ma9070552

Shinde PB, Suryawanshi SA, Chougule AD (2016) A Characteristic Study of Light Weight Geopolymer Concrete. International Research Journal of Engineering and Technology (IRJET) 3:1555. https://www.irjet.net/archives/V3/i2/IRJET-V3I2271.pdf

Duchesne J, Duong L, Bostrom T, Frost R (2010) Microstructure study of early in situ reaction of fly ash geopolymer observed by environmental scanning electron microscopy (ESEM). Waste Biomass Valorization 1:367–377. https://doi.org/10.1007/s12649-010-9036-4

Rees CA, Provis JL, Lukey GC, van Deventer JSJ (2007) In situ ATR-FTIR study of the early stages of fly ash geopolymer gel formation. Langmuir 23:9076–9082. https://doi.org/10.1021/la701185g

Grant Norton M, Provis JL (2020) 1000 at 1000: Geopolymer technology—the current state of the art. J Mater Sci 55:13487–13489. https://doi.org/10.1007/s10853-020-04990-z

Lafuente B, Downs RT, Yang H, Stone N (2015) The power of databases: the RRUFF project. In: Armbruster T and Danisi R M (eds) Highlights in Mineralogical Crystallography, Berlin, Germany, W. De Gruyter

Rios Reyes CA, Williams CD (2010) Hydrothermal transformation of kaolinite in the system K2O-SiO2-Al2O3-H2O. DYNA (Colombia) 77:55–63. http://www.scielo.org.co/scielo.php?script=sci_arttext&pid=S0012-73532010000300006&lng=en&tlng=en

Fernandes L, Salomão R (2018) Preparation and characterization of mullite-alumina structures formed “in situ” from calcined alumina and different grades of synthetic amorphous silica. Mater Res. https://doi.org/10.1590/1980-5373-mr-2017-0783

Mehta NS, Sahu PK, Tripathi P, Pyare R, Majhi MR (2018) Influence of alumina and silica addition on the physico-mechanical and dielectric behavior of ceramic porcelain insulator at high sintering temperature. Boletín de la Sociedad Española de Cerámica y Vidrio 57:151–159. https://doi.org/10.1016/j.bsecv.2017.11.002

Shinohara Y (2004) Quantitative analysis of tridymite and cristobalite crystallized in rice husk ash by heating. Ind Health 42:277–285. https://doi.org/10.2486/indhealth.42.277

Anggono J (2005) Mullite ceramics: its properties structure and synthesis | jurnal teknik mesin. Jurusan Teknik Mesin 7:1–10

Obzina T, Merta V, Folta M, Bradáč J, Beňo J, Novohradská N, Gawronová M, Kroupová I, Lichý P, Radkovský F, Janovská K, Vasková I, Drobíková K, Nguyenová I (2021) Technological and quality aspects of the use of innovative inorganic binders in the production of castings. Metals 11:1779. https://doi.org/10.3390/met11111779

Smart RStC (2003) Minerals, Ceramics and Glasses. In: In: O’Connor DJ, Sexton BA, Smart RSC (eds) Surface Analysis Methods in Materials Science. Springer, Berlin, Heidelberg. pp 377–403. https://doi.org/10.1007/978-3-662-05227-3_16

Kubiliūtė R, KAMINSKAS R, (2013) The pozzolanic activity of calcined clay – silica gel composites. Mater Sci. https://doi.org/10.5755/j01.ms.19.4.2300

The Quartz Page. http://www.quartzpage.de/. Accessed 21 Feb 2021

Cullity BD (1978) Elements of X-Ray Diffraction. Addison-Wesley Publishing Company, Inc.

Ylmén R, Jäglid U, Steenari B-M, Panas I (2009) Early hydration and setting of Portland cement monitored by IR, SEM and Vicat techniques. Cem Concr Res 39:433–439. https://doi.org/10.1016/j.cemconres.2009.01.017

Gouadec G, Colomban P (2007) Raman Spectroscopy of nanomaterials: How spectra relate to disorder, particle size and mechanical properties. Prog Cryst Growth Charact Mater 53:1–56. https://doi.org/10.1016/j.pcrysgrow.2007.01.001

McNamee BD, Gunter ME (2014) Mineralogy and Optical Mineralogy Laboratory Manual, Mineralogical Society of America

Choo MS, Kok M (2019) A review on synthesis of mullite ceramics from industrial wastes. Recycling 4:39. https://doi.org/10.3390/recycling4030039

Sun Z, Li H, Bao W, Wang C (2016) Mineral phase transition of desilicated high alumina fly ash with alumina extraction in mixed alkali solution. Int J Miner Process 153:109–117. https://doi.org/10.1016/j.minpro.2016.05.004

Mullite 3Al2O3–2SiO2 Material Properties. https://www.accuratus.com/mullite.html. Accessed 27 Feb 2021

Salami BA, Megat Johari MA, Ahmad ZA, Maslehuddin M, Adewumi AA (2018) Impact of Al(OH)3 addition to POFA on the compressive strength of POFA alkali-activated mortar. Constr Build Mater 190:65–82. https://doi.org/10.1016/j.conbuildmat.2018.09.076

Halim MEL, Daoudi L, Ouahabi MEL, Amakrane J, Fagel N (2018) Mineralogy and firing characteristics of clayey materials used for ceramic purposes from Sale region (Morocco). J Mater Environ Sci 9:2263–2273

Davood V, Attarnejad MA, Massoodian SK, Akbarnejad MM (2005) Synthesis of hydrophobic silicalite adsorbent from domestic resources: the effect of alkalinity on the crystal size and morphology. Iran J Chem Chem Eng (IJCCE) 24:9–14

Zhang J, Li X, Liu J, Wang C (2018) A comparative study of MFI Zeolite derived from different silica sources: synthesis. Char Catal Perf Catal 9:13. https://doi.org/10.3390/catal9010013

Di Febo R, Casas L, Rius J, Tagliapietra R, Melgarejo J (2019) Breaking preconceptions: thin section petrography for ceramic glaze microstructures. Minerals 9:113. https://doi.org/10.3390/min9020113

Simic M, Alil A, Martinovic S, Vlahovic M, Savic A, Volkov-Husovic T (2020) High temperature materials: properties, demands and applications. Chem Ind 74:273–284. https://doi.org/10.2298/hemind200421019s

Zhou L, Huang J, Ouyang H, Cao L, Hao W, Wang X (2017) In-situ mullite whisker to improve the thermal shock resistance of silicate glass coating for SiC coated carbon/carbon composites. J Alloy Compd 712:288–295. https://doi.org/10.1016/j.jallcom.2017.03.205

Behera PS, Bhattacharyya S (2021) Effect of different alumina sources on phase formation and densification of single-phase mullite ceramic – Reference clay alumina system. Mater Today Commun 26:101818. https://doi.org/10.1016/j.mtcomm.2020.101818

Sedaghat A, Taheri-Nassaj E, Soraru GD, Ebadzadeh T (2011) A comparative study of microstructural development in the sol–gel derived alumina–mullite nanocomposites using colloidal silica and tetraethyl orthosilicate. J Sol-Gel Sci Technol 58:689–697. https://doi.org/10.1007/s10971-011-2446-3

Mahé M, Heintz J-M, Rödel J, Reynders P (2008) Cracking of titania nanocrystalline coatings. J Eur Ceram Soc 28:2003–2010. https://doi.org/10.1016/j.jeurceramsoc.2008.02.002

Mustafa Al Bakri AM, Kamarudin H, Bnhussain M, Khairul Nizar I, Ratafia A, Zarina Y (2012) The processing, characterization, and properties of fly ash based geopolymer concrete. Rev Adv Mater Sci 30:90–97

Drożdż E, Wyrwa J, Schneider K, Rękas M (2016) Electrical properties of silica-doped 3 mol% yttria-stabilized tetragonal zirconia. J Mater Sci 52:674–685. https://doi.org/10.1007/s10853-016-0361-2

Prochon P, Zhao Z, Courard L, Piotrowski T, Michel F, Garbacz A (2020) Influence of activators on mechanical properties of modified fly ash based geopolymer mortars. Materials 13:1033. https://doi.org/10.3390/ma13051033

Zhang Y, Kelly JR (2017) Dental ceramics for restoration and metal veneering. Dent Clin North Am 61:797–819. https://doi.org/10.1016/j.cden.2017.06.005

Chargui F, Hamidouche M, Belhouchet H, Jorand Y, Doufnoune R, Fantozzi G (2018) Mullite fabrication from natural kaolin and aluminium slag. Boletín de la Sociedad Española de Cerámica y Vidrio 57:169–177. https://doi.org/10.1016/j.bsecv.2018.01.001

Lazic B, Krüger H, Kaindl R, Perfler L, Kremenović A, Cvetković V, Withers RL (2013) Superstructure of Mullite-type KAl9O14. Chem Mater 25:496–502. https://doi.org/10.1021/cm3038476

Freestone IC, Middleton AP (1987) Mineralogical applications of the analytical SEM in archaeology. Mineral Mag 51:21–31. https://doi.org/10.1180/minmag.1987.051.359.03

Alehyen S, Achouri MEL, Taibi M (2017) Characterization, microstructure and properties of fly ash-based geopolymer. J Mater Environ Sci 8:1783–1796

Bell JL, Driemeyer PE, Kriven WM (2009) Formation of Ceramics from Metakaolin-Based Geopolymers. Part II: K-Based Geopolymer. J Am Ceram Soc 92:607–615. https://doi.org/10.1111/j.1551-2916.2008.02922.x

Kriven WM (2021) Geopolymers and Geopolymer-Derived Composites. Encyclopedia of Materials: Technical Ceramics and Glasses 424–438. https://doi.org/10.1016/b978-0-12-818542-1.00100-4

Ma Z, Zhang J, Maluk C, Yu Y, Seraji SM, Yu B, Wang H, Song P (2022) A lava-inspired micro/nano-structured ceramifiable organic-inorganic hybrid fire-extinguishing coating. Matter 5:911–932. https://doi.org/10.1016/j.matt.2021.12.009

Banerjee D Experimental Techniques in Thermal Analysis Thermogravimetry (TG) & Differential Scanning Calorimetry (DSC), TGA-DSC. In: https://www.iitk.ac.in/che/PG_research_lab/pdf/resources/TGA-DSC-reading-material.pdf. Accessed 21 Jan 2021

Srinivasan What does Straight line in TGA/DSC Test Signify? Research Gate, Exploring Q/A from experts -Science topic-TGA/DSC, Accessed March 2021. https://www.researchgate.net/post/What-does-a-straight-line-in-DSC-signify

Acknowledgements

The authors are thankful to the Managements of Gulf Minerals and Chemicals LLC. Umm Al Quwain and PASSIFIRE, Dubai, UAE, for the support, their cooperation in conducting experiments of this study. The authors express their sincere thanks to Dr. Gopalakrishnan GOPU—Assistant Professor, Department of Industrial Chemistry, Alagappa University, Karaikudi, Tamilnadu, India, for having helped in recording the XRD and Raman Spectrum, SEM images for the specimens used in the current study. Also, the authors acknowledge with thanks, the support offered by Mr. Kshtiz Solomon, Emphor Life and Analytical Sciences, Dubai, for hel** in providing FTIR data and Dr. Yoshihiko Arao – Associate Professor, Department of Applied Mechanics and Aerospace Engineering, Faculty of Science and Engineering-Waseda University, Arao Laboratory, Tokyo, Japan, (https://www.arao.amech.waseda.ac.jp/en/) for some useful suggestions.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Ethical approval

This article does not contain any studies with human participants or animals, performed by any of the authors.

Informed consent

For this type of study, formal consent is not required.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Vyas, P., Pandya, N. Formulating high performance fire- and flame-retardant mortars using novel, in situ alkali-activated inorganic polymeric compositions and mineral fillers. Innov. Infrastruct. Solut. 8, 137 (2023). https://doi.org/10.1007/s41062-023-01101-0

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s41062-023-01101-0