Abstract

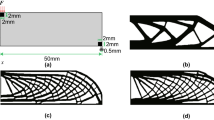

A novel hierarchical graded structure was designed based on scaling the hierarchical re-entrant cells, and its quasi-static compressive response was experimentally investigated and compared with a similar non-graded structure. The specimens were fabricated using fused deposition modeling (FDM) with Acrylonitrile Butadiene Styrene (ABS) material. The new design significantly improves the energy absorption characteristics of the structure, such as enhanced specific energy absorption up to 290% compared to the non-graded structure. The mechanical response and progressive damage of the introduced structure were successfully simulated using finite element analysis. Instead of a popular elastic–plastic model, a pressure-dependent plasticity material model, specifically the Drucker-Prager model, was employed. Verification of the results with experimental data confirms the adequacy of this model for accurately simulating the examined auxetic structure.

Similar content being viewed by others

Data availability

Data is available on request.

References

Yang OHL, West H, Cormier D (2015) Mechanical properties of 3D re-entrant honeycomb auxetic structures realized via additive manufacturing. Int J Solids Struct 69–70:475–490. https://doi.org/10.1016/j.ijsolstr.2015.05.005

Mahshid HNHR, Loft Hojbjerre K (2016) Strength analysis and modeling of cellular lattice structures manufactured using selective laser melting for tooling applications. Mater Des 104:276–283. https://doi.org/10.1016/j.matdes.2016.05.020

Bertocco LEA, Aurino A, Borrelli D, Caraviello A (2021) Influence of SLM parameters on the compressive behaviour of lattice structures in 17-4PH stainless steel. IOP Conf Ser Mater Sci Eng 1038(1):012035

Zhang GLJ, You Z (2020) Large deformation and energy absorption of additively manufactured auxetic materials and structures: a review. Compos Part B 201:108340. https://doi.org/10.1016/j.compositesb.2020.108340

Gunaydın GSK, Turkmen HS, Grande AM (2022) Failure analysis of auxetic lattice structures under crush load. Proc Struct Int 35:237–246

Ha GLNS (2020) Thin-walled corrugated structures: a review of crashworthiness designs and energy absorption characteristics. Thin Walled Struct 157:106995. https://doi.org/10.1016/j.tws.2020.106995

Ren RDX, Tran P, Ngo TD, **e YM (2018) Auxetic metamaterials and structures: a review. Smart Mater Struct 27:023001. https://doi.org/10.1088/1361-665X/aaa61c

Jiang XRW, Wang SL, Zhang XG, Zhang XY, Luo C, **e YM, Scarpa F, Alderson A, Evans KE (2022) Manufacturing, characteristics and applications of auxetic foams: a state-of-the-art review. Compos Part B 235:1–27. https://doi.org/10.1016/j.compositesb.2022.109733

** ZWX, Ning J, **ao G, Liu E, Shu X (2016) Dynamic response of sandwich structures with graded auxetic honeycomb cores under blast loading. Compos Part B 106:206–217. https://doi.org/10.1016/j.compositesb.2016.09.037

Najafi HAM, Liaghat Gh (2021) Experimental investigation on energy absorption of auxetic structures. Mater Today Proc 34:350–355. https://doi.org/10.1016/j.matpr.2020.06.075

Zhang HHX, Tian R, Xue Q, Guan H, Yang X (2022) Static compression and dynamic crushing behaviors of novel hybrid re-entrant auxetic metamaterials with enhanced energy-absorption. Compos Struct 288:115399. https://doi.org/10.1016/j.compstruct.2022.115399

Tan ZCHHL, Li E, Tan XW, Cheng AG, Li QQ (2020) Energy absorption characteristics of three-layered sandwich panels with graded re-entrant hierarchical honeycombs cores. Aerosp Sci Technol 106:106073. https://doi.org/10.1016/j.ast.2020.106073

Zhang HLET, Ng BF (2021) Novel arc-shaped ligaments to enhance energy absorption capabilities of re-entrant anti-trichiral structures. Compos Part B 227:109366. https://doi.org/10.1016/j.compositesb.2021.109366

Liu NWW, Luo T, Lin Z (2016) In-plane dynamic crushing of re-entrant auxetic cellular structure. Mater Des 100:84–91. https://doi.org/10.1016/j.matdes.2016.03.086

Wu WHW, Qian G, Liao H, Xu X, Berto F (2019) Mechanical design and multifunctional applications of chiral mechanical metamaterials: a review. Mater Des 180:107950. https://doi.org/10.1016/j.matdes.2019.107950

Qiao CQCJ (2015) Analyses on the in-plane impact resistance of auxetic double arrowhead honeycombs. J Appl Mech 82:051007. https://doi.org/10.1115/1.4030007

Wei XZL, Yu Q, Zhang W, Zhu G (2021) In-plane compression behaviors of the auxetic star honeycomb: experimental and numerical simulation. Aerosp Sci Technol 115:106797. https://doi.org/10.1016/j.ast.2021.106797

Linforth TNS, Tran P, Ruan D, Odish R (2021) Investigation of the auxetic oval structure for energy absorption through quasi-static and dynamic experiments. Int J Impact Eng 147:1–13. https://doi.org/10.1016/j.ijimpeng.2020.103741

Ebrahimi RHMS, Etemadi E (2022) In-plane energy absorption characteristics and mechanical properties of 3D printed novel hybrid cellular structures. J Mater Res Technol 20:3616–3632. https://doi.org/10.1016/j.jmrt.2022.08.064

Choudhry BPNK, Kumar S (2022) In-plane energy absorption characteristics of a modified re-entrant auxetic structure fabricated via 3D printing. Compos Part B 228:109437. https://doi.org/10.1016/j.compositesb.2021.109437

Zhang PCH, Lin G, Sun W (2022) A corrugated gradient mechanical metamaterial: Lightweight, tunable auxeticity and enhanced specific energy absorption. Thin Walled Struct 176:109355. https://doi.org/10.1016/j.tws.2022.109355

Yang CHL, Wu H, Hao L, Wei Q, Yan Ch, Shi Y (2020) Insights into unit cell size effect on mechanical responses and energy absorption capability of titanium graded porous structures manufactured by laser powder bed fusion. J Mech Behav Biomed Mater 109:103843. https://doi.org/10.1016/j.jmbbm.2020.103843

Xu XZF, Zhang H (2018) A review on functionally graded structures and materials for energy absorption. Eng Struct 171:309–325. https://doi.org/10.1016/j.engstruct.2018.05.094

Niknam AHAH (2020) Graded lattice structures: simultaneous enhancement in stiffness and energy absorption. Mater Des 196:109129. https://doi.org/10.1016/j.matdes.2020.109129

Anni KZUIA, Pagliocca N, Singh N, Rahman O, Youssef G, Koohbor B (2022) Out-of-plane load-bearing and mechanical energy absorption properties of flexible density-graded TPU honeycombs. Compos Part C Open Access 8:100284. https://doi.org/10.1016/j.jcomc.2022.100284

Yang RML, Ferrucci M, Yan C, Shi Y, Yang S (2019) Continuous graded gyroid cellular structures fabricated by selective laser melting: design, manufacturing and mechanical properties. Mater Des 162:394–404. https://doi.org/10.1016/j.matdes.2018.12.007

Li XZQ, Fan F (2022) Dynamic crushing of uniform and functionally graded origami-inspired cellular structure fabricated by SLM. Eng Struct 262:114327. https://doi.org/10.1016/j.engstruct.2022.114327

**ang ZFX, Zhang Sh, Lu G, Ha N, Liang Y, Zhang X (2021) The mechanical characteristics of graded Miura-ori metamaterials. Mater Des 211:110173. https://doi.org/10.1016/j.matdes.2021.110173

Wu X, Su Y, Shi J (2020) In-plane impact resistance enhancement with a graded cell-wall angle design for auxetic metamaterials. Compos Struct 247:112451. https://doi.org/10.1016/j.compstruct.2020.112451

**ao ZDD, Li Y, Wu W, Fang D (2019) Compression behavior of the graded metallic auxetic reentrant honeycomb: experiment and finite element analysis. Mater Sci Eng A 758:163–171. https://doi.org/10.1016/j.msea.2019.04.116

Duraibabu RPRV, Sugavaneswaran M, Arumaikkannu G (2020) Compression behavior of Functionally graded cellular materials fabricated with FDM. Mater Today Proc 24(2):1035–1041. https://doi.org/10.1016/j.matpr.2020.04.417

Mohammadi AZKM, Bodaghi M, Long J, Khoo SY, **ang Y, Zolfagharian A (2023) Sustainable Robotic Joints 4D Printing with Variable Stiffness Using Reinforcement Learning. Robot Comput Integr Manuf 85:102636. https://doi.org/10.1016/j.rcim.2023.102636

Qi QLD, He Ch, Li Y, Wu W, **ao D (2019) Impact energy absorption of functionally graded chiral honeycomb structures. Extreme Mech Lett 32:100568. https://doi.org/10.1016/j.eml.2019.100568

Novak LON, Ren Z, Vesenjak M (2020) Mechanical properties of hybrid metamaterial with auxetic chiral cellular structure and silicon filler. Compos Struct 234:111718. https://doi.org/10.1016/j.compstruct.2019.111718

Wang FLY, Zhang X, Zhang K, Wang X, Gan D, Yang B (2021) Cell-size graded sandwich enhances additive manufacturing fidelity and energy absorption. Int J Mech Sci 211:106798. https://doi.org/10.1016/j.ijmecsci.2021.106798

Plocher APJ (2020) Effect of density and unit cell size grading on the stiffness and energy absorption of short fibre-reinforced functionally graded lattice structures. Addit Manuf 33:101171. https://doi.org/10.1016/j.addma.2020.101171

Novak MBN, Al-Ketan O, Ren Z, Vesenjak M (2022) Impact and blast resistance of uniform and graded sandwich panels with TPMS cellular structures. Compos Struct 300:116174. https://doi.org/10.1016/j.compstruct.2022.116174

Liu ETZH, Wang G, Ng BF (2022) In-plane crushing behavior and energy absorption of a novel graded honeycomb from hierarchical architecture. Int J Mech Sci 221:107202. https://doi.org/10.1016/j.ijmecsci.2022.107202

Wang JZZh, Li Zh, Shi Ch (2020) On the crashworthiness of bio-inspired hexagonal prismatic tubes under axial compression. Int J Mech Sci 186:105893. https://doi.org/10.1016/j.ijmecsci.2020.105893

Keripale SBKA (2022) Analysis of impact energy absorption and dissipation capacity of different composite materials using numerical simulation. Mater Today Proc 59:661–666. https://doi.org/10.1016/j.matpr.2021.12.196

Rahman BKO (2020) Optimization of energy absorption performance of polymer honeycombs by density gradation. Compos Part C Open Access 3:100052. https://doi.org/10.1016/j.jcomc.2020.100052

Choudhry SRBNK, Panda B, Singh H (2022) Experimental and numerical analysis of the bending behavior of 3D printed modified auxetic sandwich structures. Mater Today Proc 56(3):1356–1363. https://doi.org/10.1016/j.matpr.2021.11.425

Zhang HHX, Tian R, Xue Q, Guan H, Yang X (2022) Quasi-static compression and dynamic crushing behaviors of novel hybrid re-entrant auxetic metamaterials with enhanced energy-absorption. Compos Struct 288:115399. https://doi.org/10.1016/j.compstruct.2022.115399

Zhou BFNJ, Han N, Xu Sh, Zou M (2023) Crashworthiness and optimization of bionic sandwich cores under out-of-plane compression. Int J Mech Sci 246:108137. https://doi.org/10.1016/j.ijmecsci.2023.108137

Wang WZW, Guo M, Yang J, Ma L (2023) Energy absorption characteristics of a lightweight auxetic honeycomb under low-velocity impact loading. Thin Walled Struct 185:110577. https://doi.org/10.1016/j.tws.2023.110577

Kim PNY, Kim H, Choi Y (2022) Multi-morphology cellular structure design with smooth transition of geometry and homogenized mechanical properties between adjacent cells. Mater Des 218:110727. https://doi.org/10.1016/j.matdes.2022.110727

Syaefudin EA, Kholil A, Hakim M, Wulandari DA, Riyadi, Murtinugraha E (2023) The effect of orientation on tensile strength 3D printing with ABS and PLA materials. J Phys Conf Ser 2596:012002. https://doi.org/10.1088/1742-6596/2596/1/012002

Drucker DC, Prager W (1952) Soil mechanics and plastic analysis or limit design. Quart Appl Math 10:157–165. https://doi.org/10.1090/qam/48291

Zhang ZLW, Yang J, Ma L, Lin Z, Schmidt R, Schroder K (2022) A lightweight rotationally arranged auxetic structure with excellent energy absorption performance. Mech Mater 166:104244. https://doi.org/10.1016/j.mechmat.2022.104244

Dong YLZ, Zhao T, Wu W, **ao D, Liang J (2019) Experimental and numerical studies on the compressive mechanical properties of the metallic auxetic reentrant honeycomb. Mater Des 182:108036. https://doi.org/10.1016/j.matdes.2019.108036

Li IMQM, Harrigan JJ (2006) Compressive strain at the onset of the densification of cellular solids. J Cell Plast. https://doi.org/10.1177/0021955X06063519

J. Blaber. "http://www.ncorr.com." (accessed 2018).

Namvar IMN, Zolfagharian A, Demoly F, Bodaghi M (2023) Bio-inspired design, modeling, and 3D printing of lattice-based scale model scooter decks. Int J Adv Manuf Technol 126:2887–2903. https://doi.org/10.1007/s00170-023-11185-8

Zolfagharian PPA, Bodaghi M, Fard M, Rolfe B (2023) Additive manufacturing of composite foam metamaterial springs for vibration isolation. Adv Eng Mater 25:2300356. https://doi.org/10.1002/adem.202300356

Eryildiz M (2021) Effect of build orientation on mechanical behaviour and build time of FDM 3D-printed PLA parts: an experimental investigation. Eur Mech Sci 5:116–120. https://doi.org/10.26701/ems.881254

Tolochyna NZ-LO, Podrezov Y, Verbylo D, Tolochyn O, Zgalat-Lozynskyy O (2023) The role of flexible polymer composite materials properties in energy absorption of three-dimensional auxetic lattice structures. Materi Today Commun 37:107370. https://doi.org/10.1016/j.mtcomm.2023.107370

Wu JFY, Wu Ch, Li C, Sun G, Li Q (2023) Additively manufactured materials and structures: a state-of-the-art review on their mechanical characteristics and energy absorption. Int J Mech Sci 246:108102. https://doi.org/10.1016/j.ijmecsci.2023.108102

Sun DCG, Zhu G, Li Q (2022) Lightweight hybrid materials and structures for energy absorption: a state-of-the-art review and outlook. Thin Walled Struct 172:108760. https://doi.org/10.1016/j.tws.2021.108760

Riot EPA, Cosculluela A, Montemurro M (2023) Influence of manufacturing process-induced geometrical defects on the energy absorption capacity of polymer lattice structures. Def Technol. https://doi.org/10.1016/j.dt.2023.09.003

Shi FTL, Luo Y (2023) Energy absorption characteristics of the bionic lotus petiole structure under transverse load. Thin Walled Struct 187:110748. https://doi.org/10.1016/j.tws.2023.110748

Fan RXW, Davidson M, Yin H, Lai K, Wu Q (2023) Crashworthiness and energy absorption of UHPFRC-steel composite sandwich structures under impact loading. Compos Struct 311:116813. https://doi.org/10.1016/j.compstruct.2023.116813

Nam MJR, Niknam H, Rahmat M, Ashrafi B, Naguib HE (2023) 3D printed octet plate-lattices for tunable energy absorption. Mater Des 228:111835. https://doi.org/10.1016/j.matdes.2023.111835

Rodrigo SXCh, Durandet Y, Tran Ph, Ruan D (2023) Mechanical response of functionally graded lattices with different density grading strategies. Thin Walled Struct 192:111132. https://doi.org/10.1016/j.tws.2023.111132

Rodrigo SXCh, Durandet Y, Fraser D, Ruan D (2023) Quasi-static and dynamic compression of additively manufactured functionally graded lattices: experiments and simulations. Eng Struct 284:115909. https://doi.org/10.1016/j.engstruct.2023.115909

Sang WWL, Sun Zh, Wang F, Xu J, Tian J, Zhao Y, Zhang H (2023) Reusability and energy absorption behavior of 4D-printed heterogeneous lattice structures based on biomass shape memory polyester. J Mater Res Technol 27:1563–1578. https://doi.org/10.1016/j.jmrt.2023.09.323

Novak HA-RN, Airoldi A, Krstulović-Opara L, Łodygowski T, Ren Z, Vesenjak M (2023) Quasi-static and impact behaviour of foam-filled graded auxetic panel. Int J Impact Eng 178:104606. https://doi.org/10.1016/j.ijimpeng.2023.104606

Hu KLK, Gu D, Yang J, Wang H, Yuan L (2019) Mechanical properties and deformation behavior under compressive loading of selective laser melting processed bio-inspired sandwich structures. Mater Sci Eng A 762:138089. https://doi.org/10.1016/j.msea.2019.138089

Soleimanzadeh BRH, Bodaghi M, Jamalabadi M, Zhang AZX (2023) Sustainable Robots 4D Printing. Adv Sust Syst 7:2300289. https://doi.org/10.1002/adsu.202300289

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Mortezapour, A.R., Monazzah, A.H., Sarfaraz, R. et al. Energy absorption of multi-scale hierarchically graded auxetic structures: experimental and simulation methods. Prog Addit Manuf (2024). https://doi.org/10.1007/s40964-024-00623-y

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s40964-024-00623-y