Abstract

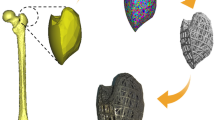

The rise of additive manufacturing gave hope to the design of orthopedic implants with comparable performance to natural human bone. The current research provides a numerical evaluation of the mechanical performance of three different Ti6Al4V cellular tibia implant designs. The investigated structures are face-centered cubic with vertical Z strut (FCCZ), reentrant and rhombic dodecahedron. Porous structures were designed with a pore size of 800 µm for bone ingrowth which improves implant fixation and osseo-integration. Porous stems were found to increase stress on the bone surface under the tibia tray accompanied by reducing both shear stress at the stem–bone interface and stress at the stem tip. Finally, proof-of-concept porous models 3D printed using Phrozen Shuffle XL demonstrated the manufacturability. A scanning electron microscope was used to measure the average pore sizes and the average strut sizes of the cellular microstructure to verify conformance to design.

Similar content being viewed by others

References

Enab TA, Bondok NE (2013) Material selection in the design of the tibia tray component of cemented artificial knee using finite element method. Mater Des 44:454–460. https://doi.org/10.1016/j.matdes.2012.08.017

AJRR (2020) The Seventh Annual Report of the AJRR on hip and knee arthroplasty. aaos.org/AJRRannualreport

Yao C, Lu J, Webster TJ (2010) Titanium and cobalt-chromium alloys for hips and knees. Biomaterials for Artificial Organs. Elsevier, Netherlands, pp 34–55. https://doi.org/10.1533/9780857090843.1.34

Burton HE, Eisenstein NM, Lawless BM et al (2018) The design of additively manufactured lattices to increase the functionality of medical implants. Mater Sci Eng C 2019(94):901–908. https://doi.org/10.1016/j.msec.2018.10.052

Kamath S, Chang W, Shaari E, Bridges A, Campbell A, McGill P (2008) Comparison of peri-prosthetic bone density in cemented and uncemented total knee arthroplasty. Acta Orthop Belg 74(3):354–359

Arabnejad S, Johnston B, Tanzer M, Pasini D (2017) Fully porous 3D printed titanium femoral stem to reduce stress-shielding following total hip arthroplasty. J Orthop Res 35(8):1774–1783. https://doi.org/10.1002/jor.23445

Han C, Li Y, Wang Q et al (2017) Continuous functionally graded porous titanium scaffolds manufactured by selective laser melting for bone implants. J Mech Behav Biomed Mater 2018(80):119–127. https://doi.org/10.1016/j.jmbbm.2018.01.013

Ran Q, Yang W, Hu Y et al (2018) Osteogenesis of 3D printed porous Ti6Al4V implants with different pore sizes. J Mech Behav Biomed Mater 84:1–11. https://doi.org/10.1016/j.jmbbm.2018.04.010

Wang L, Kang J, Sun C, Li D, Cao Y, ** Z (2017) Map** porous microstructures to yield desired mechanical properties for application in 3D printed bone scaffolds and orthopaedic implants. Mater Des 133:62–68. https://doi.org/10.1016/j.matdes.2017.07.021

Pałka K, Pokrowiecki R (2018) Porous titanium implants: a review. Adv Eng Mater 20(5):1–18. https://doi.org/10.1002/adem.201700648

Yuan L, Ding S, Wen C (2019) Additive manufacturing technology for porous metal implant applications and triple minimal surface structures: a review. Bioact Mater 4(1):56–70. https://doi.org/10.1016/j.bioactmat.2018.12.003

Gao C, Wang C, ** H et al (2018) Additive manufacturing technique-designed metallic porous implants for clinical application in orthopedics. RSC Adv 8(44):25210–25227. https://doi.org/10.1039/c8ra04815k

Kumaresan T, Gandhinathan R, Ramu M, Ananthasubramanian M (2015) Conceptual design and fabrication of porous structured scaffold for tissue engineering applications. Biomed Res 26(4):S42–S48

Taniguchi N, Fujibayashi S, Takemoto M et al (2016) Effect of pore size on bone ingrowth into porous titanium implants fabricated by additive manufacturing: an in vivo experiment. Mater Sci Eng C 59:690–701. https://doi.org/10.1016/j.msec.2015.10.069

Mazur M, Leary M, Sun S, Vcelka M, Shidid D, Brandt M (2016) Deformation and failure behaviour of Ti-6Al-4V lattice structures manufactured by selective laser melting (SLM). Int J Adv Manuf Technol 84(5–8):1391–1411. https://doi.org/10.1007/s00170-015-7655-4

Eldesouky I, Harrysson O, West H, Elhofy H (2017) Electron beam melted scaffolds for orthopedic applications. Addit Manuf 17:169–175. https://doi.org/10.1016/j.addma.2017.08.005

Cheng XY, Li SJ, Murr LE et al (2012) Compression deformation behavior of Ti-6Al-4V alloy with cellular structures fabricated by electron beam melting. J Mech Behav Biomed Mater 16(1):153–162. https://doi.org/10.1016/j.jmbbm.2012.10.005

Arabnejad Khanoki S, Pasini D (2013) Fatigue design of a mechanically biocompatible lattice for a proof-of-concept femoral stem. J Mech Behav Biomed Mater 22:65–83. https://doi.org/10.1016/j.jmbbm.2013.03.002

Eltlhawy B, Fouda N, Eldesouky I (2021) Numerical Evaluation of a Porous Tibial-Knee Implant using Gyroid Structure. J Biomed Phys Eng. https://doi.org/10.31661/jbpe.v0i0.2005-1116

Tawakol AE, Noha Fouda IE (2021) Comparison of functionally graded hip stem implants with various second-generation titanium alloys. J Appl Comput Mech. https://doi.org/10.22055/JACM.2020.32964.2115

Fouda N, Eltlhawy B, El-Midany T (2015) The effect of using PLA-HA coating on uncemented tibia prosthesis to decrease aseptic loosening and stress shielding. Int J Mech Mechatron Eng 15(6):76–83

Harrysson OLA, Cansizoglu O, Marcellin-Little DJ, Cormier DR, West HA (2008) Direct metal fabrication of titanium implants with tailored materials and mechanical properties using electron beam melting technology. Mater Sci Eng C 28(3):366–373. https://doi.org/10.1016/j.msec.2007.04.022

Moiduddin K, Al-Ahmari A, Kindi MA, Nasr ESA, Mohammad A, Ramalingam S (2016) Customized porous implants by additive manufacturing for zygomatic reconstruction. Biocybern Biomed Eng 36(4):719–730. https://doi.org/10.1016/j.bbe.2016.07.005

Lai YS, Chen WC, Huang CH, Cheng CK, Chan KK, Chang TK (2015) The effect of graft strength on knee laxity and graft in-situ forces after posterior cruciate ligament reconstruction. PLoS ONE 10(5):1–11. https://doi.org/10.1371/journal.pone.0127293

Bahraminasab M, Sahari BB, Edwards KL, Farahmand F, Hong TS, Naghibi H (2013) Material tailoring of the femoral component in a total knee replacement to reduce the problem of aseptic loosening. Mater Des 52:441–451. https://doi.org/10.1016/j.matdes.2013.05.066

Asiri S, Fouda N, Hedia H (2016) Functionally graded coating material of cementless knee prosthesis. Br J Appl Sci Technol 15(5):1–12. https://doi.org/10.9734/bjast/2016/25618

Navarro M, Michiardi A, Castaño O, Planell JA (2008) Biomaterials in orthopaedics. J R Soc Interface 5(27):1137–1158. https://doi.org/10.1098/rsif.2008.0151

Chahine G, Atharifar H, Smith P, Kovacevic R (2009) Design optimization of a customized dental implant manufactured via Electron Beam Melting®. 20th Annu Int Solid Free Fabr Symp SFF 2009. Published online. p 631–640

Completo A, Fonseca F, Simões JA (2008) Strain shielding in proximal tibia of stemmed knee prosthesis: experimental study. J Biomech 41(3):560–566. https://doi.org/10.1016/j.jbiomech.2007.10.006

Nambu SN, Lewis G (2004) Influences of the temporal nature of the applied load and the tibial baseplate material on the stress distribution in a three-dimensional model of the human knee joint containing a prosthetic replacement. Biomed Mater Eng 14(2):203–217

Enab TA (2012) A comparative study of the performance of metallic and FGM tibia tray components in total knee replacement joints. Comput Mater Sci 53(1):94–100. https://doi.org/10.1016/j.commatsci.2011.09.032

Mangado N, Quevedo C, Lozano L, Suso S, Cerrolaza M (2015) To what extent the combination of stem length and stem inclination do affect the performance of the tibial component in knee implants? Biomed Eng - Appl Basis Commun 27(2):1–11. https://doi.org/10.4015/S1016237215500180

Chong DYR, Hansen UN, Amis AA (2010) Analysis of bone-prosthesis interface micromotion for cementless tibial prosthesis fixation and the influence of loading conditions. J Biomech 43(6):1074–1080. https://doi.org/10.1016/j.jbiomech.2009.12.006

Mattila RH, Laurila P, Rekola J et al (2009) Bone attachment to glass-fibre-reinforced composite implant with porous surface. Acta Biomater 5(5):1639–1646. https://doi.org/10.1016/j.actbio.2009.01.020

El-Zayat BF, Heyse TJ, Fanciullacci N, Labey L, Fuchs-Winkelmann S, Innocenti B (2016) Fixation techniques and stem dimensions in hinged total knee arthroplasty: a finite element study. Arch Orthop Trauma Surg 136(12):1741–1752. https://doi.org/10.1007/s00402-016-2571-0

Barrack RL, Stanley T, Burt M, Hopkins S (2004) The effect of stem design on end-of-stem pain in revision total knee arthroplasty. J Arthroplasty 19(7 SUPPL):119–124. https://doi.org/10.1016/j.arth.2004.06.009

Eldesouky I, Harrysson O, Marcellin-Little DJ, West H, El-Hofy H (2017) Pre-clinical evaluation of the mechanical properties of a low-stiffness cement-injectable hip stem. J Med Eng Technol 41(8):681–691. https://doi.org/10.1080/03091902.2017.1394391

Buechel FF, Pappas MJ (2015) Principles of human joint replacement. Springer, Cham. https://doi.org/10.1007/978-3-319-15311-7

Wang X, Xu S, Zhou S et al (2016) Topological design and additive manufacturing of porous metals for bone scaffolds and orthopaedic implants: a review. Biomaterials 83:127–141. https://doi.org/10.1016/j.biomaterials.2016.01.012

Ataee A, Li Y, Fraser D, Song G, Wen C (2018) Anisotropic Ti-6Al-4V gyroid scaffolds manufactured by electron beam melting (EBM) for bone implant applications. Mater Des 137:345–354. https://doi.org/10.1016/j.matdes.2017.10.040

Ataee A, Li Y, Brandt M, Wen C (2018) Ultrahigh-strength titanium gyroid scaffolds manufactured by selective laser melting (SLM) for bone implant applications. Acta Mater 158:354–368. https://doi.org/10.1016/j.actamat.2018.08.005

Acknowledgements

The authors acknowledge the support of Egypt-Japan University of Science and Technology (E-JUST) for providing the software used in this research.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Data availability

The datasets generated and analyzed during the current study are not publicly available but may be obtained from the corresponding author at reasonable request.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Eltlhawy, B., Fouda, N., El-Midany, T. et al. Numerical assessment of advanced porous tibia implant designs based on different cellular structures. Prog Addit Manuf 8, 807–817 (2023). https://doi.org/10.1007/s40964-022-00358-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40964-022-00358-8