Abstract

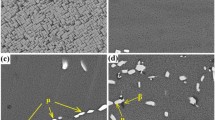

The purpose of this research was to investigate the effect of solidification cooling rate on the microstructural characteristics of IN939 superalloy. Microstructure of castings was investigated using X-ray diffraction, optical microscopy and field emission SEM microscopes, and the most important phases in the microstructure, their morphology and micro-mechanisms of formation of these phases were evaluated. In addition, thermodynamic simulation was carried out using JMatPro software to predict the type and amount of phases in different microstructural regions, the chemical compositions of γ and γ′ phases, as well as the γ/γ′ lattice misfits. The results showed that with increasing the cooling rate, MC carbides became more regular and more polygonal, while with decreasing cooling rates, carbides morphologies changed to Chinese script form. At cooling rates around 0.13 °C/s, the γ′ particles in dendrite cores were formed into coarse and cubic patterns, whereas in interdendritic regions, γ′ particles were observed as very coarse and flower-like structures. At cooling rates around 1.1 °C/s, the morphology of γ′ precipitates in the dendrite cores was mainly spherical, and in the interdendritic areas, γ′ precipitates were a mixture of spherical and cubic particles. It was shown that the major factors controlling the morphology of γ′ particles in different regions of the microstructure are the size of these particles combined with the γ/γ′ lattice misfit. Finally, the results showed that the following equation relates the secondary dendrite arm spacing (SDAS) to the solidification cooling rate (SCR) for IN939 superalloy: SDAS = 43.177 (SCR)−0.305.

Similar content being viewed by others

References

L. Gong, B. Chen, L. Zhang, Y. Ma, K. Liu, Effect of cooling rate on microstructure, microsegregation and mechanical properties of cast Ni-based superalloy K417G. J. Mater. Sci. Technol. 34, 811–820 (2018). https://doi.org/10.1016/j.jmst.2017.03.023

Y. Zhang, B. Huang, J. Li, Microstructural evolution with a wide range of solidification cooling rates in a Ni-based superalloy. Metall. Mater. Trans. A 44, 1641–1644 (2013). https://doi.org/10.1007/s11661-013-1645-7

H.S. Whitesell, L. Li, R.A. Overfelt, Influence of solidification variables on the dendrite arm spacings of Ni-based superalloys. Metall. Mater. Trans. B 31, 546–551 (2000). https://doi.org/10.1007/s11663-000-0162-4

C. Yang, Q. Xu, B. Liu, Primary dendrite spacing selection during directional solidification of multicomponent nickel-based superalloy: multiphase-field study. J. Mater. Sci. 53, 9755–9770 (2018). https://doi.org/10.1007/s10853-018-2236-1

W. Zhang, L. Liu, X. Zhao, T. Huang, Z. Yu, M. Qu, H. Fu, Effect of cooling rates on dendrite spacings of directionally solidified DZ125 alloy under high thermal gradient. Rare Met. 28, 633–640 (2009). https://doi.org/10.1007/s12598-009-0121-4

L. Liu, T.W. Huang, J. Zhang, H.Z. Fu, Microstructure and stress rupture properties of single crystal superalloy CMSX-2 under high thermal gradient directional solidification. Mater. Lett. 61, 227–230 (2007). https://doi.org/10.1016/j.matlet.2006.04.037

M.F. Moreira, L.B. Fantin, C.R.F. Azevedo, Microstructural characterization of Ni-base superalloy as-cast single crystal (CMSX-4). Int. Metalcast. 15, 676–691 (2021). https://doi.org/10.1007/s40962-020-00496-1

F. Wang, D. Ma, A. Bührig-Polaczek, Microsegregation behavior of alloying elements in single-crystal nickel-based superalloys with emphasis on dendritic structure. Mater Charact 127, 311–316 (2017). https://doi.org/10.1016/j.matchar.2017.02.030

X. Shi, S. Duan, W. Yang, H. Guo, J. Guo, Effect of cooling rate on microsegregation during solidification of superalloy INCONEL 718 under slow-cooled conditions. Metall. Mater. Trans. B 49, 1883–1897 (2018). https://doi.org/10.1007/s11663-018-1169-z

V.C.I. Strutt, B.M. Jenkins, J.M. Woolrich, M. Appleton, M.P. Moody, P.A.J. Bagot, Effect of microsegregation and heat treatment on localised γ and γ′ compositions in single crystal Ni-based superalloys. J. Alloys Compd. 949, 169861 (2023). https://doi.org/10.1016/j.jallcom.2023.169861

M. Mostafaei, S.M. Abbasi, Solutioning and solidification process control in Ta-modified CM247 LC superalloy. J. Mater. Process. Technol. 231, 113–124 (2016). https://doi.org/10.1016/j.jmatprotec.2015.12.021

M.F. Moreira, L.B. Fantin, F. Beneduce Neto, C.R.F. Azevedo, Microstructural and mechanical characterization of as-cast nickel-based superalloy (IN-713C). Int. Metalcast. 15, 1129–1148 (2021). https://doi.org/10.1007/s40962-020-00540-0

M.T. La**ton, D.J. Crudden, R.C. Reed, M.P. Moody, P.A.J. Bagot, Characterization of phase chemistry and partitioning in a family of high-strength nickel-based superalloys. Metall. Mater. Trans. A 49, 2302–2310 (2018). https://doi.org/10.1007/s11661-018-4558-7

H. Yu, Z. Wang, B. Zhang, Y. Ning, M.W. Fu, Re-precipitation mechanisms of the γ′ phase with sphere, near-sphere, cubic, octets and finally-dendrite in as-cast Ni-based superalloys. J. Alloys Compd. 876, 160104 (2021). https://doi.org/10.1016/j.jallcom.2021.160104

Y.T. Tang, N. D’Souza, B. Roebuck, P. Karamched, C. Panwisawas, D.M. Collins, Ultra-high temperature deformation in a single crystal superalloy: mesoscale process simulation and micromechanisms. Acta Mater. 203, 116468 (2021). https://doi.org/10.1016/j.actamat.2020.11.010

G. Liu, L. Kong, X. **ao, S. Birosca, Microstructure evolution and phase transformation in a nickel-based superalloy with varying Ti/Al ratios: Part 1—microstructure evolution. Mater. Sci. Eng. A 831, 142228 (2022). https://doi.org/10.1016/j.msea.2021.142228

A.J. Goodfellow, E.I. Galindo-Nava, K.A. Christofidou, N.G. Jones, T. Martin, P.A.J. Bagot, C.D. Boyer, M.C. Hardy, H.J. Stone, Gamma prime precipitate evolution during aging of a model nickel-based superalloy. Metall. Mater. Trans. A 49, 718–728 (2018). https://doi.org/10.1007/s11661-017-4336-y

T.B. Gibbons, R. Stickler, IN939: metallurgy, properties and performances, in Proceedings of the High Temperature Alloys for Gas Turbines, Liege, Belgium. ed. by A. Anu (Springer, Berlin, 1982), pp.369–394. https://doi.org/10.1007/978-94-009-7907-9_15

G.P. Sjöberg, E. Dahl, Design with high temperature capacity cast superalloy IN 939 in large aircraft engine structures. ISABE, 1036-1046 (2005).

M.T. Jovanovic, Z. Miskovic, B. Lukic, Microstructure and stress-rupture life of polycrystal, directionally solidified and single crystal castings of nickel-based IN 939 superalloy. Mater Charact 40, 261–268 (1998). https://doi.org/10.1016/S1044-5803(98)00013-8

Z. Miskovic, M. Jovanovic, M. Gligic, B. Lukic, Microstructural investigation of IN 939 superalloy. Vacuum 43, 709–711 (1992). https://doi.org/10.1016/0042-207X(92)90115-D

K.M. Delargy, G.D.W. Smith, Phase composition and phase stability of a high-chromium nickel-based superalloy, IN939. Metall. Trans. A 14, 1771–1783 (1983). https://doi.org/10.1007/BF02645547

T.B. Gibbons, S. Osgerby, F. Gabrielli, V. Lupine, Factors controlling creep strength of cast Ni–Cr–base alloys. Mater. Sci. Technol. 3, 268–274 (1987). https://doi.org/10.1179/mst.1987.3.4.268

M.R. Jahangiri, S.M.A. Boutorabi, H. Arabi, Study on incipient melting in cast Ni base IN939 superalloy during solution annealing and its effect on hot workability. Mater. Sci. Technol. 28, 1402–1413 (2012). https://doi.org/10.1179/1743284712Y.0000000090

P. Kontis, E. Alabort, D. Barba, D. Collins, A. Wilkinson, R. Reed, On the role of boron on improving ductility in a new polycrystalline superalloy. Acta Mater. 124, 489–500 (2017). https://doi.org/10.1016/j.actamat.2016.11.009

N. El-Bagoury, A. Nofal, Microstructure of an experimental Ni base superalloy under various casting conditions. Mater. Sci. Eng. A 527, 7793–7800 (2010). https://doi.org/10.1016/j.msea.2010.08.050

L. Zheng, G. Zhang, C. **ao, T.L. Lee, B. Han, Z. Li, D. Daisenberger, J. Mi, The interdendritic-melt solidification control (IMSC) and its effects on the porosity and phase change of a Ni-based superalloy. Scr. Mater. 74, 84–87 (2014). https://doi.org/10.1016/j.scriptamat.2013.11.001

X. Li, C. Jia, Z. Jiang, Y. Zhang, S. Lv, Investigation of solidification behavior in a new high alloy Ni-based superalloy. JOM 72, 4139–4147 (2020). https://doi.org/10.1007/s11837-020-04346-7

J.R. Davis, Heat Resistant Materials, ASM Specialty Handbook (ASM International, Russell Township, 1997)

G. Matache, D.M. Stefanescu, C. Puscasu, E. Alexandrescu, Dendritic segregation and arm spacing in directionally solidified CMSX-4 superalloy. Int. J. Cast Met. Res. 29, 303–316 (2016). https://doi.org/10.1080/13640461.2016.1166726

A. Formenti, A. Eliasson, H. Fredriksson, On the dendritic growth and microsegregation in Ni-base superalloys Ιn718, In625 and In939. High Temp. Mater. Proc. 24, 221–238 (2005). https://doi.org/10.1515/HTMP.2005.24.4.221

A.K. Bhambri, T.Z. Kattamis, J.E. Morral, Cast microstructure of Inconel 713C and its dependence on solidification variables. Metall. Trans. B 6, 523–537 (1975). https://doi.org/10.1007/BF02913844

S.L. Semiatin, R.C. Kramb, R.E. Turner, F. Zhang, M.M. Antony, Analysis of the homogenization of a nickel-base superalloy. Scr. Mater. 51, 491–495 (2004). https://doi.org/10.1016/j.scriptamat.2004.05.049

J.H. Boswell, D. Clark, W. Li, M.M. Attallah, Cracking during thermal post-processing of laser powder bed fabricated CM247LC Ni-superalloy. Mater. Des. 174, 107793 (2019). https://doi.org/10.1016/j.matdes.2019.107793

E.C. Caldwell, F.J. Fela, G.E. Fuchs, The segregation of elements in high-refractory-content single-crystal nickel-based superalloys. JOM 56, 44–48 (2004). https://doi.org/10.1007/s11837-004-0200-9

L. Yu, Y. Zhao, S. Yang, W. Sun, S. Guo, X. Sun, Z. Hu, As-cast microstructure and solidification behavior of a high Al- and Nb-containing superalloy. J. Mater. Sci. 45, 3448–3456 (2010). https://doi.org/10.1007/s10853-010-4372-0

G.B. Viswanathan, R. Shi, A. Genc, V.A. Vorontsov, C.M.F. Rae, M.J. Mills, Segregation at stacking faults within the γ′ phase of two Ni-base superalloys following intermediate temperature creep. Scr. Mater. 94, 5–8 (2015). https://doi.org/10.1016/j.scriptamat.2014.06.032

D. Mukherji, J. Rosler, Effect of the γ′ volume fraction on the creep strength of Ni-base superalloys. Int. J. Mater. Res. 94, 478–484 (2003). https://doi.org/10.1515/ijmr-2003-0086

S. Neumeier, F. Pyczak, M. Goken, The temperature dependent lattice misfit of rhenium and ruthenium containing nickel-base superalloys-experiment and modelling. Mater. Des. 198, 109362 (2021). https://doi.org/10.1016/j.matdes.2020.109362

R. Gilles, D. Mukherji, M. Hoelzel, P. Strunz, D.M. Toebbens, B. Barbier, Neutron and X-ray diffraction measurements on micro- and nano-sized precipitates embedded in a Ni-based superalloy and after their extraction from the alloy. Acta Mater. 54, 1307–1316 (2006). https://doi.org/10.1016/j.actamat.2005.11.004

F. Pyczak, B. Devrient, H. Mughrabi, The effects of different alloying elements on the thermal expansion coefficients, lattice constants and misfit of nickel-based superalloys investigated by X-ray diffraction. Superalloys 2004, 827–836 (2004)

N.J. Krutz, Y. Gao, Y. Ren, I. Spinelli, M.J. Mills, In-situ γ–γ′ lattice parameter evolution and tertiary burst phenomena during controlled cooling of commercial PM Nickel-Base superalloys. Metall. Mater. Trans. A 52, 2973–2991 (2021). https://doi.org/10.1007/s11661-021-06292-8

P. Caron, High γ′ solvus new generation nickel-based superalloys for single crystal turbine blade applications. Superalloys 2000, 737–746 (2000)

Standard Guide for Quantitative Analysis by Energy-Dispersive Spectroscopy, ASTM Designation: E 1508-98 (Reapproved 2003) (2003).

X. Llovet, A. Moy, P.T. Pinard, J.H. Fournelle, Electron probe microanalysis: a review of recent developments and applications in materials science and engineering. Prog. Mater. Sci. 120, 100818 (2021). https://doi.org/10.1016/j.pmatsci.2021.100818

C.M. Katsari, S. Katnagallu, S. Yue, Microstructural characterization of three different size of gamma prime precipitates in Rene 65. Mater Charact 169, 110542 (2020). https://doi.org/10.1016/j.matchar.2020.110542

T. Link, A. Epishin, U. Brückner, P. Portella, Increase of misfit during creep of superalloys and its correlation with deformation. Acta Mater. 48, 1981–1994 (2000). https://doi.org/10.1016/S1359-6454(99)00456-5

J. Coakley, E.A. Lass, D. Ma, M. Frost, H.J. Stone, D.N. Seidman, D.C. Dunand, Lattice parameter misfit evolution during creep of a cobalt-based superalloy single crystal with cuboidal and rafted gamma-prime microstructures. Acta Mater. 136, 118–125 (2017). https://doi.org/10.1016/j.actamat.2017.06.025

M.R. Jahangiri, H. Arabi, S.M.A. Boutorabi, Comparison of microstructural stability of IN939 superalloy with two different manufacturing routes during long-time aging. Trans. Nonferr. Met. Soc. 24, 1717–1729 (2014). https://doi.org/10.1016/S1003-6326(14)63245-3

M.R. Jahangiri, M. Abedini, Effect of long time service exposure on microstructure and mechanical properties of gas turbine vanes made of IN939 alloy. Mater. Des. 64, 588–600 (2014). https://doi.org/10.1016/j.matdes.2014.08.035

S. Huang, K. An, Y. Gao, A. Suzuki, Determination of γ/γ′ lattice misfit in Ni-based single-crystal superalloys at high temperatures by neutron diffraction. Metall. Mater. Trans. A 49, 740–751 (2018). https://doi.org/10.1007/s11661-017-4455-5

M. Durand, J. Cormier, F. Paumier, S. Katnagallu, A. Saksena, P. Kontis, F. Pettinari-Sturmel, M. Hantcherli, J. Franchet, C. Dumont, N. Bozzolo, Chemical redistribution and change in crystal lattice parameters during stress relaxation annealing of the AD730TM superalloy. Acta Mater. 237, 118141 (2022). https://doi.org/10.1016/j.actamat.2022.118141

S.T. Wlodek, M. Kelly, D.A. Alden, The structure of Rene 88 DT, in Superalloys. ed. by R.D. Kissinger, D.J. Deye, D.L. Anton, A.D. Cetel, M.V. Nathal, T.M. Pollock, D.A. Woodford (The Minerals, Metals and Materials Society, Warrendale, 1996), pp.129–136

C. Schulze, M. Feller-Kniepmeier, Transmisson electron microscopy of phase composition and lattice misfit in the Re-containing nickel-base superalloy CMSX-10. Mater. Sci. Eng. A 281, 204–212 (2000). https://doi.org/10.1016/S0921-5093(99)00713-3

J. Tiley, G.B. Viswanathan, J.Y. Hwang, A. Shiveley, R. Banerjee, Evaluation of gamma prime volume fractions and lattice misfits in a nickel base superalloy using the external standard X-ray diffraction method. Mater. Sci. Eng. A 528, 32–36 (2010). https://doi.org/10.1016/j.msea.2010.07.036

C. Schulze, M. Feller-Kniepmeier, Phase compositions and lattice misfit in CMSX-11B partition coefficients in single crystal nickel base superalloys. Scr. Mater. 44, 731–736 (2001). https://doi.org/10.1016/S1359-6462(00)00670-9

R. Dupke, W. Reimers, X-ray diffraction investigations on individual grains in the polycrystalline Ni-base superalloy IN939 during cyclic loading I: X-ray rocking curve broadening. Int. J. Mater. Res. 86, 371–377 (1995). https://doi.org/10.1515/ijmr-1995-860515

R.C. Reed, The Superalloys: Fundamentals and Applications (Cambridge University Press, Cambridge, 2008)

D. Migas, S. Roskosz, G. Moskal, Quantitative and qualitative assessment of as-cast microstructure and microporosity of γ–γ′ co-based superalloys. Int. Metalcast. 17, 2147–2156 (2023). https://doi.org/10.1007/s40962-022-00918-2

J. Zhou, S. Cui, Effect of mismatch degree on mechanical properties of Ni-based single crystal alloy under force-temperature coupling. Mater. Res. Exp. 6, 076503 (2019). https://doi.org/10.1088/2053-1591/ab11fc

H. Mughrabi, The importance of sign and magnitude of γ/γ′ lattice misfit in superalloys-with special reference to the new γ′-hardened cobalt-base superalloys. Acta Mater. 81, 21–29 (2014). https://doi.org/10.1016/j.actamat.2014.08.005

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that there is no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Jahangiri, M. Influence of Cooling Rate During Solidification on Microstructural Features and γ′ Size and Morphology in Cast IN939 Superalloy. Inter Metalcast (2023). https://doi.org/10.1007/s40962-023-01183-7

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s40962-023-01183-7