Abstract

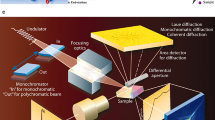

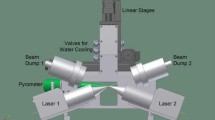

Synchrotron radiation-based micro-Laue technique has showcased great application potentials in materials science study for its unprecedented crystal orientation and lattice strain/stress resolution. Here we report the updated progress in the development of the micro-Laue technique on the X-ray test beamline at Shanghai Synchrotron Radiation Facility. So far, 40 µm (h) × 50 µm (v) X-ray beam spot is routinely obtained, with the convergent angle of 0.2 mrad (h) × 0.12 mrad (v). Area scans are conducted on a GH3535 Ni-based superalloy base metal and weld joint with the same chemical composition. By analyzing the tremendous amount of Laue diffraction patterns using in-house developed software packages, the crystal orientation, elastic strain, and defect distributions are mapped and investigated. Such a successful proof-of-principle study offers first-hand experience on the further optimization of the design and construction of the scanning micro-Laue facility on the superbend beamline with improved spatial resolution and multiple functions for simultaneous chemical fluorescence map** and in-situ microstructural evolution studies. The micro-Laue diffraction beamline at Shanghai Synchrotron Radiation Facility will provide a versatile and powerful tool for the orientation and strain/stress map** combined with phase identification with micron-sized spatial resolution.

摘要

同步辐射微束劳厄技术以其超高的晶体取向和晶格应力/应变分辨率而在材料科学研究中显示出重要的应用潜力. 本文报道了我国上海光源在微束劳厄技术方面的最新进展. 目前已获得40× 50 μm2的X射线束斑尺寸, 在我国(不含台湾省)首次实现了白光微束劳厄二维扫描实验, 利用我国首套完全独立研发、具有自主知识产权的数据分析软件系统, 成功定量研究了镍基高温合金GH3535母材与焊缝区域晶体取向、应变和显微缺陷等微观组织结构特征, 并提出了后续线站优化设计方案. 在未来工作中, 将进一步提高空间分辨率, 加入X射线荧光分析与原位测试装置. 上海光源微束劳厄射线站将为材料科学研究提供更高的分辨率和更多的测试表征功能与能力.

Similar content being viewed by others

References

Friedrich W, Knip** P, Laue M. Interferenzerscheinungen bei Röntgenstrahlen. Ann Phys, 1913, 346: 971–988

Ice GE, Budai JD, Pang JWL. The race to X-ray microbeam and nanobeam science. Science, 2011, 334: 1234–1239

Larson BC, Yang W, Ice GE, et al. Three-dimensional X-ray structural microscopy with submicrometre resolution. Nature, 2002, 415: 887–890

Li R, **e Q, Wang YD, et al. Unraveling submicron-scale mechanical heterogeneity by three-dimensional X-ray microdiffraction. Proc Natl Acad Sci USA, 2018, 115: 483–488

Chen K, Huang R, Li Y, et al. Rafting-enabled recovery avoids recrystallization in 3D-printing-repaired single-crystal superalloys. Adv Mater, 2020, 32: 1907164

Ma EY, Cui YT, Ueda K, et al. Mobile metallic domain walls in an all-in-all-out magnetic insulator. Science, 2015, 350: 538–541

Cao J, Gu Y, Fan W, et al. Extended map** and exploration of the vanadium dioxide stress-temperature phase diagram. Nano Lett, 2010, 10: 2667–2673

Tselev A, Budai JD, Strelcov E, et al. Electromechanical actuation and current-induced metastable states in suspended single-crystalline VO2 nanoplatelets. Nano Lett, 2011, 11: 3065–3073

Budai JD, Tselev A, Tischler JZ, et al. In situ X-ray microdiffraction studies inside individual VO2 microcrystals. Acta Mater, 2013, 61: 2751–2762

Chen K, Kunz M, Tamura N, et al. Residual stress preserved in quartz from the San Andreas Fault Observatory at Depth. Geology, 2015, 43: 219–222

Marcus MA, Amini S, Stifler CA, et al. Parrotfish teeth: Stiff bio-minerals whose microstructure makes them tough and abrasion-resistant to bite stony corals. ACS Nano, 2017, 11: 11856–11865

Chen K, Tamura N, Tang W, et al. High precision thermal stress study on flip chips by synchrotron polychromatic X-ray microdiffraction. J Appl Phys, 2010, 107: 063502

Lupinacci A, Chen K, Li Y, et al. Characterization of ion beam irradiated 304 stainless steel utilizing nanoindentation and Laue microdiffraction. J Nucl Mater, 2015, 458: 70–76

Zhou G, Pantleon W, Xu R, et al. Quantification of local dislocation density using 3D synchrotron monochromatic X-ray microdiffraction. Mater Res Lett, 2021, 9: 182–188

Ice GE, Larson BC. 3D X-ray crystal microscope. Adv Eng Mater, 2000, 2: 643–646

Kunz M, Tamura N, Chen K, et al. A dedicated superbend X-ray microdiffraction beamline for materials, geo-, and environmental sciences at the advanced light source. Rev Sci Instrum, 2009, 80: 035108

Chen X, Dejoie C, Jiang T, et al. Quantitative microstructural imaging by scanning Laue X-ray micro- and nanodiffraction. MRS Bull, 2016, 41: 445–453

Hocine S, Van Swygenhoven H, Van Petegem S, et al. Operando X-ray diffraction during laser 3D printing. Mater Today, 2020, 34: 30–40

Hofmann F, Song X, Dolbnya I, et al. Probing intra-granular deformation by micro-beam Laue diffraction. Procedia Eng, 2009, 1: 193–196

Hamilton JG, Reid JW, Feng R, et al. Evaluating synchrotron-based scanning Laue microdiffraction for mineralogy map** in heterogeneous samples. ACS Earth Space Chem, 2018, 2: 1161–1167

Ulrich O, Biquard X, Bleuet P, et al. A new white beam X-ray microdiffraction setup on the BM32 beamline at the European Synchrotron Radiation Facility. Rev Sci Instrum, 2011, 82: 033908

Jiang MH, Yang X, Xu HJ, et al. Shanghai Synchrotron Radiation Facility. Chin Sci Bull, 2009, 54: 4171–4181

Li Y, Chen K, Dang X, et al. XtalCAMP: A comprehensive program for the analysis and visualization of scanning Laue X-ray micro-/nanodiffraction data. J Appl Crystlogr, 2020, 53: 1392–1403

Brückner S. Estimation of the background in powder diffraction patterns through a robust smoothing procedure. J Appl Crystlogr, 2000, 33: 977–979

Chung JS, Ice GE. Automated indexing for texture and strain measurement with broad-bandpass X-ray microbeams. J Appl Phys, 1999, 86: 5249–5255

Pavese A. About the relations between finite strain in non-cubic crystals and the related phenomenological P-V equation of state. Phys Chem Miner, 2005, 32: 269–276

Kou J, Chen K, Tamura N. A peak position comparison method for high-speed quantitative Laue microdiffraction data processing. Scripta Mater, 2018, 143: 49–53

Li Y, Chen K, Tamura N. Mechanism of heat affected zone cracking in Ni-based superalloy DZ125L fabricated by laser 3D printing technique. Mater Des, 2018, 150: 171–181

Busing WR, Levy HA. Angle calculations for 3- and 4-circle X-ray and neutron diffractometers. Acta Cryst, 1967, 22: 457–464

Jiang L, Ye XX, Wang DJ, et al. Synchrotron radiation-based materials characterization techniques shed light on molten salt reactor alloys. Nucl Sci Tech, 2020, 31: 6

Wang W, Li C, Jiang L, et al. Evolution of carbide precipitates in Hastelloy N joints during welding and post weld heat treatment. Mater Charact, 2018, 135: 311–316

Zhou G, Zhu W, Shen H, et al. Real-time microstructure imaging by Laue microdiffraction: A sample application in laser 3D printed Ni-based superalloys. Sci Rep, 2016, 6: 28144

Li Y, Qian D, Xue J, et al. A synchrotron study of defect and strain inhomogeneity in laser-assisted three-dimensionally-printed Ni-based superalloy. Appl Phys Lett, 2015, 107: 181902

Chen K, Kunz M, Li Y, et al. Compressional residual stress in Bastogne boudins revealed by synchrotron X-ray microdiffraction. Geophys Res Lett, 2016, 43: 6178–6185

Gäumann M, Bezençon C, Canalis P, et al. Single-crystal laser deposition of superalloys: Processing-microstructure maps. Acta Mater, 2001, 49: 1051–1062

Pham MS, Dovgyy B, Hooper PA, et al. The role of side-branching in microstructure development in laser powder-bed fusion. Nat Commun, 2020, 11: 749

Acknowledgements

This work was supported by the National Key Research and Development Program of China (2016YFB0700404), and the National Natural Science Foundation of China (91860109, U2032205, 51671154, and 51927801). Chen K appreciates the support from the International Joint Laboratory for Micro/Nano Manufacturing and Measurement Technologies and the Collaborative Innovation Center of High-End Manufacturing Equipment.

Author information

Authors and Affiliations

Contributions

Tai R and Huang X proposed and supervised this work. Liu M, Dong X and Li ZL designed and built the micro-Laue beamline on BL09B. Jiang L, Yan S, Li L and Li ZJ prepared the superalloy specimens and conducted the 2D scans. Ren C, Kou J and Chen K developed the software packages, analyzed the data and interpreted the results. Chen K, Ren C, Li ZJ, Li ZL and Huang X wrote the paper. All authors contributed to the discussion.

Corresponding authors

Additional information

Conflict of interest

The authors declare that they have no conflict of interest.

Chenyu Ren is currently a PhD student at the Center for Advancing Materials Performance from the Nanoscale (CAMP-Nano), **’an Jiaotong University. Her research interests focus on the microstructure study of laser-processed Ni-based superalloys.

Li Jiang obtained his Master degree from Northwestern Polytechnical University in 2012 and PhD degree from the University of Chinese Academy of Sciences in 2017. He is now an associate professor at Shanghai Institute of Applied Physics, Chinese Academy of Sciences. His research interests focus on the design of superalloys for nuclear applications and the alloy corrosion behavior by fission products using advanced material characterization approaches such as synchrotron radiation-based techniques.

Jiawei Kou obtained his Bachelor degree in 2018 and then continued his graduate study at the CAMP-Nano, **’an Jiaotong University. He is dedicated to the development of high-speed in-depth Laue diffraction data mining algorithms and software packages. He applies these new approaches to the study of the microstructures of advanced alloys.

Kai Chen obtained his Bachelor and PhD degrees from Peking University and the University of California Los Angeles in 2005 and 2009, respectively. After two postdoctoral stints at the University of California Berkeley and Lawrence Berkeley National Laboratory, he has been a professor at **’an Jiaotong University since 2011. He is interested in pushing the software and hardware developments for synchrotron micro-Laue diffraction and applying this advanced characterization method to the study of advanced engineering materials.

Zhongliang Li obtained his PhD degree from the National Synchrotron Radiation Laboratory, University of Science and Technology of China in 2011. He is currently an associate professor in the optical group of Shanghai Synchrotron Radiation Facility. His research interests focus on the X-ray measurement methodology of beam-line instruments and optical elements, synchrotron radiation-based science and technology, and the microstructural evolution of alloys under corrosive conditions of fission products.

Zhijun Li obtained his PhD degree from Harbin Institute of Technology in 2007. He holds the professorship at Shanghai Institute of Applied Physics, Chinese Academy of Sciences. His research interests focus on the design and characterization of alloys for nuclear energy applications using advanced synchrotron radiation-based techniques.

Renzhong Tai obtained his PhD degree from the Graduate University for Advanced Studies, Japan in 1999. After postdoctoral research on coherent X-ray applications at Japan Atomic Energy Research Institute, he holds the professorship at Shanghai Institute of Applied Physics, Chinese Academy of Sciences. He is currently the executive deputy director of Shanghai Synchrotron Radiation Facility. His research interests focus on synchrotron radiation science and techniques, X-ray microscopy, X-ray detector technology, X-ray interference lithography, photon correlation spectroscopy, and beamline development.

Rights and permissions

About this article

Cite this article

Ren, C., Jiang, L., Kou, J. et al. Development of micro-Laue technique at Shanghai Synchrotron Radiation Facility for materials sciences. Sci. China Mater. 64, 2348–2358 (2021). https://doi.org/10.1007/s40843-021-1648-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40843-021-1648-3