Abstract

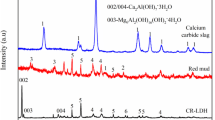

Multi-channel exploitation and utilization of lithium-bearing resources may be the future sustainable development trend of the lithium industry. Lithium-rich bauxite flotation tailings are a potential lithium resource. This study proposed a green and effective lithium extraction process employing sodium bicarbonate solutions to leach lithium-rich bauxite flotation tailings. 91.75% of lithium could be leached over a time of 60 min using a 300 g/L sodium bicarbonate solution at 280 °C with a liquid–solid ratio of 10. Notably, potassium’s leaching efficiency was lower than lithium’s, whereas other elements, such as aluminum and silicon, were difficult to leach. Furthermore, the experimental results verify the results of the thermodynamic analysis. The leaching mechanism of lithium and potassium in sodium bicarbonate solution is that sodium ions in the sodium bicarbonate solution substituted Li+ of cookeite and K+ of illite, respectively. Thus, this research could provide a new way to efficiently and economically utilize clay-rich lithium resources.

Graphical Abstract

The mechanism of leaching lithium and potassium from tailings was considered to involve the ion-substitution reaction. Sodium ion in the sodium bicarbonate solution substituted Li+ of cookeite and K+ of illite, respectively.

Similar content being viewed by others

References

Bradley DC, Stillings LL, Jaskula BW et al (2017) Critical mineral resources of the United States-economic and environmental geology and prospects for future supply. US Geological Survey, Reston, pp K1–K21

Friedman-Rudovsky J (2011) Dreams of a lithium empire. Science 334:896–897

Choubey PK, Kim MS, Srivastava RR et al (2016) Advance review on the exploitation of the prominent energy-storage element: lithium—Part I: from mineral and brine resources. Miner Eng 89:119–137

Kalantzakos S (2020) The race for critical minerals in an era of geopolitical realignments. Int Spec 55(3):1–16

Qiao D, Wang G, Gao T et al (2021) Potential impact of the end-of-life batteries recycling of electric vehicles on lithium demand in China: 2010–2050. Sci Total Environ 764:142835

Kesler SE, Gruber PW, Medina PA et al (2012) Global lithium resources: relative importance of pegmatite, brine and other deposits. Ore Geol Rev 48:55–69

Meshram P, Pandey BD, Mankhand TR (2014) Extraction of lithium from primary and secondary sources by pre-treatment, leaching and separation: a comprehensive review. Hydrometallurgy 150:192–208

Peiró LT, Méndez GV, Ayres RU (2013) Lithium: sources, production, uses, and recovery outlook. JOM 65:986–996

Swain B (2017) Recovery and recycling of lithium: a review. Sep Purif Technol 172:388–403

Li H, Eksteen J, Kuang G (2019) Recovery of lithium from mineral resources: state-of-the-art and perspectives-a review. Hydrometallurgy 189:105129

Chen Y, Zhang T, Lv G et al (2022) Extraction and utilization of valuable elements from bauxite and bauxite residue: a review. B Environ Contanm Tox 109(1):228–237

Zhang YS, Zhang J (2019) Study on the occurrence state of lithium in low-grade diasporic bauxite from central Guizhou province, China. JOM 71:4594–4599

Fan HP, Lin Y, Huang ZL (2021) The associated lithium resource in bauxite (bauxite-bearing rock). Acta Mineralogica Sinica 41:32–390 (in Chinese)

Yingzhong T, **n G, Peng R (2020) Research on comprehensive utilization of bauxite resources. TRAVAUX 49, Proc 38th Int ICSOBA Conf, 16–18 Nov:79–86.

Wang X, Zhang R, Yang S et al (2020) Studying on the process mineralogy and existing state of lithium in bauxite ore from Mianchi district, Henan Province. Multipurp Util Miner Resour 6:163–170

Amer AM (2008) The hydrometallurgical extraction of lithium from Egyptian montmorillonite-type clay. JOM 60:55–57

Zhao H, Wang Y, Cheng H (2023) Recent advances in lithium extraction from lithium-bearing clay minerals. Hydrometallurgy 217:106025

Gu HN, Guo TF, Wen HJ et al (2020) Leaching efficiency of sulfuric acid on selective lithium leachability from bauxitic claystone. Miner Eng 145:106076

Zhang YS, Zhang J, Wu L et al (2021) Extraction of lithium and aluminium from bauxite mine tailings by mixed acid treatment without roasting. J Hazard Mater 404:124044

Han D, Peng Z, Song E et al (2022) Leaching behavior of lithium-rich beneficiation tailings in caustic solution. JOM 74:1027–1034

Ya C, Qian-qiu T, Bai-zhen C, **-chang S, Ting L (2011) Preparation of lithium carbonate from spodumene by a sodium carbonate autoclave process. Hydrometallurgy 109:43–46

Li XB, Yang LQ, Zhou QS et al (2020) A split-combination method for estimating the thermodynamic properties (Gfo and Hfo) of multicomponent minerals. Appl Clay Sci 185:1–10

Yang X, He A, Yuan B (1983) Handbook of thermodynamic data calculation for high temperature aqueous solution. Metallurgical Industry Press, Bei**g

Zheng F, Hao LS, Li JY et al (2019) Corrosion characteristics of aluminum in sodium bicarbonate aqueous solution at 50°C. Int J Electrochem Sci 14:7303–7316

Sharygin AV, Wood RH (1998) Densities of aqueous solutions of sodium carbonate and sodium bicarbonate at temperatures from (298 to 623) K and pressures to 28MPa. J Chem Thermodyn 30:1555–1570

Gasteiger HA, FrederickWJ SRC (1992) Solubility of aluminosilicates in alkaline solutions and a thermodynamic equilibrium model. Ind Eng Chem Res 31:1183–1190

Bailey SW, Lister JS (1989) Structures, compositions, and X-ray diffraction identification of dioctahedral chlorites. Clays Clay Miner 37:193–202

Shao HZ, Chang J, Lu Z et al (2019) Probing anisotropic surface properties of illite by atomic force microscopy. Langmuir 35:6532–6539

Ishida N, Sakamoto M, Miyahara M, Higashitani K (2000) Attraction between hydrophobic surfaces with and without gas phase. Langmuir 16:5681–5687

Luo GC, Liao LB, Wang SP (2002) Activation potasstion method and mechanism of illite. J Liaoning Tec Univ (Nat Sci) 21:160–163

Acknowledgements

The authors thank AiMi Academic Services (www.aimieditor.com) for English language editing and review services.

Funding

This work was supported by the National Key Research and Development Program (No. 2022YFC3900902).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Additional information

The contributing editor for this article was Atsushi Shibayama.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Han, Dz., Shen, Lt., Song, Ew. et al. Leaching Behaviors of Lithium-Rich Bauxite Flotation Tailings in Sodium Bicarbonate Solution. J. Sustain. Metall. 10, 241–249 (2024). https://doi.org/10.1007/s40831-024-00787-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40831-024-00787-5