Abstract

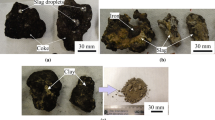

Five samples of scales collected from various locations in a high-temperature Bayer process plant were characterized via X-ray diffraction, Fourier transform infrared spectroscopy, scanning electron microscopy, X-ray spectroscopy, and X-ray photoelectron spectroscopy analyses. Then, a method for preventing the formation of scales was proposed. Results showed that the minerals in scales, such as hematite, hydroxyapatite, and sodium aluminate silicate hydrate, are arranged in a layered structure. The difference in arrangement resulted in variations in physical properties, including thickness and hardness. Hematite was facilitated to form thicker layers than magnetite during the scale formation process. Therefore, converting hematite into magnetite by adding a reductant (e.g., glycerol) during Bayer digestion is a feasible strategy for preventing the formation of scales.

Graphical Abstract

Similar content being viewed by others

References

Power G, Gräfe M, Klauber C (2011) Bauxite residue issues: I. Current management, disposal and storage practices. Hydrometallurgy 108:33–45

Alkan G, Schier C, Gronen L, Stopic S, Friedrich B (2017) A mineralogical assessment on residues after acidic leaching of bauxite residue (red mud) for titanium recovery. Metals 7:458

Kawashima N, Shi LN, Xu N, Li J, Gerson A (2016) Characterisation of single-stream Bayer plant heat exchanger scale. Hydrometallurgy 159:75–86

Liu GH, Liu P, Zhou QS, Qi TG, Wu HW, Peng ZH, Li XB (2016) Relationship between composition of scale in pipe and surface property in preheating diasporic slurry process. Chin J Nonferrous Met (in Chinese) 206:1143–1150

Cao WZ, Li HN, Tian WW, Zhong H (2014) Pipeline scaling prevention and removal methods in Bayer digestion process. In: Light metals 2014, pp 67–72

Akpinar İH, Uysal O, Şahin Y, Güldogan Y, Demir GK, Baygül M (2012) Acid cleaning of titanium-based scales formed on preheaters in the Bayer process. In: Light metals 2012, pp 225–228

Ruan S, Shi LN, Li J, Gerson AR (2017) Desilication of hematite, goethite and iron powder seeded low alumina to caustic liquors. Hydrometallurgy 169:297–305

Donald PS, Alan SR, Howard IH, Frank K (2004) Method of preventing or reducing aluminosolicate scale in a Bayer process. US patent No. 0011744.

Everett CP, Timothy L, Sawant A (2016) Reducing aluminosilicate scale in the Bayer process. US patent No. 9487408

Alan SR, Peter WA, Robert C, Frank K (1998) Use of hydroxamated polymers to alter Bayer process scale. US patent No. 5733459.

Chen WK, Peng GC (1997) Intensity digestion technology for diasporic bauxite. Metallurgical Industry Press, New York

Armstrong JA, Dann SE (2000) Investigation of zeolite scales formed in the Bayer process. Micropor Mesopor Mater 41:89–97

Gerson AR, Zheng K (1997) Bayer process plant scale: transformation of sodalite to cancrinite. Cryst Growth 171:209–218

Ho GE, Robertson WA, Roach GID, Antonovsky A (1992) Morphological study of Bayer process desilication product and its application to laboratory and plant digests. Ind Eng Chem Res 31:982–986

Ma HZ, Huang F, Liu SR, Xu B, Liu HL (2014) Classification and morphological structure of scale in the process of alumina production high pressure digestion. Adv Mater Res 960–961:274–280

Wang YL, Li XB, Zhou QS, Wang B, Zhou KC (2020) Observation of sodium titanate and sodium aluminate silicate hydrate layers on diaspore particles in high-temperature Bayer digestion. Hydrometallurgy 193:105255

Peter S (2017) Reactions of lime under high temperature Bayer digestion conditions. Hydrometallurgy 170:16–23

Liu JX, Guo XY, Jiang XJ (2016) Study on the phase equilibrium of quaternary saline system NaOH-Na2SnO3-Na2PbO2-H2O. Nonferrous Met Sci Eng 007(001):1–4

Chester H (2003) A study of scale formed in the bayer process. Doctoral dissertation, Loughborough University

Ballirano P, Maras A (2004) The crystal structure of a “disordered” cancrinite. Mineral 16:135–141

Sudip M, Panchanathan M, Subramaniyan B, Madhappan SM, Van N, Hye K (2017) Hydroxyapatite coated iron oxide nanoparticles: a promising nanomaterial for magnetic hyperthermia cancer treatment. Nanomaterials 7:426

Li XB, Liu N, Qi TG, Wang YL, Zhou QS, Peng ZH, Liu GH (2015) Conversion of ferric oxide to magnetite by hydrothermal reduction in Bayer digestion process. Trans Nonferr Metal Soc 25:3467–3474

Liu N (2016) Study on reduction and magnetic separation of iron minerals in alumina production. Doctoral dissertation, Central South University.

Gupta RP, Sen SK (1974) Calculation of multiplet structure of core p-vacancy levels. Phys Rev B 10:71–77

Kovalev AI, Wainstein DL, Rashkovskiy AY, Osherov A, Golan Y (2010) Size shift of XPS lines observed from PbS nanocrystals. Surf Interface Anal 42:850–854

Boda SK, Anupama AV, Basu B, Sahoo B (2015) Structural and magnetic phase transformations of hydroxyapatite-magnetite composites under inert and ambient sintering atmospheres. J Phys Chem C 119:6539–6555

Raikar NG (1996) Hydroxyapatite characterized by XPS. Surf Sci Spectra 4:9–13

Li XB, Zhou ZY, Wang YL, Zhou QS, Qi TG, Liu GH, Peng ZH (2020) Enrichment and separation of iron minerals in gibbsitic bauxite residue based on reductive Bayer digestion. Trans Nonferr Metal Soc 30:1980–1990

Acknowledgements

This work was financially supported by the Natural Science Foundation of China (Nos. 51604309 and 51804142).

Author information

Authors and Affiliations

Corresponding authors

Additional information

The contributing editor for this article was Hongmin Zhu.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Cheng, Lw., Wang, Yl., Zhou, Qs. et al. Scale Formation During the Bayer Process and a Potential Prevention Strategy. J. Sustain. Metall. 7, 1293–1303 (2021). https://doi.org/10.1007/s40831-021-00417-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40831-021-00417-4