Highlights

-

An ultralight and flexible supercapacitor is developed by an effective 3D fabrication method that uses MXene to fabricate waste denim felt through needling and carbonization.

-

The electrodes have a maximum specific capacitance of 1748.5 mF cm−2 and demonstrate remarkable cycling stability with more than 94% after 15,000 galvanostatic charge/discharge cycles

-

The loaded more MXene onto Z-directional fiber bundles results in enhanced specific capacitance, energy density and power density of supercapacitors.

Abstract

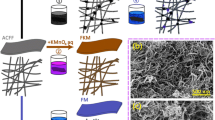

MXene, a transition metal carbide/nitride, has been prominent as an ideal electrochemical active material for supercapacitors. However, the low MXene load limits its practical applications. As environmental concerns and sustainable development become more widely recognized, it is necessary to explore a greener and cleaner technology to recycle textile by-products such as cotton. The present study proposes an effective 3D fabrication method that uses MXene to fabricate waste denim felt into ultralight and flexible supercapacitors through needling and carbonization. The 3D structure provided more sites for loading MXene onto Z-directional fiber bundles, resulting in more efficient ion exchange between the electrolyte and electrodes. Furthermore, the carbonization process removed the specific adverse groups in MXenes, further improving the specific capacitance, energy density, power density and electrical conductivity of supercapacitors. The electrodes achieve a maximum specific capacitance of 1748.5 mF cm−2 and demonstrate remarkable cycling stability maintaining more than 94% after 15,000 galvanostatic charge/discharge cycles. Besides, the obtained supercapacitors present a maximum specific capacitance of 577.5 mF cm−2, energy density of 80.2 μWh cm−2 and power density of 3 mW cm−2, respectively. The resulting supercapacitors can be used to develop smart wearable power devices such as smartwatches, laying the foundation for a novel strategy of utilizing waste cotton in a high-quality manner.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Two-dimensional (2D) materials, including disulfides (MoS2, ZnS), graphene and transition metal carbides/nitrides (MXene), possess stratified structures that have promising potential for energy storage [1,2,26]:

where i (A cm−2) represents the current density of GCD tests, U (V) represents the voltage window, A (cm2) represents the electrode working area and ∆t (s) represents the discharge time.

As for CMDF symmetric supercapacitors, the specific capacitance (Csc, mF cm−2), power density (Psc, W cm−2) and energy density (Esc, Wh cm−2) are computed by the following formula [27]:

3 Results and Discussion

3.1 Chemical Analysis and Structural Characteristics of MXene and MDF

Figure 2 displays the characterization findings on MXene, DF and MDF. The products obtained display supernatant liquid form, suggesting their high stability for subsequent impregnation procedures (Fig. 2a). The XRD peak detected at 7.68° could be ascribed to the typical (002) plane of MXene (Fig. 2b), inferring the successful synthesis of MXene. The TEM image reveals the typical two-dimensional layered structure of the MXene sheet (Fig. 2c), similar to graphene and molybdenum disulfides [28]. Typically, MXene can be synthesized by wet etching of more than 30 different MAX phase precursors, where M is a transition metal element, A is a main group element and X is carbon or nitrogen. MXene obtained in this work displays a nanostructure formed by strip** the Al layer in the MAX phase and attaching –F, –OH and -O to the Ti surface [29]. Spectral analysis reveals the typical peaks for F, Ti, C and O, which concur with the reported chemical components of MXene (Fig. 2d–h). A peak corresponding to a Ti–C bond (282 eV) could be attributed to the core [TiC6] octahedral building block of MXene [30]. Three independent peaks in the O 1 s spectrum of MXene correspond to the Ti–O bond, C–Ti–Ox bond and C–Ti–(OH)x bond. Several symmetric peaks of the Ti 2p spectrum point to the existence of a Ti–C peak around 455.6 eV, which agrees with the XPS measurements. According to the O 1s spectrum, the peaks around 459 eV (Ti 2p3/2) and 462.5 eV (Ti 2p1/2) are most likely caused by O surface groups with partial surface oxidation (Fig. 2e). The presence of two narrow peaks for F 1s spectrum (Fig. 2h) also consistent with the reported works [31]. Therefore, the results above indicate the successful synthesis of MXene.

It has been determined that the MXene has been successfully introduced into MDF based on the presence of a typical (002) diffraction peak located around 7.68°, whereas the peak is not present in DF (Fig. 2i). Figure 2j shows the cross-sectional structure and schematic diagram (the insert image) of DF, revealing the presence of Z-direction channels in the thickness direction of DF. Additionally, Fig. 2k highlights the needle hole present on the surface of DF. The Z-directional fiber bundles along the thickness direction of the DF would allow MXene to penetrate and fill up DF voids, thereby ensuring complete contact between electrolytes and electrodes. There are obvious attachments of MXene on MDF shown in Fig. 2l and its local enlarged image (the insert image), indicating that MXene is effectively loaded after impregnation.

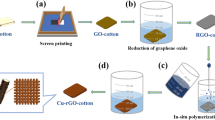

3.2 Carbonization Mechanism of MXene and Architectural Feature of CMDF

The diameter of the fibers in MDF and CMDF that adhere to one another is wider than those of DF and CDF. This is likely due to the effectiveness of the MXene loading during the impregnation process (Fig. 3). There was a negligible effect of carbonization on the needled felt pore structure (Fig. S6). Furthermore, the Ti 2s spectrum of MDF is similar to that of MXene while no peak was detected for DF and CDF (Fig. 2d). It is observed that the CMDF presents two typical peaks at 459 eV (Ti–O) and 465 eV (Ti-C), suggesting Ti element was transformed into TiO2 and further converted into TiC during the high carbonization temperature. No signal of the F 1s spectrum was detected for CMDF, implying the removal of -F groups in MXene during the carbonization process. Figure 3d1–d4 demonstrates the water droplets drop vertically on the surface of samples for 10 s. It was found that the coating of MXene had improved the hydrophilicity of the denim needled felt where the contact angle was reduced from 115° to 80°. At elevated temperatures, the hydrophilic –OH group of cellulose and MXene disappears, yet the carbonized denim fiber attains a fine texture that enhances water transfer [32]. This has led to the reduction in CMDF contact angle due to competitive effects between the two. The consequent increase in hydrophilicity is advantageous for electrolyte penetration, thereby elevating the electrochemical properties of CMDF. Figures S7 and S8 show the EDX map** and electrochemical test of CMDF under various carbonization temperatures (800, 1000 and 1200 °C).

3.3 Performance of CMDF Electrode

In order to ascertain the most effective MXene loading concentration, various MXene concentration solutions were utilized for verification. As evidenced in Fig. S9, when subjected to the same carbonization temperature, the specific capacitance of 1000CM6%DF exceeded that of 1000CM8%DF, which in turn surpassed that of 1000CM4%DF, with 1000CM2%DF being the least effective. In addition, when the current density is increased to 6 mA cm−2, the capacitance of the CMDF electrode remains at 888 mF cm−2, showing excellent rate performance. The findings obtained can potentially be attributed to the reduction in spacing between neighboring fibers and MXene sheets due to the coated MXene layer. This increases the overall bulk density of the electrochemically active material, thereby affecting its performance. However, it was observed that excessive MXene loading can lead to surface sealing of the DF, thereby hindering the complete contact of the material with the electrolyte, ultimately leading to compromised electrochemical performance. Therefore, it was concluded that a 6% MXene load is optimal under these circumstances.

During low scanning rates, CV curves of the CMDF electrode exhibit rectangular symmetric behavior, but at high scanning rates with significant capacitance, they become fusiform due to polarization (Fig. 4a). However, the analysis reveals that CDF exhibits negligible electrochemical properties (refer to Fig. S10), indicating that the electrochemical properties of CMDF are highly comparable to carbonized MXene. Notably, carbonized MXene exhibits a notably larger interlayer spacing than MXene. This is primarily attributed to the generation of TiC and TiO2 at high temperatures, which facilitates the entry of the electrolyte into the interlayer, thereby enhancing the electrochemical performance of the material. The curves exhibit a triangle-like structure when the current density increases, indicating good reversibility, and also there are no obvious voltage drops, which further implies high electrical conductivity (Fig. 4b). The optimum specific capacitance of the CMDF (1748.5 mF cm−2) was detected at a current density of 0.5 mA cm−2, suggesting that CMDF could demonstrate higher performance compared to other MXene supercapacitors. The fitting curves of CMDF show a higher slope at the low-frequency zone than the pristine Nyquist curve, indicating rapid ion diffusion occurs (Fig. 4c). Besides, the CMDF showed a 94% capacitance retention and a 99% coulombic efficiency after 15,000 GCD cycles (Fig. 4d), suggesting that the CMDF has excellent potential as an electrode for high-performance supercapacitors in the future.

a CV graphs under different scanning rates. b GCD graphs under different current densities. c EIS spectra. d Cycling stability (at 6 mA cm−2) of the CMDF. e MXene load and capacitance of the CMDF with other reported MXene relevant textiles. f TG-IR-MS 3D results, g TG curves and h FTIR spectra of MDF heated from 0 to 1,200 °C. i Decomposition gas analysis of DF and MDF during 0 to 1,200 °C

This study shows that the MXene load of CMDF is higher than most existing studies, thus demonstrating the structural superiority of 3D needled felt (Table S1, Fig. 4). At 0.5 mA cm−2 current density, the CMDF specific capacitance detected was 1748.5 mF cm−2 (Fig. 4e) which is significantly higher than the MXene-coated cotton fabric (362 mF cm−2) [33]. Furthermore, the specific capacitance of CMDF calculated from CV curves (1290 mF cm−2) is also higher than MXene/silk fabric (707 mF cm−2) at 2 mV s−1 [34], MXene/cotton fabric (794.2 mF cm−2) [35] and MXene/carbon fabric (416 mF cm−2) at 10 mV s−1 [4i), which could be ascribed to the existence of MXene.

3.4 Supercapacitor Performance of CMDF

For the purpose of examining the practical application of CMDF as a flexible energy storage device, two pieces of CMDF were assembled into a symmetric supercapacitor, and the results of electrochemical measurements are shown in Fig. 5. Based on the GCD curves and the symmetrical structure, the supercapacitors show good reversibility, and increased current density reduces the charge–discharge time. On the basis of the GCD curves, the specific capacitance of supercapacitors can be computed (Fig. 5b). Whenever the current density escalates from 0.5 to 6 mA cm−2, specific capacitance falls from 577.5 to 158.4 mF cm−2. The volume and mass specific capacitance of CMDF are 8.3 F cm−3 and 12.3 F g−1, respectively, when the current density escalates to 0.5 mA cm−2. In addition, the energy and power densities of supercapacitors can also be estimated based on GCD curves. As shown in Fig. 5c, d, energy density gradually decreases from 80.2 to 22 μWh cm−2 with escalating current density, achieving the maximum current density of 0.5 mA cm−2. Also, there is a reverse trend in power density, which increases from 0.25 to 3 mW cm−2.

a GCD graphs, b Specific capacitance, c energy density and d power density of the CMDF supercapacitor under various current densities. e GCD graphs of supercapacitors in series and parallel. f Cycling stability of the supercapacitor; g charging curve of the supercapacitor to a PVDF film. h Capacitance retention of the supercapacitor at various bending angles and i the display of the device's application in practice

Compared to a single supercapacitor, two connected devices generate twice the current and specific capacitance (Fig. 5e). Furthermore, two series-connected supercapacitors have a voltage window of 2 V, or twice that of a single supercapacitor, leading to a higher voltage output for the same operating period. This would broaden their operating voltage window when applied to practical applications. Besides, Fig. 5f displays the GCD curves for 15,000 cycles of the supercapacitor at 2 mA cm−2, which could evaluate the energy storage durability of the obtained flexible supercapacitor. It can be observed from the results that capacitance retention and coulombic efficiency were maintained after 15,000 cycles at 78.94% and 98%, respectively, indicating remarkable cycling stability.

Flexible supercapacitors can improve energy utilization and provide ultra-long endurance in self-generating systems by collecting electrical energy from electric devices. For this purpose, the SC was connected to a piezoelectric generator. Figure 5g shows that a signal is generated by slap** the film and transmitted to the supercapacitor across a rectifier circuit, which leads to a voltage of 0.84 V after 140 s. Figure 5h shows the capacitance retention of the supercapacitor at various bending angles. Approximately 96% of capacitance retention is maintained whenever the bending angle escalates from 0 to 180 degrees, which indicates excellent flexibility and electrochemical stability. While bending at 180°, the two supercapacitors (1 cm × 2 cm) can still illuminate the electronic screen of the hygrothermograph (Fig. 5i), proving their practical application in smart wearable technology. The experimental results demonstrate that the supercapacitor exhibits remarkable durability against bending and folding, as evidenced by its capacitance retention of 97% and 89.6% (Figs. S11 and S12), respectively, after 1000 cycles of testing.

4 Conclusions

This study proposes high-performance electrodes and supercapacitors by combining MXene with 3D needled waste denim felts. It is, therefore, possible to ensure that a high MXene load can be achieved on needled felt by impregnation, while carbonization can remove adverse functional groups and enhance electrical conductivity, resulting in improved supercapacitive electrochemical performance. The obtained CMDF electrode and the supercapacitor achieved remarkable maximum specific capacitance with superior long-term cycling stability. Overall, the CMDF derived from a problematic waste denim textile demonstrates the remarkable potential for utilization in the smart wearable field.

References

Z. Lin, X. Li, H. Zhang, B. Xu, P. Wasnik et al., Research progress of MXenes and layered double hydroxides for supercapacitors. Inorg. Chem. Front. 10, 4358–4392 (2023). https://doi.org/10.1039/D3QI00819C

M. Pathak, C.S. Rout, Hierarchical NiCo2S4 nanostructures anchored on nanocarbons and Ti3C2Tx MXene for high-performance flexible solid-state asymmetric supercapacitors. Adv. Compos. Hybrid Mater. 5, 1404–1422 (2022). https://doi.org/10.1007/s42114-022-00466-7

J. Wang, H. Kang, H. Ma, Y. Liu, Z. **e et al., Super-fast fabrication of MXene film through a combination of ion induced gelation and vacuum-assisted filtration. Eng. Sci. 15, 57–66 (2021)

S. Uzun, S. Seyedin, A.L. Stoltzfus, A.S. Levitt, M. Alhabeb et al., Knittable and washable multifunctional MXene-coated cellulose yarns. Adv. Funct. Mater. 29(45), 1905015 (2019). https://doi.org/10.1002/adfm.201905015

A. Sarycheva, Y. Gogotsi, Raman spectroscopy analysis of the structure and surface chemistry of Ti3C2Tx MXene. Chem. Mater. 32(8), 3480–3488 (2020). https://doi.org/10.1021/acs.chemmater.0c00359

J. Zhang, N. Kong, S. Uzun, A. Levitt, S. Seyedin et al., Scalable manufacturing of free-standing, strong Ti3C2Tx MXene films with outstanding conductivity. Adv. Mater. 32(23), 2001093 (2020). https://doi.org/10.1002/adma.202001093

M.R. Lukatskaya, S. Kota, Z. Lin, M. Zhao, N. Shpigel et al., Ultra-high-rate pseudocapacitive energy storage in two-dimensional transition metal carbides. Nat. Energy 2(8), 17105 (2017). https://doi.org/10.1038/nenergy.2017.105

S.A. Kazemi, Y. Wang, Super strong 2D titanium carbide MXene-based materials: a theoretical prediction. J. Phys. Con. Matter. 32(11), 11LT01 (2019). https://doi.org/10.1088/1361-648X/ab5bd8

Y. Wei, W. Luo, Z. Zhuang, B. Dai, J. Ding et al., Fabrication of ternary MXene/MnO2/polyaniline nanostructure with good electrochemical performances. Adv. Compos. Hybrid Mater. 4, 1082–1091 (2021). https://doi.org/10.1007/s42114-021-00323-z

L. Pu, J. Zhang, N. Jiresse, Y. Gao, H. Zhou et al., N-doped MXene derived from chitosan for the highly effective electrochemical properties as supercapacitor. Adv. Compos. Hybrid Mater. 5, 356–369 (2022). https://doi.org/10.1007/s42114-021-00371-5

V.S. Sivasankarapillai, T.S.K. Sharma, K.H. Hwa, M. Wabaidur, S. Angaiah et al., MXene based sensing materials: current status and future perspectives. ES Energy Environ. 15, 4–14 (2022). https://doi.org/10.30919/esee8c618

Y. Zhai, Y. Dou, D. Zhao, F.F. Pasquale, T.M. Richard et al., Carbon materials for chemical capacitive energy storage. Adv. Mater. 23(42), 4828–4850 (2011). https://doi.org/10.1002/adma.201100984

J. Liang, C. Jiang, W. Wu, Toward fiber-, paper-, and foam-based flexible solid-state supercapacitors: electrode materials and device designs. Nanoscale 11, 7041–7061 (2019). https://doi.org/10.1039/C8NR10301A

J. Yan, Y. Ma, C. Zhang, X. Li, W. Liu et al., Polypyrrole-MXene coated textile-based flexible energy storage device. RSC Adv. 8(69), 39742–39748 (2018). https://doi.org/10.1039/C8RA08403C

Z. Zhou, W. Panatdasirisuk, T.S. Mathis, B. Anasori, C. Lu et al., Layer-by-layer assembly of MXene and carbon nanotubes on electrospun polymer films for flexible energy storage. Nanoscale 10(13), 6005–60139 (2018). https://doi.org/10.1039/C8NR00313K

M. Hu, Z. Li, G. Li, T. Hu, C. Zhang et al., All-solid-state flexible fiber-based MXene supercapacitors. Adv. Mater. Technol. 2(10), 1700143 (2017). https://doi.org/10.1002/admt.201700143

Q. Wang, Y. Yang, W. Chen, K. Rong, C. Zhang et al., Reliable coaxial wet spinning strategy to fabricate flexible MnO2-based fiber supercapacitors. J. Alloy. Compd. 935, 168110 (2023). https://doi.org/10.1016/j.jallcom.2022.168110

S. Zhen, G. Haocheng, Z. Chuan, Rational design of electrode–electrolyte interphase and electrolytes for rechargeable proton batteries. Nano-Micro Lett. 15, 96 (2023). https://doi.org/10.1007/s40820-023-01071-z

P. Jiang, F. Qi, Z. Yong, W. **n, H. Lei et al., A bilayer high-temperature dielectric film with superior breakdown strength and energy storage density. Nano-Micro Lett. 15, 154 (2023). https://doi.org/10.1007/s40820-023-01121-6

L.V. Haule, C.M. Carr, M. Rigout, Preparation and physical properties of regenerated cellulose fibres from cotton waste garments. J. Clean. Prod. 112, 4445–4451 (2016). https://doi.org/10.1016/j.jclepro.2015.08.086

L.J.R. Nunes, R. Godina, J.C.O. Matias, J.P.S. Cataldo, Economic and environmental benefits of using textile waste for the production of thermal energy. J. Clean. Prod. 171, 1353–1360 (2018). https://doi.org/10.1016/j.jclepro.2017.10.154

L. Lu, W. Fan, X. Meng, L. Xue, S. Ge et al., Current recycling strategies and high-value utilization of waste cotton. Sci. Total. Environ. 856, 158798 (2023). https://doi.org/10.1016/j.scitotenv.2022.158798

W.M. Qiao, M. Huda, Y. Song, S.H. Yoon, Y. Korai et al., Carbon fibers and films based on biomass resins. Energy Fuels 19(6), 2576–2582 (2005). https://doi.org/10.1021/ef050046j

W. **n, M. Tian, Y. Ge, Intrinsic self-healing chemistry for next-generation flexible energy storage devices. Nano-Micro Lett. 15, 99 (2023). https://doi.org/10.1007/s40820-023-01075-9

X. Meng, W. Fan, Y. Ma, T. Wei, H. Dou et al., Recycling of denim fabric wastes into high-performance composites using the needle-punching nonwoven fabrication route. Text. Res. J. 90(5–6), 695–709 (2020). https://doi.org/10.1177/0040517519870317

Y. Li, Z. Lu, B. **n, Y. Liu, Y. Cui et al., All-solid-state flexible supercapacitor of carbonized MXene/cotton fabric for wearable energy storage. Appl. Surf. Sci. 528, 146975 (2020). https://doi.org/10.1016/j.apsusc.2020.146975

L. Wang, L. Chen, B. Yan, C. Wang, F. Zhu et al., In situ preparation of SnO2@polyaniline nanocomposites and their synergetic structure for high-performance supercapacitors. J. Mater. Chem. A 2, 8334–8341 (2014). https://doi.org/10.1039/c3ta15266a

M. Seredych, C.E. Shuck, D. Pinto, M. Alhabeb, E. Precetti et al., High-temperature behavior and surface chemistry of carbide MXenes studied by thermal analysis. Chem. Mater. 31(9), 3324–3332 (2019). https://doi.org/10.1021/acs.chemmater.9b00397

M. Alhabeb, K. Maleski, B. Anasori, P. Lelyukh, L. Clark et al., Guidelines for synthesis and processing of two-dimensional titanium carbide (Ti3C2Tx MXene). Chem. Mater. 29(18), 7633–7644 (2017). https://doi.org/10.1021/acs.chemmater.7b02847

Y.B. Li, H. Shao, Z. Lin, J. Lu, L. Liu et al., A general Lewis acidic etching route for preparing MXenes with enhanced electrochemical performance in non-aqueous electrolyte. Nat. Mater. 19, 894–899 (2020). https://doi.org/10.1038/s41563-020-0657-0

L.A. Naslund, I. Persson, XPS spectra curve fittings of Ti3C2Tx based on first principles thinking. Appl. Surf. Sci. 593, 153442 (2022). https://doi.org/10.1016/j.apsusc.2022.153442

B. Yousefi, S. Mohammad, S. Saharkhiz, Z.K. Toussi, The effect of inner layer fiber diameter and fabric structure on transplanar water absorption and transfer of double-layered knitted fabrics. Fibers Polym. 22(2), 578–586 (2021). https://doi.org/10.1007/s12221-021-9430-5

A. Levitt, D. Hegh, P. Phillips, S. Uzun, M. Anayee et al., 3D knitted energy storage textiles using MXene-coated yarns. Mater. Today 34, 17–29 (2020). https://doi.org/10.1016/j.mattod.2020.02.005

M. Hu, T. Hu, R. Cheng, J. Yang, C. Cui et al., MXene-coated silk-derive d carbon cloth toward flexible electrode for supercapacitor application. J. Energy Chem. 27, 161–166 (2018). https://doi.org/10.1016/j.jechem.2017.10.030

Q. Jiang, N. Kurra, M. Alhabeb, Y. Gogotsi, H.N. Alshareef, All pseudocapacitive MXene-RuO2 asymmetric supercapacitors. Adv. Energy Mater. 8(13), 1703043 (2018). https://doi.org/10.1002/aenm.201703043

Acknowledgements

The authors acknowledge the financial support from the National Natural Science Foundation of China (Nos. 52073224, 32201491), the Textile Vision Basic Research Program of China (No. J202110), the Scientific Research Project of Shaanxi Provincial Education Department, China (No. 22JC035), the Advanced Manufacturing Technology Program of **'an Science and Technology Bureau, China (No. 21XJZZ0019), the Research Fund for the Doctoral Program of **'an Polytechnic University (No. BS202053) and the Youth Innovation Team of Shaanxi Universities and Institute of Flexible electronics and Intelligent Textile.

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare no interest conflict. They have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Supplementary Information

Supplementary file1 (MP4 7432 kb)

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Fan, W., Wang, Q., Rong, K. et al. MXene Enhanced 3D Needled Waste Denim Felt for High-Performance Flexible Supercapacitors. Nano-Micro Lett. 16, 36 (2024). https://doi.org/10.1007/s40820-023-01226-y

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s40820-023-01226-y