Abstract

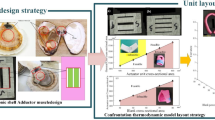

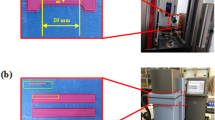

Smart structures realize sequential motion and self-assembly through external stimuli. With the advancement of four-dimensional (4D) printing, the programming of sequential motions of smart structures is endowed with more design and manufacturing possibilities. In this research, we present a method for physically programming the timescale of shape change in 4D-printed bilayer actuators to enable the sequential motion and self-assembly of smart structures. The effects of the geometric and printing parameters on the time-dependent behavior of 4D-printed bilayer actuators are investigated. The results show that the thickness of the active layer directly affects the timescale of motion, and increasing the thickness leads to faster motion until the thickness ratio is close to 4:6. Similarly, a higher printing speed results in faster motion. Conversely, a higher printing temperature and a greater layer height result in a slower shape change. The effects of the length-width ratio, line width, and filling ratio on the timescale of motion are not as straightforward. Finally, we demonstrate several smart structures that exhibit sequential motion, including a labyrinth-like self-folding structure that is choreographed to achieve multi-step self-sha** and a flower-shaped structure where each part completes its movement sequentially to avoid collisions. The presented method extends the programmability and functional capabilities of 4D printing.

Similar content being viewed by others

Reference

Lendlein A, Behl M, Hiebl B et al (2010) Shape-memory polymers as a technology platform for biomedical applications. Expert Rev Med Dev 7(3):357–379

Maidin S, Wee KJ, Sharum MA et al (2023) A review on 4D additive manufacturing—the application, smart materials & effect of various stimuli on 4D printed objects. J Teknol 85(8):63–71

Aldawood FK (2023) A comprehensive review of 4D printing: state of the arts, opportunities, and challenges. Actuators 12(3):101. https://doi.org/10.3390/act12030101

Carrell J, Gruss G, Gomez E (2020) Four-dimensional printing using fused-deposition modeling: a review. Rapid Prototy** J 26(5):855–869

Sharma S, Chhetry A, Zhang SP et al (2021) Hydrogen-bond-triggered hybrid nanofibrous membrane-based wearable pressure sensor with ultrahigh sensitivity over a broad pressure range. ACS Nano 15(3):4380–4393

Wu HZ, Zhang X, Ma Z et al (2020) A material combination concept to realize 4D printed products with newly emerging property/functionality. Adv Sci 7(9):1903208. https://doi.org/10.1002/advs.201903208

Wang X, **a Z, Zhao C et al (2020) Microstructured flexible capacitive sensor with high sensitivity based on carbon fiber-filled conductive silicon rubber. Sensor Actuat A-Phys 312:112147. https://doi.org/10.1016/j.sna.2020.112147

Kurakula M, Koteswara Rao GSN (2020) Moving polyvinyl pyrrolidone electrospun nanofibers and bioprinted scaffolds toward multidisciplinary biomedical applications. Eur Polym J 136:109919. https://doi.org/10.1016/j.eurpolymj.2020.109919

Tao R, Ji L, Li Y et al (2020) 4D printed origami metamaterials with tunable compression twist behavior and stress-strain curves. Compos Part B-Eng 201:108344. https://doi.org/10.1016/j.compositesb.2020.108344

Zeng S, Feng Y, Gao Y et al (2022) Layout design and application of 4D-printing bio-inspired structures with programmable actuators. Bio-Des Manuf 5(1):189–200

Stuart MAC, Huck WTS, Genzer J et al (2010) Emerging applications of stimuli-responsive polymer materials. Nat mater 9(2):101–113

Sun L, Huang WM, Ding Z et al (2012) Stimulus-responsive shape memory materials: a review. Mater Des 33:577–640

Gladman SA, Matsumoto EA, Nuzzo RG et al (2016) Biomimetic 4D printing. Nat mater 15(4):413–418

Deng D, Chen Y (2015) Origami-based self-folding structure design and fabrication using projection based stereolithography. J Mech Des 137(2):021701. https://doi.org/10.1115/1.4029066

Peraza-Hernandez EA, Hartl DJ, Malak RJ Jr (2013) Design and numerical analysis of an SMA mesh-based self-folding sheet. Smart Mater Struct 22(9):094008. https://doi.org/10.1088/0964-1726/22/9/094008

Le Duigou A, Castro M, Bevan R et al (2016) 3D printing of wood fibre biocomposites: from mechanical to actuation functionality. Mater Des 96:106–114

Teoh JEM, Zhao Y, An J et al (2017) Multi-stage responsive 4D printed smart structure through varying geometric thickness of shape memory polymer. Smart Mater Struct 26(12):125001. https://doi.org/10.1088/1361-665X/aa908a

Correa D, Pop**a S, Mylo MD et al (2020) 4D pine scale: biomimetic 4D printed autonomous scale and flap structures capable of multi-phase movement. Philos T R Soc A 378(2167):20190445. https://doi.org/10.1098/rsta.2019.0445

Alshebly YS, Nafea M (2023) Effects of printing parameters on 4D-printed PLA actuators. Smart Mater Struct 32(6):064008. https://doi.org/10.1088/1361-665X/acd504

Wang J, Wang Z, Song Z et al (2019) Programming multistage shape memory and variable recovery force with 4D printing parameters. Adv Mater Technol 4(11):1900535. https://doi.org/10.1002/admt.201900535

Ghazal AF, Zhang M, Mujumdar AS et al (2022) Progress in 4D/5D/6D printing of foods: applications and R&D opportunities. Crit Rev Food Sci 63(25):7399–7422

Testoni O, Lumpe T, Huang JL et al (2021) A 4D printed active compliant hinge for potential space applications using shape memory alloys and polymers. Smart Mater Struct 30(8):085004. https://doi.org/10.1088/1361-665X/ac01fa

Bodaghi M, Damanpack AR, Liao WH (2016) Self-expanding/shrinking structures by 4D printing. Smart Mater Struct 25(10):105034. https://doi.org/10.1088/0964-1726/25/10/105034

Mao Y, Yu K, Isakov MS et al (2015) Sequential self-folding structures by 3D printed digital shape memory polymers. Sci Rep 5:13616. https://doi.org/10.1038/srep13616

Lai J, Ye X, Liu J et al (2021) 4D printing of highly printable and shape morphing hydrogels composed of alginate and methylcellulose. Mater Des 205:109699. https://doi.org/10.1016/j.matdes.2021.109699

Yamamura S, Iwase E (2021) Hybrid hinge structure with elastic hinge on self-folding of 4D printing using a fused deposition modeling 3D printer. Mater Des 203:109605. https://doi.org/10.1016/j.matdes.2021.109605

Soleimanzadeh H, Rolfe B, Bodaghi M et al (2020) Closed-loop 4D-printed soft robots. Mater Des 188:108411. https://doi.org/10.1016/j.matdes.2019.108411

Zhou X, Ren L, Song Z et al (2023) Advances in 3D/4D printing of mechanical metamaterials: from manufacturing to applications. Compos Part B-Eng. https://doi.org/10.1016/j.compositesb.2023.110585

Le Duigou A, Fruleux T, Matsuzaki R et al (2021) 4D printing of continuous flax-fibre based shape-changing hygromorph biocomposites: towards sustainable metamaterials. Mater Des 211:110158. https://doi.org/10.1016/j.matdes.2021.110158

Demoly F, Dunn ML, Wood KL et al (2021) The status, barriers, challenges, and future in design for 4D printing. Mater Des 212:110193. https://doi.org/10.1016/j.matdes.2021.110193

Li X, Fan L, Li R et al (2023) 3D/4D printing of β-cyclodextrin-based high internal phase emulsions. J Food Eng 348:111455. https://doi.org/10.1016/j.jfoodeng.2023.111455

Yao T, Wang Y, Zhu B et al (2020) 4D printing and collaborative design of highly flexible shape memory alloy structures: a case study for a metallic robot prototype. Smart Mater Struct 30(1):015018. https://doi.org/10.1088/1361-665X/abcc0a

Tahouni Y, Krüger F, Pop**a S et al (2021) Programming sequential motion steps in 4D-printed hygromorphs by architected mesostructure and differential hygro-responsiveness. Bioinspir Biomim 16(5):055002. https://doi.org/10.1088/1748-3190/ac0c8e

El Magri A, Vaudreuil S, Ayad B et al (2023) Effect of printing parameters on tensile, thermal and structural properties of 3D-printed poly (ether ketone ketone) PEKK material using fused deposition modeling. J Appl Polym Sci 29(140):54078. https://doi.org/10.1002/app.54078

Zeng S, Gao Y, Feng Y et al (2019) Programming the deformation of a temperature-driven bilayer structure in 4D printing. Smart Mater Struct 28(10):105031. https://doi.org/10.1088/1361-665X/ab39c9

Zeng S, Gao Y, Tan J et al (2022) Self-assembly by 4D printing: design and fabrication of sequential self-folding. In: Proceedings of the ASME conference on smart materials, adaptive structures and intelligent systems, Vol 86274, p V001T03A005. https://doi.org/10.1115/SMASIS2022-89459

Timoshenko S (1925) Analysis of bi-metal thermostats. J Opt Soc Am 11(3):233–255

Zeng S, Gao Y, Qiu H et al (2022) Design, fabrication and application of self-spiraling pattern-driven 4D-printed actuator. Sci Rep 12:18874. https://doi.org/10.1038/s41598-022-23425-0

Westbrook KK, Parakh V, Chung T et al (2010) Constitutive modeling of shape memory effects in semicrystalline polymers with stretch induced crystallization. J Eng Mater Technol 132(4):041010. https://doi.org/10.1115/1.4001964

Acknowledgments

This work is supported by the National Natural Science Foundation of China (Grant No. 52375272), the Natural Science Foundation of Zhejiang Provincial (Grant No. LR22E050006), and the Postdoctoral Fellowship Program of CPSF (Grand No. GZB20230339).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Gao, YC., Duan, DX., Zeng, SY. et al. Programming time-dependent behavior in 4D printing by geometric and printing parameters. Adv. Manuf. (2024). https://doi.org/10.1007/s40436-024-00489-x

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s40436-024-00489-x