Abstract

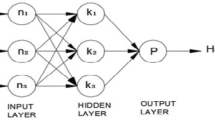

This study attempts to investigate the geometrical tolerance of AA4032-based metal matrix composites (MMC) machined using EDM. Two variants of AA4032-based composites are created with titanium carbide (TiC) and boron nitride (BN) using stir casting method. Before machining through EDM, the composites are examined for mechanical properties. Eighty-one experiments are designed and conducted to explore the geometrical tolerance recorded during EDM under the considered operating conditions. From the experiments, it is inferred that adding TiC particles to AA4032 base composites increases the tensile and hardness. At the same time, geometric tolerance decreases with the addition of TiC wt% and increases with the BN wt% towards the base composites. As a secondary objective, this study designed and developed two neural network-based machine learning models to predict the geometric tolerance recorded by the real-time EDM. For this, current, pulse on time, and gap voltage are considered as input. Circularity, cylindricity, perpendicularity and overcut are considered as the outputs. Both the proposed models recorded an overall prediction accuracy of around 99%. To ensure the results predicted by NN models, validation experiments are conducted and compared with the model-predicted results. The results of validation experiments are in line with the results predicted by the model.

Similar content being viewed by others

References

Hong YS, Chang TC (2002) A comprehensive review of tolerancing research. Int J Prod Res 40:2425–2459. https://doi.org/10.1080/00207540210128242

Ali SHR, Mohamed HH, Bedewy MK (2009) Identifying cylinder liner wear using precise coordinate measurements. Int J Precis Eng Manuf 10:19–25. https://doi.org/10.1007/s12541-009-0088-y

Golinitskiy P, Antonova U, Cherkasova E, Temasova G, Toygambaev S (2021) Metrological support of cylinder liner inspection. In: journal of physics: conference series, vol 1889. https://doi.org/10.1088/1742-6596/1889/5/052023

Ho KH, Newman ST (2003) State of the art electrical discharge machining (EDM). Int J Mach Tools Manuf 43:1287–1300. https://doi.org/10.1016/S0890-6955(03)00162-7

Nicholls CJ, Boswell B, Davies IJ, Islam MN (2017) Review of machining metal matrix composites. Int J Adv Manuf Technol 90:2429–2441. https://doi.org/10.1007/s00170-016-9558-4

Pachaury Y, Tandon P (2017) An overview of electric discharge machining of ceramics and ceramic based composites. J Manuf Process 25:369–390. https://doi.org/10.1016/j.jmapro.2016.12.010

Risto M, Haas R, Munz M (2016) Optimization of the EDM drilling process to increase the productivity and geometrical accuracy. Procedia CIRP 42:537–542. https://doi.org/10.1016/j.procir.2016.02.247

Dhanabalan S, Sivakumar K, Narayanan CS (2014) Analysis of form tolerances in electrical discharge machining process for inconel 718 and 625. Mater Manuf Process 29:253–259. https://doi.org/10.1080/10426914.2013.852213

Kumar S, Dhanabalan S (2019) Influence on machinability and form tolerance of Inconel 718 in Edm using different diameter multi hole Cu electrodes. SN Appl Sci 1:1–17. https://doi.org/10.1007/s42452-019-0403-x

Selvarajan L, Narayanan CS, Jeyapaul R (2016) Optimization of EDM parameters on machining Si 3N4-TiN composite for improving circularity, cylindricity, and perpendicularity. Mater Manuf Process 31:405–412. https://doi.org/10.1080/10426914.2015.1058947

Selvarajan L, Mouri P, Ramesh Raja R (2018) Experimental investigation of EDM parameters on machining Si3N4-TiN conductive ceramic composite using hallow tube electrode for improving geometrical accuracy. Mater Today Proc 5:8080–8088. https://doi.org/10.1016/j.matpr.2017.11.494

Selvarajan L, Sathiya Narayanan C, Jeyapaul R, Manohar M (2016) Optimization of EDM process parameters in machining Si3N4-TiN conductive ceramic composites to improve form and orientation tolerances. Meas J Int Meas Confed 92:114–129. https://doi.org/10.1016/j.measurement.2016.05.018

Carlini GC, Moura CR, Amorim FL, Weingaertner WL (2020) On geometrical characteristics of WC-Co round cavities after ED-machining with different grades of CuW electrodes. Mater Res. https://doi.org/10.1590/1980-5373-MR-2020-0041

Chawla KK, Chawla N (2014) Metal matrix composites: automotive applications. Encycl Automot Eng. https://doi.org/10.1002/9781118354179.auto279

Uvaraja VC, Natarajan N, Rajendran I, Sivakumar K (2013) Tribological behavior of novel hybrid composite materials using Taguchi technique. J Tribol 135:1–12. https://doi.org/10.1115/1.4023147

Kumar GBV, Rao CSP, Selvaraj N (2011) Mechanical and tribological behavior of particulate reinforced aluminum metal matrix composites–a review. J Miner Mater Charact Eng 10:59–91. https://doi.org/10.4236/jmmce.2011.101005

Lu Y, Watanabe M, Miyata R, Nakamura J, Yamada J, Kato H, Yoshimi K (2020) Microstructures and mechanical properties of TiC-particulate-reinforced Ti–Mo–Al intermetallic matrix composites. Mater Sci Eng A 790:139523. https://doi.org/10.1016/j.msea.2020.139523

Wojcik A, Olejnik E, Bigos A, Chulist R, Bobrowski P, Kurtyka P, Tarasek A, Rylko N, Szymanski L, Maziarz W (2020) Microstructural characterization and mechanical properties of in situ cast nanocomposites Al/TiC type. J Mater Res Technol 9:12707–12715. https://doi.org/10.1016/j.jmrt.2020.09.012

Pandey U, Purohit R, Agarwal P, Dhakad SK, Rana RS (2017) Effect of TiC particles on the mechanical properties of aluminium alloy metal matrix composites (MMCs). Mater Today Proc 4:5452–5460. https://doi.org/10.1016/j.matpr.2017.05.057

Harichandran R, Selvakumar N (2018) Microstructure and mechanical characterization of (B4C+ h-BN)/Al hybrid nanocomposites processed by ultrasound assisted casting. Int J Mech Sci 144:814–826. https://doi.org/10.1016/j.ijmecsci.2017.08.039

Kannan C, Ramanujam R, Balan ASS (2018) Machinability studies on Al 7075/BN/Al2O3 squeeze cast hybrid nanocomposite under different machining environments. Mater Manuf Process 33:587–595. https://doi.org/10.1080/10426914.2017.1401718

Senthilkumar TS, Muralikannan R (2019) Role of TiC and h-BN particles on morphological characterization and surface effects of Al 4032 hybrid composites using EDM process. J Mech Sci Technol 33:4255–4264. https://doi.org/10.1007/s12206-019-0822-z

Kandpal BC, Kumar J, Singh H (2015) Machining of aluminium metal matrix composites with electrical discharge machining-a review. Mater Today Proc 2:1665–1671. https://doi.org/10.1016/j.matpr.2015.07.094

Ahamed AR, Asokan P, Aravindan S (2009) EDM of hybrid Al-SiCp-B4Cp and Al-SiC p-Glassp MMCs. Int J Adv Manuf Technol 44:520–528. https://doi.org/10.1007/s00170-008-1839-0

Mahanta S, Chandrasekaran M, Samanta S, Arunachalam RM (2018) EDM investigation of Al 7075 alloy reinforced with B4C and fly ash nanoparticles and parametric optimization for sustainable production. J Braz Soc Mech Sci Eng 40:1–17. https://doi.org/10.1007/s40430-018-1191-8

Rengasamy NV, Rajkumar M, Senthil Kumaran S (2016) An analysis of mechanical properties and optimization of EDM process parameters of Al 4032 alloy reinforced with Zrb2 and Tib2 in-situ composites. J Alloys Compd 662:325–338. https://doi.org/10.1016/j.jallcom.2015.12.023

Selvarajan L, Sasikumar R, Senthil Kumar N, Kolochi P, Naveen Kumar P (2019) Effect of EDM parameters on material removal rate, tool wear rate and geometrical errors of aluminium material. Mater Today Proc 46:9392–9396. https://doi.org/10.1016/j.matpr.2020.03.054

Prakash B, Sridharan M (2022) Predicting the thermal performance of double pipe heat exchanger using the generalized regression neural network model. Int J Ambient Energy. https://doi.org/10.1080/01430750.2022.2127885

Sridharan M (2020) Application of generalized regression neural network in predicting the performance of solar photovoltaic thermal water collector. Ann Data Sci. https://doi.org/10.1007/s40745-020-00273-1

Bendu H, Deepak BBVL, Murugan S (2017) Multi-objective optimization of ethanol fuelled HCCI engine performance using hybrid GRNN–PSO. Appl Energy 187:601–611. https://doi.org/10.1016/j.apenergy.2016.11.072

Bendu H, Deepak BBVL, Murugan S (2016) Application of GRNN for the prediction of performance and exhaust emissions in HCCI engine using ethanol. Energy Convers Manag 122:165–173. https://doi.org/10.1016/j.enconman.2016.05.061

Javidani M, Larouche D (2014) Application of cast Al-Si alloys in internal combustion engine components. Int Mater Rev 59:132–158. https://doi.org/10.1179/1743280413Y.0000000027

Senthil Kumar S, Sudhakara Pandian R, Pitchipoo P, Rajakarunakaran S, Rajesh S (2021) Investigation of Al-Mg based composite incorporated with MoS2 through powder metallurgy. Proc Inst Mech Eng Part E J Process Mech Eng 235:986–996. https://doi.org/10.1177/0954408920985761

Kumar SS, Uthayakumar M, Kumaran ST, Parameswaran P (2014) Electrical discharge machining of Al(6351)-SiC-B4C hybrid composite. Mater Manuf Process 29:1395–1400. https://doi.org/10.1080/10426914.2014.952024

Sridharan M (2019) Application of generalized regression neural network in predicting the performance of natural convection solar dryer. J Sol Energy Eng. https://doi.org/10.1115/1.4045384

Shenbagaraj S, Sharma PK, Sharma AK, Raghav G, Kota KB, Ashokkumar V (2021) Gasification of food waste in supercritical water: an innovative synthesis gas composition prediction model based on artificial neural networks. Int J Hydrogen Energy 46:12739–12757. https://doi.org/10.1016/j.ijhydene.2021.01.122

Sridharan M (2021) Application of Mamdani fuzzy inference system in predicting the thermal performance of solar distillation still. J Ambient Intell Humaniz Comput. https://doi.org/10.1007/s12652-020-02810-5

Sridharan M (2020) Predicting performance of double-pipe parallel-and counter-flow heat exchanger using fuzzy logic. J Therm Sci Eng Appl 12:031006. https://doi.org/10.1115/1.4044696

Sridharan M (2021) Short review on various applications of fuzzy logic-based expert systems in the field of solar energy. Int J Ambient Energy. https://doi.org/10.1080/01430750.2021.1927839

Charles Franklin J, Chandrasekar M, Sridharan M (2021) Performance of a downstream finned solar photovoltaic thermal air system. J Therm Sci Eng Appl 13:1–12. https://doi.org/10.1115/1.4049426

Siva Sankaran NV, Sridharan M (2022) Experimental research and performance study of double slope single basin solar distillation still using CFD techniques. Int J Ambient Energy. https://doi.org/10.1080/01430750.2020.1852109

Kumar S, Dave HK, Desai KP (2016) Experimental investigation on performance of different tool movement strategies in EDM process for boring operation. Int J Adv Manuf Technol 87:1609–1620. https://doi.org/10.1007/s00170-016-8443-5

Selvarajan L, Rajavel R, Prakash B, Mohan DG, Gopi S (2019) Investigation on spark electrical discharge machining of Si3N4 based advanced conductive ceramic composites. Mater Today Proc 27:2174–2178. https://doi.org/10.1016/j.matpr.2019.09.090

Gowda BMU, Ravindra HV, Prakash GVN, Nishanth P, Ugrasen G (2015) Optimization of process parameters in drilling of epoxy Si3N4 composite material. Mater Today Proc 2:2852–2861. https://doi.org/10.1016/j.matpr.2015.07.300

Selvarajan L, Narayanan CS, Jeyapaul R (2015) Optimization of EDM hole drilling parameters in machining of MoSi2-SiC intermetallic/composites for improving geometrical tolerances. J Adv Manuf Syst 14:259–272. https://doi.org/10.1142/S0219686715500171

Selvarajan L, Katherasan D, Srivijai B, Rajavel R, Ramamoorthi M (2018) Experimental analysis of en 19 alloy material on EDM for improving geometrical errors using copper pentagon shaped electrode. Mater Today Proc 5:4508–4514. https://doi.org/10.1016/j.matpr.2017.12.020

Senthilkumar TS, Muralikannan R (2019) Enhancing the geometric tolerance of aluminium hybrid metal matrix composite using EDM process. J Braz Soc Mech Sci Eng 41:1–15. https://doi.org/10.1007/s40430-018-1553-2

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

All authors declare that they have no conflicts of interest to disclose.

Additional information

Technical Editor: Izabel Fernanda Machado.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Senthilkumar, T.S., Muralikannan, R., Sridharan, M. et al. AA4032-TiC-h-BN-related composites: a machine learning model-based experimental study with performance prediction. J Braz. Soc. Mech. Sci. Eng. 46, 30 (2024). https://doi.org/10.1007/s40430-023-04615-x

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s40430-023-04615-x