Abstract

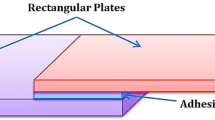

An experimental study of the single-lap joints at different loading rates and ambient temperatures was investigated. In the experiment, a single lap joint was formed using plain woven glass fiber reinforced epoxy (GFRE) laminates, plain woven aramid fiber reinforced laminates (AFRE), and Araldite 138 M / HV998 epoxy adhesive. The composite laminates were produced using Vacuum-Assisted Resin Transfer Molding (VARTM) process. Adhesively bonded joints were created using similar and dissimilar adherends. Experiments were carried out under different loading rates (1 mm/min, 10 mm/min, 50 mm/min, 100 mm/min) and ambient temperatures (23°C,60°C,100°C). Stress–strain graphs were obtained for each experimental condition. It is seen that the maximum stress values increase as the loading rate increases in all single lap joints at all different temperatures. However, in all single lap joints, at all different loading rates, the maximum stress value decreases as the ambient temperature increases.

Similar content being viewed by others

References

Grant LDR, Adams RD, daSilva LFM (2009) Experimental and numerical analysis of single-lap joints for the automotive industry. Int J Adhes Adhes 29:405–413. https://doi.org/10.1016/j.ijadhadh.2008.09.001

Seong MS, Kim TH, Nguyen KH, Kweon JH, Choi JH (2008) A parametric study on the failure of bonded single-lap joints of carbon composite and aluminum. Compos Struct 86:135–145. https://doi.org/10.1016/j.compstruct.2008.03.026

Karachalios EF, Adams RD, daSilva LFM (2013) Single lap joints loaded in tension with high strength steel adherends. Int J Adhes Adhes 43:81–95. https://doi.org/10.1016/j.ijadhadh.2013.01.016

Karachalios EF, Adams RD, daSilva LFM (2013) The behaviour of single lap joints under bending loading. J Adhes Sci Technol 16:1811–1827. https://doi.org/10.1080/01694243.2012.761926

daSilva LFM, Critchlow GW, Figueiredo MAV (2008) Parametric study of adhesively bonded single lap joints by the taguchi method. J Adhes Sci Technol 22:1477–1494. https://doi.org/10.1163/156856108X309585

Safar AA, Ayatollahi MR, daSilva LFM (2017) Strength prediction of adhesively bonded single lap joints with different bondline thicknesses: a critical longitudinal strain approach. Int J Solids Struct 109:189–198. https://doi.org/10.1016/j.ijsolstr.2017.01.022

Sancaktar E, Gomatam R (2001) A study on the effects of surface roughness on the strength of single lap joints. J Adhes Sci Technol 15:97–117. https://doi.org/10.1163/156856101743346

Wang S, Liang W, Duan L, Li G, Cui J (2020) Effects of loading rates on mechanical property and failure behavior of single-lap adhesive joints with carbon fiber reinforced plastics and aluminum alloys. Int J Adv Manuf Technol 106:2569–2581. https://doi.org/10.1007/s00170-019-04804-w

Atahan MG, Apalak MK (2022) Loading-rate effect on tensile and bending strength of 3D-printed polylactic acid adhesively bonded joints. J Adhes Sci Technol 36:317–344. https://doi.org/10.1080/01694243.2021.1922022

Gupta BNVSG, Hiremath MM, Sen B, Prusty RK, Ray BC (2020) Influence of loading rate on adhesively bonded tin-glass/epoxy single lap joint. Mater Today Proc 26:1850–1854. https://doi.org/10.1016/j.matpr.2020.02.406

Brewis DM, Comyn J, Shalash RJA (1982) The effect of moisture and temperature on the properties of an epoxide-polyamide adhesive in relation to its performance in single lap joints. Int J Adhes Adhes 2:215–222. https://doi.org/10.1016/0143-7496(82)90028-8

Machado JJM, Marques EAS, da Silva LFM (2018) Mechanical behaviour of adhesively bonded composite single lap joints under quasi-static and impact conditions with variation of temperature and overlap. J Compos Mater 52:3621–3625. https://doi.org/10.1177/0021998318766641

Sayman O, Arikan V, Dogan A, Soykok IF, Dogan T (2013) Failure analysis of adhesively bonded composite joints under transverse impact and different temperatures. Compos Part B 54:409–414. https://doi.org/10.1016/j.compositesb.2013.06.017

Adams RD, Coppendale J, Mallick V, AI-Hamdan H (1992) The effect of temperature on thestrength of adhesive joints. Int J Adhes Adhes 12:185–190. https://doi.org/10.1016/0143-7496(92)90052-W

Arikan V, Dogan A, Dogan T, Sabanci E, Kadum A, Shamary JA (2015) Effects of temperature and hole drilling on adhesively bonded single-lap joints. J Adhes 91:177–185. https://doi.org/10.1080/00218464.2013.874293

Clarke MI, Broughton JG, Hutchinson AR, Buckley M (2013) Application of the design of experiments procedure to the behaviour of adhesively bonded joints with plastically deformable adherends to enable further understanding of strain rate sensitivity. Int J Adhes Adhes 44:226–231. https://doi.org/10.1016/j.ijadhadh.2013.03.003

Liao L, Sawa T, Huang C (2013) Experimental and FEM studies on mechanical properties of single-lap adhesive joint with dissimilar adherends subjected to impact tensile loadings. Int J Adhes Adhes 44:91–98. https://doi.org/10.1016/j.ijadhadh.2013.02.007

Banea MD, da Silva LFM, Campilho RDSG (2014) Effect of temperature on the shear strength of aluminium single lap bonded joints for high temperature applications. J Adhes Sci Technol 28:1367–1381. https://doi.org/10.1080/01694243.2012.697388

Avendaño R, Carbas RJC, Marques EAS, da Silva LFM, Fernandes AA (2016) Effect of temperature and strain rate on single lap joints with dissimilar lightweight adherends bonded with an acrylic adhesive. Compos Struct 152:34–44. https://doi.org/10.1016/j.compstruct.2016.05.034

Yao M, Zhu D, Yao Y, Zhang H, Mobasher B (2016) Experimental study on basalt FRP/steel single-lap joints under different loading rates and temperatures. Compos Struct 145:68–79. https://doi.org/10.1016/j.compstruct.2016.02.061

Erbayrak E, Yuncuoglu EU, Kahraman Y, Gumus BE (2021) An experimental and numerical determination on low-velocity impact response of hybrid composite laminate. Iran J Sci Technol Trans Mech Eng 45:665–681. https://doi.org/10.1007/s40997-020-00402-4

Azevedo JCS, Campilho RDSG, da Silva FJG, Faneco TMS, Lopes RM (2015) Cohesive law estimation of adhesive joints in mode II condition. Theor Appl Fract Mech 80:143–154. https://doi.org/10.1016/j.tafmec.2015.09.007

Eksi S, Genel K (2017) Comparison of mechanical properties of unidirectional and woven carbon, glass and aramid fiber reinforced epoxy composites. Acta Phys Pol A 132:879–882. https://doi.org/10.12693/APhysPolA.132.879

Yang L, Yan Y, Kuang N (2013) Experimental and numerical investigation of aramid fibre reinforced laminates subjected to low velocity impact. Polym Test 32:1163–1173. https://doi.org/10.1016/j.polymertesting.2013.07.010

Setiawan M, Gifari MAL, Putra RH (2018) Tensile strength improvement of LLBC material for low speed wind turbine rotor blade by varying composite matrix. IOP Con Ser Mater Sci Eng 288:1–4. https://doi.org/10.1088/1757-899X/288/1/012013

Salam SS, Mehat NM, Kamaruddin S (2019) Optimization of laminated composites characteristics via integration of chamis equation, taguchi method and principal component analysis. IOP Conf Ser Mater Sci Eng 551:1–8. https://doi.org/10.1088/1757-899X/551/1/012110

Urbina SR, Ayre D, Nezhad HY (2018) Effect of hygrothermal cycles on mechanical performance of composite adhesively bonded joints. In: 18th European conference on composite materials, ECCM18, Athens

Carbas RJC, Marques EAS, da Silva LFM, Lopes AM (2014) Effect of cure temperature on the glass transition temperature and mechanical properties of epoxy adhesives. J Adhes 90:104–119. https://doi.org/10.1080/00218464.2013.779559

Magalhaes AG, Pinto AMG, Campilho RDSG, deMoura MFSF, Baptista APM (2009) Single-lap joints of similar and dissimilar adherends bonded with an acrylic adhesive. J Adhes 85:351–376. https://doi.org/10.1080/00218460902880313

Kanani AY, Hou X, Ye J (2020) A novel dissimilar single-lap joint with interfacial stiffness improvement. Compos Struct 252:112741. https://doi.org/10.1016/j.compstruct.2020.112741

Author information

Authors and Affiliations

Corresponding author

Additional information

Technical Editor: João Marciano Laredo dos Reis.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Erbayrak, E., Gumus, B.E. & Yuncuoglu, E.U. Experimental study of adhesively bonded joints with dissimilar composite laminates under different loading rates and ambient temperatures. J Braz. Soc. Mech. Sci. Eng. 45, 260 (2023). https://doi.org/10.1007/s40430-023-04195-w

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s40430-023-04195-w