Abstract

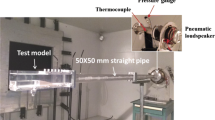

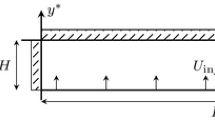

An injection head system was designed and mounted to generate a falling water film in a circular duct with five air jets. The internal diameter of the duct is 94.56 mm. Reynolds number for water is in the range of \(\text {Re}_{\text {in},w}\) = 16,046–19,366; whereas, for the air we have \(\text {Re}_{\text {in},a}\) = 0–32,177. The system is able to generate a uniform water film inside a circular duct. The water film flow is measured with the PIV technique. An air flow is injected into the center of the injection head through five nozzles. The stability and resistance of the water film to the air jets for different flow conditions are verified. In addition, numerical simulations for the water film flow are performed with the open source CFD library OpenFOAM. In particular, the interFoam solver is coupled to a LES \(\kappa\)-equation turbulence model to capture the water-air interface. In all cases, it is observed an undulatory flow behavior described by the axial variation of the interaction of the air and water phases. Although the nature of the flow is unstable, numerical and experimental results show a stable water film thickness.

Similar content being viewed by others

References

Morison K, Worth Q, O’dea N (2006) Minimum wetting and distribution rates in falling film evaporators. Food Bioprod Process 84(4), 302–310. https://doi.org/10.1205/fbp06031. Fouling, Cleaning and Disinfection in Food Processing

Yan L, Wang Y, Wu Z, Dai Z, Yu G, Wang F (2017) Research of vertical falling film behavior in scrubbing-cooling tube. Chem Eng Res Des 117:627–636. https://doi.org/10.1016/j.cherd.2016.11.010

Frías-Esquivel J, González-Alatorre G, Díaz-Ovalle C, Lesso-Arroyo R, Ramos-Ojeda E (2017) Hydrodynamic analysis of the falling-film formation in evaporators using cfd simulation. Food Bioprod Process 101:56–67. https://doi.org/10.1016/j.fbp.2016.10.006

Wei Z, Wang Y, Wu Z, Peng X, Yu G, Wang F (2020) Flow characteristics of the vertical turbulent falling film at high reynolds numbers. Ind Eng Chem Res 60(1):678–696

Knuth E (1954) The mechanism of film cooling. PhD thesis, California Institute of Technology

Paramalingam S, Winchester J, Marsh C (2000) On the fouling of falling film evaporators due to film break-up. Food Bioprod Process 78(2):79–84. https://doi.org/10.1205/096030800532770

Shine S, Shri-Nidhi S (2018) Review on film cooling of liquid rocket engines. Prop Power R 7(1):1–18. https://doi.org/10.1016/j.jppr.2018.01.004

Shine S, Sunil-Kumar S, Suresh B (2013) Numerical study of wave disturbance in liquid cooling film. Prop Power R 2(2):107–118. https://doi.org/10.1016/j.jppr.2013.04.008

Azzopardi B (2006) Gas-Liquid Flows. Begell House, Wallingford, U.K.

De la Cruz-Ávila M, Martínez-Espinosa E, Polupan G, Vicente W (2017) Numerical study of the effect of jet velocity on methane-oxygen confined inverse diffusion flame in a 4 lug-bolt array. Energy 141:1629–1649. https://doi.org/10.1016/j.energy.2017.11.094

Borraz L (2015) Estudio numérico de la estabilidad de una película de líquido descendente en el interior de un conducto circular. Master’s thesis, Instituto Politécnico Nacional, Escuela Superior de Ingeniería Mecánica y Eléctrica, Unidad Culhuacán

Larrainzar-Solís E, Moctezuma-Reyes J, Sánchez-Silva F, Carvajal-Mariscal I, García-Demedices L (2020) Evaluation of a vertical downward water film thickness using visualization and image recognition techniques. Ingeniería, investigación y tecnología 21(1)

De la Cruz-Ávila M (2017) Estudio numérico de la dispersión de gotas de agua en una llama difusiva turbulenta metano-oxigeno. PhD thesis, Instituto Politécnico Nacional, Laboratorio de Ingeniería Térmica e Hidráulica Aplicada

Wang L, Wang Y, Guo Q, Yan L, Yu G (2013) Flow characteristics of vertical falling film in scrubbing-cooling pipe. Huagong Xuebao/CIESC J 64:1959–1968. https://doi.org/10.3969/j.issn.0438-1157.2013.06.009

White F (2011) Fluid-Mechanics. Mc Graw Hill, New York, USA

Zeng J, Wang Y, Wei Z, Wang L, Li T, Yu G (2022) Thickness distribution and fluctuation characteristics of liquid falling film under turbulent conditions. Chem Eng Sci 248:117172. https://doi.org/10.1016/j.ces.2021.117172

Huang X, Wang Y, Wang L, Yu G, Wang F (2022) Effect of structural optimization of scrubbing cooling rings on vertical falling film flow characteristics. ACS Omega. https://doi.org/10.1021/acsomega.2c02492

Far J, Jawad M (2001) Guidebook for the Design of ASME Section VIII Pressure Vessels. ASME Press

Larrainzar-Solís E (2016) Estudio experimental de una película de líquido helicoidal descendente, interactuando con un jet de gases concurrentes usando piv. Master’s thesis, Instituto Politécnico Nacional, Escuela Superior de Ingeniería Mecánica y Eléctrica, Unidad Culhuacán

Shigley J, Mischke C, Budynas R, Liu X, Gao Z (2006) Mechanical Engineering Design. McGraw-Hill, Vol. 89., New York

Webb D, Hewitt G (1975) Downwards co-current annular flow. Int J Multiph Flow 2(1):35–49. https://doi.org/10.1016/0301-9322(75)90027-0

Fan W, Anglart H (2020) varrhoturbvof: A new set of volume of fluid solvers for turbulent isothermal multiphase flows in openfoam. Comput Phys Commun 247:106876. https://doi.org/10.1016/j.cpc.2019.106876

Neumann S, Dubberstein T, Chaves H, Kirmse C, Schwarze R (2016) Influencing parameter study on primary breakup of free falling steel melt jets using volume of fluid simulation. Steel Res. Int. 87(8), 1002–1013 https://onlinelibrary.wiley.com/doi/pdf/10.1002/srin.201500338. https://doi.org/10.1002/srin.201500338

Fernández-Oro J (2012) Técnicas Numéricas en Ingeniería de Fluidos. Reverté, Barcelona, España

Zamorano R (2018) Firefoam (CFD solver) validation in compartment fire scenario using high resolution data. PhD thesis, Pontificia Universidad Católica de Chile

Le D, Labahn J, Beji T, Devaud C, Weckman E, Bounagui A (2018) Assessment of the capabilities of firefoam to model large-scale fires in a well-confined and mechanically ventilated multi-compartment structure. J Fire Sci 36(1):3–29. https://doi.org/10.1177/0734904117733427

Brackbill J, Kothe D, Zemach C (1992) A continuum method for modeling surface tension. J Comput Phys 100(2):335–354. https://doi.org/10.1016/0021-9991(92)90240-Y

FR M (2021) Best Practice: Scale-Resolving Simulations in Ansys CFD. Ansys Germany GmbH

Li H, Cao Y, Wang X, Wan X, **ang Y, Yuan H, Lv P, Duan H (2022) Accurate PIV measurement on slip boundary using single pixel algorithm. Meas Sci Technol 33(5):055302

Acknowledgements

A preliminary comparison between experimental and numerical results was presented at the 8th OpenFOAM Conference. Authors acknowledge LABINTHAP and CONACYT-SENER 147061 D10/CH2010-02 integral system for steam generation at the bottom of an oil well project for the financial support; as well as, the computer resources, technical expertise, and support provided by the Laboratorio Nacional de Supercómputo del Sureste de México, CONACYT member of the network of national laboratories. L. Borraz acknowledges support through a doctoral scholarship from CONACYT-SENER Fondo Sectorial Sustentabilidad CTAFSE-2-X-15-02. Finally, L. Borraz and A. Beltrán would also like to acknowledge SENER CONACYT 2014-246911 Clúster de Biocombustibles Sólidos para la Generación Térmica y Eléctrica.

Author information

Authors and Affiliations

Corresponding author

Additional information

Technical Editor by Erick Franklin.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Borraz, L., Larrainzar, F., Sánchez-Silva, F. et al. An injection head to generate a stable falling liquid film within a circular duct. J Braz. Soc. Mech. Sci. Eng. 44, 583 (2022). https://doi.org/10.1007/s40430-022-03885-1

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s40430-022-03885-1