Abstract

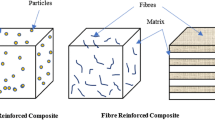

Fibre-reinforced polymer (FRP) composites have proliferated in the last few decades over conventional materials. The rapid growth and preference of FRP composites are attributed to their strength-to-weight, high stiffness-to-weight ratio, cost-effectiveness, and ease of manufacturing. The modern FRP composites emerged as an important class of tribo-material in the field of automotive, aerospace, transportation, and mining industries. In these industrial applications, the FRP composites experienced tribological complications. These applications of FRP composite materials as, for example, FRP conveyer belt, FRP leaf spring, FRP bearing, marine boat, exterior body component of the automobile, space shuttles, wing, fuselage and FRP bridge deck panel are subjected to severe tribological complications That is why tribological characteristics are important criteria in designing of FRP components. In this paper, an attempt has been made to review the fundamental aspects of tribology and explore the nature of ongoing researches carried out in recent past on the tribo-performance of carbon or glass fibre-reinforced thermoset polymer composites, specifically the adhesive wear. This paper also focuses on the transfer film characteristics of fibre-reinforced thermosets polymer composites and attempts to throw light upon the areas requiring extensive probing for the upcoming investigations in future.

Similar content being viewed by others

References

Bhushan B (2002) Introduction to tribology. John Wiley & Sons, New York

Rezaei A, Ost W, Van Paepegem W, De Baets P, Degrieck J (2011) Experimental study and numerical simulation of the large-scale testing of polymeric composite journal bearings: Three-dimensional and dynamic modelling. Wear 270:431–438. https://doi.org/10.1016/j.wear.2010.11.005

Wong VW, Tung SC (2016) Overview of automotive engine friction and reduction trends–effects of surface, material, and lubricant-additive technologies. Friction 4:1. https://doi.org/10.1007/s40544-016-0107-9

Kumar S, Singh KK, Ramkumar J (2020) Comparative study of the influence of graphene nanoplatelets filler on the mechanical and tribological behaviour of glass fabric-reinforced epoxy composites. Polym Compos 41:5403–5417. https://doi.org/10.1002/pc.25804

Jost HP (1966) Lubrication (Tribology): a report on the present position and industry’s needs. H.M Stationary Office, London, UK

Findik F (2014) Latest Progress on tribological properties of industrial materials. Mater Des 57:218–244. https://doi.org/10.1016/j.matdes.2013.12.028

Holmberg K, Andersson P, Nylund NO, Makela K, Erdemir A (2014) Global energy consumption due to friction in trucks and buses. Tribol Int 78:94. https://doi.org/10.1016/j.triboint.2014.05.004

Holmberg K, Erdemir A (2017) Influence of tribology on global energy consumption, costs and emissions. Friction 5:263. https://doi.org/10.1007/s40544-017-0183-5

Suh NP (1986) Tribophysics. Prentice-Hall Inc, New Jersey

Prajapati PK, Kumar S, Singh KK (2020) Optimization of tribological behavior of CFRP composites under dry sliding condition using taguchi method. Mater Today Proc 21:1320–1329. https://doi.org/10.1016/j.matpr.2020.01.169

Shrivastava R, Singh KK (2022) Mechanical property characterization of glass/epoxy composite with varying fiber percentage and mid-plane ply orientation. J Braz Soc Mech Sci Eng 44:122. https://doi.org/10.1007/s40430-022-03402-4

Friedrich K, Lu Z, Hager AM (1995) Recent advances in polymer composites’ tribology. Wear 190:139–144. https://doi.org/10.1016/0043-1648(96)80012-3

Kumar S, Singh KK (2020) Tribological behaviour of fibre-reinforced thermoset polymer composites: a review. Proc IMechE Part L J Mater Design Appl 234(11):1439–1449. https://doi.org/10.1177/1464420720941554

Sharma M, Bijwe J, Mitschang P (2012) Abrasive wear studies on composites of PEEK and PES with modified surface of carbon fabric. Tribol Int 44:81–91

Zhang D, Wang C, Wang QH, Wang TM (2019) High thermal stability and wear resistance of porous thermosetting heterocyclic polyimide impregnated with silicone oil. Tribol Int 140:105728–105737. https://doi.org/10.1016/j.triboint.2019.04.012

Singh AK, Gupta P, Singh PK (2018) Evaluation of mechanical and erosive wear characteristics of TiO2 and ZnO filled Bi-Directional e-glass fiber based vinyl ester composites. SILICON 10(2):309–327

Friedrich K, Chang L, Haupert F (2011) Current and future applications of polymer composites in the field of tribology. In: Nicolais L, Meo M, Miletta E (eds) Composite materials. Springer, New York, pp 129–167

Briscoe BJ, Sinha SK (2005) Tribology of polymeric solids and their composites. In: Stachowiak G (ed) Wear–materials, mechanism and practice. John Wiley & Sons, England, p 223

Kumar S, Singh KK (2019) Tribological performances of woven carbon fabric/epoxy composites under dry and oil lubrication condition: an experimental investigation. In: Singh I, Bajpai P, Panwar K (eds) Trends in materials engineering. Lecture Notes on Multidisciplinary Industrial Engineering, Springer, Singapore, p 43

Fang H, Bai Y, Liu W, Qi Y, Wang J (2019) Connections and structural applications of fibre reinforced polymer composites for civil infrastructure in aggressive environments. Compos B Eng 164:129–143. https://doi.org/10.1016/j.compositesb.2018.11.047

Friedrich K, Haupert F, Chen C, Flock J (1996) New manufacturing techniques for thermoplastic composite bearings. In: Progress in Advanced Materials and Mechanics, Proceedings of International Conference on Advanced Materials, ICAM-96, Bei**g, China, vol 1996, Peking University Press, p 91.

Mathew MT, Naveen V, Padaki LA, Rocha JR, Gomes R, Algirusamy BL et al (2007) Tribological properties of the directionally oriented warp knit GFRP composites. Wear 263:930–938. https://doi.org/10.1016/j.wear.2006.12.001

Zhang L, Qi H, Li G, Wang D, Wang T, Wang Q et al (2017) Significantly enhanced wear resistance of PEEK by simply filling with modified graphitic carbon nitride. Mater Design 129:192–200. https://doi.org/10.1016/j.matdes.2017.05.041

Zhang Y, Zhu S, Liu Y, Yang B, Wang X (2015) The mechanical and tribological properties of nitric acid-treated carbon fiber-reinforced polyoxymethylene composites. J Appl Polym Sci. https://doi.org/10.1002/app.41812

Agrawal S, Singh KK, Sarkar PK (2018) Comparative investigation on the wear and friction behaviors of carbon fiber reinforced polymer composites under dry sliding, oil lubrication and inert gas environment. Mater Today Proc 5:1250–1256. https://doi.org/10.1016/j.matpr.2017.11.208

Seydibeyoglu MO, Mohanty AK, Misra M (2017) Fiber Technology for fiber-reinforced composites, Woodhead Publishing, p 51.

Geier N, Paulo Davim J, Szalay T (2019) Advanced cutting tools and technologies for drilling carbon fibre reinforced polymer (CFRP) composites: a review. Compos Part A Appl Sci Manuf. https://doi.org/10.1016/j.compositesa.2019.105552

Poór DI, Geier N, Pereszlai C, Xu J (2021) A critical review of the drilling of CFRP composites: burr formation, characterisation and challenges. Compos Part B Eng 223:109155. https://doi.org/10.1016/j.compositesb.2021.109155

Naqvi SR, Prabhakara HM, Bramer EA, Dierkes W, Akkerman R, Brem G (2018) A critical review on recycling of end-of-life carbon fibre/glass fibre reinforced composites waste using pyrolysis towards a circular economy. Resour Conserv Recycl 136:118–129. https://doi.org/10.1016/j.resconrec.2018.04.013

Singh KK, Kumar S (2021) Tribological performance of graphene nanoplatelets filled glass/epoxy composites under dry, inert gas and oil-lubricated environmental conditions. Mater Lett 282:128881. https://doi.org/10.1016/j.matlet.2020.128881

Chang L, Zhang Z, Ye L, Friedrich K (2007) Tribological properties of high temperature resistant polymer composites with fine particles. Tribol Int 40(7):1170–1178. https://doi.org/10.1016/j.triboint.2006.12.002

Zhao F, Zhang J, Myshkin NK, Zhang G (2022) Significant friction and wear-reduction role of attapulgite nanofibers compounded in PEEK-Based materials. Compos Sci and Technol. https://doi.org/10.1016/j.compscitech.2022.109449

Zhang G, Wetzel B, Wang Q (2015) Tribological behavior of PEEK-based materials under mixed and boundary lubrication conditions. Tribol Int 88:153–161. https://doi.org/10.1016/j.triboint.2015.03.021

Friedrich K, Zhang Z, Schlarb AK (2005) Effects of various fillers on the sliding wear of polymer composites. Compos Sci Technol 65:2329–2343. https://doi.org/10.1016/j.compscitech.2005.05.028

Keller J, Fridrici V, Kapsa P, Huard JF (2009) Surface topography and tribology of cast iron in boundary lubrication. Tribol Int 42:1011–1018. https://doi.org/10.1016/j.triboint.2009.02.008

Zhao F, Gao C, Wang H, Wang T, Wetzel B, Jim B-C et al (2016) Tribological behaviors of carbon fiber reinforced epoxy composites under PAO lubrication conditions. Tribol Lett 62(3):37. https://doi.org/10.1007/s11249-016-0685-8

Zhang SW (1998) State-of-the-art of polymer tribology. Tribol Int 31:49. https://doi.org/10.1016/S0301-679X(98)00007-3

Sung NH, Suh HP (1979) Effect of fibre orientation on friction and wear of fibre reinforced polymer composites. Wear 53:129–141. https://doi.org/10.1016/0043-1648(79)90224-2

Bijwe J, Logani CM, Tewari US (1990) Influence of fillers and fiber reinforcement on abrasive wear resistance of some polym153eric composites. Wear 138(1–2):77–92. https://doi.org/10.1016/0043-1648(90)90169-B

Tewari US, Bijwe J, Mathura JN, Indu S (1992) Studies on abrasive wear of carbon fiber (short) reinforced polyamide composites. Tribol Int 29:53–60. https://doi.org/10.1016/0301-679X(92)90121-3

Bijwe J, Rattan R (2007) Influence of weave of carbon fabric in polyetherimide composites in various wear situations. Wear 263:984–991. https://doi.org/10.1016/j.wear.2006.12.030

Giltrow JP, Lancaster JK (1970) The role of the counterface in the friction and wear of carbon fibre reinforced thermosetting resins. Wear 16:359–374

Kumar S, Singh KK, Ramkumar J (2020) The effects of graphene nanoplatelets on the tribological performance of glass fiber-reinforced epoxy composites. Proc Inst Mech Eng Part J J Eng Tribol 235:1514–1525. https://doi.org/10.1177/1350650120965756

Tsukizoe T, Ohmae N (1983) Friction and wear of advanced composite-materials. Fibre Sci Technol 18(4):265–286. https://doi.org/10.1016/0015-0568(83)90021-0

Tsukizoe T, Ohmae N (1986) Friction and wear performance of unidirectionally oriented glass, carbon, aramid and stainless steel fiber-reinforced plastics. In: Friedrich K (ed) Friction and wear of polymer composites. Elsevier, Amsterdam, p 205

Aldousiri B, Shalwan A, Chin CW (2013) A review on tribological behaviour of polymeric composites and future reinforcements. Adv Mater Sci Eng 2013:1–8. https://doi.org/10.1155/2013/645923

Greenwood JA, Williamson JBP (1966) Contact of nominally flat surfaces. Proc R Soc A295:300–319. https://doi.org/10.1098/rspa.1966.0242

Agarwal G, Patnaik A, Sharma RK (2014) Thermomechanical properties and abrasive wear behavior of silicon carbide filled woven glass fiber composites. SILICON 6(3):155–168. https://doi.org/10.1007/s12633-014-9184-4

Fox M, Academy R (2016) Lube-Tech Polymer Tribology Lube-Tech. 106: 32

Stachowiak GW, Batchelor AW (2005) Engineering tribology. Butteworth Heinemann, Melbourne, Australia

Quaglini V, Dubini P (2011) Friction of polymers sliding on smooth surfaces. Adv Tribol 2011:1–8. https://doi.org/10.1155/2011/178943

Frich D, Economy J (1997) Thermally stable liquid crystalline thermosets based on aromatic copolyesters: preparation and properties. J Polym Sci Part A Polymer Chem 35:1061–1067. https://doi.org/10.1002/(SICI)1099-0518(19970430)35:6%3c1061:AID-POLA9%3e3.0.CO;2-7

Kumar S, Singh KK, Kumar S (2020) Tribological Behaviour of glass/epoxy laminated composite reinforced with graphene and MWCNT. Mater Today Proc 22:2791–2797. https://doi.org/10.1016/j.matpr.2020.03.410

Zhang J, Demas NG, Polycarpou AA, Economy J (2008) A new family of low wear, low coefficient of friction polymer blend based on polytetrafluoroethylene and an aromatic thermosetting polyester. Polym Adv Technol 19:1105–1112. https://doi.org/10.1002/pat.1086

Gaddam SK, Pothu R, Boddula R (2020) Graphitic carbon nitride (g-C3N4) reinforced polymer nanocomposite systems—a review. Polym Compos 41:430–442. https://doi.org/10.1002/pc.25410

Pıhtılı H, Tosun N (2002) Investigation of the wear behaviour of a glass fibre-reinforced composite and plain polyester resin. Compos Sci Technol 62(3):367–370. https://doi.org/10.1016/S0266-3538(01)00196-8

Demas NG, Zhang J, Polycarpou AA, Economy J (2008) Tribological characterization of aromatic thermosetting copolyester–PTFE blends in air conditioning compressor environment. Tribol Lett 29(3):253–258. https://doi.org/10.1007/s11249-008-9303-8

Kohl JG, Schwarzer N, Ngo TT, Favaro G, Rengnet E, Bierwisch N (2015) Determining the viscoelastic properties obtained by depth sensing microindentation of epoxy and polyester thermosets using a new phenomenological method. Mater Res Express 2:1–8. https://doi.org/10.1088/2053-1591/2/1/015301

Samyn P, Zsidai L (2017) Temperature effects on friction and wear of thermoset polyester fabric composites. Polym Plast Technol Eng 56(9):1003–1016. https://doi.org/10.1080/03602559.2016.1247281

Sharma N, Kumar S, Singh KK (2022) Taguchi’s DOE and artificial neural network analysis for the prediction of tribological performance of graphene nano-platelets filled glass fiber reinforced epoxy composites under the dry sliding condition. Tribo int 172:107580. https://doi.org/10.1016/j.triboint.2022.107580

Tang H, Zhou H, Cheng XH (2022) Friction process analysis of carbon fiber-carbon nanotube multiscale hybrid reinforced epoxy with excellent tribological performance. Tribol Int 171:107559

Kishore SP, Seetharamu S et al (2000) SEM observations of the effects of velocity and load on the sliding wear characteristics of glass fabric–epoxy composites with different fillers. Wear 237:20–27. https://doi.org/10.1016/S0043-1648(99)00300-2

Basavarajappa S, Ellangovan S, Arun KV (2009) Studies on dry sliding wear behaviour of graphite filled glass-epoxy composites. Mater Des 30:2670–2675. https://doi.org/10.1016/j.matdes.2008.10.013

Shivamurthy B, Udaya BK, Anandhan S (2013) Mechanical and sliding wear properties of multi-layered laminates from glass fabric/graphite/epoxy composites, https://doi.org/10.1016/j.matdes.2012.07.059.

Sen M, Sarkar P, Modak N et al (2015) Woven E-glass fiber reinforced epoxy composite preparation and woven E-glass fiber reinforced epoxy composite – preparation and tribological characterization. IJMCP 1(2):189–197

Agrawal S, Singh KK, Sarkar PK (2016) A comparative study of wear and friction characteristics of glass fiber reinforced epoxy resin, sliding under dry, oil-lubricated and inert gas environments. Tribol Int 96:217–224. https://doi.org/10.1016/j.triboint.2015.12.033

Zhang G, Burkhart T, Wetzel B (2013) Tribological behavior of epoxy composites under diesel-lubricated conditions. Wear 307(1–2):174–181. https://doi.org/10.1016/j.wear.2013.08.014

El-Tayep NS, Gadelrap RM (1996) Friction and wear properties of E-glass fiber reinforced epoxy composites under different sliding contact conditions. Wear 192:112–117. https://doi.org/10.1016/0043-1648(95)06770-1

Gao CP, Guo GF, Zhao FY et al (2016) Tribological behaviors of epoxy composites under water lubrication conditions. Tribol Int 95:333–341. https://doi.org/10.1016/j.triboint.2015.11.041

Khun NW, Zhang H, Sun DW et al (2016) Tribological behaviors of binary and ternary epoxy composites functionalized with different microcapsules and reinforced by short carbon fibers. Wear 350–351:89–98. https://doi.org/10.1016/j.wear.2016.01.007

Zhang G, Sebastian R, Burkhart T et al (2012) Role of monodispersed nanoparticles on the tribological behavior of conventional epoxy composites filled with carbon fibers and graphite lubricants. Wear 292–293:176–187. https://doi.org/10.1016/j.wear.2012.05.012

Zhang L, Zhang G, Chang L et al (2016) Distinct tribological mechanisms of silica nanoparticles in epoxy composites reinforced with carbon nanotubes, carbon fibers and glass fibers. Tribol Int 104:225–236. https://doi.org/10.1016/j.triboint.2016.09.001

Zhang G, Häusler I, Österle W et al (2015) Formation and function mechanisms of nanostructured tribofilms of epoxy-based hybrid nanocomposites. Wear 342–343:181–188. https://doi.org/10.1016/j.wear.2015.08.025

Guo QB, Rong MZ, Jia GL et al (2009) Sliding wear performance of nano-SiO2/short carbon fiber/epoxy hybrid composites. Wear 266(7–8):658–665. https://doi.org/10.1016/j.wear.2008.08.005

Pihtili H (2009) An experimental investigation of wear of glass fibre–epoxy resin and glass fibre–polyester resin composite materials. Eur Polym J 45(1):149–154. https://doi.org/10.1016/j.eurpolymj.2008.10.006

El-Tayeb NSM, Yousif BF, Yap TC (2008) An investigation on worn surfaces of chopped glass fibre reinforced polyester through SEM observations. Tribolo Int 41:331–340. https://doi.org/10.1016/j.triboint.2007.07.007

Yousif BF, El-Tayeb NSM, Yusaf TF (1998) Influence of material structure properties on sliding contact performance of CGRP composite. IJMST 10:1524–1548

Chauhan SR, Kumar A, Singh I (2009) Study on friction and sliding wear behavior of woven S-glass fiber reinforced vinylester composites manufactured with different comonomers. J Mater Sci 44:6338–6347. https://doi.org/10.1007/s10853-009-3873-1

Thakur S, Chauhan SR (2013) Taguchi method to optimize the micron and submicron size cenosphere particulates filled E-glass fiber-reinforced vinylester composites. Polym Comps 35:775–787. https://doi.org/10.1002/pc.22721

Thakur S, Chauhan SR (2014) Tribological behavior of micrometer- and submicrometer-size cenosphere particulate-filled glass fiber-reinforced vinylester composites under dry and water-lubricated sliding conditions. Tribol Trans 57(6):1007–1016. https://doi.org/10.1080/10402004.2014.928397

Viswnath B, Verma AP, Kameswara rao CVS. (1993) Effect of reinforcement on friction and wear of fabric reinforced polymer composites. Wear 167:93–99. https://doi.org/10.1016/0043-1648(93)90313-B

Fei J, Zhang C, Luo D, Yali C et al (2018) Vertically aligned TiO2nanorods-woven carbon fiber for reinforcement of both mechanical and anti-wear properties in resin composite. Appl Surf Sci 435:156–162. https://doi.org/10.1016/j.apsusc.2017.10.182

Rui H et al (2022) Influence of fiber/matrix interface on the texture evolution and fracture toughness of C/C. Diamond Relat Mater. https://doi.org/10.1016/j.diamond.2022.109112

Zhao F, Li G, Österle W, Häusler I, Zhang G, Wang T (2016) Tribological investigations of glass fiber reinforced epoxy composites under oil lubrication conditions. Tribol Int 103:208–217. https://doi.org/10.1016/j.triboint.2016.07.002

Hua Y, Li F, Hud N, Shao-Yun Fu (2022) Frictional characteristics of graphene oxide-modified continuous glass fiber reinforced epoxy composite. Compos Sci Technol 223:109446. https://doi.org/10.1016/j.compscitech.2022.109446

Funding

The author(s) received no financial support for the research, authorship, and/or publication of this article.

Author information

Authors and Affiliations

Corresponding author

Additional information

Technical Editor João Marciano Laredo dos Reis.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Kumar, S., Singh, K.K. Tribological characteristics of glass/carbon fibre-reinforced thermosetting polymer composites: a critical review. J Braz. Soc. Mech. Sci. Eng. 44, 496 (2022). https://doi.org/10.1007/s40430-022-03817-z

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s40430-022-03817-z