Abstract

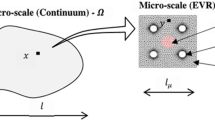

The analytical criterion proposed by Gurson is an important reference for modeling the plastic behavior of porous ductile media. However, the Gurson model assumes a simplified representative porous cell, whose morphology is formed by a ductile spherical matrix with a centered spherical void. Other limitations of this model are related to: (i) the simplified trial velocity field adopted; (ii) the disregard of the Lode angle effect due to a linearization of the microscopic dissipation. In this context, the present article explores a 3D computational homogenization approach to fill a gap in the complete geometric representation of isotropic yield surfaces of porous ductile media, relaxing the previous mentioned simplifications. A large number of numerical simulations in finite elements were carefully performed aiming to create full yield surfaces. In particular, the influence of the void morphology inserted in the ductile matrix is addressed, considering two representative volume elements (RVEs): (i) cube with a spherical void; (ii) cube with a cubic void. Spherical and cubic voids are interesting because the yield surfaces may provide reference limits for other voids with similar morphology. It is worth mentioning that the strategy allows us to investigate in detail the effect of the Lode angle on the geometry of full yield surfaces. The kinematic field provided by the numerical simulations also allows a better description of the yield surfaces for low triaxialities compared to Gurson simplified trial velocity field. The ductile matrix is governed by the von Mises model with perfect elasto-plastic behavior. Small strain hypothesis is used in the numerical analyses. The main findings are as follows. The strength of the RVE with a cubic void is lower compared to the RVE with a spherical void, especially for intermediate/high triaxialities. The Lode angle has a strong influence on the geometry of yield surfaces for intermediate triaxialities. Furthermore, yield surfaces by computational homogenization have significant differences compared to the Gurson criterion.

Similar content being viewed by others

Availability of data and materials

Not applicable.

References

McClintock FA (1968) A criterion for ductile fracture by the growth of holes. J Appl Mech 35(2):363–371

Rice JR, Tracey DM (1969) On the ductile enlargement of voids in triaxial stress fields. J Mech Phys Solids 17(3):201–217

Gurson AL (1977) Continuum theory of ductile rupture by void nucleation and growth: part I-yield criteria and flow rules for porous ductile media. J Eng Mater Technol 99:2–15

Tvergaard V (1981) Influence of voids on shear band instabilities under plane strain conditions. Int J Fract 17(4):389–407

Tvergaard V (1982) On localization in ductile materials containing spherical voids. Int J Fract 18(4):237–252

Tvergaard V, Needleman A (1984) Analysis of the cup-cone fracture in a round tensile bar. Acta Metall 32(1):157–169

Nahshon K, Hutchinson JW (2008) Modification of the Gurson model for shear failure. European J Mech - A Solids 27(1):1–17

Monchiet V, Charkaluk E, Kondo D (2011) A micromechanics-based modification of the Gurson criterion by using Eshelby-like velocity fields. European J Mech - A Solids 30(1):940–949

Eshelby JD (1957) The determination of the elastic field of an ellipsoidal inclusion, and related problems. Proc Math Phys Eng Sci 241:376–396

Eshelby JD (1959) The elastic field outside an ellipsoidal inclusion. Proc Math Phys Eng Sci 252:561–569

Benallal A, Desmorat R, Fournage M (2014) An assessment of the role of the third stress invariant in the Gurson approach for ductile fracture. European J Mech - A Solids 47:400–414

Li S, Sauer RA, Wang G (2007) The Eshelby tensors in a finite spherical domain-part I: theoretical formulations. J Appl Mech 74:770–783

Gologanu M, Leblond J-B, Devaux J (1993) Approximate models for ductile metals containing non-spherical voids-Case of axisymmetric prolate ellipsoidal cavities. J Mech Phys Solids 41(11):1723–1754

Gologanu M, Leblond J-B, Devaux J (1994) Approximate models for ductile metals containing non-spherical voids-case of axisymmetric oblate ellipsoidal cavities. J Eng Mater Technol 116(3):290–297

Madou K, Leblond J-B (2012) A Gurson-type criterion for porous ductile solids containing arbitrary ellipsoidal voids–I: limit-analysis of some representative cell. J Mech Phys Solids 60(5):1020–1036

Madou K, Leblond J-B (2012) A Gurson-type criterion for porous ductile solids containing arbitrary ellipsoidal voids–II: determination of yield criterion parameters. J Mech Phys Solids 60(5):1037–1058

Leblond J-B, Morin L (2014) Gurson’s criterion and its derivation revisited. J Appl Mech 81(5):1–7

Thoré P, Pastor F, Pastor J (2011) Hollow sphere models, conic programming and third stress invariant. European J Mech - A Solids 30(2):63–71

Cazacu O, Revil-Baudard B, Lebensohn RA, Gărăjeu M (2013) On the combined effect of pressure and third invariant on yielding of porous solids with von mises matrix. J Appl Mech 80(6):1–5

Giusti SM, Blanco PJ, Souza Neto EA, Feijóo RA (2009) An assessment of the Gurson yield criterion by a computational multi-scale approach. Eng Comput 26(3):281–301

Fritzen F, Forest S, Böhlke T, Kondo D, Kanit T (2012) Computational homogenization of elasto-plastic porous metals. Int J Plast 29:102–119

Khdir Y.-K, Kanit T, cZaïri F, Naït-Abdelaziz M (2015) A computational homogenization of random porous media: effect of void shape and void content on the overall yield surface. European J Mech - A Solids 49:137–145

Carvalho RP, Lopes IAR, Pires FMA (2018) Prediction of the yielding behaviour of ductile porous materials through computational homogenization. Eng Comput 35(2):604–621

Dæhli LEB, Hopperstad OS, Benallal A (2019) Effective behaviour of porous ductile solids with a non-quadratic isotropic matrix yield surface. J Mech Phys Solids 130:56–81

Hershey AV (1954) The plasticity of an isotropic aggregate of anisotropic face-centered cubic crystals. J Appl Mech 21:241–249

Hosford WF (1972) A generalized isotropic yield criterion. J Appl Mech 39(2):607–609

Bishop WJ F, Hill R (1951) XLVI. A theory of the plastic distortion of a polycrystalline aggregate under combined stresses, Philosophical Magazine Series 5(42): 414–427

Mandel J (1971) Plasticite classique et viscoplasticite. Springer-Verlag, Udine

Hill R (1948) A variational principle of maximum plastic work in classical plasticity the quarterly. J Mech Appl Math 1:18–28

Tekoxtildglu C, Leblond JB, Pardoen T (2012) A criterion for the onset of void coalescence under combined tension and shear. J Mech Phys Solids 60(7):1363–1381

Benallal A (2017) Constitutive equations for porous solids with matrix behaviour dependent on the second and third stress invariants. Int J Impact Eng 108:47–62

Acknowledgements

The authors would like to gratefully acknowledge Conselho Nacional de Desenvolvimento Científico e Tecnológico (CNPq) and Coordenação de Aperfeiçoamento de Pessoal de Nível Superior - Brasil (CAPES) for the research grants.

Funding

Not applicable.

Author information

Authors and Affiliations

Contributions

Not applicable.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that we have no conflict of interest.

Ethics approval

Not applicable.

Consent to participate

Not applicable.

Consent for publication

Not applicable.

Code availability

Not applicable.

Additional information

Technical Editor: Joao Marciano Laredo dos Reis.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

dos Santos, W.F., Ferreira, A.R. & Proença, S.P.B. Complete geometric representation of yield surfaces for porous ductile media by a 3D computational homogenization approach: an assessment of the Gurson yield criterion. J Braz. Soc. Mech. Sci. Eng. 44, 163 (2022). https://doi.org/10.1007/s40430-022-03483-1

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s40430-022-03483-1