Abstract

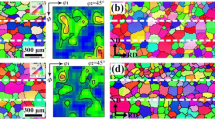

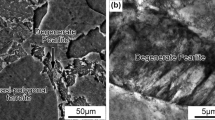

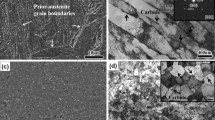

Synergic evolution of microstructure-texture-stored energy in interstitial-free (IF) steels has been investigated to elaborate the effect of dissolved rare-earth (RE) elements on static recrystallization. Grain size, texture fraction and geometrically necessary dislocation distribution of IF steel samples annealed for different times were compared, suggesting that RE elements could postpone recrystallization nucleation but accelerate grain coarsening. The visco-plastic self-consistent model was primarily adopted and verified, then used to calculate the relative activities of different slip systems. It was proved that the compatible deformation of IF steels was very sensitive to dissolved RE elements, in particular the {110}6<111>2 slip systems became extremely inactive, leading to an α-fibre textures rich configuration of RE-IF steels. Although both IF steels have the same stored energy sequence of which γ-fibre takes precedence in nucleation followed by α-fibre, the nucleation rates of α/γ-fibres driven by the reduced stored energy slowed down in RE-IF steels. Further nucleation-path analyses revealed that shear bands within γ-fibre mainly sacrificed for grain nucleation of {111}<110> orientation, while α-fibre especially prior grain boundaries therein preferred supplying nucleation sites for {554}<225> grains, which accounting for the competitive growth of γ-fibre textures in RE-IF steels rather than being dominated by a single orientation. After grain growth, the major texture of Normal-IF steels had been transferred to {554}<225> from {111}<110>, while {554}<225> in RE-IF steels still inherited the orientation advantage and grew up rapidly, thus inducing the grain coarsening. As this work offers a significant understanding of RE microalloying effect on static recrystallization, it will provide references for alloy design and industrial application of IF steels.

Similar content being viewed by others

References

S. Ghosh, S. Mula, Mater. Sci. Eng. A 646, 218 (2015)

A. Haldar, R.K. Ray, Mater. Sci. Eng. A 391, 402 (2005)

B.J. Duggan, Y.Y. Tse, G. Lam, M.A. Quadir, Mater. Manuf. Process. 26, 51 (2011)

S. Ghosh, A.K. Singh, S. Mula, P. Chanda, V.V. Mahashabde, T.K. Roy, Mater. Sci. Eng. A 684, 22 (2017)

Y. Nagataki, Y. Hosoya, ISIJ Int. 36, 451 (1996)

S. Ghosh, S. Mula, Mater. Charact. 159, 110003 (2020)

M. Oyarzábal, A. Martínez-de-Guerenu, I. Gutiérrez, Mater. Sci. Eng. A 485, 200 (2008)

M. Sánchez-Araiza, S. Godet, P.J. Jacques, J.J. Jonas, Acta Mater. 54, 3085 (2006)

A. Bodin, J. Sietsman, S. Van Der Zwaag, Metall. Mater. Trans. A 33, 1589 (2002)

H. Chen, Z.B. He, L. Lu, J. Mater. Sci. Technol. 36, 37 (2020)

J. Suharto, Y.G. Ko, Mater. Sci. Eng. A 558, 90 (2012)

R. Saha, R.K. Ray, Scr. Mater. 57, 841 (2007)

L. Zhang, Z. Chen, Y.H. Wang, G.Q. Ma, T.L. Huang, G.L. Wu, D.J. Jensen, Scr. Mater. 141, 111 (2017)

S.L. **e, Z.B. Wang, K. Lu, J. Mater. Sci. Technol. 35, 460 (2019)

A. De Paepe, J.C. Herman, P. Hekker, E.F.M. Jansen, Rev. Metall. 97, 905 (2000)

P. Juntunen, P. Karjalainen, D. Raabe, G. Bolle, T. Kopio, Metall. Mater. Trans. A 32, 1989 (2001)

W.C. Jeong, Metall. Mater. Trans. A 37, 3737 (2006)

P. Ghosh, C. Ghosh, R.K. Ray, Acta Mater. 58, 3842 (2010)

C.Y. Yang, P. Liu, Y.K. Luan, D.Z. Li, Y.Y. Li, Int. J. Fatigue 128, 105193 (2019)

H.H. Liu, P.X. Fu, H.W. Liu, Y.F. Cao, C. Sun, N.Y. Du, D.Z. Li, J. Mater. Sci. Technol. 50, 245 (2020)

D.Z. Li, P. Wang, X.Q. Chen, P.X. Fu, Y.K. Luan, X.Q. Hu, H.W. Liu, M.Y. Sun, Y. Chen, Y.F. Cao, L.G. Zheng, J.Z. Gao, Y.T. Zhou, L. Zhang, X.L. Ma, C.L. Dai, C.Y. Yang, Z.H. Jiang, Y. Liu, Y.Y. Li, Nat. Mater. 21, 1137 (2022)

R.X. Yang, X. Cai, L.G. Zheng, X.Q. Hu, D.Z. Li, Acta Metall. Sin-Engl. Lett. (2022). https://doi.org/10.1007/s40195-022-01467-7

J.C. Yang, C.Q. Yang, X.J. Liu, Z. Jian, Forg. Stamp. Technol. 39, 91 (2014)

H. Wang, Y.P. Bao, C.Y. Duan, L. Lu, Y. Liu, Q. Zhang, Materials 13, 1473 (2020)

M. Mehdi, Y. He, E.J. Hilinski, A. Edrisy, Metall. Mater. Trans. A 50, 3343 (2019)

R. Tuttle, Int. J. Metalcast. 6, 51 (2012)

E.O. Hall (ed.), The Deformation and Aging of Mild Steel (1951)

M. Mehdi, Y.L. He, E.J. Hilinski, L.A.I. Kestens, A. Edrisy, Steel Res. Int. 90, 1800582 (2019)

J.T. Park, J.A. Szpunar, Acta Mater. 51, 3037 (2003)

D. Dorner, S. Zaefferer, D. Raabe, Acta Mater. 55, 2519 (2007)

H.J. Gao, Y.G. Huang, Scr. Mater. 48, 113 (2003)

W. Oliferuk, M. Maj, Eur. J. Mech. A-Solids 28, 266 (2009)

J.F. Nye, Acta Mater. 1, 153 (1953)

W. Oliferuk, S.P. Gadaj, M.W. Grabski, Mater. Sci. Eng. A 70, 131 (1985)

G.X. Hu, Z. Cai, Y.H. Rong (eds.), Fundamentals of Materials Science, 3rd edn. (Shanghai Jiaotong University Press, Shanghai, 2010), pp. 172–178

W. Oliferuk, M. Maj, Eur. J. Mech. A-Solid 28, 266 (2009)

W.M. Mao, P. Yang (ed.), Material Science Pricoples on Electrical Steels, 1st edn. (Higher Education Press, Bei**g, 2013), Chapter 3.2

C. Tome, R. Lebensohn (ed.), Material Modeling with the Visco-Plastic Self-Consistent (VPSC) Approach-Theory and Practical Applications, 1st edn. ISBN: 9780128207130 (2023)

Y. Rika, T. Ichiro, I. Tsuyoshi, S. Tadashi, ISIJ Int. 34, 70 (1994)

S.S. Hazra, A.A. Gazder, E.V. Pereloma, Mater. Sci. Eng. A 524, 158 (2009)

B.J. Duggan, M.Z. Quadir, Y.Y. Tse, K. Shen, G.L. Liu, Q.Z. Chen, Mater. Sci. Forum 558, 61 (2007)

M. Mehdi, Y.L. He, E.J. Hilinski, L.A.I. Kestens, A. Edrisy, Acta Mater. 185, 540 (2020)

A. Samet-Meziou, A.L. Etter, T. Baudin, R. Penelle, Scr. Mater. 53, 1001 (2005)

S.H. Choi, Acta Mater. 51, 1775 (2003)

Y.H. Guo, Z.D. Wang, L.Q. Wei, J. Mater. Eng. Perform. 23, 1214 (2014)

Acknowledgements

This work was financially supported by the National Natural Science Foundation of China under Grant Nos. 52101165, 52031013, 52071322 and U1708252, the Key Research Program of the Chinese Academy of Sciences, Grant No. ZDRW-CN-2021-3 and the supporting project, Grant No. KFG-2018107. The authors express their gratitude to C.N. Tomé (Material Science and Technology Division, Los Alamos National Laboratory) for providing the VPSC code to conduct the simulations.

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

The authors state that there are no conflicts of interest to disclose.

Additional information

Available online at http://springer.longhoe.net/journal/40195.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Liu, P., Hou, X., Yang, C. et al. Synergic Evolution of Microstructure-Texture-Stored Energy in Rare-Earth-Added Interstitial-Free Steels Undergoing Static Recrystallization. Acta Metall. Sin. (Engl. Lett.) 36, 661–680 (2023). https://doi.org/10.1007/s40195-022-01492-6

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40195-022-01492-6