Abstract

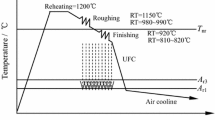

The effects of various cooling paths on uniformity of through-thickness microstructure and mechanical properties of X80 pipeline steel of 22.0 mm in thickness were studied. The finite difference method was employed to calculate the temperature field during cooling. It was confirmed by the experimental result and temperature field calculation that the optimizing process was achieved by the ultra-fast cooling with medium cooling capacity (cooling rate of ~23 K/s) followed by ultimate cooling capacity (cooling rate of ~50 K/s). After optimization, the experimental steel displayed much uniform microstructure and the deviation of through-thickness hardness was controlled within 20 HV. In addition, the yield strength, tensile strength and elongation of the experimental steel were 621, 728 MPa and 21.5%, respectively, meeting the requirements of the API standard for X80 pipeline steels.

Similar content being viewed by others

References

N. Sanchez-Mourino, R. Petrov, J.H. Bae, K. Kim, L.A.I. Kestens, Steel Res. Int. 82, 352 (2011)

S.Y. Shin, Metall. Mater. Trans. A 44, 2613 (2013)

S.Y. Han, S.Y. Shin, S. Lee, N.J. Kim, J.H. Bae, K. Kim, Metall. Mater. Trans. A 41, 329 (2010)

J.Q. Sun, H. Dai, Y.C. Zhang, Mater. Des. 32, 1612 (2011)

M. Zhou, L.X. Du, X.H. Liu, Acta Metall. Sin. (Engl. Lett.) 23, 171 (2010)

W. Deng, X.H. Gao, X.M. Qin, X. Gao, D.W. Zhao, L.X. Du, Acta Metall. Sin. 46, 959 (2010). (in Chinese)

F. Zhou, K.M. Wu, W. Zhou, M. Matrosov, J. Coast. Res. SI, 443 (2015)

X.G. Zhou, Z.Y. Liu, S.Y. Song, D. Wu, G.D. Wang, J. Iron. Steel Res. Int. 21, 86 (2014)

S.S. Mohapatra, S.V. Ravikumar, S.K. Pal, S. Chakraborty, Steel Res. Int. 84, 229 (2013)

F. Zhou, K.M. Wu, C. Zhang, O. Isayev, P.D. Hodgson, Steel Res. Int. 87, 511 (2016)

Y. Tian, Q. Li, Z.D. Wang, G.D. Wang, J. Mater. Eng. Perform. 24, 3307 (2015)

X.L. Chen, G.D. Wang, Y. Tian, B.X. Wang, G. Yuan, Z.D. Wang, J. Iron. Steel Res. Int. 21, 481 (2014)

S. Serajzadeh, Appl. Math. Model. 27, 861 (2003)

S.X. Zhou, J. Mater. Process Tech. 134, 338 (2003)

C.H. Moon, Y. Lee, Int. J. Heat Mass Trans. 55, 310 (2012)

N. Sanchez, N. Ilic, M. Liebeherr, in Proceedings of the 9th International Pipeline Conference, (Calgary, Alberta, Canada) 24–28 Sep 2013

W. Deng, X.H. Gao, X.M. Qin, D.W. Zhao, L.X. Du, G.D. Wang, Acta Metall. Sin. 46, 533 (2010). (in Chinese)

L.Y. Zhao, Y. Wei, Y.Y. Shan, K. Yang, J. Iron. Steel Res. Int. 18, 312 (2011)

C.N. Li, G. Yuan, F.Q. Ji, D.S. Ren, G.D. Wang, Mater. Sci. Eng. A 665, 98 (2016)

R. Song, D. Ponge, D. Raabe, Acta Mater. 53, 4881 (2005)

N. Tsuji, S. Okuno, Y. Koizumi, Y. Minamino, Mater. Trans. 45, 2272 (2004)

J. Kang, C.N. Li, G. Yuan, G.D. Wang, Mater. Lett. 175, 157 (2016)

D.L. Bourell, Metall. Trans. A 14, 2487 (1983)

D.L. Bourell, O.D. Sherby, Metall. Trans. A 14, 2563 (1983)

M.S. Joo, D.W. Suh, J.H. Bae, H.K.D.H. Bhadeshia, Mater. Sci. Eng. A 546, 314 (2012)

X.L. Yang, Y.B. Xu, X.D. Tan, D. Wu, Mater. Sci. Eng. A 641, 96 (2015)

R. Song, D. Ponge, D. Raabe, J.G. Speer, D.K. Madock, Mater. Sci. Eng. A 441, 1 (2006)

Acknowledgements

This work was financially supported by the National Natural Science Foundation of China (No. 51234002) and the Fundamental Research Funds for the Central Universities (N130407001).

Author information

Authors and Affiliations

Corresponding author

Additional information

Available online at http://springer.longhoe.net/journal/40195.

Rights and permissions

About this article

Cite this article

Li, XD., Li, CN., Yuan, G. et al. Effects of Cooling Paths on Through-Thickness Microstructure and Mechanical Properties of Heavy Gauge X80 Pipeline Steel. Acta Metall. Sin. (Engl. Lett.) 30, 483–492 (2017). https://doi.org/10.1007/s40195-017-0557-8

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40195-017-0557-8