Abstract

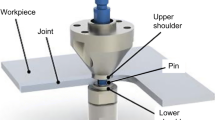

Different defects of the upper stationary shoulder bobbin tool friction stir welding (SSUBTFSW) were identified in this study, and the Coupled Eulerian–Lagrangian model of SSUBTFSW was used to illustrate the forming mechanism of groove defect. Defects can be classified into groove, crack, and flash, which form simultaneously under excessive heat, while only the groove appears under lower heat during processing. There is a layered asymmetrical material flow from lower to upper surfaces, leading to a groove at the edge of the probe on the advancing side of the joint. Increasing rotation speed and decreasing welding speed reduce the groove defect to the point of elimination. The groove defect size goes through minimum value with the increase of the side tilt angle and the reactive forces of the upper stationary shoulder.

Similar content being viewed by others

Data availability

The datasets generated during and/or analyzed during the current study are available from the corresponding author on reasonable request.

References

Tan MJ, Wu CS, Su H (2023) Ultrasonic effects on microstructures and mechanical properties of friction stir weld joints of dissimilar AA2024/AZ31B alloys. Weld World 67:373–384. https://doi.org/10.1007/s40194-022-01429-8

Meng XC, Huang YX, Cao J, Shen JJ, dos Santos JF (2021) Recent progress on control strategies for inherent issues in friction stir welding. Prog Mater Sci 115:100706. https://doi.org/10.1016/j.pmatsci.2020.100706

Meng XC, **e YM, Ma XT, Liang MY, Peng XY, Han SW, Kan L, Wang X, Chen SH, Huang YX (2023) Towards friction stir remanufacturing of high-strength aluminum components. Acta Metall Sin-Engl 36(1):91–102. https://doi.org/10.1007/s40195-022-01444-0

Fu BL, Shen JJ, Suhuddin UFHR, Pereira AAC, Maawad E, dos Santos JF, Klusemann B, Rethmeier M (2021) Revealing joining mechanism in refill friction stir spot welding of AZ31 magnesium alloy to galvanized DP600 steel. Mater Design 209:109997. https://doi.org/10.1016/j.matdes.2021.109997

Fu BL, Shen JJ, Suhuddin UFHR, Chen T, dos Santos JF, Klusemann B, Rethmeier M (2023) Improved mechanical properties of cast Mg alloy welds via texture weakening by differential rotation refill friction stir spot welding. Scripta Mater 203:114113. https://doi.org/10.1016/j.scriptamat.2021.114113

Liu Z, Guan W, Li HJ, Wang DP, Cui L (2022) Study on the relationship between welding force and defects in bobbin tool friction stir welding. J Manuf Process 84:1122–1132. https://doi.org/10.1016/j.jmapro.2022.10.069

Li GH, Chen T, Fu BL, Shen JJ, Bergmann L, Zhou L, Chen K, dos Santos JF, Klusemann B (2023) Semi-stationary shoulder bobbin-tool: A new approach in tailoring macrostructure and mechanical properties of bobbin-tool friction stir welds in magnesium alloy. J Mater Process Tech 317:117984. https://doi.org/10.1016/j.jmatprotec.2023.117984

Lampeas GN, Diamantakos ID (2015) Effects of nonconventional tools on the thermo-mechanical response of friction stir welded materials. J Manuf Sci Eng 137(5):051020. https://doi.org/10.1115/1.4029857

Lafly AL, Alléhaux D, Marie F, Donne C, Biallas G (2006) Microstructure and mechanical properties of the aluminum alloy 6056 welded by friction stir welding techniques. Weld World 50:98–106. https://doi.org/10.1007/BF03263466

Maltin C, Nolton L, Scott J, Toumpis A, Galloway A (2014) The potential adaptation of stationary shoulder friction stir welding technology to steel. Mater Design 64:614–624. https://doi.org/10.1016/j.matdes.2014.08.017

Wu H, Chen YC, Strong D, Prangnell P (2015) Stationary shoulder FSW for joining high strength aluminum alloy. J Mater Process Tech 221:187–196. https://doi.org/10.1016/j.jmatprotec.2015.02.015

Zhou ZL, Yue YM, Ji SD, Li ZW, Zhang L (2017) Effect of rotating speed on joint morphology and lap shear properties of stationary shoulder friction stir lap welded 6061–T6 aluminum alloy. Int J Adv Manuf Tech 88:2135–2141. https://doi.org/10.1007/s00170-016-8924-6

Hilgert J, dos Santos JF, Huber N (2012) Numerical simulation in bobbin tool FSW process development. Proceedings of the 9th International Symposium on Friction Stir Welding, TWI, Cambridge, UK

Scupin P (2015) Semi-stationary shoulder bobbin tool (S3BT): a new approach in high speed friction stir welding. Technischen Universität Hamburg-Harburg, These

Liu HJ, Hou JC, Guo H (2013) Effect of welding speed on microstructure and mechanical properties of self-reacting friction stir welded 6061–T6 aluminum alloy. Mater Design 50:872–878. https://doi.org/10.1016/j.matdes.2013.03.105

Goebel J, Reimann M, Norman A, Dos Santos JF (2017) Semi-stationary shoulder bobbin tool friction stir welding of AA2198-T851. J Mater Process Tech 245:37–45. https://doi.org/10.1016/j.jmatprotec.2017.02.011

Chauhan P, Jain R, Pal SK, Singh SB (2018) Modeling of defects in friction stir welding using coupled Eulerian and Lagrangian method. J Manuf Process 34:158–166. https://doi.org/10.1016/j.jmapro.2018.05.022

Al-Badour F, Merah N, Shuaib A, Bazoune A (2013) Coupled Eulerian Lagrangian finite element modeling of friction stir welding processes. J Mater Process Tech 213(8):1433–1439. https://doi.org/10.1016/j.jmatprotec.2013.02.014

Cao JY, Wang M, Kong L, Yin YH, Guo LJ (2017) Numerical modeling and experimental investigation of material flow in friction spot welding of Al 6061–T6. Int J Adv Manuf Tech 89:2129–2139. https://doi.org/10.1007/s00170-016-9247-3

Gu C, Yang X, Tang W, Luo T, Wang R (2022) Softening behavior of stationary shoulder friction stir welded joint for thick-plate Al-Li-Cu alloy. J Mater Res Technol 20:3008–3024. https://doi.org/10.1016/j.jmrt.2022.08.060

Wen Q, Li WY, Gao YJ, Yang J, Wang FF (2019) Numerical simulation and experimental investigation of band patterns in bobbin tool friction stir welding of aluminum alloy. Int J Adv Manuf Tech 100:9–12. https://doi.org/10.1007/s00170-018-2750-y

Podržaj P, Jerman B, Klobčar D (2015) Welding defects at friction stir welding. Metalurgija 54(2):387–389

Moussawi M, Smith AJ (2018) Defects in friction stir welding of steel. Metallogr Microstruct Anal 7:194–202. https://doi.org/10.1007/s13632-018-0438-1

Kim YG, Fujii H, Tsumura T, Komazaki T (2006) Three defect types in friction stir welding of aluminum die casting alloy. Mat Sci Eng A 415(1–2):250–254. https://doi.org/10.1016/j.msea.2005.09.072

Okamoto K, Sato A, Park SHC, Hirano S (2012) Microstructure and mechanical properties of FSWed aluminum extrusion with bobbin tools. Mater Sci Forum 706:990–995. https://doi.org/10.4028/www.scientific.net/MSF.706-709.990

Acknowledgements

Quan Wen would like to acknowledge the China Scholarship Council (No. 201806290070) for the financial support.

Funding

China Scholarship Council,201806290070,quan wen. Project of Key Areas of Innovation Team in Shaanxi Province, 2024RS-CXTD-20.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Recommended for publication by Commission III - Resistance Welding, Solid State Welding, and Allied Joining Process

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Quan, W., Wenya, L., **aogang, D. et al. Clarify the forming mechanism and affecting factors of defects in semi-stationary shoulder bobbin tool friction stir welding. Weld World 68, 1783–1790 (2024). https://doi.org/10.1007/s40194-024-01707-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40194-024-01707-7