Abstract

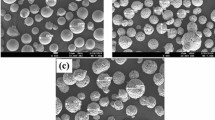

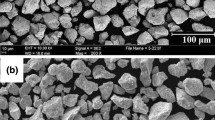

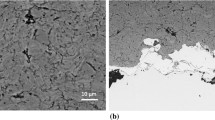

Surface protection is crucial in industrial equipment and tools to prevent wear and friction in harsh environments, particularly at high temperatures, where anti-friction coatings are essential for optimal performance. The present research investigates the tribological properties of high-velocity oxy-fuel sprayed coatings of 17-4PH stainless steel reinforced with tungsten carbide and chromium carbide powders. The coatings are deposited onto a maraging steel substrate. A dry sliding wear test was performed using an alumina ball as a counter body under various test temperatures (25 °C, 300 °C, and 600 °C) and loads (10 N and 30 N). The coating is characterized by employing SEM, XRD, micro-hardness tester, particle analyzer, and bond strength tester, and the mechanism of wear reduction was discussed. The post-wear analysis was carried out on the wear track using SEM/EDS and 3D non-contact optical profilometers. The micro-hardness and bond strength of both (17-4PH-30%WC-Co and 17-4PH-30%Cr3C2) coatings are compared. The test results revealed that at all temperatures and loads, 17-4PH-30%WC-Co coating shows better wear resistance and lower friction coefficient than the 17-4PH-30%Cr3C2 coating. The significant influence of the tribo-oxide layer at high temperatures, which contributed to decreasing wear rate and coefficient of friction, was premeditated.

Similar content being viewed by others

References

He Y, Yang K, Qu W et al (2002) Strengthening and toughening of a 2800-MPa grade maraging steel. Mater Lett 56:763–769. https://doi.org/10.1016/S0167-577X(02)00610-9

Limited WP (2012) 11 11.1. https://doi.org/10.1533/9780857095152.232

Cajner F, Landek D, Leskovšek V (2010) Surface modifications of maraging steels used in the manufacture of moulds and dies. Mater Tehnol 44:101–107

** G, Cai Z, Guan Y et al (2018) High temperature wear performance of laser-cladded FeNiCoAlCu high-entropy alloy coating. Appl Surf Sci 445:113–122. https://doi.org/10.1016/j.apsusc.2018.03.135

Behera N, Medabalimi S, Ramesh MR (2023) Effect of impact angles and temperatures on the solid particle erosion behavior of HVOF sprayed WC-Co/NiCr/Mo and Cr3C2-CoNiCrAlY coatings. J Therm Spray Technol. https://doi.org/10.1007/s11666-023-01654-7

Behera N, Medabalimi SR, Ramesh MR (2023) Elevated temperatures erosion wear behavior of HVOF sprayed WC-Co-Cr/Mo coatings on Ti6Al4V substrate. Surf Coat Technol 470:129809. https://doi.org/10.1016/J.SURFCOAT.2023.129809

Wu JH, Lin CK (2003) Influence of high temperature exposure on the mechanical behavior and microstructure of 17-4 PH stainless steel. J Mater Sci 38:965–971. https://doi.org/10.1023/A:1022377225704

Wang J, Zou H, Li C et al (2008) The spinodal decomposition in 17-4PH stainless steel subjected to long-term aging at 350 °C. Mater Charact 59:587–591. https://doi.org/10.1016/j.matchar.2007.04.018

Sidhu TS, Prakash S, Agrawal RD (2006) Characterisations of HVOF sprayed NiCrBSi coatings on Ni- and Fe-based superalloys and evaluation of cyclic oxidation behaviour of some Ni-based superalloys in molten salt environment. Thin Solid Films 515:95–105. https://doi.org/10.1016/j.tsf.2005.12.041

Chavana N, Bhajantri FV, Jambagi SC (2022) Improvement in slurry erosion and corrosion resistance of plasma-sprayed fly ash coatings for marine applications. ACS Omega 7:32369–32382. https://doi.org/10.1021/acsomega.2c03800

Rao MS (2021) Solid particle erosion behavior of partially oxidized Al with NiCr composite coating at elevated temperature. J Mater Eng Perform. https://doi.org/10.1007/s11665-021-05668-6

Jagadeeshanayaka N, Awasthi S, Jambagi SC, Srivastava C (2022) Bioactive surface modifications through thermally sprayed hydroxyapatite composite coatings: a review of selective reinforcements. Biomater Sci. https://doi.org/10.1039/d2bm00039c

Hu Y, Wang Z, Pang M (2022) Effect of WC content on laser cladding Ni-based coating on the surface of stainless steel. Mater Today Commun 31:103357. https://doi.org/10.1016/j.mtcomm.2022.103357

Srinath GSMRRMS (2022) Development of self-lubricating nickel based composite clad using microwave heating in improving resistance to wear at elevated temperatures. Met Mater Int 28:2000–2011. https://doi.org/10.1007/s12540-021-01078-4

Nath G (2018) Studies on slurry erosion behavior of HVOF applied Y2O3-added WC–10Co–4Cr cermet on 13-4 martensitic stainless steel. Metallogr Microstruct Anal 7:133–142. https://doi.org/10.1007/s13632-018-0426-5

Purushotham N, Parthasarathi NL, Babu PS et al (2023) Effect of thermal expansion on the high temperature wear resistance of Ni-20% Cr detonation spray coating on IN718 substrate. Surf Coat Technol 462:129490. https://doi.org/10.1016/j.surfcoat.2023.129490

Ksiazek M, Boron L, Tchorz A (2019) Microstructure, mechanical properties and wear behavior of high-velocity oxygen-fuel (HVOF) sprayed (Cr3C2-NiCr+Al) composite coating on ductile cast iron. Coatings 9. https://doi.org/10.3390/coatings9120840

Zhou W, Zhou K, Deng C et al (2017) Hot corrosion behaviour of HVOF-sprayed Cr3C2-NiCrMoNbAl coating. Surf Coat Technol 309:849–859. https://doi.org/10.1016/j.surfcoat.2016.10.076

Zapico P, Giganto S, Barreiro J, Martínez-Pellitero S (2020) Characterisation of 17-4PH metallic powder recycling to optimise the performance of the selective laser melting process. J Mater Res Technol 9:1273–1285. https://doi.org/10.1016/j.jmrt.2019.11.054

Pasebani S, Ghayoor M, Badwe S et al (2018) Effects of atomizing media and post processing on mechanical properties of 17-4 PH stainless steel manufactured via selective laser melting. Addit Manuf 22:127–137. https://doi.org/10.1016/j.addma.2018.05.011

Murr LE, Martinez E, Hernandez J et al (2012) Microstructures and properties of 17-4 PH stainless steel fabricated by selective laser melting. J Mater Res Technol 1:167–177. https://doi.org/10.1016/S2238-7854(12)70029-7

Kultamaa M, Kari M (2022) Self-lubrication of porous metal injection molded (MIM) 17-4PH stainless steel by impregnated paraffin wax. Tribol Int 174. https://doi.org/10.1016/j.triboint.2022.107735

Lin X, Cao Y, Wu X et al (2012) Microstructure and mechanical properties of laser forming repaired 17-4PH stainless steel. Mater Sci Eng A 553:80–88. https://doi.org/10.1016/j.msea.2012.05.095

Walczak M, Szala M (2021) Effect of shot peening on the surface properties, corrosion and wear performance of 17-4PH steel produced by DMLS additive manufacturing. Arch Civ Mech Eng 21:1–20. https://doi.org/10.1007/s43452-021-00306-3

Quinn TFJ, Sullivan JL, Rowson DM (1984) Origins and development of oxidational wear at low ambient temperatures. Wear 94:175–191. https://doi.org/10.1016/0043-1648(84)90053-X

DellaCorte C (1996) The effect of counterface on the tribological performance of a high temperature solid lubricant composite from 25 to 650°C. Surf Coatings Technol 86–87:486–492. https://doi.org/10.1016/S0257-8972(96)02959-3

Emami S, Jafari H, Mahmoudi Y (2019) Effects of combustion model and chemical kinetics in numerical modeling of hydrogen-fueled dual-stage HVOF system. J Therm Spray Technol 28:333–345. https://doi.org/10.1007/s11666-019-00826-8

Medabalimi SR, Ananthu MR, Gudala S, Ramesh MR (2022) Effect of microwave hybrid heating on high-temperature adhesive wear behavior of high-velocity oxygen fuel-sprayed WC-CrC-Ni and WC-Co/NiCrFeSiB coatings. J Mater Eng Perform. https://doi.org/10.1007/s11665-022-07756-7

Purushotham N, Rajasekaran B, Parthasarathi NL et al (2022) Sliding wear behaviour of Ni-5%Al coating deposited by detonation spray on IN718. Mater Today Proc 65:3741–3747. https://doi.org/10.1016/j.matpr.2022.06.425

Ghahabi E, Shajari Y, Razavi M et al (2020) Effect of iron content on the wear behavior and adhesion strength of TiC–Fe nanocomposite coatings on low carbon steel produced by air plasma spray. Ceram Int 46:2670–2676. https://doi.org/10.1016/J.CERAMINT.2019.09.255

Sue JA, Tucker RC (1987) High temperature erosion behavior tungsten- and chromium-carbide-based coatings. Surf Coat Technol 32:237–248. https://doi.org/10.1016/0257-8972(87)90110-1

Mishra TK, Kumar A, Sinha SK (2021) Experimental investigation and study of HVOF sprayed WC-12Co, WC-10Co-4Cr and Cr3C2-25NiCr coating on its sliding wear behaviour. Int J Refract Met Hard Mater 94. https://doi.org/10.1016/j.ijrmhm.2020.105404

Kaur M, Singh H, Prakash S (2009) High-temperature corrosion studies of HVOF-sprayed Cr3C2-NiCr coating on SAE-347h boiler steel. J Therm Spray Technol 18:619–632. https://doi.org/10.1007/s11666-009-9371-9

Chivavibul P, Watanabe M, Kuroda S, Shinoda K (2007) Effects of carbide size and Co content on the microstructure and mechanical properties of HVOF-sprayed WC-Co coatings. Surf Coat Technol 202:509–521. https://doi.org/10.1016/j.surfcoat.2007.06.026

Pattnayak A, Gupta A, Abhijith NV et al (2023) Development of rGO doped alumina-based wear and corrosion resistant ceramic coatings on steel using HVOF thermal spray. Ceram Int 49:17577–17591. https://doi.org/10.1016/j.ceramint.2023.02.124

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Recommended for publication by Commission I - Additive Manufacturing, Surfacing, and Thermal Cutting

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Chandramouli, T.V., Joladarashi, S., Ramesh, M.R. et al. Effect of temperature on wear and friction performance of WC-Co and Cr3C2 reinforced with 17-4PH Fe-based composite coatings. Weld World 68, 91–105 (2024). https://doi.org/10.1007/s40194-023-01628-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40194-023-01628-x