Abstract

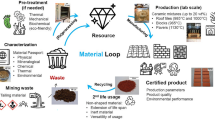

World is bestowed with self-sufficient magnetite and hematite iron ores. Huge volume of mining waste, namely iron ore tailings (IOT), is generated during processing of iron ore, leading to environmental concerns. At the same time, due to excessive usage and environmental regulations, there is scarcity of naturally available granular material. This paper presents the detailed laboratory study carried out to ascertain the feasibility of adopting iron ore tailings as an alternate granular backfill material in mechanically stabilized earth wall. A comprehensive study on mineralogical, physiochemical, and geotechnical characteristics was carried out on IOT procured from Lakhya dam, Chikkamagaluru district, Karnataka, India. X-ray fluorescence study indicates the presence of silica as major mineral along with hematite as major iron-bearing mineral. IOT is classified as a poorly graded sand with high friction angle value varying between 44° and 50° under loose and dense states and negligible particle breakage under compaction. The environmental risk connected with IOT was assessed through leaching studies and it was characterized as low contamination low ecological risk material. Design of mechanically stabilized earth (MSE) wall with IOT and granular soil as backfill using tie-back wedge method revealed that identical number of reinforcement layers are required when iron ore tailing or granular soil is used as backfill. Further, finite element modeling of MSE wall with IOT and river sand as backfill was carried out to compare the deformation behavior. MSE wall with IOT as backfill showed 70% reduction in horizontal facing displacement in comparison with sand backfill.

Similar content being viewed by others

Data Availability

The data from the study are available from corresponding author on request.

References

Frey PA, Reed GH (2012) The ubiquity of iron. ACS Chem Biol 7:1477–1481. https://doi.org/10.1021/cb300323q

Swamy K, Suresh N, Sharath Kumar P (2022) Resource management and utilization of lean grade iron ore resources of Karnataka, India. J Mines Met Fuels. https://doi.org/10.18311/jmmf/2022/29942

Chaturvedi N, Patra HK (2016) Iron ore mining, waste generation, environmental problems and their mitigation through phytoremediation technology. Int J Sci Res Methodol 5:397–420

Singh RK, Pal D, Signh SK et al (2021) Utilization of iron ore tailings for brick manufacture from donimalai mines of Karnataka, India. J Sci Ind Res (India) 80:210–220

Piciullo L, Storrøsten EB, Liu Z et al (2022) A new look at the statistics of tailings dam failures. Eng Geol. https://doi.org/10.1016/j.enggeo.2022.106657

Vacca S, Capra GF, Banov M et al (2008) Possibilities for reclamation of disturbed environments in the mining district of Vratza, Northwestern Bulgaria. In: Dazzi C, Costantini E (eds) soils tomorrow soils. Catena Verlag, Stuttgart, pp 669–684

Simeoni L, Tosatti G, Lucchi G, Longo M (2017) The Stava catastrophic failure of July 19, 1985 (Italy): technical-scientific data and socioeconomic aspects. CSE-City Saf Energy 1985:17–30

Li C, Sun H, Bai J, Li L (2010) Innovative methodology for comprehensive utilization of iron ore tailings. Part 1. The recovery of iron from iron ore tailings using magnetic separation after magnetizing roasting. J Hazard Mater 174:71–77. https://doi.org/10.1016/j.jhazmat.2009.09.018

Hatje V, Pedreira RMA, De Rezende CE et al (2017) The environmental impacts of one of the largest tailing dam failures worldwide. Sci Rep 7:1–13. https://doi.org/10.1038/s41598-017-11143-x

Silva Rotta LH, Alcântara E, Park E et al (2020) The 2019 Brumadinho tailings dam collapse: possible cause and impacts of the worst human and environmental disaster in Brazil. Int J Appl Earth Obs Geoinf. https://doi.org/10.1016/j.jag.2020.102119

Sarkar B, Ullah M, Sarkar M (2022) Environmental and economic sustainability through innovative green products by remanufacturing. J Clean Prod 332:129813. https://doi.org/10.1016/j.jclepro.2021.129813

Salehi S, Arashpour M, Kodikara J, Guppy R (2021) Sustainable pavement construction: a systematic literature review of environmental and economic analysis of recycled materials. J Clean Prod 313:127936. https://doi.org/10.1016/j.jclepro.2021.127936

Shettima AU, Hussin MW, Ahmad Y, Mirza J (2016) Evaluation of iron ore tailings as replacement for fine aggregate in concrete. Constr Build Mater 120:72–79. https://doi.org/10.1016/j.conbuildmat.2016.05.095

Tang K, Mao XS, Wu Q et al (2020) The concrete performance with iron tailings sand modified by polypropylene fibers under aggressive environment. Adv Mater Sci Eng. https://doi.org/10.1155/2020/4368592

Lv X, Shen W, Wang L et al (2019) A comparative study on the practical utilization of iron tailings as a complete replacement of normal aggregates in dam concrete with different gradation. J Clean Prod 211:704–715. https://doi.org/10.1016/j.jclepro.2018.11.107

Yellishetty M, Karpe V, Reddy EH et al (2008) Reuse of iron ore mineral wastes in civil engineering constructions: a case study. Resour Conserv Recycl 52:1283–1289. https://doi.org/10.1016/j.resconrec.2008.07.007

Zhao S, Fan J, Sun W (2014) Utilization of iron ore tailings as fine aggregate in ultra-high performance concrete. Constr Build Mater 50:540–548. https://doi.org/10.1016/j.conbuildmat.2013.10.019

Li J, Tian Y, Sun Q, Pan C (2015) Research on iron ore tailing improving compressive strength of alkali-activated slag foamed concrete. In 5th Int Confer Civil Eng Trans, pp 1371–1375. https://doi.org/10.2991/iccet-15.2015.256

Das SK, Kumar S, Ramachandrarao P (2000) Exploitation of iron ore tailing for the development of ceramic tiles. Waste Manag 20:725–729. https://doi.org/10.1016/S0956-053X(00)00034-9

Modi JV, Sujeet B, Aruna M, Harsha V (2014) Utilization of mining wastes in manufacturing of bricks

Behera K, Bose BP, Mondal MK (2019) Production of construction bricks using iron ore tailings and clay. Waste Manag Resour Effic. https://doi.org/10.1007/978-981-10-7290-1_49

Chen Y, Zhang Y, Chen T et al (2011) Preparation of eco-friendly construction bricks from hematite tailings. Constr Build Mater 25:2107–2111. https://doi.org/10.1016/j.conbuildmat.2010.11.025

Kuranchie FA, Shukla SK, Habibi D, Kazi M (2016) Load-settlement behaviour of a strip footing resting on iron ore tailings as a structural fill. Int J Min Sci Technol 26:247–253. https://doi.org/10.1016/j.ijmst.2015.12.010

Ojuri OO, Adavi AA, Oluwatuyi OE (2017) Geotechnical and environmental evaluation of lime–cement stabilized soil–mine tailing mixtures for highway construction. Transp Geotech 10:1–12. https://doi.org/10.1016/j.trgeo.2016.10.001

Barati S, Tabatabaie Shourijeh P, Samani N, Asadi S (2020) Stabilization of iron ore tailings with cement and bentonite: a case study on Golgohar mine. Bull Eng Geol Environ 79:4151–4166. https://doi.org/10.1007/s10064-020-01843-6

Etim RK, Eberemu AO, Osinubi KJ (2017) Stabilization of black cotton soil with lime and iron ore tailings admixture. Transp Geotech 10:85–95. https://doi.org/10.1016/j.trgeo.2017.01.002

Bandyopadhyay TS, Chakrabortty P, Hegde A (2023) Seismic performance of mechanically stabilized earth walls with sand-crumb rubber backfills of varying proportion. Constr Build Mater 389:131717. https://doi.org/10.1016/j.conbuildmat.2023.131717

Yu Y, Bathurst RJ, Miyata Y (2015) Numerical analysis of a mechanically stabilized earth wall reinforced with steel strips. Soils Found 55:536–547. https://doi.org/10.1016/j.sandf.2015.04.006

Guler E, Hamderi M, Demirkan MM (2007) Numerical analysis of reinforced soil-retaining wall structures with cohesive and granular backfills. Geosynth Int 14:330–345. https://doi.org/10.1680/gein.2007.14.6.330

Arefnia A, Dehghanbanadaki A, Kassim KA (2021) Sustainable implementation of recycled tire-derived aggregate as a lightweight backfill for retaining walls. KSCE J Civ Eng 25:4196–4206. https://doi.org/10.1007/s12205-021-0218-3

Malik M, Soni NK, Kanagasabapathy KV et al (2016) Characterisation of fly ash from coal-fired thermal power plants using energy dispersive X-Ray fluorescence spectrometry. Sci Rev Chem Commun 6:91–101

IS 2720–4 (1985) Methods of Test for Soils, part 4: grain size analysis. Bureau of Indian standards, Reaffirmed, pp 1–38

IS 1498 (1970) Classification and identification of soils for general engineering purposes. Bureau of Indian standards, pp 1–28

ASTM D2487 (2011) Standard practice for classification of soils for engineering purposes (unified soil classification system). ASTM international. https://doi.org/10.1520/D2487-11

IS 2720-3 (1980) Determination of specific gravity. Bureau of Indian standards. https://doi.org/10.1093/jaoac/20.3.535

IS 2720–21 (1977) Methods of test for soils, part XXI: determination of total soluble solids. Bureau of Indian standards

Agarwal A, Ramana GV, Datta M et al (2022) Environmental assessment of unprocessed sand-sized construction & demolition waste for geotechnical reuse. J Clean Prod 363:132504. https://doi.org/10.1016/j.jclepro.2022.132504

AASHTO T-267 (2009) Standard method of test for determination of organic content in soils by loss on ignition (AASHTO T267). vol 86, pp 1–4

FHWA-NHI-10–024 (2010) Design and construction of mechanically stabilized earth walls and reinforced soil slopes—geotechnical engineering circular No. 11. vol 2, pp 1–404

IS:2720–7 (1980) Methods of test for soils, determination of water content dry density relation using light compaction. Bureau of Indian standards, pp 1–16

Arulrajah A, Naeini M, Mohammadinia A et al (2020) Recovered plastic and demolition waste blends as railway cap** materials. Transp Geotech 22:100320. https://doi.org/10.1016/j.trgeo.2020.100320

IS 2720–17 (1986) Methods of test for soils, part 17: laboratory determination of permeability. Bureau of Indian standards

IS 2720–13 (1997) Method of test for soils, part 13 direct shear test. Bureau of Indian standards

Krieger J, Thamm BR (1991) Studies of failure mechanisms and design methods for geotextile-reinforced soil walls. Geotext geomembranes, vol 10, pp 53–63. https://doi.org/10.1016/0266-1144(91)90017-Q

Liu CN, Ho YH, Huang JW (2009) Large scale direct shear tests of soil/PET-yarn geogrid interfaces. Geotext Geomembr 27:19–30. https://doi.org/10.1016/j.geotexmem.2008.03.002

ASTM D5321 (2019) Standard test method for determining the shear strength of soil-geosynthetic and geosynthetic-geosynthetic interfaces by direct shear. ASTM Int, pp 1–11. https://doi.org/10.1520/D5321-12.2

Jewell RA (1989) Direct shear tests on sand. Geotechnique 39:309–322. https://doi.org/10.1680/geot.1989.39.2.309

En BS (2002) 12457–2, Characterisation of waste–leaching–compliance test for leaching of granular waste materials and sludges. Br stand UK

Vieira CS, Pereira PM, Lopes MDL (2016) Recycled construction and demolition wastes as filling material for geosynthetic reinforced structures. Int Prop J Clean Prod 124:299–311. https://doi.org/10.1016/j.jclepro.2016.02.115

Pant A, Datta M, Ramana GV (2019) Bottom ash as a backfill material in reinforced soil structures. Geotext Geomembr 47:514–521. https://doi.org/10.1016/j.geotexmem.2019.01.018

ASTM D4972 (2019) Standard test method for pH of soils. ASTM Int. https://doi.org/10.1520/D4972-19.2

ASTM D4327 (2019) Standard test method for anions in water by suppressed ion chromatography. ASTM Int. https://doi.org/10.1520/D4327-17.2

Hakanson L (1980) An ecological risk index for aquatic pollution control.a sedimentological approach. Water Res 14:975–1001. https://doi.org/10.1016/0043-1354(80)90143-8

Abrahim GMS, Parker RJ (2008) Assessment of heavy metal enrichment factors and the degree of contamination in marine sediments from Tamaki Estuary, Auckland, New Zealand. Environ Monit Assess 136:227–238. https://doi.org/10.1007/s10661-007-9678-2

Yadav A, Kumar Yadav P (2018) Pollution load index (PLI) of field irrigated with wastewater of Mawaiya Drain in Naini suburbs of Allahabad District. Curr World Environ 13:159–164. https://doi.org/10.12944/cwe.13.1.15

Leão LP, Da CRDVF, Leite MGP et al (2021) Distribution and assessment of trace elements contamination in sediments of conceição river basin, brazil. Geosci 11:1–16. https://doi.org/10.3390/geosciences11060236

Hu P, Zhang Y, Zhou Y et al (2018) Preparation and effectiveness of slow-release silicon fertilizer by sintering with iron ore tailings. Environ Prog Sustain Energy 37:1011–1019. https://doi.org/10.1002/ep.12776

Das P, Matcha B, Hossiney N et al (2020) Utilization of iron ore mines waste as civil construction material through geopolymer reactions. Geopolym Other Geosynth. https://doi.org/10.5772/intechopen.81709

Carmignano OR, Vieira SS, Teixeira APC et al (2021) Iron ore tailings: characterization and applications. J Braz Chem Soc 32:1895–1911. https://doi.org/10.21577/0103-5053.20210100

Yu J, Han Y, Li Y, Gao P, Sun Y (2017) Separation and recovery of iron from a low-grade carbonate-bearing iron ore using magnetizing roasting followed by magnetic separation. Sep Sci Technol Taylor & Francis 52:1768–1774

FDOT (2019) Florida department of transportation standard specifications for road and bridge construction July 2019

NVDOT (2014) Nevada DOT standard specification for road and bridge construction 2014

Geoguide 6 (2002) Guide to reinforced fill structure and slope design. Geotech Eng Off Hong Kong, China pp 1–239

BS 8006 (1995) Code of practice for strengthened/reinforced soils and other fills

IRC: SP:102 (2014) Guidelines for design and construction of reinforced soil walls

Hu L, Wu H, Zhang L et al (2017) Geotechnical properties of mine tailings. J Mater Civ Eng 29:04016220. https://doi.org/10.1061/(asce)mt.1943-5533.0001736

Song XR, Gao JL, Qu JY (2008) Experimental study on physical and mechanical properties of GRC formwork. Bei**g Gongye Daxue XuebaoJ Bei**g Univ Technol 34:708–713

Prasad PS, Ramana GV (2016) Feasibility study of copper slag as a structural fill in reinforced soil structures. Geotext Geomembr 44:623–640. https://doi.org/10.1016/j.geotexmem.2016.03.007

Prasad PS, Ramana GV (2016) Imperial smelting furnace (zinc) slag as a structural fill in reinforced soil structures. Geotext Geomembr 44:406–428. https://doi.org/10.1016/j.geotexmem.2016.01.009

Indraratna B, Nutalaya P, Koo KS, Kuganenthira N (1991) Engineering behaviour of a low carbon, pozzolanic fly ash and its potential as a construction fill. Can Geotech J 28:542–555. https://doi.org/10.1139/t91-070

Ashfaq M, Heeralal M, Moghal AAB (2020) Characterization studies on coal gangue for sustainable geotechnics. Innov Infrastruct Solut 5:1–12. https://doi.org/10.1007/s41062-020-0267-3

Gopal Ranjan ASRR (1991) Basic and applied soil mechanics. Wiley Eastern

Elhakim AF (2016) Estimation of soil permeability. Alexandria Eng J 55:2631–2638. https://doi.org/10.1016/j.aej.2016.07.034

Nicholson PG (2014) Chapter 14—geosynthetic reinforced soil

Bakeer RM, Sayed SM, Cates P, Subramanian R (1998) Pullout and shear tests on geogrid reinforced lightweight aggregate. Geotext Geomembr 16:119–133. https://doi.org/10.1016/S0266-1144(97)10025-5

Tatlisoz N, Edil TB, Benson CH (1998) Interaction between reinforcing geosynthetics and soil-tire chip mixtures. J Geotech Geoenviron Eng 124:1109–1119. https://doi.org/10.1061/(asce)1090-0241(1998)124:11(1109)

Al-amoudi OSB (1992) Effect of chloride and sulfate contamination in soils on corrosion of steel and concrete. Pp 67–73

Pant A, Ramana GV, Datta M, Gupta SK (2019) Coal combustion residue as structural fill material for reinforced soil structures. J Clean Prod 232:417–426. https://doi.org/10.1016/j.jclepro.2019.05.354

Kasharina TP (2016) Calculated justification of reinforced soil structures in the design and construction of transport systems. Procedia Eng 150:2308–2314. https://doi.org/10.1016/j.proeng.2016.07.307

Dobie M (2021) Reinforced soil retaining walls - an outline of design methods and sources of conservatism (in English )

PWD (Vol-1) 2021–2022 Karnataka schedule of rates (Vol-1). PWD 5–24

Hatami K, Bathurst RJ (2005) Development and verification of a numerical model for the analysis of geosynthethic-reinforced soil segmental walls under working stress conditions. Can Geotech J 42:1066–1085. https://doi.org/10.1139/t05-040

Smith M (2012) ABAQUS/standard user’s manual, version 6.12

Mandloi P, Sarkar S, Hegde A (2022) Performance assessment of mechanically stabilised earth walls with sustainable backfills. Proc Inst Civ Eng Eng Sustain 175:302–318. https://doi.org/10.1680/jensu.22.00012

Kerry Rowe R, Skinner GD (2001) Numerical analysis of geosynthetic reinforced retaining wall constructed on a layered soil foundation. Geotext Geomembranes 19:387–412. https://doi.org/10.1016/S0266-1144(01)00014-0

Funding

Not applicable.

Author information

Authors and Affiliations

Contributions

All authors conceived and designed the study. Material preparation, experiments were performed by First Author and first draft of the manuscript was prepared by all authors. All authors commented on the manuscript and approved the manuscript.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no potential conflict of interest to declare.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Satheesh, A., Gangaputhiran, S. & Packiam, S. Comprehensive Assessment on Utilization of Iron Ore Tailing as Backfill Material in Mechanically Stabilized Earth Wall. Indian Geotech J (2024). https://doi.org/10.1007/s40098-024-01001-9

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s40098-024-01001-9