Abstract

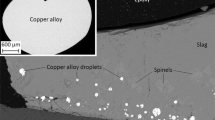

The recycling of household aluminium waste metals will be very effective and efficient only when a proper process of recycling is chosen. This paper is an attempt to provide a non-traditional method of utilising the exothermic heat of different Al sources (from automobiles, appliances, windows and doors and other products) for recycling and producing ferrotitanium alloy. Titania slag (75% TiO2) produced from carbothermic reduction of low-grade ilmenite (50% TiO2) and its produced fine dust from top dome are taken as a feed material. Aluminothermic processing of fine dust gives a possibility in the direction of ferrotitanium, followed by the successful execution with titania slag, which include smelting of titania slag with household Al scrap chips and lime in a thermal plasma reactor. The alloy formation is supported with characteristic properties of XRD and FESEM.

Similar content being viewed by others

References

Ilmenite:Indian Rare Earths Limited. http://www.irel.co.in/content/1472_1_Ilmenite.aspx

A.K. Mohanty, V. Vijayan, D. Sengupta, S.K. Das, S.K. Saha, Geochemical characteristics of ilmenite sands Of Chhatrapur Beach placer deposit of Odisha, India: a PIXE study. Int. J. PIXE 13(03–04), 121–131 (2003). https://doi.org/10.1142/s0129083503000178

C. Sasikumar, D.S. Rao, S. Srikanth, B. Ravikumar, N.K. Mukhopadhyay, S.P. Mehrotra, Effect of mechanical activation on the kinetics of sulfuric acid leaching of beach sand ilmenite from Odisha, India. Hydrometallurgy 75(1–4), 189–204 (2004). https://doi.org/10.1016/j.hydromet.2004.08.001

T.K.G. Namboodhiri, Titanium-metal of the gods. Executive knowledge lines 7(7), pp11–14 (2012)

G. Lütjering, J.C. Williams, Titanium (Springer, Berlin, 2007)

B.P. Bhardwaj, F. Chrome, The complete book on ferroalloys. NIIR Proj. Consult. Serv., p. 387 (2014). 2nd Edn. ISBN: 9789381039298

M. Pourabdoli, S. Raygan, H. Abdizadeh, K. Hanaei, A new process for the production of ferrotitanium from titania slag. Can. Metall. Q. 46(1), 17–23 (2007). https://doi.org/10.1179/000844307794535614

M. Mohammadaliha, F. Shahri, S. Boutorabi, The Role of Ferrotitanium as an Inoculant on the microstructure and mechanical properties oflow-alloy steel. J. Test. Eval (2019). https://doi.org/10.1520/JTE20180838

Ferro-titanium prices breach $6 per kg on high end| Metal Bulletin.com. https://www.metalbulletin.com/Article/3832426/TITANIUM-SNAPSHOT-Ferro-titanium-prices-breach-6-per-kg-on-high-end.html

N.G. Bernard, J.M. Bultitude-Paull, Production of ferrotitanium by aluminothermic reduction. WO2013029119A1 (2013)

R. Warrings, J. Fellner, Current status of circularity for aluminum from household waste in Austria. Waste Manag. 76, 217–224 (2018). https://doi.org/10.1016/j.wasman.2018.02.034

G.H. Nijhof, Aluminium separation out of household waste using the Eddy current technique and re-use of the metal fraction. Resour. Conserv. Recycl. 10(1), 161–169 (1994). https://doi.org/10.1016/0921-3449(94)90049-3

F. Cardarelli, Method for electrowinning of titanium metal or alloy from titanium oxide containing compound in the liquid state. US7504017B2 (2009)

V.M. Sokolov, Y.N. Voitenkov, V.G. Lisenko, V.D. Babyuk, Study of the possibility of ferrotitanium production from ilmenite concentrate in esr furnace. in 9-th World Conference on Titanium, Russia, Saint Petersburg (1999)

M. Panigrahi, R.K. Paramguru, R.C. Gupta, E. Shibata, T. Nakamura, An overview of production of titanium and an attempt to titanium production with Ferro-Titanium. High Temp. Mater. Process. (2010). https://doi.org/10.1515/htmp.2010.29.5-6.495

Z. Gao, G. Cheng, H. Yang, X. Xue, J. Ri, Preparation of Ferrotitanium using ilmenite with different reduction degrees. Metals 9(9), 962 (2019)

S. Samal, B.K. Mohapatra, P.S. Mukherjee, S.K. Chatterjee, Integrated XRD, EPMA and XRF study of ilmenite and titania slag used in pigment production. J. Alloys Compd. 474(1–2), 484–489 (2009)

S. Samal, P.S. Mukherjee, T.K. Mukherjee, Thermal plasma processing of ilmenite: a review. Miner. Process. Extr. Metall. 119(2), 116–123 (2010)

P.S. Mukherjee, S. Samal, T.K. Mukherjee, In-flight thermal plasma processing of pre-reduced ilmenite. Trans. Indian Inst. Met. 59(3), 353–358 (2006)

YuE Tokach, YuK Rubanov, O.V. Doroganova, Extraction of metals from wastes of metallurgical production. Solid State Phenom. 284, 845–849 (2018). https://doi.org/10.4028/www.scientific.net/SSP.284.845

J. Chae, J.-M. Oh, S. Yoo, J.-W. Lim, Eco-friendly pretreatment of titanium turning scraps and subsequent preparation of Ferro-Titanium ingots. Korean J. Met. Mater. 57(9), 569–574 (2019)

O. Takeda, T.H. Okabe, Current status of titanium recycling and related technologies. JOM 71(6), 1981–1990 (2019)

Acknowledgments

The first author (Janakiram) sincerely thanks “The Board of Research in Nuclear Sciences” (DAE) for Senior Research Fellowship Grant under Raja Ramanna Fellow Scheme to carry out the research work.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Janakiram, V., Jayasankar, K., Babu, T.D. et al. An Innovative Approach of Recycling Aluminium Scrap for Ferrotitanium Production. J. Inst. Eng. India Ser. D 101, 7–13 (2020). https://doi.org/10.1007/s40033-020-00218-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40033-020-00218-1