Abstract

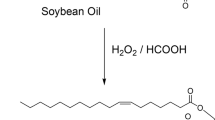

Fossil fuel-derived products have produced environmental concerns due to their non-degradability. Now a days, low-cost, renewable, and biodegradable products are being used to replace such non-degradable petroleum-based polymeric materials. So, in this study, soybean oil-derived polyols and sodium alginate have been used to develop antimicrobial polyurethane dispersions for textiles. These polyurethane dispersions have been synthesized via prepolymer method using cycloaliphatic diisocyanate and soybean oil polyol followed by chain extension using different mole ratios of sodium alginate/1,4-butnediol. The route of polyurethane dispersions synthesis was analyzed using Attenuated Total Reflectance based Fourier Transform Infrared (ATR-FT-IR) spectrophotometer. The physical properties of synthesized dispersions, such as solid contents and stabilities, were studied before applying it on the fabrics. After applying these dispersions on fabrics, the tensile strengths and tear strengths were studied following standard methods for textile testing. The results have shown improvement in the tensile strengths (ISO No. 13934–2) on warp and weft sides of treated fabrics from 857.56 to 938.79 N/m and 599.76 to 755.13 N/m, respectively as concentration of sodium alginate was increased. However, tear strength (ISO 13937–2) gradually decreased on warp and weft sides from 12.82 to 11.52 lbf/in and 10.29 to 9.06 lbf/in, respectively as concentration of sodium alginate was increased. Fastness properties were rated following the ISO methods for washing (3–4/5), rubbing (dry rubbing 3–4/5 and wet rubbing 2–3/4), and pilling test (2/3–4/5) also exhibited promising results when compared with untreated ones. The anti-microbial activities of treated fabrics were also improved as concentration of sodium alginate was increased in polyurethane dispersions. Hence, these polyurethane dispersions can be a suitable environmental friendly alternative to petroleum-based textile finishes.

Similar content being viewed by others

References

Adekunle KF (2015) A review of vegetable oil-based polymers: synthesis and applications. Open J Polym Chem 5:34–40

Adhvaryu A, Liu Z, Erhan S (2005) Synthesis of novel alkoxylated triacylglycerols and their lubricant base oil properties. Ind Crops Prods 21:113–119

Alagi P, Ghorpade R, Jang JH, Patil C, Jirimali H, Gite V, Hong SC (2018) Controlled hydroxyl functionality of soybean oil-based polyols for polyurethane coatings with improved anticorrosion properties. Macromol Res 26:696–703

Anastas P, Warner J (2008) Green chemistry: theory and practice 2000. Oxford university press: oxford). In: Polshettiwar V, Varma Rs, Chem Soc Rev. 37: 1546

Arshad N, Zia KM, Jabeen F, Anjum MN, Akram N, Khosa MK (2018) Performance behavior of chitosan based water dispersible polyurethanes: physicochemical properties. Fiber Polym 19:2219–2228

Asghar T, Javid A, Zia KM, Tabasum S (2024) Green synthesis of polyurethanes using soybean oil-based polyols for bioactive functional fabrics. Arab J Sci Eng 49(1):531–545

Borrelle SB et al (2020) Predicted growth In plastic waste exceeds efforts to mitigate plastic pollution. Sci 369(6510):1515–1518

Chan YY, Ma C, Zhou F, Hu Y, Schartel B (2021) Flame retardant flexible polyurethane foams based on phosphorous soybean-oil polyol and expandable graphite. Polym Degrad Stab 191:109656

Chavan VP, Patwardhan AV, Gogate PR (2012) Intensification of epoxidation of soybean oil using sonochemical reactors. Chem Eng Process 54:22–28

Chen J, De Liedekerke BM, Gyurik L, Dorresteijn J, Otte M, Gebbink RJK (2019) Highly efficient epoxidation of vegetable oils catalyzed by a manganese complex with hydrogen peroxide and acetic acid. Green Chem 21:2436–2447

Clark AJ, Hoong SS (2014) Copolymers of tetrahydrofuran and epoxidized vegetable oils: application to elastomeric polyurethanes. Polym Chem 5:3238–3244

Cunha FOVD, Melo DHR, Veronese VB, Forte MMC (2004) Study of castor oil polyurethane-poly (methyl methacrylate) semi-interpenetrating polymer network (sipn) reaction parameters using a 23 factorial experimental design. Mater Res 7:539–543

Dieterich D (1981) Aqueous emulsions, dispersions and solutions of polyurethanes; synthesis and properties. Prog Org Coat 9:281–340

Eryuruk SH, Kalaoğlu F (2015) The effect of weave construction on tear strength of woven fabrics. Autex Res J 15(3):207–214

Garrison TF, Kessler MR, Larock RC (2014) Effects of unsaturation and different ring-opening methods on the properties of vegetable oil-based polyurethane coatings. Polym 55:1004–1011

Germán-Ayuso L, Cuevas JM, Seoane-Rivero R, Navarro R, Marcos-Fernández A, Vilas-Vilela JL (2023) Improving the performance of biobased polyurethane dispersion by the incorporation of photo-crosslinkable coumarin. J Coat Technol Res 20(5):1677–1690

Geyer R, Jambeck JR, Law KL (2017) Production, use, and fate of all plastics ever made. Sci adv 3:e1700782

Gruber KJN (2018) Cleaning up our future. Health 555:S20–S22

Guelcher SA, Gallagher KM, Didier JE, Klinedinst DB, Doctor JS, Goldstein AS, Wilkes GL, Beckman EJ, Hollinger JO (2005) Synthesis of biocompatible segmented polyurethanes from aliphatic diisocyanates and diurea diol chain extenders. Acta Biomater 1:471–484

Guo A, Cho Y, Petrović ZS (2000) Structure and properties of halogenated and nonhalogenated soy-based polyols. J Polym Sci 38:3900–3910

Hu L, Luo D, Wang L, Yu M, Zhao S, Wang Y, Mei S, Zhang G (2021) Levels and profiles of persistent organic pollutants in breast milk in china and their potential health risks to breastfed infants: a review. Sci Total Environ 753:142028

Jasińska I (2009) Assessment of a fabric surface after the pilling process based on image analysis. Fibres Text East Eur 17(2):73

John J, Bhattacharya M, Turner RB (2002) Characterization of polyurethane foams from soybean oil. J Appl Polym Sci 86:3097–3107

Karadag R (2023) Cotton dyeing with cochineal by just in time extraction, mordanting, dyeing, and fixing method in the textile industry. J Nat Fibers 20(1):1–11

Kiatsimkul PP, Suppes GJ, Hsieh FH, Lozada Z, Tu YC (2008) Preparation of high hydroxyl equivalent weight polyols from vegetable oils. Ind Crops Prod 27:257–264

Kim HJ, Hong JP, Kim MJ, Kim SY, Kim JH, Kwon DJ (2022) Improving the digital to garment inkjet printing properties of cotton by control the butyl acrylate content of the surface treatment agent. Appl Surf Sci 583:152322

Lathi PS, Mattiasson B (2007) Green approach for the preparation of biodegradable lubricant base stock from epoxidized vegetable oil. Appl Catal b: Environ 69:207–212

Lee KY, Mooney DJ (2012) Alginate: properties and biomedical applications. Prog Polym Sci 37:106–126

Li F, Hanson M, Larock R (2001) Soybean oil–divinylbenzene thermosetting polymers: synthesis, structure, properties and their relationships. Polym 42:1567–1579

Liu Y, **e J, Wu N, Wang L, Ma Y, Tong J (2019) Influence of silane treatment on the mechanical, tribological and morphological properties of corn stalk fiber reinforced polymer composites. Tribol Int 131:398–405

Madbouly SA, Otaigbe JU (2009) Recent advances in synthesis, characterization and rheological properties of polyurethanes and poss/polyurethane nanocomposites dispersions and films. Prog Polym Sci 34:1283–1332

Mathiesen L, Buerki-Thurnherr T, Pastuschek J, Aengenheister L, Knudsen LE (2021) Fetal exposure to environmental chemicals; insights from placental perfusion studies. Placenta 106:58–66

Mielewski DF, Flanigan CM, Perry C, Zaluzec MJ, Killgoar PC (2005) Soybean oil auto applications: develo** flexible polyurethane foam formulations containing functionalized soybean oil for automotive applications. Ind Biotechnol 1:32–34

Misbah BIA, Zia KM, Bhatti HN, Shahid M (2019) Synthesis, biological efficiency evaluation and application of sodium alginate-based polyurethane dispersions using cycloaliphatic isocyanate, as antibacterial textile coating. J Ind Text 50(10):1625–1642

Mucci VL, Ivdre A, Buffa JM, Cabulis U, Stefani PM, Aranguren MI (2018) Composites made from a soybean oil biopolyurethane and cellulose nanocrystals. Polym Eng Sci 58:125–132

Mucci VL, Hormaiztegui ME, Amalvy JI, Aranguren MI (2024) Formulation, structure and properties of waterborne polyurethane coatings: a brief review. J Adhes Sci Technol 38(4):489–516

Mumtaz F, Zuber M, Zia KM, Jamil T, Hussain R (2013) Synthesis and properties of aqueous polyurethane dispersions: influence of molecular weight of polyethylene glycol. Korean J Chem Eng 30(12):2259–2263

Muzaffar S, Bhatti IA, Zuber M, Bhatti HN, Shahid M (2018) Synthesis and characterization of aqueous chitosan-polyurethanes dispersion for textile applications with multipurpose performance profile. Text Res J 19:587–598

Muzaffar S, Abbas M, Siddiqua U, Arshad M, Tufail A, Ahsan M, Alissa S, Abubshait S, Abubshait H, Iqbal M (2021) Enhanced mechanical, uv protection and antimicrobial properties of cotton fabric employing nanochitosan and polyurethane based finishing. J Mater Res Technol 11:946–956

Naeem F, Asim F, Tufail M (2022) Performance evaluation of anti pilling and easy-care finished rayon and rayon/cotton satin fabric. J Nat Fibers 19:1033–1047

Nagle DJ, Celina M, Rintoul L, Fredericks PM (2007) Infrared microspectroscopic study of the thermo-oxidative degradation of hydroxy-terminated polybutadiene/isophorone diisocyanate polyurethane rubber. Polym Degrad Stab 92:1446–1454

Naidu R, Biswas B, Willett IR, Cribb J, Singh BK, Nathanail CP, Coulon F, Semple KT, Jones KC, Barclay A (2021) Chemical pollution: a growing peril and potential catastrophic risk to humanity. Environ Int 156:106616

Naveed T, Babar AA, Rashdi SY, Rehman F, Naeem MA, Wang W, Abbas M, Ramzan MB (2021) Dyeing and colorfastness properties of tencel fabric treated with natural dye extracted from orange peel. Surf Rev Lett 28:2050055

Patti A, Costa F, Perrotti M, Barbarino D, Acierno D (2021) Polyurethane impregnation for improving the mechanical and the water resistance of polypropylene-based textiles. Mater 14:1951

Petrović ZS, Zhang W, Javni I (2005) Structure and properties of polyurethanes prepared from triglyceride polyols by ozonolysis. Biomacromol 6:713–719

Rahman MM, Haque TMA, Sourav NS, Rahman S, Yesmin S, Mia R, Begum K (2021) Synthesis and investigation of dyeing properties of 8-hydroxyquinoline-based azo dyes. J Iran Chem Soc 18(4):817–826

Rayung M, Abd Ghani N, Hasanudin N (2024) A review on vegetable oil-based non isocyanate polyurethane: towards a greener and sustainable production route. RSC Adv 14(13):9273–9299

Sahoo S, Mohanty S, Nayak SK (2018) Biobased polyurethane adhesive over petroleum based adhesive: use of renewable resource. J Macromol Sci 55:36–48

Shumilina J, Soboleva A, Abakumov E, Shtark OY, Zhukov VA, Frolov A (2023) Signaling in legume–rhizobia symbiosis. Int J Mol Sci 24(24):17397

Sidra TS, Zia KM, Parveen B, Shahid M (2022) Polyurethane dispersions prepared from vegetable oil and their application as textile finishes. Text Res J 92(23–24):4639–4651

Singh Y, Singh NK, Sharma A. (2024) Biolubricants: Feedstocks, catalysts, and nanotechnology (Vol. 1). Walter de Gruyter GmbH & Co KG

Stradolini P, Gryczak M, Petzhold CL (2024) Polyols from castor oil (ricinus communis) and epoxidized soybean oil (glycine max) for application as a lubricant base. J Am Oil Chem Soc 101(3):321–334

Sultan M, Zia KM, Bhatti HN, Jamil T, Hussain R, Zuber M (2012) Modification of cellulosic fiber with polyurethane acrylate copolymers. part i: physicochemical properties. Carbohyd Polym 87:397–404

Suppes GJ, Dasari MA (2003) Synthesis and evaluation of alkyl nitrates from triglycerides as cetane improvers. Ind Eng Chem Res 42:5042–5053

Szycher M (1999) Szycher’s handbook of polyurethanes. Crc Press, Boca Raton

Tabasum S, Zuber M, Jabbar A, Zia KM (2013a) Properties of the modified cellulosic fabrics using polyurethane acrylate copolymers. Carbohyd Polym 94:866–873

Tabasum S, Zuber M, Jamil T, Shahid M, Hussain R (2013b) Antimicrobial and pilling evaluation of the modified cellulosic fabrics using polyurethane acrylate copolymers. Int J Biol Macromol 56:99–105

Tan S, Abraham T, Ference D, Macosko CW (2011) Rigid polyurethane foams from a soybean oil-based polyol. Polym 52:2840–2846

Uprety BK, Reddy JV, Dalli SS, Rakshit SK (2017) Utilization of microbial oil obtained from crude glycerol for the production of polyol and its subsequent conversion to polyurethane foams. Bioresour Technol 235:309–315

Vinod A, Sanjay M, Suchart S, Jyotishkumar P (2020) Renewable and sustainable biobased materials: an assessment on biofibers, biofilms, biopolymers and biocomposites. J Clean Prod 258:120978

Wang Z, Walker GW, Muir DC, Nagatani-Yoshida K (2020) Toward a global understanding of chemical pollution: a first comprehensive analysis of national and regional chemical inventories. J Environ Sci Technol 54:2575–2584

Wang CS, Zhang J, Wang H, He M, Ding L, Zhao WW (2021) Simultaneously improving the fracture toughness and flame retardancy of soybean oil-based waterborne polyurethane coatings by phosphorus-nitrogen chain extender. Ind Crop Prod 163:113328

Witkowska B, Frydrych I (2004) A Comparative analysis of tear strength methods. Fibre Text East Eur 12(2):42–47

** T, Jianqing H (2006) Preparation and characterization of two-component waterborne polyurethane comprised of water-soluble acrylic resin and hdi biuret. Chines J Chem Eng 14:99–104

Yagci M, Bolca S, Heuts J, Ming W, De With G (2011) Self-stratifying antimicrobial polyurethane coatings. Prog Org Coat 72:305–314

Zaghloul S, El-Shafie A, El-Bisi M, Refaie R (2017) Herbal textile finishes–natural antibacterial finishes for cotton fabric. Egypt J Chem 60:161–180

Zayed M, Ghazal H, Othman H, Hassabo AG (2022) Psidium guajava leave extract for improving ultraviolet protection and antibacterial properties of cellulosic fabrics. Biointerf Res Appl Chem 12:3811–3835

Zhao H, Zhang K, Fang K, Shi F, Pan Y, Sun F, Chen W (2022) Insights into coloration enhancement of mercerized cotton fabric on reactive dye digital inkjet printing. Rsc Advanc 12(17):10386–10394

Zlatanić A, Lava C, Zhang W, Petrović ZS (2004) Effect of structure on properties of polyols and polyurethanes based on different vegetable oils. J Polym Sci Part b: Polym Phy 42:809–819

Zuber M, Shah SAA, Jamil T, Asghar MI (2014) Performance behavior of modified cellulosic fabrics using polyurethane acrylate copolymer. Int J Biol Macromol 67:254–259

Acknowledgements

The authors are very thankful to the Department of Applied Chemistry, GCUF, Punjab, Pakistan for providing facilities to accomplish the present project successfully.

Author information

Authors and Affiliations

Corresponding author

Additional information

Editorial responsibility: Maryam Shabani.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Asghar, T., Zia, K.M., Rehman, F.U. et al. Synthesis and characterization of isophorone diisocyanate based environmental friendly antimicrobial polyurethane dispersions for textile applications. Int. J. Environ. Sci. Technol. (2024). https://doi.org/10.1007/s13762-024-05813-3

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s13762-024-05813-3