Abstract

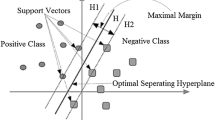

This paper presents an efficient approach to diagnose defects in various components of bearings in rotating machines using vibration signature analysis. This Automated fault investigation scheme (AFI) method integrates the Fisher Score (FS) and Genetic algorithm (GA) feature selection methods and an efficient hyperparameter tunned model with Support Vector Machine (SVM) classifier to accurately classify defects in rolling ball bearings. This approach ensures accurate classification of bearing defects through the simple machine learning models within a reduced computation time. This work is carried out with recorded vibration signals from a laboratory experimental setup on Machine Fault Simulator (MFS), focusing on rolling ball bearings with defects in inner race, outer race and ball itself, especially focusing on the combined faults. Statistical analysis based on both time and frequency domain is employed to compute feature vectors for fault investigation in ball bearings using machine learning models. The computed results demonstrate that the proposed feature selection method with hyperparameter tuning achieved remarkable maximum accuracy with 97% in FS and 99% in GA with SVM classifier. Notably, these models accuracies improved with feature selection algorithms as compared to the normal model computation. Consequently, the testing loss using this hyperparameter tuning function remains very low. Overall, this paper compares the results of time and frequency domain analysis and introduces a promising approach for both efficient and accurate fault detection in bearings of rotating machines, potentially reducing the need for extensive manpower and sensor usage. The outcomes of this study can be used to develop efficient intelligent health monitoring schemes for industrial machines that can help in smooth and cost-effective operation.

Similar content being viewed by others

Data availability

The data underlying the analysis of this study is recorded in the Institute’s department laboratory and will be made available as per request.

References

Yadav, O.P., Pahuja, G.L.: Bearing health assessment using time domain analysis of vibration signal. Int. J. Image, Graph. Sig. Process. 12(3), 27–40 (2020). https://doi.org/10.5815/ijigsp.2020.03.04

Jain, P.H., Bhosle, S.P.: A review on vibration signal analysis techniques used for detection of rolling element bearing defects. Int. J. Mech. Eng. 8(1), 14–29 (2021). https://doi.org/10.14445/23488360/ijme-v8i1p103

Kumar, N., Satapathy, R.K.: Bearings in aerospace, application, distress, and life: a review. J. Fail. Anal. Prev. 23(3), 915–947 (2023). https://doi.org/10.1007/s11668-023-01658-z

Choudhary, A., Goyal, D., Shimi, S.L., Akula, A.: Condition monitoring and fault diagnosis of induction motors: a review. Arch. Comput Methods Eng. 26(4), 1221–1238 (2019). https://doi.org/10.1007/s11831-018-9286-z

Yang, Y., Fu, P., He, Y.: Bearing fault automatic classification based on deep learning. IEEE Access 6, 71540–71554 (2018). https://doi.org/10.1109/ACCESS.2018.2880990

Singh, P., Harsha, S.P.: Statistical and frequency analysis of vibrations signals of roller bearings using empirical mode decomposition. Proc. Inst. Mech. Eng., Part K: J. Multi-body Dyn. 233(4), 856–870 (2019). https://doi.org/10.1177/1464419319847921

Han, X., Xu, J., Song, S., Zhou, J.: Crack fault diagnosis of vibration exciter rolling bearing based on genetic algorithm–optimized Morlet wavelet filter and empirical mode decomposition. Int. J. Distrib. Sens. Netw. 18(8), 15501329221114566 (2022). https://doi.org/10.1177/15501329221114566

Karabacak, Y.E., Özmen, N.G., Gümüşel, L.: Intelligent worm gearbox fault diagnosis under various working conditions using vibration, sound and thermal features. Appl. Acoust. 186, 108463 (2022). https://doi.org/10.1016/j.apacoust.2021.108463

Zhang, S., Zhang, S., Wang, B., Habetler, T.G.: Deep learning algorithms for bearing fault diagnostics—A comprehensive review. IEEE Access 8, 29857–29881 (2020). https://doi.org/10.1109/ACCESS.2020.2972859

Saucedo-Dorantes, J.J., Delgado-Prieto, M., Ortega-Redondo, J.A., Osornio-Rios, R.A., Romero-Troncoso, R.D.J.: Multiple-fault detection methodology based on vibration and current analysis applied to bearings in induction motors and gearboxes on the kinematic chain. Shock. Vib. (2016). https://doi.org/10.1155/2016/5467643

Zhang, Y., **ao, X., Hu, X., **ng, B., and Huang, Q.: (2021). Vibration normalization processing for fault diagnostics under varying conditions. In: The 2nd International Conference on Computing and Data Science (pp. 1-5).https://doi.org/10.1145/3448734.3450465

Helmi, H., Forouzantabar, A.: Rolling bearing fault detection of electric motor using time domain and frequency domain features extraction and ANFIS. IET Electr. Power Appl. 13(5), 662–669 (2019). https://doi.org/10.1049/iet-epa.2018.5274

Kumar, R., Anand, R.S.: Statistical analysis of vibration signal frequency during inner race fault of rolling ball bearings. J. Fail. Anal. Prev. (2023). https://doi.org/10.1007/s11668-023-01760-2

Nayana, B.R., Geethanjali, P.: Analysis of statistical time-domain features effectiveness in identification of bearing faults from vibration signal. IEEE Sens. J. 17(17), 5618–5625 (2017). https://doi.org/10.1109/JSEN.2017.2727638

Seninete S., Mimi M., eddine Cherif, B. D. and Ould Ali A.: (2019) Vibration signal analysis for bearing fault diagnostic of asynchronous motor using HT-DWT technique. In: 2019 6th International Conference on Image and Signal Processing and their Applications (ISPA), Mostaganem, Algeria, 2019: 1–5, https://doi.org/10.1109/ispa48434.2019.8966801.

Lin, H.C., Ye, Y.C., Huang, B.J., Su, J.L.: Bearing vibration detection and analysis using enhanced fast Fourier transform algorithm. Adv. Mech. Eng. 8(10), 1–14 (2016). https://doi.org/10.1177/1687814016675080

Nishat Toma, R., Kim, C.H., Kim, J.M.: Bearing fault classification using ensemble empirical mode decomposition and convolutional neural network. Electronics 10(11), 1248 (2021). https://doi.org/10.3390/electronics10111248

Wang, N. and Liu, X.: (2018). Bearing fault diagnosis method based on hilbert envelope demodulation analysis. In: IOP Conference Series: Materials Science and Engineering (Vol. 436: 012009). IOP Publishing.https://doi.org/10.1088/1757-899X/436/1/012009

Salunkhe, V.G., Khot, S.M., Desavale, R.G., Yelve, N.P.: Unbalance bearing fault identification using highly accurate hilbert-huang transform approach. J. Nondestruct Eval. Diagn. Progn. Eng. Syst. 6(3), 031005 (2023). https://doi.org/10.1115/1.4062929

Resendiz-Ochoa, E., Osornio-Rios, R.A., Benitez-Rangel, J.P., Morales-Hernandez, L.A., and Romero-Troncoso, R.D.J.: (2017). Segmentation in thermography images for bearing defect analysis in induction motors. In: 2017 IEEE 11th International Symposium on Diagnostics for Electrical Machines, Power Electronics and Drives (SDEMPED) (pp. 572-577). IEEE.https://doi.org/10.1109/DEMPED.2017.8062412.

Chi, K., Kang, J., Bajric, R., Zhang, X.: Bearing fault diagnosis through stochastic resonance by full-wave signal construction with half-cycle delay. Measurement 148, 106893 (2019). https://doi.org/10.1016/j.measurement.2019.106893

Zhang, X., Hu, N., Hu, L., Chen, L.: A bearing fault diagnosis method based on sparse decomposition theory. J. Cent. South Univ. 23(8), 1961–1969 (2016). https://doi.org/10.1007/s11771-016-3253-3

Lee, D.H., Hong, C., Jeong, W.B., Ahn, S.: Time–frequency envelope analysis for fault detection of rotating machinery signals with impulsive noise. Appl. Sci. 11(12), 5373 (2021). https://doi.org/10.3390/app11125373

Deng, W., Yao, R., Zhao, H., Yang, X., Li, G.: A novel intelligent diagnosis method using optimal LS-SVM with improved PSO algorithm. Soft. Comput. 23(7), 2445–2462 (2019). https://doi.org/10.1007/s00500-017-2940-9

Hasan, A.I.: (2021). Vibration classification of power plant equipment using decision tree algorithm approach. In: 2021 International Conference on Technology and Policy in Energy and Electric Power (ICT-PEP) (pp. 97-101). IEEE. https://doi.org/10.1109/ICT-PEP53949.2021.9601062.

T. Abedin et al.,: (2023). Vibration signal for bearing fault detection using random forest. In: Journal of Physics: Conference Series (Vol. 2467, No. 1, p. 012017). IOP Publishing.https://doi.org/10.1088/1742-6596/2467/1/012017

Shah, K., Patel, H., Sanghvi, D., Shah, M.: A comparative analysis of logistic regression, random forest and KNN models for the text classification. Augment. Human Res. 5(1), 12 (2020). https://doi.org/10.1007/s41133-020-00032-0

Korba, K.A., Arbaoui, F.: SVM multi-classification of induction machine’s bearings defects using vibratory analysis based on empirical mode decomposition. Int. J. Appl. Eng. Res. 13(9), 6579–6586 (2018)

Zhang, N., Wu, L., Wang, Z., Guan, Y.: Bearing remaining useful life prediction based on Naive Bayes and weibull distributions. Entropy 20(12), 944 (2018). https://doi.org/10.3390/e20120944

Jain, N., Kumar, R.: A review on machine learning & it’s algorithms. Int. J. Soft Comput. Eng. 12(5), 1–5 (2022). https://doi.org/10.35940/ijsce.E3583.1112522

Mo, C., Han, H., Liu, M., Zhang, Q., Yang, T., Zhang, F.: Research on SVM-based bearing fault diagnosis modeling and multiple swarm genetic algorithm parameter identification method. Mathematics 11(13), 2864 (2023). https://doi.org/10.3390/math11132864

Kafeel, A., Aziz, S., Awais, M., Khan, M.A., Afaq, K., Idris, S.A., Mostafa, S.M.: An expert system for rotating machine fault detection using vibration signal analysis. Sensors 21(22), 7587 (2021). https://doi.org/10.3390/s21227587

Borhana, A.A., Kamal, D.D.B.M., Latif, S.D., Ali, Y.H., Almahfoodh, A.N.A., and El-Shafie, A.: (2020). Fault detection of bearing using support vector machine-SVM. In: 2020 8th International Conference on Information Technology and Multimedia (ICIMU) (pp. 309-315). IEEE.

**, B., Xu, X.: Forecasting wholesale prices of yellow corn through the Gaussian process regression. Neural Comput. Appl. (2024). https://doi.org/10.1007/s00521-024-09531-2

Akkem, Y., Biswas, S.K., Varanasi, A.: A comprehensive review of synthetic data generation in smart farming by using variational autoencoder and generative adversarial network. Eng. Appl. Artif. Int. 131, 107881 (2024). https://doi.org/10.1016/j.engappai.2024.107881

Akkem, Y., Biswas, S.K., Varanasi, A.: Smart farming using artificial intelligence: a review. Eng. Appl. Artif. Intell. 120, 105899 (2023). https://doi.org/10.1016/j.engappai.2023.105899

Xu, X., Zhang, Y.: Corn cash price forecasting with neural networks. Comput. Electron. Agri. 184, 106120 (2021). https://doi.org/10.1016/j.compag.2021.106120

Mohamad, T.H., Abbasi, A., Kappaganthu, K., Nataraj, C.: On extraction, ranking and selection of data-driven and physics-informed features for bearing fault diagnostics. Knowl. Based Syst. 276, 110744 (2023). https://doi.org/10.1016/j.knosys.2023.110744

Deng, L., Zhang, A., Zhao, R.: Intelligent identification of incipient rolling bearing faults based on VMD and PCA-SVM. Adv. Mech. Eng. 14(1), 16878140211072990 (2022). https://doi.org/10.1177/16878140211072990

Urbanowicz, R.J., Meeker, M., La Cava, W., Olson, R.S., Moore, J.H.: Relief-based feature selection: introduction and review. J. Biomed. Inform. 85, 189–203 (2018). https://doi.org/10.1016/j.jbi.2018.07.014

Zhang, Y., Guo, W., and Ray, S.: (2016). On the consistency of feature selection with lasso for non-linear targets. In: International Conference on Machine Learning (pp. 183-191). PMLR.

Yan, X., Jia, M.: Intelligent fault diagnosis of rotating machinery using improved multiscale dispersion entropy and mRMR feature selection. Knowl. Based Syst. 163, 450–471 (2019). https://doi.org/10.1016/j.knosys.2018.09.004

Aalaei, S., Shahraki, H., Rowhanimanesh, A., Eslami, S.: Feature selection using genetic algorithm for breast cancer diagnosis: experiment on three different datasets. Iran. J. Basic Med. Sci. 19, 1–7 (2016)

Chuanlei, Z., Shanwen, Z., Jucheng, Y., Yancui, S., Jia, C.: Apple leaf disease identification using genetic algorithm and correlation based feature selection method. Int. J. Agri. Biol. Eng. 10(2), 74–83 (2017). https://doi.org/10.3965/j.ijabe.20171002.2166

Ahmed, H., Nandi, A.K.: Compressive sampling and feature ranking framework for bearing fault classification with vibration signals. IEEE Access 6, 44731–44746 (2018). https://doi.org/10.1109/ACCESS.2018.2865116

Lin, C.J., Chu, W.L., Wang, C.C., Chen, C.K., Chen, I.T.: Diagnosis of ball-bearing faults using support vector machine based on the artificial fish-swarm algorithm. J. Low Freq. Noise Vib. Act. Control 39(4), 954–967 (2020). https://doi.org/10.1177/1461348419861822

Cascales-Fulgencio, D., Quiles-Cucarella, E., García-Moreno, E.: Computation and statistical analysis of bearings’ time-and frequency-domain features enhanced using cepstrum pre-whitening: a ML-and DL-based classification. Appl. Sci. 12(21), 10882 (2022). https://doi.org/10.3390/app122110882

Esakimuthu Pandarakone, S., Mizuno, Y., Nakamura, H.: A comparative study between machine learning algorithm and artificial intelligence neural network in detecting minor bearing fault of induction motors. Energies 12(11), 2105 (2019). https://doi.org/10.3390/en12112105

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The author(s) declare that there are no potential conflicts in this manuscript.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Kumar, R., Anand, R.S. Bearing fault diagnosis using multiple feature selection algorithms with SVM. Prog Artif Intell (2024). https://doi.org/10.1007/s13748-024-00324-1

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s13748-024-00324-1