Abstract

Polystyrene (PS) is a widely used matrix material in selective laser sintering (SLS). Polystyrene is inexpensive and its powdered form, used as a matrix material in selective laser sintering, enables high accuracy in prototype production, similar to the casting process of wax molds. However, the performance of polystyrene varies significantly due to the differences in its synthetic process and added fillers of different grades available in the market, leading to varying outcomes when used in selective laser sintering technology. Therefore, it is necessary to study the polystyrene materials available in the market to identify the most suitable ones for selective laser sintering technology. In this study, three different grades of polystyrene powder (75–100 µm) were selected as research objects and treated to sintering experiments using a “selective laser sintering” rapid prototy** machine. The research results indicated that the molecular weight affects the quality of selective laser sintering parts by influencing the melt viscosity of polystyrene, which in turn affects the density and accuracy of the fabricated parts. Guided by these research findings, two 75–100 µm polystyrene powder materials were selected, and their sintering performance and thermal weight loss characteristics were investigated. Under optimized processing parameters, the test specimens with high accuracy were fabricated by selective laser sintering, and its mechanical property was further reinforced through epoxy resin post-processed, and the microstructure of the tensile fracture surface was examined using electron microscopy. In conclusion, the PS1 type polystyrene material and its process parameters, suitable in selective laser sintering and its post-processing, were determined. The research findings presented in this paper provided a methodology for the selection of selective laser sintering materials.

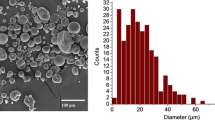

Graphical abstract

Similar content being viewed by others

Data availability

The datasets generated during and/or analysed dur-ing the current study are available from the corresponding author on reasonable request.

References

Goodridge RD, Tuck CJ, Hague RJM (2018) Laser sintering of polyamides and other polymers. Prog Mater Sci 57:229–267

Fina F, Madla CM, Goyanes A, Alvaro G, Zhang J, Simon G, Abdul Basit W (2018) Fabricating 3D printed orally disintegrating printlets using selective laser sintering. Int J Pharm 541:101–107

Vasquez M, Cross J, Hopkinson N, Haworth B (2012) Develo** new laser sintering materials for snowboarding applications. Proc Eng 34:325–330

Yan C, Shi Y, Hao L (2011) Investigation into the differences in the selective laser sintering between amorphous and semi-crystalline polymers. Int Polym Proc 26:416–423

Goodridge RD, Hague RJ, Tuck CJ (2010) An empirical study into laser sintering of ultra-high molecular weight polyethylene (UHMWPE). J Mater Proc Technol 210:72–80

Bai J, Zhang B, Song J, Bi G, Wang P, Wei J (2016) The effect of processing conditions on the mechanical properties of polyethylene produced by selective laser sintering. Polym Test 52:89–93

Goodridge RD, Shofner ML, Hague RJ, McClell M, Schlea MR, Johnson RB, Tuck CJ (2011) Processing of a polyamide-12/carbon nanofibre composite by laser sintering. Polym Test 30:94–100

Goodridge RD, Tuck CJ, Hague RJM (2012) Laser sintering of polyamides and other polymers. Prog Mater Sci 57:229–267

Verbelen L, Dadbakhsh S, Van den Eynde M, Kruth JP, Goderis B, Van Puyvelde P (2016) Characterization of polyamide powders for determination of laser sintering processability. Eur Polym J 75:163–174

Zhu W, Yan C, Shi Y, Wen S, Han C, Cai C, Liu J, Shi Y (2016) Study on the selective laser sintering of a low-isotacticity polypropylene powder. Rapid Proto J 22:621–629

Tan LJ, Zhu W, Sagar K, Zhou K (2021) Comparative study on the selective laser sintering of polypropylene homopolymer and copolymer: Processability, crystallization kinetics, crystal phases and mechanical properties. Add Manuf 37:101610

Berretta S, Wang Y, Davies R, Ghita OR (2016) Polymer viscosity particle coalescence and mechanical performance in high-temperature laser sintering. J Mater Sci 51:4778–4794

Yan M, Tian X, Peng G, Zhang X (2018) High temperature rheological behavior and sintering kinetics of CF/PEEK composites during selective laser sintering. Compos Sci Technol 165:140–147

Chavez LA, Ibave P, Hassan MS, Hall-Ssnchez SE, Billah KMM, Leyva A, Marquez C, Espalin D, Torres S, Robison T, Lin Y (2022) Low-temperature selective laser sintering 3D printing of PEEK-nylon blends: Impact of thermal post-processing on mechanical properties and thermal stability. J Appl Polym Sci 139:52290

Zhou H, Cheng X, Jiang X, Zheng G, Zhang J, Li Y, Tang M (2023) Study of the interlayer bonding strength for combined 3D printing and milling of polyetheretherketone. J Appl Polym Sci 140:e53773

Yang L, Zhou W, Wang B, Yang F (2017) Experimental study on the process parameters of selective laser sintering of polystyrene (PS)/ABS composite powder. Eng Plast Appl 45:57–62

Hock TS, Trevor S, Christodoulou P, Yarlagadda PKDV (2003) Experimental studies on the accuracy of wax patterns used in investment casting. Proc Instit Mech Eng Part B J Eng Manuf 217:285–289

Zhao B, Shi F, Feng T (2002) Studies on numerical simulations of temperature field in selective laser sintering of polystyrene powders. Laser J 23:66–69

Liu H, Fan Z, Huang N, Dong X (2003) A note on rapid manufacturing process of metallic parts based on SLS plastic prototype. J Mater Proc Technol 142:710–713

Shi Y, Li Z, Sun H, Huang S, Zeng F (2004) Effect of the properties of the polymer materials on the quality of selective laser sintering parts. Proc Inst Mech Eng Part L J Mater Des Appl 218:247–252

Shi Y, Li Z, Sun H, Huang S, Zeng F (2004) Development of a polymer alloy of polystyrene (PS) and polyamide (PA) for building functional part based on selective laser sintering (SLS). Proc Instit Mech Eng Part L J Mater Des Appl 218:299–306

Chen J, Chen J, Yang J, Wu Y (2023) Selective laser sintering of acrylonitrile butadiene styrene polymer and post-processing enhancement: an experimental study. Iran Polym J 32:1537–1550

Chen J, LiuB HuM, Shi Q, Chen J, Yang J, Wu Y (2023) Research oncharacterization of nylon composites functional material filled with Al2O3 particle. Polymers 15:2369

Shi Y, Chen J, Wang Y, Li Z, Huang S (2007) Study of the selective laser sintering of polycarbonate and post process for parts enhancement. Proc Instit Mech Eng, Part L J Mater Des Appl 221:37–42

Shi Y, Wang Y, Chen J, Li Z, Huang S (2008) Experimental investigation into the selective laser sintering of high impact polystyrene. J Appl Polym Sci 108:535–540

Yang J, Shi Y, Shen Q, Yan C (2009) Selective laser sintering of HIPS and investment casting technology. J Mater Proc Technol 209:1901–1908

Khazaee S, Kiani A, Badrossamay M, Foroozmehr E (2021) Selective laser sintering of polystyrene: preserving mechanical properties without post-processing. J Mater Eng Perform 30:3068–3078

Wei X (2016) Research on precision of selective laser sintering technology. Food Technol 37:1698–1700

Zeng Z, Deng X, Cui J, Jiang H, Yan S (2019) Improvement on selective laser sintering and post-processing of polystyrene. Polymers 11:956

Zhang H, Li W, Xu J, Shang S, Song Z (2021) Synthesis and characterization of bio-based epoxy thermosets using rosin-based epoxy monomer. Iran Polym J 30:643–654

Jia L, Chen B, Zhao H, Lan X (2022) Mechanical and thermal properties of elastic epoxy thermoset cured by cardanol-based diglycidyl epoxy modified polyetheramine. Iran Polym J 31:1107–1115

Singh S, Sharma VS, Sachdeva A (2019) Application of response surface methodology to analyze the effect of selective laser sintering parameters on dimensional accuracy. Prog Add Manuf 4:3–12

Han W, Kong L, Xu M (2022) Advances in selective laser sintering of polymers. Int J Extr Manuf 4:19–56

Acknowledgements

Financial support from the Science and Technology Project of Department of Science and Technology in Hubei Province (No.2022EHB020) is gratefully acknowledged. The authors also acknowledge the Analytical and Testing Center of Wuhan Polytechnic University (WHPU) for their analytical work.

Funding

Science and Technology Program of Hubei Province,2022EHB020,Jibing Chen.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Chen, J., Shi, Q., Chen, J. et al. Polystyrene powder materials for selective laser sintering. Iran Polym J 33, 543–553 (2024). https://doi.org/10.1007/s13726-023-01268-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13726-023-01268-4