Abstract

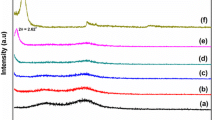

In this study, polystyrene/organoclay nanocomposites were developed using two different methodologies, i.e., in-situ bulk process and solution process. A comparative analysis of the thermal and mechanical properties was carried out for the nanocomposites obtained by these two distinct methods. The in-situ bulk method resulted in nanocomposites having good exfoliation and high thermal stability, while in-situ solution method resulted in materials with good mechanical properties and high thermal stability upon intercalation of the polymer matrix into the clay galleries. Two kinds of organically modified clays were used as labeled as CTA-Mag(1CEC) and CTA-Mag(2CEC) modified by a quaternary ammonium surfactant which was cetyltrimethylammonium bromide (CTAB). Maghnite is a natural clay (in Algeria) that can act as a catalyst and an inorganic reinforcement, both. These organoclays were utilized for the synthesis of polystyrene/clay nanocomposites. The impacts of the CTA-Mag on the morphology and properties of the nanocomposites were examined. However, polystyrene/CTA-Maghnite (PS/CTA-Mag) nanocomposites were characterized by various physicochemical techniques, i.e., XRD, FTIR, TGA, and transmission electron microscopy (TEM). Gel permeation chromatography (GPC) illustrated the ability of the CTA-Mag organoclay to effectively minimize the average molecular weight of the PS particles. The greatest improvement in thermal stabilities of the nanocomposites was obtained with 5 wt% of CTA-Mag for both organoclays. The nanocomposite containing 3 wt% organoclay showed the greatest improvement in Young’s modulus, impact strength, and tensile strength. The addition of organoclay reduced the MFI value of the polystyrene nanocomposites. The measurement of Young’s modulus, shock resistance, and breaking stress enabled the evolution of the mechanical properties to be assessed.

Graphical abstract

Similar content being viewed by others

References

Chozhan CK, Chandramohan A, Alagar M (2019) Development and characterization of 1,1-bis(3-methyl-4-hydroxyphenyl) cyclohexane-based benzoxazine and cyanate ester hybrid polymer matrices: thermal and morphological properties. Polym Polym Compos 27(9):609–618

Kherroub DE, Boulaouche T (2020) Maghnite: novel inorganic reinforcement for single-step synthesis of PDMS nanocomposites with improved thermal, mechanical and textural properties. Res Chem Intermed 46:5199–5217

Bashal AH, Khalafalla M, Abdel-Basset TA (2021) Dielectric properties and AC conductivity of chitosan-La2O3 nanocomposite. Arab J Sci Eng 46:5859–5864. https://doi.org/10.1007/s13369-020-04958-w

Yamaguchi I, Morisaka R (2017) Synthesis and electrical properties of copolymers of o-phenylenediamine with aniline, 3,4-ethylenedioxythiophene and 2,3,5,6-tetrafluoroaniline. Polym Int 66:320–326

Yamaguchi I, Kinugawa S, Wang A (2019) Synthesis and chemical properties of pyrophosphoric acid-doped polyaniline and copolymers of o-phenylenediamine with aniline and 3,4-ethylenedioxythiophene. Polym Bull 76:4035–4046

Neto CP, Bischoff E, Santos KS, Oliveira RVB, Mauler RS (2017) The effects of styrenic oligomers on the thermomechanical properties of toughened polystyrene nanocomposites. Polym Bull 75(2):569–580

Wu H, Yang J, Liu J, Sun M, Wang Y, Tang L (2020) Synergistic flame retardancy of tris(1-methoxy-2,2,6,6-tetramethyl-piperidin-4-yl)phosphite and tris(2,4,6-tribromophenoxy)-1,3,5-triazine/Sb2 O3 in high-impact polystyrene. Fire Mater 44:573–584

Silvestre C, Pezzuto M, Duraccio D, Mitchel GR, Cimmino S (2017) Quiescent and shear-induced non-isothermal crystallization of isotactic polypropylene-based nanocomposites. Polym Bull 74:145–165

Wang Z, Sun D, Wang X, Yang Y, Li Y, Zuo B, Huang J, Wang X (2021) Enhanced dynamics of PMMA brushes induced by the chain ends of a flexible polymer chain. Macromolecules 54:647–654

Pinto CP, Pachekoski WM, Dalmolin C, Becker D (2017) Plasticizer effect and electronic diffusive behavior of polyaniline-modified clay in polystyrene nanocomposites. Polym Compos 40:37–45

Luna CBB, Araújo EM, Siqueira DD, de Morais DD, S, Filho EA dos S, Fook MVL, (2019) Incorporation of a recycled rubber compound from the shoe industry in polystyrene: effect of SBS compatibilizer content. J Elastom Plast 52:3–28

Gulstan SE, Sarkawt AH, Shujahadeen BA (2021) Structure and optical properties of nanocomposites based on polystyrene (PS) and calcium titanate (CaTiO3) perovskite nanoparticles. Optic 241:166963

Mohit H, Selvan VAM (2019) Physical and thermomechanical characterization of the novel aluminum silicon carbide-reinforced polymer nanocomposites. Iran Polym J 28:823–837

Tekay E, Nugay N, Nugay T, Şen S (2018) Tuning of nanotube/elastomer ratio for high dam**/tough and creep resistant polypropylene/SEBS-g-MA/HNT blend nanocomposites. J Compos Mater 53(8):1005–1022

Bischoff E, Simon DA, Liberman SA, Mauler RS (2019) Compounding sequence as a critical factor in the dispersion of OMMT/hydrocarbon resin/PP-g-MA/PP nanocomposites. Polym Bull 76:849–863

Vahidi M, Azizi H (2017) Preparation and properties of styrene butadiene styrene/nano calcium carbonate thermoplastics elastomer composite foams: morphology and mechanical properties. Cell Polym 36(5):251–268

Akelah A, Rehab A, Abdelwahab M, Betiha MA (2017) Synthesis and thermal properties of nanocomposites based on exfoliated organoclay polystyrene and poly(methylmethacrylate). Nanocomposites 3(1):20–29

Mrah L, Meghabar R (2020) Dispersion and improvement of organoclays in nanocomposites based on poly(propylene oxide). J Thermoplast Compos Mater. https://doi.org/10.1177/0892705720939172

Boulaouche T, Kherroub DE, Benzerafa A, Khimeche K, Belbachir M (2020) New synthesis of polyurethane nanocomposites based on Maghnite used both as a catalyst and as an inorganic improver of thermal, mechanical and textural properties. J Mater Res Technol 9:15222–15232

Dike AS, Yilmazer U (2020) Mechanical, thermal and rheological characterization of polystyrene/organoclay nanocomposites containing aliphatic elastomer modifiers. Mater Res Express 7:015055

Moustafa H, Lawandy SN, Rabee M, Zahran MAH (2020) Effect of green modification of nanoclay on the adhesion behavior of EPDM rubber to polyester fabric. J Adhes Adhes 100:102617

Veiseh S, Yousefi AA (2021) Compressive behavior and thermal conductivity-density correlation of expanded polystyrene thermal insulators. Iran Polym J 30:849–854

Mrah L, Meghabar R (2020) In situ polymerization of styrene–clay nanocomposites and their properties. Polym Bull 78:3509–3526. https://doi.org/10.1007/s00289-020-03274-5

Mrah L, Meghabar R, Belbachir M (2015) In-situ polymerization of styrene to produce polystyrene/montmorillonite nanocomposites. Bull Chem React Eng Catal 10:249–255

Mrah L, Meghabar R, Belbachir M (2015) The characteristics of poly propylene oxide/montmorillonite nanocomposites. J Nanomed Nanotechnol 6:263

Mrah L, Meghabar R (2020) Influence of clay modification process in polypyrrole-layered silicate nanocomposite. SN Appl Sci 2:659

Givi S, Ebadi-Dehaghani H (2020) Design of experiments for the effect of ph, storage time and zinc oxide content on the antibacterial properties of low-density polyethylene (ldpe)/zinc oxide nanocomposites. J Macromol Sci Part B 60:257–271

Yang L, Ke Y (2014) Synthesis of polystyrene nanolatexes via emulsion polymerization using sodium dodecyl sulfonate as the emulsifier. High Perform Polym 26:900–905

Brito DF, da Silva Filho EC, Fonseca MG, Jaber M (2018) Organophilic bentonites obtained by microwave heating as adsorbents for anionic dyes. J Environ Chem Eng 6:7080–7090

Faucheu J, Gauthier C, Chazeau L, Cavaillé J, Mellon V, Bourgeat Lami E (2010) Miniemulsion polymerization for synthesis of structured clay/polymer nanocomposites: short review and recent advances. Polymer 51:6–17

El Messabeb-Ouali A, Benna-Zayani M, Ayadi-Trabelsi M, Sauvé S (2013) Morphology, structure, thermal stability, XR-diffraction, and infrared study of hexadecyltrimethylammonium bromide–modified smectite. Int J Chem 5:12–28. https://doi.org/10.5539/ijc.v5n2p12

Niroumand JS, Peighambardoust SJ, Shenavar A (2016) Polystyrene-based composites and nanocomposites with reduced brominated-flame retardant. Iran Polym J 25:607–614

Zhu R, Chen Q, Zhou Q, ** Y, Zhu J, He H (2016) Adsorbents based on montmorillonite for contaminant removal from water. A review. Appl Clay Sci 123:239–258

Moustafa H, Duquesne S, Haidar B, Vallat MF (2017) Influence of the degree of exfoliation of an organoclay on the flame-retardant properties of cross-linked ethylene-co-propylene-co-diene monomer-g-maleic anhydride-based composites. Polym Compos 38:966–973

Khezri K, Fazli Y (2017) Characterization of diatomite platelets and its application for in situ atom transfer radical random copolymerization of styrene and butyl acrylate: normal approach. J Inorg Organomet Polym Mater 27:266–274

Cazotti JC, Alves GM, Santos AM (2021) Surfactant-free hybrid adhesives based on poly(vinyl acetate) and commercial montmorillonite nanoclays. Polym Bull. https://doi.org/10.1007/s00289-021-03787-7

Roghani-Mamaqani H, Haddadi-Asl V, Sobhkhiz Z, Ghaderi-Ghahfarrokhi M (2015) Grafting poly (methyl methacrylate) from azo-functionalized graphene nanolayers via reverse atom transfer radical polymerization. Colloid Polym Sci 293:735–750

Hassanabadi HM, Wilhelm M, Rodrigue DA (2014) Rheological criterion to determine the percolation threshold in polymer nano-composites. Rheol Acta 53:869–882

Kanbur Y, Tayfun U (2019) Development of multifunctional polyurethane elastomer composites containing fullerene: mechanical, dam**, thermal, and flammability behaviors. J Elastom Plast 51:262–279

**ao C, Leng X, Wang H, Su Z, Zhang X, Chen L, Zheng K, Tian X (2017) Synergistic effect of selectively distributed AlN/MWCNT hybrid fillers on the morphological, mechanical and thermal properties of polycarbonate/maleated poly[styrene-b-(ethylene-co-butylene)- b-styrene] triblock copolymer (SEBS-g-MA) composites. Mater Res Express 4:025101

Alghadi AM, Tirkes S, Tayfun U (2020) Mechanical, thermo-mechanical and morphological characterization of ABS based composites loaded with perlite mineral. Mater Res Express 7:015301

Othman MH, Rosli MS, Hasan S, Amin AM, Hashim MY, Marwah OMF, Amin SYM (2018) The optimisation of processing condition for injected mould polypropylene-nanoclay-gigantochloa scortechinii based on melt flow index. IOP Conf Ser Mater Sci Eng 324:012073

Zhang D, Guo J, Zhang K (2013) Effects of compatilizers on mechanical and dynamic mechanical properties of polypropylene–long glass fiber composites. J Thermoplast Compos Mater 28:643–655

Samantaray SK, Gope SK, Satapathy BK (2021). In: Pant P, Mishra SK, Mishra PC (eds) Advances in mechanical processing and design. Springer Nature, Singapore

Savas LA, Tayfun U, Dogan M (2016) The use of polyethylene copolymers as compatibilizers in carbon fiber reinforced high density polyethylene composites. Compos Part B Eng 99:188–195. https://doi.org/10.1016/j.compositesb.2016.06.043

Li X, Zhou X, Shi C, Xu J, Li Y, Tang S, Huang K, Wang X (2017) Preparation of a long-alkyl-chain silane grafted organic montmorillonite and its nanocomposite with SEBS. Polym Bull 74:107–120

Abolghasemi Fakhri L, Ghanbarzadeh B, Dehghannya J, Abbasi F, Ranjbar H (2018) Optimization of mechanical and color properties of polystyrene/nanoclay/nano ZnO based nanocomposite packaging sheet using response surface methodology. Food Packag Shelf Life 17:11–24

Prahsarn C, Roungpaisan N, Suwannamek N, Klinsukhon W, Hayashi H, Kawasaki K, Ebina T (2014) Influence of molecular structure of quaternary phosphonium salts on Thai bentonite intercalation. Clays Clay Miner 62:13–19

Kajaks J, Kalnins K, Sn U, Matvejs J (2014) Physical and mechanical properties of composites based on polypropylene and timber industry waste. Cent Eur J Eng 4:385–390

Shulga G, Jaunslavietis J, Ozolins J, Neiberte B, Verovkins A, Vitolina S, Shakels V (2016) Properties of recycled polypropylene based composites incorporating treated hardwood sawdust. AIP Conf Proc 1736:020111

Author information

Authors and Affiliations

Corresponding author

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Megherbi, R., Mrah, L. & Marref, M. Maghnite: an innovative inorganic reinforcement used in the synthesis of polystyrene nanocomposites with optimized thermal and mechanical properties. Iran Polym J 31, 223–236 (2022). https://doi.org/10.1007/s13726-021-00995-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13726-021-00995-w