Abstract

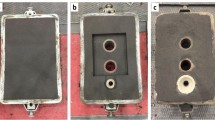

Research on the use of WC-Co tool tip scraps inserts into Hadfield austenitic manganese steel was conducted to enhance the wear resistance of a material and utilize WC-Co tool tip scraps for mining industry applications fabricated using in situ metal casting. Microstructure, mechanical properties, and wear resistance were investigated in this study. The results of microstructure observations revealed that austenite grains near the interface region had a grain size of G 4.16. However, as the distance of the austenite grains from the interface increased, the grain size of austenite also increased and had a value of G 1.02. The interface zone between WC-Co and Hadfield austenitic manganese steel exhibited scattered agglomerates of WC-Co particles that detached from the main body, allowing for the infiltration of liquid metal inside the WC-Co tool tip scraps. The hardness testing results in the interface region showed lower values compared to the WC-Co tool tip scraps, with a hardness value of 612 VHN. Meanwhile, the hardness in the base metal region tended to decrease as the distance from the interface increased. The material with the addition of WC-Co tool tip scraps exhibited improved wear resistance compared to the wear in the base steel region.

Similar content being viewed by others

References

N.I. Denisenko, V.A. Maslyuk, R.V. Yakovenko, Reinforced powder chromium steels and their use for the hardening of feed mill hammers. Powder Metall. Met. Ceram. 57(11), 740–746 (2019). https://doi.org/10.1007/s11106-019-00039-2

H. Liu, S. Fan Rong, Wu.Y. He, P. Hui Yang, X. Lan Duan, Y. Chang Zhu, Study on diagonal hammer of three kind metals composite casting with block protecting handle. MATEC Web Confer. 63, 03011 (2016). https://doi.org/10.1051/matecconf/20166303011

X.M. Zhao, H.T. Zhou, S.F. Rong, B.G. Yang, C.H. Li, Research on the new combined type crusher hammer. Appl. Mech. Mater. 488, 1160–1164 (2014). https://doi.org/10.4028/www.scientific.net/AMM.488-489.1160

S.R. Allahkaram, Causes of catastrophic failure of high Mn steel utilized as crusher overlaying shields. Int. J. Eng. 21(1), 55–64 (2008)

S. W. Bhero, B. Nyembe, K. Lentsoana, Common causes of premature failure of Hadfield steel crushers and hammers used in the mining industry. in International Conference on Mining, Mineral Processing and Metallurgical Engineering 174-175 (2013)

F. Haakonsen, Optimizing of strømhard austenitic manganese steel. Doctoral Thesis, Available from NTNU Institutt for materialteknologi. Thesis completed (2009)

C. Okechukwu, O.A. Dahunsi, P.K. Oke, I.O. Oladele, M. Dauda, Development of hardfaced crusher jaws using ferro-alloy hardfacing inserts and low carbon steel substrate. J. Tribol. 18, 20–39 (2018)

I. Hutchings, P. Shipway, Tribology: friction and wear of engineering materials. Butterworth–Heinemann (2017)

E. Olejnik, P. Batóg, T. Tokarski, P. Kurtyka, TiC-FeCr local composite reinforcements obtained in situ in steel casting. J. Mater. Process. Tech. 275, 116157 (2020). https://doi.org/10.1016/j.jmatprotec.2019.03.017

Y. Song, H. Wang, High speed sliding wear behavior of recycled WCP-reinforced ferrous matrix composites fabricated by centrifugal cast. Wear. 276, 105–110 (2012). https://doi.org/10.1016/j.wear.2011.12.017

C. Efstathiou, H. Sehitoglu, Strain hardening and heterogeneous deformation during twinning in hadfield steel. Acta Mater. 58(5), 1479–1488 (2010). https://doi.org/10.1016/j.actamat.2009.10.054

M.K. El-Fawakhry, I. Salem, A.A. El-Amir, T.M. Mattar, Ceramic metal composite approach for the advanced hadfield steel. J. Phys. Confer. Ser. 2047(1), 012010 (2021)

T. Kıvak, E. Ekici, G. Uzun, The experimental and statistical investigation of the effects of cutting parameters and coating materials on the machinability of Hadfield steel. Gazi Univ. J. Sci. 29(1), 9–17 (2016)

E. Kuljanic, M. Sortino, G. Totis, F. Prosperi, Evaluation of commercial tools for machining special-alloy hadfield steel. Int. Virtual J. Sci. Tech. Innov. Ind. Mach. Technol. Mater. 1, 96–99 (2012)

J.O. Olawale, S.A. Ibitoye, M.D. Shittu, Workhardening behaviour and microstructural analysis of failed austenitic manganese steel crusher jaws. Mater. Res. 16, 1274–1281 (2013)

W. Purwadi, B. Bandanadjaja, D. Idamayanti, N. Lilansa, Consecutive casting of iron bimetal with low-carbon steel interface plate. Arch. Foundry Eng. (2020). https://doi.org/10.24425/afe.2020.131289

P. Skoczylas, A. Krzyńska, M. Kaczorowski, The comparative studies of ADI versus Hadfield cast steel wear resistance. Arch. Foundry Eng. 11(2), 123–212 (2011)

J. Du, X. Chong, Y. Jiang, J. Feng, Numerical simulation of mold filling process for high chromium cast iron matrix composite reinforced by ZTA ceramic particles. Int. J. Heat Mass Transf. 89, 872–883 (2015). https://doi.org/10.1016/j.ijheatmasstransfer.2015.05.046

H. Vasudev, Hardfaced layer on mild steel made by paste technique with SMAW electrode to improve surface properties. Int. J. Adv. Res. Ideas Innov. Technol. 1(1), 1–7 (2014)

M. Vrabeľ, J. Viňáš, I. Maňková, J. Brezinová, B. Savkovič, P. Kovač, Analysis of tool wear patterns in rough turning of chromium hardfacing material. J. Prod. Eng. 20, 35–38 (2017). https://doi.org/10.24867/JPE-2017-01-035

S. Venkateswaran, W.D. Schubert, B. Lux, M. Ostermann, B. Kieffer, W-scrap recycling by the melt bath technique. Int. J. Refrac. Met. Hard Mater. 14(4), 263–270 (1996). https://doi.org/10.1016/0263-4368(95)00055-0

M. Li, X. **, Z. Nie, L. Ma, Q. Liu, Recovery of tungsten from WC–Co hard metal scraps using molten salts electrolysis. J. Mater. Res. Technol. 8(1), 1440–1450 (2019). https://doi.org/10.1016/j.jmrt.2018.10.010

C. Edtmaier, R. Schiesser, C. Meissl, W.D. Schubert, A. Bock, A. Schön, B. Zeiler, Selective removal of the cobalt binder in WC/Co based hardmetal scraps by acetic acid leaching. Hydrometall. 76(1–2), 63–71 (2005). https://doi.org/10.1016/j.hydromet.2004.09.002

S. Kim, B. Seo, S.H. Son, Dissolution behavior of cobalt from WC–Co hard metal scraps by oxidation and wet milling process. Hydrometall. 143, 28–33 (2014). https://doi.org/10.1016/j.hydromet.2014.01.004

B. Seo, S. Kim, Cobalt extraction from tungsten carbide-cobalt (WC-Co) hard metal scraps using malic acid. Int. J. Miner. Process. 151, 1–7 (2016). https://doi.org/10.1016/j.minpro.2016.04.002

G.G. Lee, H.S. Kwon, G.H. Ha, Oxidation kinetics of WC–Co hard metal alloy. J. Korean Powder Metall. Inst. 11(2), 111–117 (2004)

W.G. Jung, Recovery of tungsten carbide from hard material sludge by oxidation and carbothermal reduction process. J. Ind. Eng. Chem. 20(4), 2384–2388 (2014). https://doi.org/10.1016/j.jiec.2013.10.017

B. Casas, X. Ramis, M. Anglada, J.M. Salla, L. Llanes, Oxidation-induced strength degradation of WC–Co hardmetals. Int. J. Refrac. Met. Hard Mater. 19(4–6), 303–309 (2001). https://doi.org/10.1016/S0263-4368(01)00033-6

V.B. Voitovich, V.V. Sverdel, R.F. Voitovich, E.I. Golovko, Oxidation of WC-Co, WC-Ni and WC-Co-Ni hard metals in the temperature range 500–800 C. Int. J. Refrac. Met. Hard Mater. 14(4), 289–295 (1996). https://doi.org/10.1016/0263-4368(96)00009-1

W.H. Gu, Y.S. Jeong, K. Kim, J.C. Kim, S.H. Son, S. Kim, Thermal oxidation behavior of WC–Co hard metal machining tool tip scraps. J. Mater. Process. Technol. 212(6), 1250–1256 (2012). https://doi.org/10.1016/j.jmatprotec.2012.01.009

C. Ruskandi, D.F. Undayat, G.N. Hermana, M.R.G. Nadi, W. Purwadi, Study on thermal behaviour of tungsten cemented carbide tip scraps. in 6th Mechanical Engineering, Science and Technology International Conference (MEST 2022). 107-113 (2023)

A.C. Cuevas, E.B. Becerril, M.S. Martínez, J.L. Ruiz, Metal matrix composites (Springer Nature, Switzerland, 2018)

A.B. Moreira, L.M. Ribeiro, M.F. Vieira, Cast ferrous alloys reinforced with WC-metal matrix composites fabricated by ex-situ methods, 3rd edn (Prime Archives in Material Science, Khan, MI, 2021)

K.M. Sree Manu, L. Ajay Raag, T.P.D. Rajan, M. Gupta, B.C. Pai, Liquid metal infiltration processing of metallic composites: a critical review. Metall. Mater. Trans. B. 47(5), 2799–2819 (2016). https://doi.org/10.1007/s11663-016-0751-5

S.L. Tang, Y.M. Gao, Y.F. Li, Recent developments in fabrication of ceramic particle reinforced iron matrix wear resistant surface composite using infiltration casting technology. Ironmak. Steelmak. 41(8), 633–640 (2014). https://doi.org/10.1179/1743281213Y.0000000175

ASTM. ASTM E112: Standard test methods for determining average grain size. ASTM International, USA (2021)

A.K. Srivastava, K. Das, In-situ synthesis and characterization of tic-reinforced Hadfield manganese austenitic steel matrix composite. ISIJ Int. 49(9), 1372–1377 (2009). https://doi.org/10.2355/isi**ternational.49.1372

T. Kresse, D. Meinhard, T. Bernthaler, G. Schneider, Hardness of WC-Co hard metals: preparation, quantitative microstructure analysis, structure-property relationship and modelling. Int. J. Refrac. Met. Hard Mater. 75, 287–293 (2018). https://doi.org/10.1016/j.ijrmhm.2018.05.003

A.K. Srivastava, K. Das, Microstructural characterization of hadfield austenitic manganese steel. J. Mater. Sci. 43(16), 5654–5658 (2008). https://doi.org/10.1007/s10853-008-2759-y

S. Hosseini, M.B. Limooei, M.H. Zade, E. Askarnia, Z. Asadi, Optimization of heat treatment due to austenising temperature, time and quenching solution in hadfield steels. Int. J. Mater. Metall. Eng. 7(7), 582–585 (2013)

M. Sabzi, M. Farzam, Hadfield manganese austenitic steel: a review of manufacturing processes and properties. Mater. Res. Express. 6(10), 1065c2 (2019). https://doi.org/10.1088/2053-1591/ab3ee3

B. Zorc, A. Nagode, B. Kosec, L. Kosec, Analysis of weld cracking in shotblasting chambers made of hadfield steel. Eng. Fail. Anal. 33, 48–54 (2013). https://doi.org/10.1016/j.engfailanal.2013.04.023

Acknowledgements

The authors acknowledge financial support from the Ministry of Education, Culture, Research, and Technology, Indonesia. The author is also thankful for the help from Bandung Polytechnic for Manufacturing.

Author information

Authors and Affiliations

Contributions

All authors contributed to the study conception and design. Material preparation and analysis were performed by GNH, MRGN, and WP. Data collection were performed by CR, DFU, and AS. The first draft of the manuscript was written by GNH, and all authors commented on previous versions of the manuscript. All authors read and approved the final manuscript.

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Nadi, M.R.G., Hermana, G.N., Purwadi, W. et al. An Evaluation of WC-Co Tool Tip Scraps Reinforcement in the Hadfield Austenitic Manganese Steel Fabricated In Situ Steel Casting. Metallogr. Microstruct. Anal. 12, 802–808 (2023). https://doi.org/10.1007/s13632-023-01005-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13632-023-01005-6