Abstract

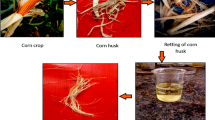

The primary objective of this investigation is to conduct a thorough analysis of carbon quantum dots (CQDs) particles derived from onion peel, comparing them with carbon nanotubes (CNTs) particles. The synthesis of CQDs involves the meticulous application of the hand layup method, a methodology replicated in the fabrication of CNT composites. Both filler composites undergo additional reinforcement with Kevlar fibers. Test specimens are precisely sectioned from the composite plates utilizing an abrasive cutting machine. Subsequent characterization is performed in strict adherence to the American Society of Testing and Materials (ASTM) standards, encompassing mechanical, wear, thermal conductivity, and water contact angle properties. In the realm of mechanical properties, the composite designation EKCQ3, comprising 2 vol.% of CQDs with 35 vol.% of Kevlar, exhibits remarkable mechanical strength. In comparison to EKCN3 (designation with 2 vol.% of CNTs), EKCQ3 demonstrates an 8.75% improvement in tensile strength, a 12.1% enhancement in flexural strength, a 27.2% boost in compression strength, and a 13.5% increase in impact resistance. Similarly, in wear properties, the CQD composite designation showcases superior wear resistance. EKCQ3 exhibits high wear resistance with a specific wear rate of 0.07 mm3/Nm and a coefficient of friction (COF) of 0.22. The reduced particle size of CQDs contributes to uniform dispersion, enhancing bonding and adhesion with Kevlar fibers in the matrix, thereby leading to improved mechanical and wear properties. In thermal conductivity, the CNTs composite designation demonstrates a high thermal conductivity of 0.47 W/mK. However, CQDs also deliver very close thermal conductivity values of 0.45 W/mK, highlighting their comparable performance in this aspect. Regarding water contact angle, the overall composite designation exhibits hydrophobic behavior, showcasing water contact angles ranging between 90 and 95°. In summary, CQDs outperform CNTs in mechanical and wear properties. In terms of thermal conductivity, CQDs demonstrate slightly superior performance, with only a marginal difference observed between CQDs and CNTs. Carbon quantum dots (CQDs) emerge as the preferred material for applications requiring optimal mechanical strength, wear resistance, and thermal conductivity, coupled with inherent hydrophobic characteristics.

Similar content being viewed by others

Data availability

All data are in the manuscript.

References

Rajadurai A (2016) Thermo-mechanical characterization of siliconized E-glass fiber/hematite particles reinforced epoxy resin hybrid composite. Appl Surf Sci 384:99–106. https://doi.org/10.1016/j.apsusc.2016.04.185

Arun Prakash VR, Jayaseelan V, Mothilal T, Manoj Kumar S, Depoures MV, Jayabalakrishnan D, Ramesh G (2020) Effect of silicon coupling grafted ferric oxide and e-glass fibre in thermal stability, wear and tensile fatigue behaviour of epoxy hybrid composite. Silicon 12:2533–2544. https://doi.org/10.1007/s12633-019-00347-7

Dinesh T, Kadirvel A, Vincent A (2019) Effect of silane modified E-glass fibre/iron (III) oxide reinforcements on UP blended epoxy resin hybrid composite. Silicon 11:2487–2498. https://doi.org/10.1007/s12633-018-9886-0

Prakash VA, Jaisingh SJ (2018) Mechanical strength behaviour of silane treated E-glass fibre/Al 6061 & SS-304 wire mesh reinforced epoxy resin hybrid composite. Silicon 10:2279–2286. https://doi.org/10.1007/s12633-018-9762-y

Alshahrani H, Pathinettampadian G, Gujba AK, Arun Prakash VR (2022) Effect of Palmyra sprout fiber and biosilica on mechanical, wear, thermal and hydrophobic behavior of epoxy resin composite. J Ind Text 52:15280837221137382. https://doi.org/10.1177/15280837221137382

Ben Samuel J, Julyes Jaisingh S, Sivakumar K, Mayakannan AV, Arunprakash VR (2021) Viscoelastic, thermal, antimicrobial and dielectric behaviour of areca fibre-reinforced nano-silica and neem oil-toughened epoxy resin bio composite. Silicon 13(6):1703–1712. https://doi.org/10.1007/s12633-020-00569-0

Giridharan R (2019) Preparation and property evaluation of glass/ramie fibers reinforced epoxy hybrid composites. Compos Part B 167:342–345. https://doi.org/10.1016/j.compositesb.2018.12.049

Jayabalakrishnan D, Saravanan K, Ravi S, Prabhu P, Maridurai T, Prakash VA (2021) Fabrication and characterization of acrylonitrile butadiene rubber and stitched E-glass fibre tailored Nano-silica epoxy resin composite. Silicon 13(8):2509–2517. https://doi.org/10.1007/s12633-020-00612-0

Suresh S, Saravanan P, Jayamoorthy K, Kumar SA, Karthikeyan S (2016) Development of silane grafted ZnO core shell nanoparticles loaded diglycidyl epoxy nanocomposites film for antimicrobial applications. Mater Sci Eng C 64:286–292. https://doi.org/10.1016/j.msec.2016.03.096

Yao S, Liu H, Zhang C, Zhang W, Ma C, Rehman ZU, Shen X (2024) Enhanced polysulfides conversion with hybrid bipolar membrane composed of CoSe2 and amide-functionalized CNTs composites for lithium sulfur batteries. J Energy Storage 78:110087. https://doi.org/10.1016/j.est.2023.110087

Aravinth V, Navaneethakrishnan V, Vishvanathperumal S, Gurumoorthi G (2024) Effect of modified nanographene oxide (mGO)/carbon nanotubes (CNTs) hybrid filler on the cure, mechanical and swelling properties of silicone rubber composites. J Inorg Organomet Polym Mater 34(1):282–301. https://doi.org/10.1007/s10904-023-02818-2

Kalaoglu-Altan OI, Karagüzel Kayaoğlu B, Trabzon L (2024) Fabrication and characterization of graphene-loaded recycled poly (ethylene terephthalate) electrospun composite nanofibrous mats with improved thermal conductivity. Polym Compos 45(1):709–721. https://doi.org/10.1002/pc.27809

Li J, Huang Z, Wang C, Tian L, Yang X, Zhou R et al (2024) Linkage effect in the bandgapbroken V2O5-GdCrO3 heterojunction by carbon allotropes for boosting photocatalytic H2 production. Appl Catal B Environ 340:123181. https://doi.org/10.1016/j.apcatb.2023.123181

Hussain K, Abbas M, Liu J, Obeid MM, Dastgeer G, Sun Q (2024) Newly designed 3D carbon allotrope with high hardness and strong UV–vis light absorption. J Phys Chem C. https://doi.org/10.1021/acs.jpcc.3c07918

Tarbi A, Chtouki T, Bouich A, Sellam MA, Erguig H, Migalska-Zalas A (2024) Towards estimating the thermal properties of carbon allotropes and their derivatives: hybridization between the artificial neural network method and the experimental design approach. Results Chem 7:101295. https://doi.org/10.1016/j.rechem.2023.101295

Liu H, Wei Y, Wu D, Wang S (2024) A novel 2D carbon allotrope for high-performance metal-ion battery anode material. Mater Sci Semicond Process 173:108146. https://doi.org/10.1016/j.mssp.2024.108146

Galhofo D, Duarte AP, Silvestre N (2024) All-scale approach to evaluate the elasticity and strength of carbon-allotrope reinforced polyimide. Compos Struct 331:117841. https://doi.org/10.1016/j.compstruct.2023.117841

Han JY, Choi TS, Kim S, Lee JW, Ha Y, Jeong KS et al (2016) Probing distinct fullerene formation processes from carbon precursors of different sizes and structures. Anal Chem 88(16):8232–8238. https://doi.org/10.1021/acs.analchem.6b02076

Langenhorst F, Campione M (2019) Ideal and real structures of different forms of carbon, with some remarks on their geological significance. J Geol Soc 176(2):337–347. https://doi.org/10.1144/jgs2018-056

Kurian M, Paul A (2021) Recent trends in the use of green sources for carbon dot synthesis–A short review. Carbon Trends 3:100032. https://doi.org/10.1016/j.cartre.2021.100032

Saravanan K, Jayabalakrishnan D, Bhaskar K, Madhu S (2023) Thermally reduced sugarcane bagasse carbon quantum dots and in-plane flax fiber unsaturated polyester composites: surface conductivity and mechanical properties. Biomass Convers Biorefinery 1–10. https://doi.org/10.1007/s13399-023-04158-0

Sivakumar K, Suvitha S, Kanna, SR, Ponnusamy M (2023) Development of peanut husk carbon quantum dots and ferrite foil epoxy composite for EMI shielding at high frequency bands. Biomass Convers Biorefinery 13(6):5435–5443. https://doi.org/10.1007/s13399-022-03469-y

Alshahrani H, Arun Prakash VR (2023) Electromagnetic interference shielding behavior of hybrid nano Fe3O4/lychee biomass carbon quantum dots-PVA composite at high-frequency bands. J Mater Sci Mater Electron 34(29):1988. https://doi.org/10.1007/s10854-023-11418-2

Zeleniuc O, Mazaherifar MH, Coșereanu C, Suciu A (2024) Date-palm-based sustainable hybrid composite with cotton and Kevlar fibre participation. Appl Sci 14(3):1008. https://doi.org/10.3390/app14031008

Navidfar A, Peker MI, Budak E, Unlu C, Trabzon L (2022) Carbon quantum dots enhanced graphene/carbon nanotubes polyurethane hybrid nanocomposites. Compos Part B 247:110310. https://doi.org/10.1016/j.compositesb.2022.110310

Alshahrani H, Arun Prakash VR (2024) Load bearing investigations on novel acrylonitrile butadiene styrene-carbon quantum dots 3D printed core/bamboo fiber polyester sandwich composite for structural applications. Polym Compos 45(4):3081–3093. https://doi.org/10.1002/pc.27972

Sundeep M, Limbadri K, Manikandan N, Savio AP, Joseph J (2023) Study of mechanical properties of pineapple leaf fiber and E-glass fiber reinforced hybrid epoxy matrix composite materials. Proc Mater Today. https://doi.org/10.1016/j.matpr.2023.06.319

Vincent A, Ramesh G, Kumar SM (2018) Microwave shielding behaviour of surface treated MWCNT-epoxy composites in I & J band-s note. Colloid Interface Sci Commun 24:89–92. https://doi.org/10.1016/j.colcom.2018.04.007

Ghosh S, Greenfeld I, Wagner HD (2023) CNT coating and anchoring beads enhance interfacial adhesion in fiber composites. Compos A: Appl Sci Manuf 167:107427. https://doi.org/10.1016/j.compositesa.2023.107427

Mindivan FERDA, Göktaş M (2023) The green synthesis of carbon quantum dots (CQDs) and characterization of polycaprolactone (PCL/CQDs) films. Colloids Surf A Physicochem Eng Asp 677:132446. https://doi.org/10.1016/j.colsurfa.2023.132446

Jiang L, Nie S, Yang J, Dong J (2023) Synthesis and application of Setaria viridis-like heterostructures using nickel phyllosilicate decorating polyaniline nanorods: toward the robust and wear-resisting epoxy-based composites. Polym Compos 44(12):8541–8558. https://doi.org/10.1002/pc.27718

Alshahrani H, Prakash VA (2023) Development of highly flexible electromagnetic interference shielding composites for electronic applications using Cobalt/Hevea brasiliensis seed husk carbon dots/bamboo microfibrepolyvinyl alcohol. Ind Crop Prod 191:115967. https://doi.org/10.1016/j.indcrop.2022.115967

Hu E, Su E, Subedi A, Liu S, Wang J, Zhong H, Hu K (2023) Investigate on the dry friction tribological behaviors and mechanism of carbon quantum dot/polyimide composites coating. Wear 530:205048. https://doi.org/10.1016/j.wear.2023.205048

Prakash VA, Viswanthan R (2019) Fabrication and characterization of echinoidea spike particles and kenaf natural fibre-reinforced Azadirachta-Indica blended epoxy multi-hybrid bio composite. Compos A: Appl Sci Manuf 118:317–326. https://doi.org/10.1016/j.compositesa.2019.01.008

Kocaman M, Çuvalcı H, Çanakçı A (2023) The effect of novel advanced method on the properties of novolac hybrid nanocomposites reinforced with carbon nanotube and glass fiber. J Appl Polym Sci 140(36):e54366. https://doi.org/10.1002/app.54366

Thiyagu TT, Gokilakrishnan G, Uvaraja VC, Maridurai T, Prakash VA (2022) Effect of SiO2/TiO2 and ZnO nanoparticle on cardanol oil compatibilized PLA/PBAT biocomposite packaging film. Silicon 14(7):3795–3808. https://doi.org/10.1007/s12633-021-01577-4

Hosseini M, Gaff M, Li H, Konvalinka P, Lair J, Hui D et al (2023) A review of the performance of fibre-reinforced composite laminates with carbon nanotubes. Nanotechnol Rev 12(1):20230164. https://doi.org/10.1515/ntrev-2023-0164

Prabhu P, Jayabalakrishnan D, Balaji V, Bhaskar K, Maridurai T, Prakash VA (2024) Mechanical, tribology, dielectric, thermal conductivity, and water absorption behaviour of Caryota urens woven fibre-reinforced coconut husk biochar toughened wood-plastic composite. Biomass Convers Biorefinery 14(1):109–116. https://doi.org/10.1007/s13399-021-02177-3

Mahdavian F, Allahbakhsh A, Rodrigue D, Bahramian AR (2024) Polyethylene glycol-impregnated carbon quantum dots-phenolic phase change composites for highly efficient thermal energy storage. Carbon 219:118840. https://doi.org/10.1016/j.carbon.2024.118840

Ghosh T, Das TK, Das P, Banerji P, Das NC (2022) Current scenario and recent advancement of doped carbon dots: a short review scientocracy update (2013–2022). Carbon Lett 32(4):953–977. https://doi.org/10.1007/s42823-022-00339-5

Arun Prakash VR, Xavier JF, Ramesh G, Maridurai T, Kumar KS, Raj RBS (2022) Mechanical, thermal and fatigue behaviour of surface-treated novel Caryota urens fibre–reinforced epoxy composite. Biomass Convers Biorefinery 12(12):5451–5461. https://doi.org/10.1007/s13399-020-00938-0

Khan MK, Faisal M, Prakash VR (2024) Characterization of sea urchin spike chitin macromolecule and basalt-encapsulated bamboo fiber-epoxy environmental friendly composite for human prosthetic application. Polym Bull 1-19. https://doi.org/10.1007/s00289-024-05208-x

Ganguly S, Das P, Banerjee S, Das NC (2019) Advancement in science and technology of carbon dot-polymer hybrid composites: a review. Funct Compos Struct 1(2):022001. https://doi.org/10.1088/2631-6331/ab0c80

Author information

Authors and Affiliations

Contributions

Shakthi Prasad M – research, writing and testing.

C. Ramesh– material arrangement and writing.

Corresponding author

Ethics declarations

Ethical approval

Not applicable.

Competing interests

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

M., S.P., Ramesh, C. Mechanical, wear, thermal conductivity and hydrophobicity behavior of Kevlar fiber-epoxy structural composites reinforced with onion peel carbon quantum dot and commercial carbon nanotubes: a comparative study. Biomass Conv. Bioref. (2024). https://doi.org/10.1007/s13399-024-05591-5

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s13399-024-05591-5