Abstract

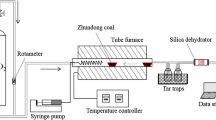

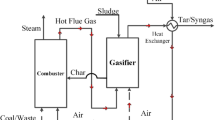

A special biomass waste, Chinese herb residues (CHR) was considered to be disposed of by the (co-) pyrolysis and the steam gasification with anthracitic coal (AC) through TGA and horizontal tubular furnace reactor (HTFR) coupled with gas chromatography (GC). TGA results showed that the interaction effects between CHR and AC during co-pyrolysis were negligible at the low CHR blending ratio, but there existed an inhibiting effect at the high CHR blending ratio. Co-pyrolysis kinetics results showed that the activation energies rose with the reaction proceeding. The HTFR pyrolysis showed that, with the temperature growing, the contents of CO and H2 increased, but the content of CO2 and CH4 decreased. In the steam gasification tests, the main product in the syngas was H2, and the gasification performances were influenced by the temperature and steam flow rate. FTIR results showed that the absorption peaks of functional groups in the residues from the HTFR pyrolysis reduced with the temperature increasing. For the steam gasification of the 50CHR/50AC blend, the contents of CO and H2 increased obviously as compared to those from the gasification of CHR. The syngas yield of 50CHR/50AC increased with the gasification temperatures increasing, and the value was clearly higher than that from CHR.

Graphical Abstract

Similar content being viewed by others

Data availability

All required/mentioned data are available in the manuscript.

References

Gouws SM, Carrier M, Bunt JR, Neomagus HWJP (2021) Co–pyrolysis of coal and raw/ torrefied biomass: a review on chemistry, kinetics and implementation. Renew Sustain Energy Rev 135:110189

Chen J, Fan X, Jiang B, Mu L, Yao P, Yin H (2015) Pyrolysis of oil–plant wastes in a TGA and a fixed–bed reactor: thermochemical behaviors, kinetics, and products characterization. Bioresource Technol 192:592–602

Bach QV, Chen WH (2017) Pyrolysis characteristics and kinetics of microalgae via thermogravimetric analysis (TGA): a state–of–the–art review. Bioresource Technol 246:88–100

Ren X, Chen J, Li G, Wang Y, Lang X, Fan S (2018) Thermal oxidative degradation kinetics of agricultural residues using distributed activation energy model and global kinetic model. Bioresource Technol 246:88–100

Gai C, Liu Z, Han G, Peng N, Fan A (2015) Combustion behavior and kinetics of low–lipid microalgae via thermogravimetric analysis. Bioresource Technol 181:148–154

Guo F, Dong Y, Dong L, **g Y (2013) An innovative example of herb residues recycling by gasification in a fluidized bed. Waste Manage 33:825–832

Wang P, Zhan SH, Yu HB, Xue XF, Hong N (2010) The effects of temperature and catalysts on the pyrolysis of industrial wastes (herb residue). Bioresource Technol 101:3236–3241

Yang J, Qiu KQ (2011) Development of high surface area mesoporous activated carbons from herb residues. Chem Eng J 167:148–154

Guo F, Dong Y, Zhang T, Dong L, Guo C, Rao Z (2014) Experimental study on herb residue gasification in an air−blown circulating fluidized bed gasifier. Ind Eng Chem Res 53:13264–13273

Li Q, Lu Y, Guo X, Shan G, Huang J (2017) Properties and evolution of dissolved organic matter during co–composting of dairy manure and Chinese herbal residues. Environ Sci Pollut Res 24(9):8629–8636

Zhou Y, Selvam A, Wong JWC (2018) Chinese medicinal herbal residues as a bulking agent for food waste composting. Bioresource Technol 249:182–188

Du Y, Jiang X, Lv G, Ma X, ** Y, Wang F, Chi Y, Yan J (2014) Thermal behavior and kinetics of bio–ferment residue/coal blends during co–pyrolysis. Energy Convers Manage 88:459–463

Du Y, Jiang X, Ma X, Tang L, Wang M, Lv G, ** Y, Wang F, Chi Y, Yan J (2014) Cogasification of biofermenting residue in a coal−water slurry gasifier. Energy Fuels 28:2054–2058

Zeng X, Dong Y, Wang F, Xu P, Shao R, Dong P, Xu G, Dong L (2016) Fluidized bed two−stage gasification process for clean fuel gas production from herb residue: Fundamentals and demonstration. Energy Fuels 30(9):7277–7283

Liu F, Wu X, Zhang X, Yang L, Liu Y, Song Z (2021) Co−use of organic herbal residue and red mud waste for syngas production by chemical loo** gasification. Int J Energy Res 45:2195–2210

Lv PM, **ong ZH, Chang J, Wu CZ, Chen Y, Zhu JX (2004) An experimental study on biomass air–steam gasification in a fluidized bed. Bioresource Technol 95:95–101

Naik DK, Kalpit S, Bhargava SK, Satyavathi B, Rajarathinam P (2018) Oxygen–steam gasification of karanja press seed cake: fixed bed experiments, aspen plus process model development and benchmarking with saw dust, rice husk and sunflower husk. J Environ Chem Eng 6(2):3061–3069

Kuo JH, Lin CL, Chang TJ, Weng WC, Liu JY (2016) Experimental investigation of synthetic gas composition in a two–stage fluidized bed gasification process: effect of activated carbon as bed material. Environ Technol 38(9):2195–2210

Doherty W, Reynolds A, Kennedy D (2009) The effect of air preheating in a biomass CFB gasifier using ASPEN Plus simulation. Biomass Bioenergy 33:1158–1167

Lv P, Yuan Z, Ma L, Wu C, Chen Y, Zhu J (2007) Hydrogen–rich gas production from biomass air and oxygen/steam gasification in a downdraft gasifier. Renew Energy 32:2173–2185

Gao N, Li A, Quan C, Gao F (2008) Hydrogen–rich gas production from biomass steam gasification in an updraft fixed–bed gasifier combined with a porous ceramic re–former. Int J Hydrogen Energy 33:5430–5438

Xu J, Nyambura SM, Li C, Wang J, Li H, Zhu X, Feng X, Luo W (2022) Catalytic co-pyrolysis characteristics and kinetics analysis of food waste and chinar leaves, and the large-scale microwave disposal feasibility. Biomass Convers Bior 221:147–156

Song Y, Tahmasebi A, Yu J (2014) Co–pyrolysis of pine sawdust and lignite in a thermogravimetric analyzer and a fixed–bed reactor. Bioresource Technol 174:204–211

Wu Y, Liao Y, Liu G, Ma X (2018) Syngas production by chemical loo** gasification of biomass with steam and Cao additive. Int J Hydrogen Energy 43(42):19375–19383

Liu G, Liao Y, Wu Y, Ma X, Chen L (2017) Characteristics of microalgae gasification through chemical loo** in the presence of steam. Int J Hydrogen Energy 42(36):22730–22742

Liu G, Liao Y, Wu Y, Ma X (2018) Application of calcium ferrites as oxygen carriers for microalgae chemical loo** gasification. Energy Convers Manage 160:262–272

Yang H, Yan R, Chen H, Lee DH, Zheng C (2007) Characteristics of hemicellulose, cellulose and lignin pyrolysis. Fuel 86:1781–1788

Xu J, Yang L, Xu H, Jiang Y, Guo Y, Ran S, Gao Y (2022) Characteristics and kinetic analysis of the catalytic pyrolysis of oily sludge under new nickel-ore–based catalysts. Biomass Convers Bior:1–9

Li J, Dou B, Zhang H, Zhang H, Chen H, Xu Y, Wu C (2021) Pyrolysis characteristics and non-isothermal kinetics of waste wood biomass. Energy 226:120358

Wang C, Dou B, Song Y, Chen H, Yang M, Xu Y (2014) Kinetic study on non-isothermal pyrolysis of sucrose biomass. Energy Fuels 28:3793–3801

Lin Y, Xu H, Gao Y, Zhang X (2021) Preparation and characterization of hydrochar-derived activated carbon from glucose by hydrothermal carbonization. Biomass Convers Bior 13:3785–3796

Li H, Niu S, Lu C, Wang Y (2015) Comprehensive investigation of the thermal degradation characteristics of biodiesel and its feedstock oil through TGA–FTIR. Energy Fuels 29:5145–5153

Huang X, Yin H, Zhang B, Mei N, Mu L (2022) Pyrolysis of lignin (De–alkaline) via TG/DSC–FTIR and TG–MS: pyrolysis characteristics, thermo-kinetics, and gas products. Biomass Convers Bior:1–18

Hu Z, Ma X, Li L, Wu J (2014) The catalytic pyrolysis of microalgae to produce syngas. Energy Convers Manage 85:545–550

Fajimi LI, Chrisostomou J, Oboirien BO (2022) A techno-economic analysis (TEA) of a combined process of torrefaction and gasification of lignocellulose biomass (bagasse) for methanol and electricity production. Biomass Convers Bior:1–16

Acknowledgements

This work was financially supported by the Natural Science Foundation of the Jiangsu Higher Education Institutions of China (21KJB470004) and the Open Project of Yunnan Provincial Key Laboratory of Metal-Organic Molecular Materials and Devices (YNMOMDKF2204).

Funding

Financial support for this work has been provided by the Natural Science Foundation of the Jiangsu Higher Education Institutions of China (21KJB470004) and the Open Project of Yunnan Provincial Key Laboratory of Metal-Organic Molecular Materials and Devices (YNMOMDKF2204).

Author information

Authors and Affiliations

Contributions

Chuanzhong Zhou: investigation, writing, and draft preparation; Meng Sun: data analysis and revising; Hairui Qiao: investigation, and data analysis; Ziyang Gan: original draft preparation, and data analysis; Mingche **n: writing, software, and data analysis; Zheng Gong: investigation, and writing; Jianbiao Chen: conceptualization, writing, editing, funding acquisition, supervision; **aoyuan Wang: data analysis, revising, and editing; Haojie Gao: revising, and editing; Kai Guo: original draft preparation, and revision; Yuezhao Zhu: supervision.

Corresponding author

Ethics declarations

Ethical approval

Not applicable.

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Highlights

• Pyrolysis and steam gasification characteristics of Chinese herb residues were studied.

• Co-pyrolysis kinetic parameters were calculated from an improved Coats-Redfern method.

• Gasification efficiency of CHR increased from 45.74 to 91.75% as temperature boosted.

• Gasification was affected by the steam flow rate, clearly improved by the introduction of steam.

• Compared to single CHR, the steam gasification performances of CHR and AC were better.

Supplementary information

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Zhou, C., Qiao, H., Gan, Z. et al. (Co-) pyrolysis/steam gasification of Chinese herb residues and anthracitic coal: interaction effects, kinetic parameters, and products evaluation. Biomass Conv. Bioref. (2023). https://doi.org/10.1007/s13399-023-04584-0

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s13399-023-04584-0