Abstract

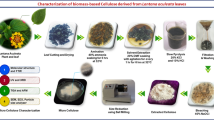

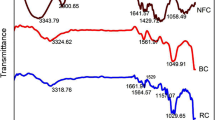

The identification of novel cellulosic materials is imperative at the moment to ensure high-quality materials for building polymer composites that possess high-performance. This study was conducted to explore the specific properties of a novel micro-sized cellulosic fillers obtained from Nelumbo nucifera leaves and thereby to establish its feasibility as composite reinforcement. The physico-chemical, surface and thermal behaviours are investigated for cellulosic micro fillers that extracted through thermo-chemical method. The density of the extracted fillers was analysed to realize its mode of applicability. Whereas chemical characterization studies were indispensable to explore the chemical nature of the material. Of which, X-ray diffraction analysis proved that Nelumbo nucifera leaves has good crystallinity index (75.9%) and crystalline size (8.2 nm). The Fourier Transform Infrared Spectrometer analysis showed that the material possesses high cellulosic contents rather very less non-cellulosic residues. Scanning electron microscope images disclosed the roughness pattern of the filler surface and subsequently the average particle size of the micro fillers is identified as 23.253±6.55μm through ImageJ tool. At the same time, atomic force microscopy images revealed that micro cellulose extracted has desired average roughness (28.296 μm). Though, the suitable surface features of Nelumbo nucifera leaves are found to be virtuous for providing interfacial bonding with other matrices during composite formulation. Along with that, good thermal stability (215°C) offers its processing and application even at relatively higher temperatures. Since, the present study has accomplished that Nelumbo nucifera leaves is a promising alternative source of micro cellulose for traditionally used sources like wood, hemp, and cotton, for the extraction of micro cellulose, which could be further used as a promising alternative to synthetic reinforcements.

Similar content being viewed by others

Data availability

The data that support the findings of this study are available on request from the corresponding author. The data are not publicly available due to privacy or ethical restrictions.

References

Miao C, Hamad WY (2013) Cellulose reinforced polymer composites and nanocomposites: a critical review. Cellulose 20:2221–2262. https://doi.org/10.1007/s10570-013-0007-3

Thulasisingh A, Kannaiyan S, Pichandi K (2021) Cellulose nanocrystals from orange and lychee biorefinery wastes and its implementation as tetracycline drug transporter. Biomass Convers Biorefin:1–14

Fareez IM, Ibrahim NA, Wan Yaacob WMH et al (2018) Characteristics of cellulose extracted from Josapine pineapple leaf fibre after alkali treatment followed by extensive bleaching. Cellulose 25:4407–4421. https://doi.org/10.1007/s10570-018-1878-0

Trache D, Hussin MH, Hui Chuin CT et al (2016) Microcrystalline cellulose: Isolation, characterization and bio-composites application—a review. Elsevier B.V

Sharma A, Thakur M, Bhattacharya M et al (2019) Commercial application of cellulose nano-composites – a review. Biotechnol Rep 21:e00316. https://doi.org/10.1016/j.btre.2019.e00316

Terea H, Selloum D, Rebiai A, Bouafia A, Ben Mya O (2023) Preparation and characterization of cellulose/ZnO nanoparticles extracted from peanut shells: effects on antibacterial and antifungal activities. Biomass Conv Bioref 1:1–12. https://doi.org/10.1007/S13399-023-03959-7

Haldar D, Purkait MK (2020) Micro and nanocrystalline cellulose derivatives of lignocellulosic biomass: a review on synthesis, applications and advancements. Carbohydr Polym 250:116937

Singh Nee Nigam P, Pandey A (2009) Biotechnology for agro-industrial residues utilisation: Utilisation of agro-residues. Springer Netherlands

Mihai M, Ton-That MT (2018) Valorization of triticale straw biomass as reinforcement in proficient polypropylene biocomposites. Waste Biomass Valoriz 9:1971–1983. https://doi.org/10.1007/S12649-017-9959-0/FIGURES/14

Okolie JA, Nanda S, Dalai AK, Kozinski JA (2021) Chemistry and specialty industrial applications of lignocellulosic biomass. Waste Biomass Valoriz 12:2145–2169. https://doi.org/10.1007/S12649-020-01123-0/FIGURES/6

Ramachandran S, Singh SK, Larroche C et al (2007) Oil cakes and their biotechnological applications - a review. Bioresour Technol 98:2000–2009. https://doi.org/10.1016/j.biortech.2006.08.002

Prieto-García F, Jiménez-Muñoz E, Acevedo-Sandoval OA et al (2019) Obtaining and optimization of cellulose pulp from leaves of agave tequilana weber var. blue. Preparation of Handmade Craft Paper. Waste Biomass Valoriz 10:2379–2395. https://doi.org/10.1007/S12649-018-0262-5/TABLES/10

Awad S, Zhou Y, Katsou E et al (2020) A critical review on date palm Tree (Phoenix dactylifera L.) fibres and their uses in bio-composites. Waste Biomass Valoriz 12:2853–2887. https://doi.org/10.1007/S12649-020-01105-2

Song YR, Han AR, Lim TG et al (2019) Isolation, purification, and characterization of novel polysaccharides from lotus (Nelumbo nucifera) leaves and their immunostimulatory effects. Int J Biol Macromol 128:546–555. https://doi.org/10.1016/j.ijbiomac.2019.01.131

Chen G, Zhu M, Guo M (2019) Research advances in traditional and modern use of Nelumbo nucifera: phytochemicals, health promoting activities and beyond. Crit Rev Food Sci Nutr 59:S189–S209. https://doi.org/10.1080/10408398.2018.1553846

Trache D, Hussin MH, Hui Chuin CT et al (2016) Microcrystalline cellulose: isolation, characterization and bio-composites application—a review. Int J Biol Macromol 93:789–804. https://doi.org/10.1016/j.ijbiomac.2016.09.056

Mtibe A, Linganiso LZ, Mathew AP et al (2015) A comparative study on properties of micro and nanopapers produced from cellulose and cellulose nanofibres. Carbohydr Polym 118:1–8. https://doi.org/10.1016/j.carbpol.2014.10.007

Paes SS, Sun S, MacNaughtan W et al (2010) The glass transition and crystallization of ball milled cellulose. Cellulose 17:693–709. https://doi.org/10.1007/s10570-010-9425-7

Muralidaran VM, Natrayan L, Kaliappan S, Patil PP (2023) Grape stalk cellulose toughened plain weaved bamboo fiber-reinforced epoxy composite: load bearing and time-dependent behavior. Biomass Convers Biorefin 1:1–8. https://doi.org/10.1007/S13399-022-03702-8/FIGURES/5

Katakojwala R, Mohan SV (2020) Microcrystalline cellulose production from sugarcane bagasse: sustainable process development and life cycle assessment. J Clean Prod 249. https://doi.org/10.1016/j.jclepro.2019.119342

Naduparambath S, **itha TV, Shaniba V, Sreejith MP, Balan AK (2018) Isolation and characterisation of cellulose nanocrystals from sago seed shells. Carbohydr Polym 180:13–20. https://doi.org/10.1016/j.carbpol.2017.09.088

Madhu S, Devarajan Y, Natrayan L (2023) Effective utilization of waste sugarcane bagasse filler-reinforced glass fibre epoxy composites on its mechanical properties - waste to sustainable production. Biomass Convers Biorefin 1:1–8. https://doi.org/10.1007/S13399-023-03792-Y/FIGURES/9

Ghalehno MD, Yousefi H (2023) Toward wheat straw valorization by its downsizing to five types of cellulose nanomaterials and nanopapers thereof. Waste Biomass Valoriz 1:1–12. https://doi.org/10.1007/S12649-023-02031-9/FIGURES/7

Mishra SK, Dahiya S, Gangil B et al (2022) (2022) Mechanical, morphological, and tribological characterization of novel walnut shell-reinforced polylactic acid-based biocomposites and prediction based on artificial neural network. Biomass Conv Bioref 1:1–12. https://doi.org/10.1007/S13399-022-03670-Z

Tarchoun AF, Trache D, Klapötke TM (2019) Microcrystalline cellulose from Posidonia oceanica brown algae: extraction and characterization. Int J Biol Macromol 138:837–845. https://doi.org/10.1016/j.ijbiomac.2019.07.176

Merci A, Urbano A, Grossmann MVE et al (2015) Properties of microcrystalline cellulose extracted from soybean hulls by reactive extrusion. Food Res Int 73:38–43. https://doi.org/10.1016/j.foodres.2015.03.020

Ciolacu D, Popa V, Ciolacu F, Popa VI (2011) Amorphous cellulosestructure and characterization related papers amorphous cellulose-st ruct ure and valent in I Popa St udies concerning t he accessibilit y of different allomorphic forms of cellulose Diana Ciolacu Cellulose Ciolacu 2-fullt ext AMORPHOUS. Cellulose Chem Technol 45:13–21

Gapsari F, Andoko A, Diharjo K et al (2022) (2022) The effectiveness of isolation and characterization nanocelullose from Timoho fiber for sustainable materials. Biomass Conv Bioref 1:1–11. https://doi.org/10.1007/S13399-022-03672-X

Nguyen PTT, Do NHN, Goh XY et al (2021) Recent progresses in eco-friendly fabrication and applications of sustainable aerogels from various waste materials. Waste and Biomass Valoriz 13:1825–1847. https://doi.org/10.1007/S12649-021-01627-3

Zhang L, Tu ZC, Wang H, Kou Y, Wen QH, Fu ZF, Chang HX (2015) Response surface optimization and physicochemical properties of polysaccharides from Nelumbo nucifera leaves. Int J Biol Macromol 74:103–110. https://doi.org/10.1016/j.ijbiomac.2014.11.020

Wang S, Peng X, Zhong L et al (2015) Choline chloride/urea as an effective plasticizer for production of cellulose films. Carbohydr Polym 117:133–139. https://doi.org/10.1016/j.carbpol.2014.08.113

Munagapati VS, Wen HY, Wen JC et al (2022) Adsorption of Reactive Red 195 from aqueous medium using Lotus (Nelumbo nucifera) leaf powder chemically modified with dimethylamine: characterization, isotherms, kinetics, thermodynamics, and mechanism assessment. Int J Phytoremediation 24:131–144. https://doi.org/10.1080/15226514.2021.1929060

Gardner DJ, Oporto GS, Mills R, Samir MASA (2008) Adhesion and surface issues in cellulose and nanocellulose. J Adhes Sci Technol 22:545–567. https://doi.org/10.1163/156856108X295509

Kumar R, Hynes NRJ, Senthamaraikannan P, Sanjay MR (2018) Physicochemical and thermal properties of Ceiba pentandra bark fiber physicochemical and thermal properties of Ceiba pentandra bark. J Nat Fibers 15:822–829. https://doi.org/10.1080/15440478.2017.1369208

Arjmandi R, Hassan A, Mohamad Haafiz MK, Zakaria Z (2016) Biodegradability and thermal properties of hybrid montmorillonite/microcrystalline cellulose filled polylactic acid composites: effect of filler ratio. Polym Polym Comp 24:741–746. https://doi.org/10.1177/096739111602400910

Fareez IM, Ibrahim NA, Wan Yaacob WMH et al (2018) Characteristics of cellulose extracted from Josapine pineapple leaf fibre after alkali treatment followed by extensive bleaching. Cellulose 25:4407–4421. https://doi.org/10.1007/s10570-018-1878-0

Sunesh NP, Indran S, Divya D, Suchart S (2022) Isolation and characterization of novel agrowaste-based cellulosic micro fillers from Borassus flabellifer flower for polymer composite reinforcement. Polym Compos 43:6476–6488. https://doi.org/10.1002/PC.26960

Kouadri I, Satha H (2018) Extraction and characterization of cellulose and cellulose nanofibers from Citrullus colocynthis seeds. Ind Crops Prod 124:787–796. https://doi.org/10.1016/j.indcrop.2018.08.051

Gabriel T, Belete A, Syrowatka F et al (2020) Extraction and characterization of celluloses from various plant byproducts. Int J Biol Macromol 158:1248–1258. https://doi.org/10.1016/j.ijbiomac.2020.04.264

Andrade Alves JA, Lisboa dos Santos MD, Morais CC et al (2019) Sorghum straw: Pul** and bleaching process optimization and synthesis of cellulose acetate. Int J Biol Macromol 135:877–886. https://doi.org/10.1016/j.ijbiomac.2019.05.014

Harini K, Chandra Mohan C (2020) Isolation and characterization of micro and nanocrystalline cellulose fibers from the walnut shell, corncob and sugarcane bagasse. Int J Biol Macromol 163:1375–1383. https://doi.org/10.1016/j.ijbiomac.2020.07.239

Phanthong P, Reubroycharoen P, Hao X, et al (2018) Nanocellulose: extraction and application. Carbon Resour Conv 1:32–43. https://doi.org/10.1016/j.crcon.2018.05.004

Ibrahim I, Al-Obaidi Y, Hussin S (2015) Removal of methylene blue using cellulose nanocrystal synthesized from cotton by ultrasonic technique. Am Chem Sci J 9:1–7. https://doi.org/10.9734/acsj/2015/20031

Collazo-Bigliardi S, Ortega-Toro R, Chiralt Boix A (2018) Isolation and characterisation of microcrystalline cellulose and cellulose nanocrystals from coffee husk and comparative study with rice husk. Carbohydr Polym 191:205–215. https://doi.org/10.1016/j.carbpol.2018.03.022

Li M, He B, Zhao L (2019) Isolation and characterization of microcrystalline cellulose from Cotton Stalk Waste. Bioresources 14:3231–3246. https://doi.org/10.15376/biores.14.2.3231-3246

Candlen K, Haque MA, Farfaras N et al (2022) Biodegradable mulch films produced from soy-filled polymer resins. Mater Today Commun 31:103331. https://doi.org/10.1016/j.mtcomm.2022.103331

Khan MN, Rehman N, Sharif A et al (2020) Environmentally benign extraction of cellulose from dunchi fiber for nanocellulose fabrication. Int J Biol Macromol 153:72–78. https://doi.org/10.1016/j.ijbiomac.2020.02.333

Sumesh KR, Kanthavel K, Kavimani V (2020) Peanut oil cake – derived cellulose fiber: extraction, application of mechanical and thermal properties in pineapple/flax natural fiber composites sumesh. Int J Biol Macromol 150:775–785. https://doi.org/10.1016/j.ijbiomac.2020.02.118

Midhun Dominic CD, Raj V, Neenu KV et al (2022) Chlorine-free extraction and structural characterization of cellulose nanofibers from waste husk of millet (Pennisetum glaucum). Int J Biol Macromol 206:92–104. https://doi.org/10.1016/j.ijbiomac.2022.02.078

Sheltami RM, Abdullah I, Ahmad I et al (2012) Extraction of cellulose nanocrystals from mengkuang leaves (Pandanus tectorius). Carbohydr Polym 88:772–779. https://doi.org/10.1016/j.carbpol.2012.01.062

Nagarajan KJ, Balaji AN, Kasi Rajan ST, Ramanujam NR (2020) Preparation of bio-eco based cellulose nanomaterials from used disposal paper cups through citric acid hydrolysis. Carbohydr Polym 235:115997. https://doi.org/10.1016/j.carbpol.2020.115997

Reddy KO, Uma Maheswari C, Muzenda E et al (2016) Extraction and characterization of cellulose from pretreated ficus (Peepal Tree) leaf fibers. J Nat Fibers 13:54–64. https://doi.org/10.1080/15440478.2014.984055

Reddy KO, Maheswari CU, Dhlamini MS et al (2018) Extraction and characterization of cellulose single fibers from native african napier grass. Carbohydr Polym 188:85–91. https://doi.org/10.1016/j.carbpol.2018.01.110

Mohammed L, Ansari MNM, Pua G et al (2015) A review on natural fiber reinforced polymer composite and its applications. Int J Polym Sci 2015:1–15. https://doi.org/10.1155/2015/243947

Thomas SK, Parameswaranpillai J, Krishnasamy S, et al (2021) A comprehensive review on cellulose, chitin, and starch as fillers in natural rubber biocomposites. Carbohydr Polym Technol Appl 2:100095. https://doi.org/10.1016/j.carpta.2021.100095

Miléo PC, Oliveira MF, Luz SM et al (2016) Thermal and chemical characterization of sugarcane bagasse cellulose/lignin-reinforced composites. Polym Bull 73:3163–3174. https://doi.org/10.1007/s00289-016-1647-x

Klemm D, Heublein B, Fink HP, Bohn A (2005) Cellulose: fascinating biopolymer and sustainable raw material. Angew Chem Int Ed Eng 44:3358–3393. https://doi.org/10.1002/anie.200460587

Xu L, Wang A, Li S et al (2022) Biomass residue cellulose-based poly(ionic liquid)s: new materials with selective metal ion adsorption. Biomass Convers Biorefin 12:3933–3942. https://doi.org/10.1007/s13399-020-00889-6

Hokkanen S, Bhatnagar A, Sillanpää M (2016) A review on modification methods to cellulose-based adsorbents to improve adsorption capacity. Water Res 91:156–173. https://doi.org/10.1016/j.watres.2016.01.008

Lavoine N, Desloges I, Dufresne A, Bras J (2012) Microfibrillated cellulose—its barrier properties and applications in cellulosic materials: a review. Carbohyd Polym 90:735–764. https://doi.org/10.1016/j.carbpol.2012.05.026

Araújo DJC, Machado AV, Vilarinho MCLG (2019) Availability and suitability of agroindustrial residues as feedstock for cellulose-based materials: Brazil case study. Waste Biomass Valoriz 10:2863–2878. https://doi.org/10.1007/S12649-018-0291-0/FIGURES/6

Yang J, An X, Liu L et al (2020) Cellulose, hemicellulose, lignin, and their derivatives as multi-components of bio-based feedstocks for 3D printing. Carbohydr Polym 250:116881. https://doi.org/10.1016/j.carbpol.2020.116881

Kouadri I, Satha H (2018) Extraction and characterization of cellulose and cellulose nanofibers from Citrullus colocynthis seeds. Ind Crops Prod 124:787–796. https://doi.org/10.1016/j.indcrop.2018.08.051

Kassab Z, Kassem I, Hannache H et al (2020) Tomato plant residue as new renewable source for cellulose production: extraction of cellulose nanocrystals with different surface functionalities. Cellulose 27:4287–4303. https://doi.org/10.1007/s10570-020-03097-7

Chung C, Lee M, Choe EK (2004) Characterization of cotton fabric scouring by FT-IR ATR spectroscopy. Carbohydr Polym 58:417–420. https://doi.org/10.1016/j.carbpol.2004.08.005

Salimi E, Taheri ME, Passadis K et al (2021) Valorisation of restaurant food waste under the concept of a biorefinery. Biomass Convers Biorefin 11:661–671. https://doi.org/10.1007/S13399-020-00613-4/FIGURES/5

Reshmy R, Philip E, Paul SA et al (2021) A green biorefinery platform for cost-effective nanocellulose production: investigation of hydrodynamic properties and biodegradability of thin films. Biomass Convers Biorefin 11:861–870. https://doi.org/10.1007/S13399-020-00961-1/FIGURES/8

Chaffa TY, Meshesha BT, Mohammed SA, Jabasingh SA (2022) Production, characterization, and optimization of starch-based biodegradable bioplastic from waste potato (Solanum tuberosum) peel with the reinforcement of false banana (Ensete ventricosum) fiber. Biomass Convers Biorefin 1:1–13. https://doi.org/10.1007/S13399-022-03426-9/FIGURES/7

Nakagaito AN, Kondo H, Takagi H (2013) Cellulose nanofiber aerogel production and applications. J Reinf Plast Compos 32:1547–1552. https://doi.org/10.1177/0731684413494110

Nagaprasad N, Stalin B, Vignesh V et al (2019) Effect of cellulosic filler loading on mechanical and thermal properties of date palm seed/vinyl ester composites. Biol Macromol 147:53–66. https://doi.org/10.1016/j.ijbiomac.2019.11.247

Bilo F, Pandini S, Sartore L et al (2018) A sustainable bioplastic obtained from rice straw. J Clean Prod 200:357–368. https://doi.org/10.1016/J.JCLEPRO.2018.07.252

Ezz H, Ibrahim MG, Fujii M, Nasr M (2021) Dual biogas and biochar production from rice straw biomass: a techno-economic and sustainable development approach. Biomass Convers Biorefin 1:1–15. https://doi.org/10.1007/S13399-021-01879-Y/TABLES/6

Cheng H, Chen L, McClements DJ et al (2021) Starch-based biodegradable packaging materials: a review of their preparation, characterization and diverse applications in the food industry. Trends Food Sci Technol 114:70–82. https://doi.org/10.1016/j.tifs.2021.05.017

Thiruchitrambalam M, Athijayamani A, Sathiyamurthy S, Syed Abu Thaheer A (2010) A review on the natural fiber-reinforced polymer composites for the development of roselle fiber-reinforced polyester composite. J Nat Fibers 7:307–323

Priyadarshana RWIB, Kaliyadasa PE, Ranawana SRWMCJK, Senarathna KGC (2020) Biowaste management: banana fiber utilization for product development. J Nat Fibers. https://doi.org/10.1080/15440478.2020.1776665

Qing Y, Sabo R, Zhu JY et al (2013) A comparative study of cellulose nanofibrils disintegrated via multiple processing approaches. Carbohydr Polym 97:226–234. https://doi.org/10.1016/j.carbpol.2013.04.086

Md Salim R, Asik J, Sarjadi MS (2021) Chemical functional groups of extractives, cellulose and lignin extracted from native Leucaena leucocephala bark. Wood Sci Technol 55:295–313. https://doi.org/10.1007/s00226-020-01258-2

Berger C, Mattos BD, Amico SC et al (2020) Production of sustainable polymeric composites using grape pomace biomass. Biomass Convers Biorefin. https://doi.org/10.1007/s13399-020-00966-w

Kunam PK, Ramakanth D, Akhila K, Gaikwad KK (2022) Bio-based materials for barrier coatings on paper packaging. Biomass Convers Biorefin. https://doi.org/10.1007/s13399-022-03241-2

Abu-Thabit NY, Judeh AA, Hakeem AS et al (2020) Isolation and characterization of microcrystalline cellulose from date seeds (Phoenix dactylifera L.). Int J Biol Macromol 155:730–739. https://doi.org/10.1016/j.ijbiomac.2020.03.255

Alshahrani H, Vr AP (2022) Mechanical, wear, and fatigue behavior of alkali-silane-treated areca fiber, RHA biochar, and cardanol oil-toughened epoxy biocomposite. Biomass Convers Biorefin. https://doi.org/10.1007/s13399-022-02691-y

Elangovan M, Perumal A, Kavisri M, Moovendhan M (2022) Isolation, chemical characterization and in vitro bioactive potential of polysaccharides from seaweed Portieria hornemannii. Biomass Convers Biorefin. https://doi.org/10.1007/s13399-022-03276-5

Stalin N, Shobhanadevi N (2021) Studies on thermal, structural, and compositional properties of agro-waste jute fiber composite reinforced with cardanol resin. Biomass Convers Biorefin. https://doi.org/10.1007/s13399-021-01958-0

Kukrety A, Singh RK, Singh P, Ray SS (2018) Comprehension on the synthesis of carboxymethylcellulose (CMC) utilizing various cellulose rich waste biomass resources. Waste Biomass Valoriz 9:1587–1595. https://doi.org/10.1007/S12649-017-9903-3/FIGURES/1

de Souza RC, Ghavami K, Stroeven P (2010) Rice husk ash as a supplementary raw material for the production of cellulose-cement composites with improved performance. Waste Biomass Valoriz 1:241–249. https://doi.org/10.1007/S12649-010-9017-7/FIGURES/6

Visakh PM, Thomas S (2010) Preparation of bionanomaterials and their polymer nanocomposites from waste and biomass. Waste Biomass Valoriz 1:121–134. https://doi.org/10.1007/S12649-010-9009-7/FIGURES/16

Kraemer E (1938) Molecular weights of celluloses determination of kinetic unit size in cellulosic solutions. Inductr Eng Chem 30:1200–1203

Kumaran P, Mohanamurugan S, Madhu S et al (2020) Investigation on thermo-mechanical characteristics of treated/untreated Portunus sanguinolentus shell powder-based jute fabrics reinforced epoxy composites. J Industr Text 50:427–459. https://doi.org/10.1177/1528083719832851

Funding

This research was fully supported by King Mongkut’s University of Technology North Bangkok under grant no. KMUTNB-Post-66-08.

Author information

Authors and Affiliations

Contributions

All authors are equally contributed to Conceptualization, Methodology, Writing - original draft, Writing - review & editing.

Corresponding author

Ethics declarations

Ethical approval

Not applicable.

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Divakaran, D., Sriariyanun, M., Basha, S.A. et al. Physico-chemical, thermal, and morphological characterization of biomass-based novel microcrystalline cellulose from Nelumbo nucifera leaf: Biomass to biomaterial approach. Biomass Conv. Bioref. (2023). https://doi.org/10.1007/s13399-023-04349-9

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s13399-023-04349-9