Abstract

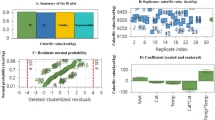

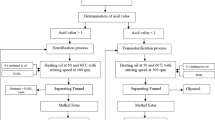

Waste cooking oil (WCO) may be recycled to produce solid alcohol fuel (SAF). The higher heating value (HHV) of recycled WCO, its micromorphology and physicochemical characteristics, and the possibility of employing SAF as a candle warmer were all explored in this work. Original waste cooking oil (O-WCO) was separated into two components by high-speed centrifugation: the supernatant of WCO (S-WCO) and the bottom of WCO (B-WCO). The mixed fatty acid sodium salts (FASSs) were created during the manufacture of SAF based on B-WCO. The best conditions for heating value of SAF based on B-WCO were 0.2 wt.% alcohol, 0.0275 wt.% NaOH, 0.7725 wt.% B-WCO, and a reaction time of 45 min. SAF based on B-WCO had a greater heating value than control groups such as SAF based on O-WCO, S-WCO, butter, and fossil fuels including coal, coke, charcoal, and carbon. The heating value of SAF based on B-WCO was similar to that of natural gas, and it can be used as a new solid fuel or a green energy source, such as a candle warmer, with many advantages such as higher melting point, environmentally friendly fuel, no harmful gases, longer combustion time, small residue, no dark smoke, ease of packing, perfectly hygienic, no need to heat, smoothness in quality, convenience in use, and easy transport and storage. In this article, the Support Vector Regression (SVR) machine learning method is used and an attempt is made to measure the importance of input parameters by predicting this artificial intelligence method. According to the prediction accuracy of the higher heating value of the biomass, the inputs’ influence was determined on the higher heating value. According to the obtained results, fixed carbon has correlation coefficient of 0.8446, volatile matter has correlation coefficient of 0.8949, and ash has correlation coefficient of 0.9214.

Similar content being viewed by others

Abbreviations

- WCO:

-

Waste cooking oil

- SAF:

-

Solid alcohol fuel

- HHV:

-

Higher heating value

- O-WCO:

-

Original waste cooking oil

- S-WCO:

-

Supernatant of WCO

- B-WCO:

-

Bottom of WCO

- SVR:

-

Support vector regression

- FTIR:

-

Fourier Transform Infrared Spectroscopy

- SEM:

-

Scanning Electron Microscope

References

Geng N, Sun Y (2021) Multiobjective optimization of sustainable WCO for biodiesel supply chain network design. Discret Dyn Nat Soc, 2021.https://doi.org/10.1155/2021/6640358

de Albuquerque Landi FF, Fabiani C, Castellani B, Cotana F, Pisello AL (2022) Environmental assessment of four waste cooking oil valorization pathways. Waste Manage 138:219–233. https://doi.org/10.1016/j.wasman.2021.11.037 (Epub 2021 Dec 10)

Aghel B, Gouran A, Nasirmanesh F (2022) Transesterification of waste cooking oil using clinoptilolite/industrial phosphoric waste as green and environmental catalysts. Energy, 123138.https://doi.org/10.1016/j.energy.2022.123138

Hossain MN, SiddikBhuyan MSU, MdAshrafulAlam AH, Seo YC (2019) Optimization of biodiesel production from waste cooking oil using S-TiO2/SBA-15 heterogeneous acid catalyst. Catalysts 9(1):67. https://doi.org/10.3390/catal9010067

Cheruiyot NK, Hou WC, Wang LC, Chen CY (2019) The impact of low to high waste cooking oil-based biodiesel blends on toxic organic pollutant emissions from heavy-duty diesel engines. Chemosphere 235:726–733. https://doi.org/10.1016/j.chemosphere.2019.06.233

Pikula KS, Zakharenko AM, Chaika VV, Stratidakis AK, Kokkinakis M, Waissi G, Golokhvast KS (2019) Toxicity bioassay of waste cooking oil-based biodiesel on marine microalgae. Toxicol Rep 6:111–117. https://doi.org/10.1016/j.toxrep.2018.12.007

**ong Y, Miao WF, Wang NN, Chen HM, Wang XR, Wang JY, Chen SP (2019) Solid alcohol based on waste cooking oil: synthesis, properties, micromorphology and simultaneous synthesis of biodiesel. Waste Manage 85:295–303. https://doi.org/10.1016/j.wasman.2018.12.036

Yang R, Tang W, Zhang J (2022) Optimal subsidy and recycling mode of waste cooking oil under asymmetric information. J Oper Res Soc 73(3):674–691. https://doi.org/10.1080/01605682.2020.1860658

Rajesh A, Gopal K, Kumar BR, Sathiyagnanam AP, Damodharan D (2020) Effect of anisole addition to waste cooking oil methyl ester on combustion, emission and performance characteristics of a DI diesel engine without any modifications. Fuel 278:118315. https://doi.org/10.1016/j.fuel.2020.118315

Jervis, X., & Moreira, C. M. Waste to energy potential of domestic waste cooking oil in Guayaquil: a review. https://doi.org/10.18687/LACCEI2020.1.1.485

Babel S, Arayawate S, Faedsura E, Sudrajat H (2016) Production of biodiesel from waste cooking oil using transesterification, with the KOH on carbon support from waste material and egg shell, as the catalyst. Environ Nat Res J 14(2):60–68. https://doi.org/10.14456/ennrj.2016.13

Hosseinzadeh-Bandbafha H, Kumar D, Singh B, Shahbeig H, Lam SS, Aghbashlo M, Tabatabaei M (2022) Biodiesel antioxidants and their impact on the behavior of diesel engines: a comprehensive review. Fuel Process Technol 232:107264. https://doi.org/10.1016/j.fuproc.2022.107264

Hosseinzadeh-Bandbafha H, Nizami AS, Kalogirou SA, Gupta VK, Park YK, Fallahi A, Tabatabaei M (2022) Environmental life cycle assessment of biodiesel production from waste cooking oil: a systematic review. Renew Sustain Energy Rev 161:112411. https://doi.org/10.1016/j.rser.2022.112411

Hosseinzadeh-Bandbafha H, Li C, Chen X, Peng W, Aghbashlo M, Lam SS, Tabatabaei M (2022) Managing the hazardous waste cooking oil by conversion into bioenergy through the application of waste-derived green catalysts: a review. J Hazard Mater 424:127636. https://doi.org/10.1016/j.jhazmat.2021.127636

Soltanian S, Aghbashlo M, Almasi F, Hosseinzadeh-Bandbafha H, Nizami AS, Ok YS, Tabatabaei M (2020) A critical review of the effects of pretreatment methods on the exergetic aspects of lignocellulosic biofuels. Energy Convers Manage 212:112792. https://doi.org/10.1016/j.enconman.2020.112792

Amid S, Aghbashlo M, Peng W, Hajiahmad A, Najafi B, Ghaziaskar HS, Tabatabaei M (2021) Exergetic performance evaluation of a diesel engine powered by diesel/biodiesel mixtures containing oxygenated additive ethylene glycol diacetate. Sci Total Environ 792:148435. https://doi.org/10.1016/j.scitotenv.2021.148435

Hosseinzadeh-Bandbafha H, Nazemi F, Khounani Z, Ghanavati H, Shafiei M, Karimi K, Tabatabaei M (2022) Safflower-based biorefinery producing a broad spectrum of biofuels and biochemicals: a life cycle assessment perspective. Sci Total Environ 802:149842. https://doi.org/10.1016/j.scitotenv.2021.149842

Hosseinzadeh-Bandbafha H, Aghbashlo M, Tabatabaei M (2021) Life cycle assessment of bioenergy product systems: a critical review. e-Prime-Adv Electr Eng Electron Energy 1:100015. https://doi.org/10.1016/j.prime.2021.100015

Singh N, Agarwal P, Porwal J, Porwal SK (2022) Evaluation of multifunctional green copolymer additives–doped waste cooking oil–extracted natural antioxidant in biolubricant formulation. Biomass Convers Biorefinery, 1-10.https://doi.org/10.1007/s13399-022-02348-w

Muhbat S, Tufail M, Hashmi S (2021) Production of diesel-like fuel by co-pyrolysis of waste lubricating oil and waste cooking oil. Biomass Convers Biorefinery, 1-11.https://doi.org/10.1007/s13399-021-01569-9

Lakovic N, Khan A, Petković B, Petkovic D, Kuzman B, Resic S, ... Azam S (2021) Management of higher heating value sensitivity of biomass by hybrid learning technique. Biomass Convers Biorefinery, 1-8.https://doi.org/10.1007/s13399-020-01223-w

Aghbashlo M, Khounani Z, Hosseinzadeh-Bandbafha H, Gupta VK, Amiri H, Lam SS, Tabatabaei M (2021) Exergoenvironmental analysis of bioenergy systems: a comprehensive review. Renew Sustain Energy Rev 149:111399. https://doi.org/10.1016/j.rser.2021.111399

Author information

Authors and Affiliations

Contributions

Dalibor Petkovic wrote the article.

Corresponding author

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Denic, N., Paunovic, M., Jaksic, K. et al. Estimation of heating value of solid alcohol fuel based on recycled waste cooking oil. Biomass Conv. Bioref. 14, 7995–8002 (2024). https://doi.org/10.1007/s13399-022-02845-y

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13399-022-02845-y