Abstract

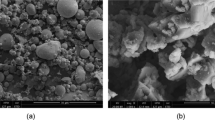

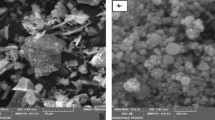

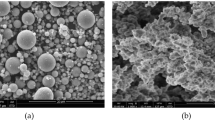

The production of Portland cement results in a large quantity of carbon dioxide gas that is dangerous for the sustainability of the environment. Thus, the researchers need to develop a sustainable replacement for Portland cement to be implemented in the construction industry. The present work investigates the mechanical, microstructural, and mineralogical properties of geopolymer (GPL) by adding microcarbon fiber (CF) and nano-alumina (NAL). The CF content was fixed to 0.5% by weight of the mix while the NAL was varied from 0 to 4% by weight of the binder to examine its effect on the behavior of GPL. The test results established the use of 3% NAL along with the combination of 0.5% CF as the optimal combination for enhancing the compressive strength of GPL by 22%, flexural strength by 46%, and impact strength by 64%. The microstructural investigation of fabricated samples using scanning electron microscopic analysis revealed that the combined use of NAL and CF works as the most effective tool for strengthening the internal matrix of GPL with improved mechanical and microstructural performance. An increase in the intensity of hump situated between 15° and 40° in the XRD analysis is noticed, it might be because expanding the GPL matrix could lead to the dissolution of NAL nanoparticles, leading to the development of calcium silicate hydrate (\(\mathrm{C}-\mathrm{S}-\mathrm{H}\)) next to the primary binder, sodium aluminosilicate.

Similar content being viewed by others

References

Singh, B.; Ishwarya, G.; Gupta, M.; Bhattacharyya, S.K.: Geopolymer concrete: a review of some recent developments. Constr. Build. Mater. 85, 78–90 (2015)

Provis, J.L.; Palomo, A.; Shi, C.: Advances in understanding alkali-activated materials. Cem. Concr. Res. 78, 110–125 (2015)

Duxson, P.; Fernández-Jiménez, A.; Provis, J.L.; Lukey, G.C.; Palomo, A.; van Deventer, J.S.: Geopolymer technology: the current state of the art. J. Mater. Sci. 42(9), 2917–2933 (2007)

Flower, D.J.; Sanjayan, J.G.: Green house gas emissions due to concrete manufacture. Int. J. Cycle Assess. 12(5), 282–288 (2007)

Wang, J., et al.: Study on the optimum initial curing condition for fly ash and GGBS based geopolymer recycled aggregate concrete. Constr. Build. Mater. 247, 118540 (2020)

Ali, N., et al.: Evaluation of the 12–24 mm basalt fibers and boron waste on reinforced metakaolin-based geopolymer. Constr. Build. Mater. 251, 118976 (2020)

Mehta, A.; Siddique, R.: Properties of low-calcium fly ash based geopolymer concrete incorporating OPC as partial replacement of fly ash. Constr. Build. Mater. 150, 792–807 (2017)

Patel, Y.J.; Shah, N.: Development of self-compacting geopolymer concrete as a sustainable construction material. Sustain. Environ. Res. 28(6), 412–421 (2018)

El-Sayed, T.A.; Algash, Y.A.: Flexural behavior of ultra-high performance geopolymer RC beams reinforced with GFRP bars. Case Stud. Constr. Mater. 15, e00604 (2021)

Provis, J.L.; Bernal, S.A.: Geopolymers and related alkali-activated materials. Annu. Rev. Mater. Res. 44, 299–327 (2014)

Das, S.K., et al.: Fresh, strength and microstructure properties of geopolymer concrete incorporating lime and silica fume as replacement of fly ash. J. Build. Eng. 32, 101780 (2020)

Bellum, R.R., et al.: Investigation on performance enhancement of fly ash-GGBFS based graphene geopolymer concrete. J. Build. Eng. 32, 101659 (2020)

Adesina, A.: Performance and sustainability overview of alkali-activated self-compacting concrete. Waste Dispos. Sustain. Energy 2(3), 165–175 (2020)

Zhuang, X.Y., et al.: Fly ash-based geopolymer: clean production, properties and applications. J. Clean. Prod. 125, 253–267 (2016)

Albitar, M., et al.: Durability evaluation of geopolymer and conventional concretes. Constr. Build. Mater. 136, 374–385 (2017)

John, S.K.; Nadir, Y.; Girija, K.: Effect of source materials, additives on the mechanical properties and durability of fly ash and fly ash-slag geopolymer mortar: a review. Constr. Build. Mater. 280, 122443 (2021)

John, S.K., et al.: Effect of addition of nanoclay and SBR latex on fly ash-slag geopolymer mortar. J. Build. Eng. 66, 105875 (2023)

Wang, Y.; Hu, S.; He, Z.: Mechanical and fracture properties of geopolymer concrete with basalt fiber using digital image correlation. Theoret. Appl. Fract. Mech. 112, 102909 (2021)

Pham, T.M.: Enhanced properties of high-silica rice husk ash-based geopolymer paste by incorporating basalt fibers. Constr. Build. Mater. 245, 118422 (2020)

Timakul, P.; Rattanaprasit, W.; Aungkavattana, P.: Improving compressive strength of fly ash-based geopolymer composites by basalt fibers addition. Ceram. Int. 42(5), 6288–6295 (2016)

Ren, D., et al.: Durability performances of wollastonite, tremolite and basalt fiber-reinforced metakaolin geopolymer composites under sulfate and chloride attack. Constr. Build. Mater. 134, 56–66 (2017)

Punurai, W., et al.: Mechanical properties, microstructure and drying shrinkage of hybrid fly ash-basalt fiber geopolymer paste. Constr. Build. Mater. 186, 62–70 (2018)

Ranjbar, N.; Zhang, M.: Fiber-reinforced geopolymer composites: a review. Cement Concr. Compos. 107, 103498 (2020)

Alvee, A.R., et al.: Experimental study of the mechanical properties and microstructure of geopolymer paste containing nano-silica from agricultural waste and crystalline admixtures. Case Stud. Constr. Mater. 16, e00792 (2022)

El Ouni, M.H., et al.: Enhancement of mechanical and toughness properties of carbon fiber-reinforced geopolymer pastes comprising nano calcium oxide. J. Austr. Ceram. Soc. 58(4), 1375–1387 (2022)

Raza, A., et al.: Experimental study on mechanical, toughness and microstructural characteristics of micro-carbon fibre-reinforced geopolymer having nano TiO2. Alex. Eng. J. (2022)

Raza, A., et al.: Mechanical performance of geopolymer composites containing nano-silica and micro-carbon fibers. Arab. J. Sci. Eng. 47(10), 12621–12632 (2022)

Adesina, A.: Durability enhancement of concrete using nanomaterials: an overview. In: Materials Science Forum. Trans Tech Publ. (2019)

Adesina, A.: Nanomaterials in cementitious composites: review of durability performance. J. Build. Pathol. Rehabilit. 5(1), 1–9 (2020)

Gülşan, M.E., et al.: Development of fly ash/slag based self-compacting geopolymer concrete using nano-silica and steel fiber. Constr. Build. Mater. 211, 271–283 (2019)

Assaedi, H., et al.: Characterization and properties of geopolymer nanocomposites with different contents of nano-CaCO3. Constr. Build. Mater. 252, 119137 (2020)

Ahmed, H.U.; Mohammed, A.A.; Mohammed, A.S.: The role of nanomaterials in geopolymer concrete composites: a state-of-the-art review. J. Build. Eng. 49, 104062 (2022)

Zidi, Z.; Ltifi, M.; Zafar, I.: Synthesis and attributes of nano-SiO2 local metakaolin based-geopolymer. J. Build. Eng. 33, 101586 (2021)

Chiranjeevi, K.; Vijayalakshmi, M.; Praveenkumar, T.: Investigation of fly ash and rice husk ash-based geopolymer concrete using nano particles. Appl. Nanosci. 13(1), 839–846 (2023)

Ghareeb, K.S., et al.: The novelty of using glass powder and lime powder for producing UHPSCC. Buildings 12(5), 684 (2022)

Tanzadeh, J.: Laboratory evaluation of self-compacting fiber-reinforced concrete modified with hybrid of nanomaterials. Constr. Build. Mater. 232, 117211 (2020)

Guler, S.; Türkmenoğlu, Z.F.; Ashour, A.: Performance of single and hybrid nanoparticles added concrete at ambient and elevated temperatures. Constr. Build. Mater. 250, 118847 (2020)

Mustakim, S.M., et al.: Improvement in fresh, mechanical and microstructural properties of fly ash-blast furnace slag based geopolymer concrete by addition of nano and micro silica. SILICON 13, 2415–2428 (2020)

Al Bakri, A., et al.: Nano geopolymer for sustainable concrete using fly ash synthesized by high energy ball milling. In: Applied Mechanics and Materials. Trans Tech Publ. (2013)

Mansourghanaei, M.; Biklaryan, M.; Mardookhpour, A.: Experimental study of the effects of adding silica nanoparticles on the durability of geopolymer concrete. Austr. J. Civil Eng. (2022). https://doi.org/10.1080/14488353.2022.2120247

Ahmed, H.U., et al.: Compressive strength of geopolymer concrete modified with nano-silica: experimental and modeling investigations. Case Stud. Constr. Mater. 16, e01036 (2022)

Alomayri, T.; Raza, A.; Shaikh, F.: Effect of nano SiO2 on mechanical properties of micro-steel fibers reinforced geopolymer composites. Ceram. Int. 47(23), 33444–33453 (2021)

Tuntachon, S., et al.: Resistance to algae and fungi formation of high calcium fly ash geopolymer paste containing TiO2. J. Build. Eng. 25, 100817 (2019)

Sastry, K.G.K.; Sahitya, P.; Ravitheja, A.: Influence of nano TiO2 on strength and durability properties of geopolymer concrete. Mater. Today: Proc. (2020). https://doi.org/10.1016/j.matpr.2020.03.139

Ali, L., et al.: Experimental investigation on the mechanical and fracture evaluation of carbon Fiber-Reinforced cementitious composites with nano-calcium carbonate. Constr. Build. Mater. 308, 125095 (2021)

Intarabut, D., et al.: Influence of graphene oxide nanoparticles on bond-slip reponses between fiber and geopolymer mortar. Nanomaterials 12(6), 943 (2022)

Rashedi, A., et al.: Mechanical, fracture, and microstructural assessment of carbon-fiber-reinforced geopolymer composites containing Na2O. Polymers 13(21), 3852 (2021)

D695-15 A.: Standard test method for compressive properties of rigid plastics, ASTM International, West Conshohocken, PA (2015)

C78M-21, A.C.: Standard test method for flexural strength of concrete (Using Simple Beam with Third-Point Loading), ASTM International, West Conshohocken, PA (2021)

Raza, A., et al.: Development of eco-friendly alkali-activated nanocomposites comprising micro-fibers at ambient curing conditions. Case Stud. Constr. Mater. 17, e01540 (2022)

Low, I., et al.: Mechanical and fracture properties of cellulose-fibre-reinforced epoxy laminates. Compos. A Appl. Sci. Manuf. 38(3), 963–974 (2007)

D785-08(2015) A.: Standard test method for rockwell hardness of plastics and electrical insulating materials, ASTM International, West Conshohocken, PA (2015)

Saini, G.; Vattipalli, U.: Assessing properties of alkali activated GGBS based self-compacting geopolymer concrete using nano-silica. Case Stud. Constr. Mater. 12, e00352 (2020)

Nuaklong, P., et al.: Influence of rice husk ash on mechanical properties and fire resistance of recycled aggregate high-calcium fly ash geopolymer concrete. J. Clean. Prod. 252, 119797 (2020)

Alomayri, T.: Experimental study of the microstructural and mechanical properties of geopolymer paste with nano material (Al2O3). J. Build. Eng. 25, 100788 (2019)

Assaedi, H.: The role of nano-CaCO3 in the mechanical performance of polyvinyl alcohol fibre-reinforced geopolymer composites. Compos. Interfaces (2020). https://doi.org/10.1080/09276440.2020.1793096

Shaikh, F.; Shafaei, Y.; Sarker, P.: Effect of nano and micro-silica on bond behaviour of steel and polypropylene fibres in high volume fly ash mortar. Constr. Build. Mater. 115, 690–698 (2016)

Yip, C.K.; Lukey, G.; Van Deventer, J.S.: The coexistence of geopolymeric gel and calcium silicate hydrate at the early stage of alkaline activation. Cem. Concr. Res. 35(9), 1688–1697 (2005)

Yip, C.K., et al.: Effect of calcium silicate sources on geopolymerisation. Cem. Concr. Res. 38(4), 554–564 (2008)

Bayiha, B.N., et al.: Effect of limestone dosages on some properties of geopolymer from thermally activated halloysite. Constr. Build. Mater. 217, 28–35 (2019)

Tchakoute, H., et al.: Influence of gibbsite and quartz in kaolin on the properties of metakaolin-based geopolymer cements. Appl. Clay Sci. 107, 188–194 (2015)

Yusuf, M.O., et al.: Strength and microstructure of alkali-activated binary blended binder containing palm oil fuel ash and ground blast-furnace slag. Constr. Build. Mater. 52, 504–510 (2014)

à Moungam, L.M.B., et al.: Properties of geopolymers made from fired clay bricks wastes and rice husk ash (RHA)-sodium hydroxide (NaOH) activator. Mater. Sci. Appl. 8(7), 537–552 (2017)

Bravo, P.I., et al.: Nanocrystalline titania coated metakaolin and rice hull ash based geopolymer spheres for photocatalytic degradation of dye in wastewater. Orient. J. Chem. 35(1), 167 (2019)

Guzmán-Aponte, L.A.; Mejía de Gutiérrez, R.; Maury-Ramírez, A.: Metakaolin-based geopolymer with added TiO2 particles: physicomechanical characteristics. Coatings 7(12), 233 (2017)

Djobo, J.Y., et al.: Synthesis of geopolymer composites from a mixture of volcanic scoria and metakaolin. J. Asian Ceram. Soc. 2(4), 387–398 (2014)

Alomayri, T.; Shaikh, F.; Low, I.M.: Mechanical and thermal properties of ambient cured cotton fabric-reinforced fly ash-based geopolymer composites. Ceram. Int. 40(9), 14019–14028 (2014)

Nana, A., et al.: Room-temperature alkaline activation of feldspathic solid solutions: development of high strength geopolymers. Constr. Build. Mater. 195, 258–268 (2019)

NobouassiaBewa, C., et al.: Water resistance and thermal behavior of metakaolin-phosphate-based geopolymer cements. J. Asian Ceram. Soc. 6(3), 271–283 (2018)

Shaikh, F.U.; Supit, S.W.: Mechanical and durability properties of high volume fly ash (HVFA) concrete containing calcium carbonate (CaCO3) nanoparticles. Constr. Build. Mater. 70, 309–321 (2014)

Acknowledgements

The authors extend their appreciation to the Deanship of Scientific Research at King Khalid University for funding this work through a large groups research program under grant number R.G.P. 2/130/44.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors have no conflicts of interest.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Arshad, M., Raza, A., Khan, Q.u.Z. et al. Evaluation of Mechanical and Microstructural Characterization of Microfiber-Reinforced Nanocomposites Comprising Nano-Alumina. Arab J Sci Eng 49, 5079–5094 (2024). https://doi.org/10.1007/s13369-023-08368-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13369-023-08368-6