Abstract

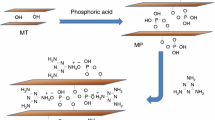

The use of natural fibres in the production of polymer composites has become widespread, but these materials are easily flammable. In this study, the fire resistance of flax fibre composites produced with polyurethane (PU)-based shape memory polymer matrix is improved with diammonium phosphate, polydopamine and titanium dioxide. Flax fibres were treated with diammonium phosphate and then coated with polydopamine, shape memory polymer matrix reinforced with titanium dioxide. Scanning electron microscope images of the produced composites before and after combustion were examined, and the protective char layer of polydopamine was observed. Thanks to this layer, the composite structure preserved its integrity after combustion and the mass loss decreased from 82 to 69%. Limiting Oxygen Index value of non-coated flax fibre composite was measured as 20%, while that of PDA-coated TiO2-doped flax fibre composite was recorded as 24% showing significant improvement for the PDA-coated TiO2-doped flax fibre composite. Flame propagation rate decreased from 81 to 21 mm/min in the horizontal burning test. The effect of polydopamine and titanium dioxide on fibres and PU-based shape memory polymer matrix was investigated by thermogravimetric analysis/differential thermal analysis. This study clearly proved that the fire resistance of natural fibre composites produced from PU-based shape memory polymer matrix is improved with diammonium phosphate, polydopamine and titanium dioxide.

Similar content being viewed by others

References

Andrew, J.; Srinivasan, S.; Arockiarajan, A.; Dhakal, H.: Parameters influencing the impact response of fiber-reinforced polymer matrix composite materials: a critical review. Compos. Struct. (2019). https://doi.org/10.1016/j.compstruct.2019.111007

Krishnasamy, S.; Thiagamani, S.M.K.; Kumar, C.M.; Nagarajan, R.; Siengchin, S.; Ismail, S.O.: Recent advances in thermal properties of hybrid cellulosic fiber reinforced polymer composites. Int. J. Biol. Macromol. (2019). https://doi.org/10.1016/j.ijbiomac.2019.08.231

Lei, M.; Chen, Z.; Lu, H.; Yu, K.: Recent progress in shape memory polymer composites: methods, properties, applications and prospects. Nanotechnol. Rev. (2019). https://doi.org/10.1515/ntrev-2019-0031

Pickering, K.L.; Efendy, M.G.A.; Le, T.M.: A review of recent developments in natural fibre composites and their mechanical performance. Compos. Part A: Appl. Sci. Manuf. (2016). https://doi.org/10.1016/j.compositesa.2015.08.038

Hobbs, C.E.: Recent advances in bio-based flame retardant additives for synthetic polymeric materials. Polymers (2019). https://doi.org/10.3390/polym11020224

Tang, Y.; Hu, Y.; Wang, S.; Gui, Z.; Chen, Z.; Fan, W.: Intumescent flame retardant-montmorillonite synergism in polypropylene-layered silicate nanocomposites. Polym. Int. (2003). https://doi.org/10.1002/pi.1270

Cho, J.H.; Vasagar, V.; Shanmuganathan, K.; Jones, A.R.; Nazarenko, S.; Ellison, J.C.: Bioinspired catecholic flame retardant nanocoating for flexible polyurethane foams. Chem. Mater. (2015). https://doi.org/10.1021/acs.chemmater.5b03013

Li, Y.; Wang, B.; Sui, X.; **e, R.; Xu, H.; Zhang, L.; Zhong, Y.; Mao, Z.: Durable flame retardant and antibacterial finishing on cotton fabrics with cyclotriphosphazene/polydopamine/silver nanoparticles hybrid coatings. Appl. Surf. Sci. (2018). https://doi.org/10.1016/j.apsusc.2017.11.269

Liu, H.; Qu, X.; Tan, H.; Song, J.; Lei, M.; Kim, E.; Payne, G.F.; Liu, C.: Role of polydopamine’s redox-activity on its pro-oxidant, radical scavenging, and antimicrobial activities. Acta Biomater. (2019). https://doi.org/10.1016/j.actbio.2019.02.032

Lin, M.; Liu, Y.; Chen, X.; Fei, S.; Ni, C.; Fang, Y.; Liu, C.; Cai, Q.: Poly(dopamine) coated gold nanocluster functionalized electrochemical immunosensor for brominated flame retardants using multienzyme-labelling carbon hollow nanochains as signal amplifiers. Biosensensors Bioelectron. (2013). https://doi.org/10.1016/j.bios.2013.01.058

Li, Y.; Wang, B.; Sui, X.; Xu, H.; Zhang, L.; Zhong, Y.; Mao, Z.: Facile synthesis of micro fibrillated cellulose/organosilicon/polydopamine composite sponges with flame retardant properties. Cellulose (2017). https://doi.org/10.1007/s10570-017-1373-z

Yang, W.; Wu, S.; Yang, W.; Yuen, A.C.; Zhou, Y.; Yeoh, G.; Boyer, C.; Wang, C.H.: Nanoparticles of polydopamine for improving mechanical and flame-retardant properties of an epoxy resin. Compos. Part B (2020). https://doi.org/10.1016/j.compositesb.2020.107828

Li, H.; Hu, Z.; Zhang, S.; Gu, X.; Wang, H.; Zhao, Q.: Progress in organic coatings effects of titanium dioxide on the flammability and char formation of water-based coatings containing intumescent flame retardants. Prog. Org. Coat. (2015). https://doi.org/10.1016/j.porgcoat.2014.08.003

Ren, D.; Li, J.; Xu, J.; Wu, Z.; Bao, Y.; Li, N.; Chen, Y.: Efficient antifungal and flame-retardant properties of ZnO-TiO2-layered double-nanostructures coated on bamboo substrate. Coatings (2018). https://doi.org/10.3390/coatings8100341

Afzal, A.; Usama, M.; Iqra, A.R.; Khalid, Z.; Mohsin, M.; Shakir, M.F.; Tariq, A.: Effect of MgOH/TiO2 on flame retardancy and mechanical behavior of composite. Mater. Res. Express (2019). https://doi.org/10.1088/2053-1591/ab624b

Wang, X.; Hu, W.; Hu, Y.: Polydopamine-Bridged synthesis of ternary h-BN@PDA@TiO2 as nanoenhancers for thermal conductivity and flame retardant of polyvinyl alcohol. Front. Chem. (2020). https://doi.org/10.3389/fchem.2020.587474

Suardana, N.P.G.; Ku, M.S.; Lim, J.K.: Effects of diammonium phosphate on the flammability and mechanical properties of bio-composites. Mater. Des. (2011). https://doi.org/10.1016/j.matdes.2010.11.069

Pham, L.H.; Pham, L.T.; Hoang, D.; Kim, J.: Effective phosphorus/phosphorus-nitrogen fire retardants applied to biocomposites based on polypropylene-wood flour: flammability, thermal behavior, and mechanical properties. Macromol. Res. (2019). https://doi.org/10.1007/s13233-019-7167-4

Chindaprasirt, P.; Hiziroglu, S.; Waisurasingha, C.; Kasemsiri, P.: Properties of wood flour/expanded polystyrene waste composites modified with diammonium phosphate flame retardant. Polym. Compos. (2015). https://doi.org/10.1002/pc.22977

Boudjellal, A.; Trache, D.; Khimeche, K.; Hafsaoui, S.L.; Bougamra, A.; Tcharkhtchi, A.; Durastanti, J.F.: Stimulation and reinforcement of shape-memory polymers and their composites: a review. J. Thermoplast. Compos. Mater. (2020). https://doi.org/10.1177/0892705720930775

Gao, J.; Chen, W.; Fan, P.; Zhao, B.; Hu, J.; Zhang, D.; Fang, G.; Peng, F.: Effect of temperature on the mechanical behaviours of a single-ply weave-reinforced shape memory polymer composite. Compos. B Eng. (2019). https://doi.org/10.1016/j.compositesb.2018.09.029

Du, W.; **, Y.; Lai, S.; Shi, L.; Shen, Y.; Yang, H.: Multifunctional light-responsive graphene-based polyurethane composites with shape memory, self-healing, and flame retardancy properties. Compos. A Appl. Sci. Manuf. (2020). https://doi.org/10.1016/j.compositesa.2019.105686

Zhu, S.; Wang, W.; Islam, Z.M.D.; Fu, Y.; Dong, Y.: Polydopamine modified ammonium polyphosphate modified shape memory water-borne epoxy composites with photo-responsive flame retardant property. J. Appl. Polym. Sci. (2020). https://doi.org/10.1002/app.49696

Hottel, H.C.: Stimulation of fire research in the United States after 1940. Combust. Sci. Technol. (1984). https://doi.org/10.1080/00102208408923781

Vermesi, I.; Roenner, N.; Pironi, P.; Hadden, R.M.; Rein, G.: Pyrolysis and ignition of a polymer by transient irradiation. Combust. Flame (2016). https://doi.org/10.1016/j.combustflame.2015.08.006

Sonnier, R.; Dorez, G.; Vahabi, H.; Longuet, C.; Ferry, L.: FTIR-PCFC coupling: a new method for studying the combustion of polymers. Combust. Flame (2014). https://doi.org/10.1016/j.combustflame.2013.11.011

Snegirev, A.Y.; Handawy, M.K.; Stepanov, V.V.; Talalov, V.A.: Pyrolysis and combustion of polymer mixtures: Exploring additivity of the heat release rate. Polym. Degrad. Stab. (2019). https://doi.org/10.1016/j.polymdegradstab.2019.01.037

Ahmed, L.; Zhang, B.; Hatanaka, L.C.; Mannan, M.S.: Application of polymer nanocomposites in the flame retardancy study. J. Loss Prev. Process Ind. (2018). https://doi.org/10.1016/j.jlp.2018.07.005

Watanabe, I.; Sakai, S.I.: Environmental release and behavior of brominated flame retardants. Environ. Int. (2003). https://doi.org/10.1016/S0160-4120(03)00123-5

Costes, L.; Laoutid, F.; Brohez, S.; Dubois, P.: Bio-based flame retardants: When nature meets fire protection. Mater. Sci. Eng. R. Rep. (2017). https://doi.org/10.1016/j.mser.2017.04.001

Hull, T.R.; Law, R.J.; Bergman, A.: Polymer green flame retardants, 1st edn. Elsevier, Amsterdam (2014)

Öktem, M.F.; Altıntop, B.: Development of chemically treated hybrid jute - flax natural composites for elevated temperature applications. Bitlis Eren Univ. J. Sci. (2019). https://doi.org/10.17798/bitlisfen.449105

ISO 4589–2: Plastics — Determination of burning behaviour by oxygen index — Part 2: Ambient-temperature test. International Organization for Standardization, Geneva, Switzerland (2017)

ASTM D635: Standard test method for rate of burning and/or extent and time of burning of plastics in a horizontal position. Am. Soc. Test. Mater. West Conshohocken, PA, USA (2018)

ASTM D3801: Standard test method for measuring the comparative burning characteristics of solid plastics in a vertical position. Am. Soc. Test. Mater. West Conshohocken, PA, USA (2020)

Alghamdi, M.N.: Titanium dioxide reinforced polypropylene composites: Preparation and characterization. International Journal of Engineering Research & Technology. (2016).

Liu, R.; Dai, S.: Dopamine as a carbon source: the controlled synthesis of hollow carbon spheres and yolk-structured carbon nanocomposites. Angew. Chem. Int. Ed. (2011). https://doi.org/10.1002/anie.201102070

Kim, H.; Kim, D.W.; Vasagar, V.; Ha, H.; Nazarenko, S.; Ellison, C.J.: Polydopamine-Graphene oxide flame retardant nanocoatings applied via an aqueous liquid crystalline scaffold. Adv. Func. Mater. (2018). https://doi.org/10.1002/adfm.201803172

Li, H.: Effects of titanium dioxide on the flammability and char formation of water-based coatings containing intumescent flame retardants. Prog. Org. Coat. (2015). https://doi.org/10.1016/j.porgcoat.2014.08.003

Funding

This study was supported by Ankara Yıldırım Beyazıt University, Projects Office (Grant Number 5649).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declared no potential conflicts of interest with respect to the research, authorship, and/or publication of this article.

Rights and permissions

About this article

Cite this article

Öktem, M.F., Aydaş, B. Development of Flame Retardant Shape Memory Polymer (SMP) Flax Fiber Composite by Using Organic Polydopamine (PDA) Coating and Nanoparticles. Arab J Sci Eng 47, 6461–6475 (2022). https://doi.org/10.1007/s13369-021-06466-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13369-021-06466-x