Abstract

In the present study, we demonstrate the properties of rubber seed oil (RSO) and its potential application for producing biodiesel by lipase-catalyzed transesterification. Rubber seed contains 39.45% of oil on a dry weight basis. Lipase was secreted from novel bacterial isolate of Pseudomonas aeruginosa strain BUP2. Response Surface Methodology (RSM) cum Box–Behnken Design (BBD) was employed to optimize the combined effect of different independent parameters namely oil–methanol ratio, enzyme unit, reaction temperature and reaction time. Biodiesel yield of 99.52% was obtained in the validation experiments at the optimal level of lipase (750 U), methanol ratio (1:10), temperature (45 °C) and time (4 h). The fuel properties of biodiesel obtained under the validation condition met the specifications as mentioned in ASTM D6751 and EN 14214 standards. Biodiesel aliquots were characterized using thin-layer chromatography (TLC), gas chromatography (GC), fourier transform infra-red spectroscopy (FTIR) and elemental analysis. The present study demonstrates an important application of a potential substitute for fossil fuel from raw feedstocks with high economic value.

Similar content being viewed by others

References

Ali CH, Mbadinga SM, Liu JF, Yang SZ, Gu JD, Mu BZ (2015) Significant enhancement of Pseudomonas aeruginosa FW_SH-1 lipase production using response surface methodology and analysis of its hydrolysis capability. J Tai Inst Chem Eng 52:7–13

Ali CH, Qureshi AS, Mbadinga SM, Liu JF, Yang SZ, Mu BZ (2017) Biodiesel production from waste cooking oil using onsite produced purified lipase from Pseudomonas aeruginosa FW_SH-1: central composite design approach. Ren Energy 109:93–100

Al-Zuhair S (2005) Production of biodiesel by lipase-catalyzed transesterification of vegetable oils: a kinetics study. Biotech Progress 21(5):1442–1448

Amini Z, Ong HC, Harrison MD, Kusumo F, Mazaheri H, Ilham Z (2017) Biodiesel production by lipase-catalyzed transesterification of Ocimum basilicum L.(sweet basil) seed oil. Energy Conv Manag 132:82–90

Aravind A, Joy ML, Nair KP (2015) Lubricant properties of biodegradable rubber tree seed (Hevea brasiliensis Muell. Arg) oil. Ind. Crops Prod 74:14–19

Azócar L, Ciudad G, Heipieper HJ, Muñoz R, Navia R (2010) Improving fatty acid methyl ester production yield in a lipase-catalyzed process using waste frying oils as feedstock. J Biosci Bioeng 109(6):609–614

Bakare IO, Okieimen FE, Pavithran C, Abdul Khalil HPS, Brahmakumar M (2010) Mechanical and thermal properties of sisal fiber reinforced rubber seed oil-based polyurethane composites. Mater Eng 31:4274–4280

Bello EI, Ogedengbe TI, Lajide L, Daniyan IA (2016) Optimization of process parameters for biodiesel production using response surface methodology. Ameri J En Eng 4(2):8

Benjamin S, Pandey A (1996) Optimization of liquid media for lipase production by Candida rugosa. Bioresour Technol 55(2):167–170

Charpe TW, Rathod VK (2011) Biodiesel production using waste frying oil. Waste Manag 31(1):85–90

Chen CS, Liu KJ, Lou YH, Shieh CJ (2002) Optimisation of kojic acid monolaurate synthesis with lipase PS from Pseudomonas cepacia. J Sci Food Agri 82(6):601–605

Chiang WD, Chang SW, Shieh CJ (2003) Studies on the optimized lipase-catalyzed biosynthesis of cis-3-hexen-1-yl acetate in n-hexane. Process Biochem 38(8):1193–1199

Coates J (2000) Interpretation of infrared spectra, a practical approach. Encycl Anal Chem 12:10815–10837

Faisal PA, Hareesh ES, Priji P, Unni KN, Sajith S, Sreedevi S, Benjamin S (2014) Optimization of parameters for the production of lipase from Pseudomonas sp. BUP6 by solid state fermentation. Adv Enz Res 2(4):125

Gupta N, Rathi P, Gupta R (2002) Simplified para-nitrophenyl palmitate assay for lipase and esterases. Anal Biochem 311:98–99

Hosamani KM, Katagi KS (2008) Characterization and structure elucidation of 12 hydroxyoctadec-cis-9-enoic acid in Jatropha gossypifolia and Hevea brasiliensis seed oils: a rich source of hydroxy fatty acid. Chem Phys Lipids 152:9–12

Ikhuoria EU, Maliki M, Okieimen FE, Aigbodion AI, Obaze EO, Bakare IO (2007) Synthesis and characterisation of chlorinated rubber seed oil alkyd resins. Prog Org Coat 7(59):134–137

Jaeger KE, Reetz MT (1998) Microbial lipases form versatile tools for biotechnology. Trends Biotechnol 16(9):396–403

Jeong GT, Park DH (2009) Optimization of biodiesel production from castor oil using response surface methodology. Appl Biochem Biotech 156(3):1–11

Kamalakar K, Rajak AK, Prasad RBN, Karuna MSL (2013) Rubber seed oil-based biolubricant base stocks: a potential source for hydraulic oils. Ind Crops Prod 51:249–257

Kittigowittana K, Wongsakul S, Krisdaphong P, Jimtaisong A, Saewan N (2013) Fatty acid composition and biological activities of seed oil from rubber (Hevea brasiliensis) cultivar RRIM 600. Inter J App Res Nat Prod 6(2):1–7

Köse O, Tüter M, Aksoy HA (2002) Immobilized Candida antarctica lipase-catalyzed alcoholysis of cotton seed oil in a solvent-free medium. Bioresour Technol 83(2):125–129

Kumar SS, Purushothaman K (2010) High FFA rubber seed oil as an alternative fuel for diesel engine—an overview. Int J Eng Sci 10(1):16–24

Li Y, Du W, Liu D (2013) Effect of phospholipids on free lipase-mediated methanolysis for biodiesel production. J Mol Cat B Enzym 91:67–71

Mohd-Setapar SH, Nian-Yian L, Mohd-Sharif NS (2014) Extraction of rubber (Hevea brasiliensis) seed oil using soxhlet method. Malay J Fund App Sci 10(1):1–6

Ndana M, Grace JJ, Baba FH, Mohammed UM (2013) Fourier transform infrared spectrophotometric analysis of functional groups in biodiesel produced from oils of Ricinus communis, Hevea brasiliensis and Jatropha curcas seeds. Inter J Sci Environ Technol 2(6):1116–1121

Nian-Yiana L, Penga WL, Mohd-Setapara SH, Idhama Z, Yunusa MAC, Muhamadb II (2014) Application of rubber (Hevea Brasiliensis) seeds oil extracted using supercritical carbon dioxide in cosmetics. Jurnal Teknologi 69(4):55–59

Onoji SE, Iyuke SE, Igbafe AI, Nkazi DB (2016a) Rubber seed oil: a potential renewable source of biodiesel for sustainable development in sub-Saharan Africa. Energy Convers Manag 110:125–134

Onoji SE, Iyuke SE, Igbafe AI (2016b) Hevea brasiliensis (Rubber Seed) oil: extraction, characterization, and kinetics of thermo-oxidative degradation using classical chemical methods. Energy Fuels 30(12):10555–10567

Priji P, Sajith S, Faisal PA, Benjamin S (2016) Microbial lipases-properties and applications. J Micro Biotech Food Sci 6(2):799–807

Priji P, Sajith S, Faisal PA, Benjamin S (2017) Pseudomonas sp. BUP6 produces a thermotolerant alkaline lipase with transesterification efficiency in producing biodiesel. 3 Biotech 7(6):369

Qin HE, Yan XU, Yun TENG, Dong WANG (2008) Biodiesel production catalyzed by whole-cell lipase from Rhizopus chinensis. Chin J Cat 29(1):41–46

Ramadhas AS, Jayaraj S, Muraleedharan C (2005) Biodiesel production from high FFA rubber seed oil. Fuel 84(4):335–340

Reshad AS, Tiwari P, Goud VV (2015) Extraction of oil from rubber seeds for biodiesel application: optimization of parameters. Fuel 150:636–644

Samukawa T, Kaieda M, Matsumoto T, Ban K, Kondo A, Shimada Y, Noda H, Fukuda H (2000) Pretreatment of immobilized Candida antarctica lipase for biodiesel fuel production from plant oil. J Biosci Bioeng 90(2):180–183

Sarkar A, Chowdhuri AK, Bhowal AJ, Mandal BK (2012) The performance and emission characteristics of SI engine running on different ethanol-gasoline blends. Int J Sci Eng Res 3(6):1–6

Sebastian J, Muraleedharan C, Santhiagu A (2016) A comparative study between chemical and enzymatic transesterification of high free fatty acid contained rubber seed oil for biodiesel production. Cogent Eng 3(1):1178370

Sebastian J, Muraleedharan C, Santhiagu A (2017) Enzyme catalyzed biodiesel production from rubber seed oil containing high free fatty acid. Int J Green Energy 21:1–7

Shieh CJ, Liao HF, Lee CC (2003) Optimization of lipase-catalyzed biodiesel by response surface methodology. Bioresour Technol 88(2):103–106

Silitonga AS, Masjuki HH, Ong HC, Yusaf T, Kusumo F, Mahlia TMI (2016) Synthesis and optimization of Hevea brasiliensis and Ricinus communis as feedstock for biodiesel production: a comparative study. Indus Crops Products 85:274–286

Sudha KC, Sugunan S, Binitha NN, Faisal PA, Benjamin S (2017) Statistical optimization for lithium silicate catalyzed production of biodiesel from waste cooking oil. Korean J Chem Eng 34(11):2840–2851

Takase M, Zhao T, Zhang M, Chen Y, Liu H, Yang L, Wu X (2015) An expatiate review of neem, jatropha, rubber and karanja as multipurpose non-edible biodiesel resources and comparison of their fuel, engine and emission properties. Renew Sustain Energy Rev 43:495–520

Tean B, Sath K, Samkol P, Ly J (2002) Utilization by pigs of diets containing cambodian rubber seed meal. Livestock Res Rural Dev 14:1–8

Unni KN, Faisal PA, Priji P, Sajith S, Sreedevi S, Hareesh ES, Roy TKN, Benjamin S (2015) Rubber seed kernel as potent solid substrate for the production of lipase by Pseudomonas aeruginosa strain BUP2. Adv Enzyme Res 3(2):31

Unni KN, Priji P, Sajith S, Faisal PA, Benjamin S (2016) Pseudomonas aeruginosa strain BUP2, a novel bacterium inhabiting the rumen of Malabari goat, produces an efficient lipase. Biologia 71(4):378–387

Vipin VC, Sebastian J, Muraleedharan C, Santhiagu A (2016) Enzymatic transesterification of rubber seed oil using Rhizopus oryzae lipase. Process Technol 25:1014–1021

Yang L, Takase M, Zhang M, Zhao T, Wu X (2014) Potential non-edible oil feedstock for biodiesel production in Africa: a survey. Rene Sustain Energy Rev 38:461–477

Acknowledgements

The financial assistance (Grant no. 1417/2014/KSCSTE) of Kerala State Council for Science, Technology and Environment (KSCSTE), Government of Kerala is gratefully acknowledged. The authors also express their gratitude to Prof. Sailas Benjamin (Ex-Professor, University of Calicut) for his immense support, help and guidance during the execution of the work.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare the nonexistence of competing or other interests.

Electronic supplementary material

Below is the link to the electronic supplementary material.

13205_2018_1477_MOESM1_ESM.docx

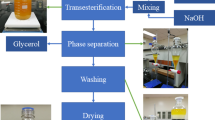

Fig. S 1 Diagrammatic representation of reaction setup. Fig. S2 Gas chromatogram of A) FAMEs obtained from rubber seed oil; B) Rubber seed oil. (DOCX 463 KB)

Rights and permissions

About this article

Cite this article

Panichikkal, A.F., Prakasan, P., Kizhakkepowathial Nair, U. et al. Optimization of parameters for the production of biodiesel from rubber seed oil using onsite lipase by response surface methodology. 3 Biotech 8, 459 (2018). https://doi.org/10.1007/s13205-018-1477-7

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s13205-018-1477-7