Abstract

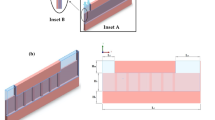

Since the high heat has a bad effect on every electric coolant device performance in small spaces, enhance thermal systems became a challenge to achieve better performance. In the present study, investigate the forced heat transfer and laminar CuO–water nanofluid flow around the sinusoidal cylindrical and cylindrical heat sink, at Reynold number less than 700, and at a constant heat flux. Which is simulated numerically by Galerkin approach finite element methods FEM. The main purpose of the study is to drop the heat spam by enhancing the heat transfer coefficient of laminar flow in different channel types of special shape (corrugate cross-section) using nanofluid. Study the effect of hydraulic diameter of sinusoidal cylindrical to classify the channels depended on (Dh ≤ 3 mm). The new design of heat sink is employed “sinusoidal cylindrical heat sink” varied according to the amplitude values (λ) and the corrugation number (G). A digest of the findings, the best enhance at φ = 0.15%vol of 16.31% and 16.53% for G = 3 and G = 10, respectively. A great drop in wall temperature about 20.47 and 16.58 for λ = 20 of G = 3, and G = 10, respectively, as the volume fraction of CuO–water nanofluid increased at Re = 478 & q″ = 127.3 kW/m2, comparing with water. In conclusion, the sinusoidal heat sink of λ = 20 with CuO–H2O nanofluid of φ = 0.15%vol showed best enhance in heat transfer coefficient. Increased the corrugate number G led to a decrease in the friction factor and thermal resistance. Furthermore, using nanofluid led to reduce the surface wall temperature, the friction factor also the thermal resistance.

Similar content being viewed by others

Availability of data and materials

No data available.

Code availability

Comsol Multiphysics.

Abbreviations

- 3D:

-

Three-dimensional.

- 2D:

-

Two-dimensional

- A s :

-

Surface area m2

- A c :

-

Cross-section area m2

- C p :

-

Specific heat at constant pressure, J/kg K

- C :

-

Circumference

- D h :

-

Hydralic diameter, m

- R mean :

-

Mean radius, m

- h av :

-

Average convection heat transfer coefficient, W/m2 K

- k :

-

Thermal conductivity, W/m K

- L ch :

-

Channels length

- ṁ:

-

Mass flow rate (kg/s)

- Nu:

-

Nusselt number=(h × Dh/k)

- P :

-

Pressure, kPa

- Q :

-

Volume flow rate (L/min)

- q″ :

-

Heat flux (W/m2)

- Re :

-

Reynolds number = (ρnfuinDh/μf)

- T :

-

Temperature, K

- u in :

-

Fluid inlet velocity, m/s

- G :

-

Corrugate number

- μ :

-

Viscosity, kg/m s

- ρ :

-

Density, kg/m3

- φ :

-

Volume fraction

- λ :

-

Amplitude

- av:

-

Average b bulk

- bf:

-

Base fluid

- nf:

-

Nanofluid

- f:

-

Fluid

- c:

-

Cross section

- ch:

-

Channel convection

- p:

-

Particle

- w:

-

Wall

References

Abbas N, Bilal M, Amer M, Muhammad S, Sajjad U, Muhammad H, Zahra N, Hussain M, Badshah MA, Turab A (2019) Applications of nanofluids in photovoltaic thermal systems: a review of recent advances. Phys A 536:122513. https://doi.org/10.1016/j.physa.2019.122513

Abdulkadhim A, Hamzah HK, Ali FH, Abed AM (2019) Natural convection among inner corrugated cylinders inside wavy enclosure filled with nanofluid superposed in porous—nanofluid layers. Int Commun Heat Mass Transfer 109:104350. https://doi.org/10.1016/j.icheatmasstransfer.2019.104350

Abdulqadur AA, Jaffal HM, Khudhur DS (2019) Performance optimiation of a cylindrical mini-channel heat sink using hybrid straight-wavy channel. Int J Therm Sci 146(August):106111. https://doi.org/10.1016/j.ijthermalsci.2019.106111

Anwar M, Tariq H, Shoukat A, Ali H, Ali H (2019) Numerical study for heat transfer enhancement using CuO-H2O nano-fluids through mini-channel heat sinks for microprocessor cooling. Therm Sci 00:22–22. https://doi.org/10.2298/tsci180722022a

Azizi Z, Alamdari A, Malayeri MR (2015) Convective heat transfer of Cu—water nanofluid in a cylindrical microchannel heat sink. Energy Convers Manag 101:515–524. https://doi.org/10.1016/j.enconman.2015.05.073

Azizi Z, Alamdari A, Malayeri MR (2016) Thermal performance and friction factor of a cylindrical microchannel heat sink cooled by Cu-water nanofluid. Appl Therm Eng 99:970–978. https://doi.org/10.1016/j.applthermaleng.2016.01.140

Bi C, Tang GH, Tao WQ (2013) Heat transfer enhancement in mini-channel heat sinks with dimples and cylindrical grooves. Appl Therm Eng. https://doi.org/10.1016/j.applthermaleng.2013.03.007

Choi SUS (1995) Enhancing thermal conductivity of fluids with nanoparticles. Am Soc Mech Eng Fluids Eng Div (publ) FED 231:99–105

Chu YM, Elham A, Quang V (2020a) Thermal two-phase analysis of nanomaterial in a pipe with turbulent flow. Appl Nanosci. https://doi.org/10.1007/s13204-020-01576-8

Chu YM, Fatemeh S, Jafaryar Quang M, Bach Vu (2020b) Simulation based on FVM for influence of nanoparticles on flow inside a pipe enhanced with helical tapes. Appl Nanosci. https://doi.org/10.1007/s13204-020-01583-9

Das DK, Vajjha RS (2014) Experimental and numerical investigations of nanofluids performance in a compact minichannel plate heat exchanger. Int J Heat Mass Transf 71:732–746. https://doi.org/10.1016/j.ijheatmasstransfer.2013.12.072

Falahat A, Bahoosh R, Noghrehabadi A, Rashidi MM (2019) Experimental study of heat transfer enhancement in a novel cylindrical heat sink with helical minichannels. Appl Therm Eng 154:585–592. https://doi.org/10.1016/j.applthermaleng.2019.03.120

Fazeli SA, Hashemi SMH, Zirakzadeh H, Ashjaee M (2012) Experimental and numerical investigation of heat transfer in a miniature heat sink utilizing silica nanofluid. Superlattices Microstruct 51(2):247–264. https://doi.org/10.1016/j.spmi.2011.11.017

Feng Z, Luo X, Guo F, Li H, Zhang J (2017) Numerical investigation on laminar flow and heat transfer in rectangular microchannel heat sink with wire coil inserts. Appl Therm Eng. https://doi.org/10.1016/j.applthermaleng.2017.01.091

Gao T, Li C, Zhang Y, Yang M, Jia D, ** T, Hou Y, Li R (2019) Dispersing mechanism and tribological performance of vegetable oil-based CNT nanofluids with different surfactants. Tribol Int 131:51–63. https://doi.org/10.1016/j.triboint.2018.10.025

Gao T, Li C, Jia D, Zhang Y, Yang M, Wang X, Cao H, Li R, Ali HM, Xuefeng Xu (2020) Surface morphology assessment of CFRP transverse grinding using CNT nanofluid minimum quantity lubrication. J Clean Prod 277:123328. https://doi.org/10.1016/j.jclepro.2020.123328

Ghasemi SE, Ranjbar AA, Hosseini MJ (2017a) Experimental and numerical investigation of circular minichannel heat sinks with various hydraulic diameter for electronic cooling application. Microelectron Reliab 73:97–105. https://doi.org/10.1016/j.microrel.2017.04.028

Ghasemi SE, Ranjbar AA, Hosseini MJ (2017b) Numerical study on effect of CuO-water nanofluid on cooling performance of two different cross-sectional heat sinks. Adv Powder Technol 28(6):1495–1504. https://doi.org/10.1016/j.apt.2017.03.019

He Y, Men Y, Zhao Y, Huilin Lu, Ding Y (2009) Numerical investigation into the convective heat transfer of TiO2 nanofluids flowing through a straight tube under the laminar flow conditions. Appl Therm Eng 29(10):1965–1972. https://doi.org/10.1016/j.applthermaleng.2008.09.020

Heris SZ, Etemad SG, Esfahany MN (2006) Experimental investigation of oxide nanofluids laminar flow convective heat transfer. Int Commun Heat Mass Transf 33(4):529–535. https://doi.org/10.1016/j.icheatmasstransfer.2006.01.005

Hosseinirad E, Khoshvaght-Aliabadi M, Hormozi F (2019) Three-dimensional numerical study on thermal-hydraulic performance of twisted mini-channel using Al2O3–H2O nanofluid. Heat Transf Eng. https://doi.org/10.1080/01457632.2018.1528063

Kandlikar SG (2012) History, advances, and challenges in liquid flow and flow boiling heat transfer in microchannels: a critical review. J Heat Transf 10(1115/1):4005126

Khoshvaght-Aliabadi M, Hassani SM, Mazloumi SH (2017) Enhancement of laminar forced convection cooling in wavy heat sink with rectangular ribs and Al2O3/water nanofluids. Exp Thermal Fluid Sci 89:199–210. https://doi.org/10.1016/j.expthermflusci.2017.08.017

Kristiawan B, Wijayanta AT, Enoki K, Miyazaki T (2021) Heat transfer enhancement of TiO2/water nanofluids flowing inside a square minichannel with a microfin structure : a numerical investigation

Labib M, Nuim JN, Afrianto H, Chung H, Jeong H (2013) International journal of thermal sciences numerical investigation on effect of base Fl uids and hybrid nano Fl uid in forced convective heat transfer. Int J Therm Sci 71:163–171. https://doi.org/10.1016/j.ijthermalsci.2013.04.003

Liu D, Leyuan Y (2011) Single-phase thermal transport of nanofluids in a minichannel. J Heat Transfer 133:1–11. https://doi.org/10.1115/1.4002462

Megatif L, Ghozatloo A, Arimi A, Shariati-Niasar M (2016) Investigation of laminar convective heat transfer of a novel Tio2-carbon nanotube hybrid water-based nanofluid. Exp Heat Transf 29(1):124–138. https://doi.org/10.1080/08916152.2014.973974

Mehendale SS, Jacob AM, Shah RK (2000) Fluid flow and heat transfer at micro- and meso-scales with application to heat exchanger design. Appl Mech Rev 53(7):175–193

Muhammad NM, Sidik NAC (2019) Numerical analysis on thermal and hydraulic performance of diverging-converging minichannel heat sink using Al2O3-H2O nanofluid. IOP Conf Ser Mater Sci Eng. https://doi.org/10.1088/1757-899X/469/1/012046

Mukesh Kumar PC, Arun Kumar CM (2019) Numerical evaluation of cooling performances of semiconductor using CuO/water nanofluids. Heliyon 5(8):e02227. https://doi.org/10.1016/j.heliyon.2019.e02227

Naji ZH, Mohammed Fowzi M, Ameer MAA (2018) Heat transfer analysis of modified solar collector plate with mini-channel. J Univ Babylon Eng Sci 26(7):314–330

Naphon P, Nakharintr L (2014) Numerical and experimental study on the heat transfer characteristics in the minichannel heat sinks. Eng Trans 17(1):29–37

Pourfayaz F, Sanjarian N, Kasaeian A, Razi Astaraei F, Sameti M, Nasirivatan Sh (2018) An experimental comparison of SiO2/water nanofluid heat transfer in square and circular cross-sectional channels. J Therm Anal Calorim 131(2):1577–1586. https://doi.org/10.1007/s10973-017-6500-4

Qi C, Chen T, Jianglin Tu, Wang Y (2020a) Effects of heat sink structure on heat transfer performance cooled by semiconductor and nanofluids. Korean J Chem Eng 37(12):2104–2116. https://doi.org/10.1007/s11814-020-0634-y

Qi C, Chen T, Jianglin Tu, Yan Y (2020b) Effects of metal foam on exergy and entropy of nanofluids in a heat sink applied for thermal management of electronic components. Int J Energy Res 44(13):10628–10651. https://doi.org/10.1002/er.5703

Rostami J, Abbassi A, Harting J (2018) Heat transfer by nanofluids in wavy microchannels. Adv Powder Technol 29(4):925–933. https://doi.org/10.1016/j.apt.2018.01.010

Sadegh F, Saeed M, Mohammad N, Mohammad A, Mehdi V, Asl S (2020) Experimental investigation of heat transfer and pressure drop in a minichannel heat sink using—Al2O3 and TiO2—water nanofluids. J Braz Soc Mech Sci Eng. https://doi.org/10.1007/s40430-020-02403-5

Sharaf OZ, Al-Khateeb AN, Kyritsis DC, Abu-Nada E (2019) Numerical investigation of nanofluid particle migration and convective heat transfer in microchannels using an Eulerian-Lagrangian approach. J Fluid Mech 878:62–97. https://doi.org/10.1017/jfm.2019.606

Sheikholeslami M, Jafaryar M, Sheremet Ahmad MA, Shafee H (2020) Nanomaterial thermal performance within a pipe in presence of turbulator. Appl Nanosci. https://doi.org/10.1007/s13204-020-01436-5

Sohel MR, Saidur R, Mohd Sabri MF, Elias MM, Khaleduzzaman SS (2014) Investigation of heat transfer performances of nanofluids flow through a circular minichannel heat sink for cooling of electronics. Adv Mater Res 832:166–171. https://doi.org/10.4028/www.scientific.net/AMR.832.166

Tuckerman DB, Pease RFW (1981) High-performance heat sinking for VLSI. IEEE Electron Device Lett 2(5):126–129

Wang X, Li C, Zhang Y, Ding W, Yang M, Gao T, Cao H, Xuefeng Xu, Wang D, Said Z, Debnath S, Jamil M, Ali HM (2020) Vegetable oil-based nanofluid minimum quantity lubrication turning: academic review and perspectives. J Manuf Process 59(March):76–97. https://doi.org/10.1016/j.jmapro.2020.09.044

**a GD, Liu R, Wang J, Du M (2016) The Characteristics of convective heat transfer in microchannel heat sinks using Al2O3 and TiO2 nanofluids. Int Commun Heat Mass Transfer 76:256–264. https://doi.org/10.1016/j.icheatmasstransfer.2016.05.034

Zhang Y, Li C, Jia D, Zhang D, Zhang X (2015) Experimental evaluation of the lubrication performance of MoS2/CNT nanofluid for minimal quantity lubrication in Ni-based alloy grinding. Int J Mach Tools Manuf 99:19–33. https://doi.org/10.1016/j.ijmachtools.2015.09.003

Zirakzadeh H, Hossein N-B, Kashan B, Mehdi A (2012) Experimental investigation of heat transfer in a novel heat sink by means of alumina. Heat Transfer Res. https://doi.org/10.1615/HeatTransRes.2012004421

Funding

No funding found.

Author information

Authors and Affiliations

Contributions

SAAA-M: develop the numerical solution, extract the results, EMA is supervising and reviewing the finding of the present study, FHA conceived of the presented idea. All authors discussed the results and contributed to the final manuscript.

Corresponding author

Ethics declarations

Conflict of interest

No conflict of interest found.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Al-Mohsen, S.A.A., Abed, I.M. & Ali, F.H. A numerical comparison of circular and corrugation heat sink for laminar CuO–water nano-fluid flow and heat transfer enhancement. Appl Nanosci 13, 2739–2766 (2023). https://doi.org/10.1007/s13204-021-02003-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13204-021-02003-2