Abstract

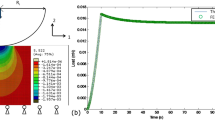

In this study, we reviewed the definitions of indentation strain and stress proposed from earlier studies and then calculated indentation strain–stress curves according to 20 combinations of five indentation strain definitions and four indentation stress definitions. The finite element method was applied to predict the load–displacement curves and the force–displacement for spherical nanoindentation and tensile test, respectively. Thus, the load–displacement data were used to determine indentation strain–stress curves, which were compared with the stress–strain curve, obtained from the tensile test simulation. Comparing with the tensile stress–strain curve, three combinations of σX − ɛK, σO − ɛA, and σH − ɛM reveal better fitting curves than the other combinations, where the subscripts of X, K, O, A, H, M are denoted as Xu and Chen (J Mater Res 25:2297-2307, 2010), Kalidindi and Pathak (Acta Mater 56:3523-3532, 2008), Oliver and Pharr (J Mater Res 7:1564-1583, 1992, J Mater Res 19:3-20, 2004), Ahn and Kwon (J Mater Res 16:3170-3178, 2001), Hill et al. (P R Soc Lond 423:301-330, 1989), and Milman et al. (Acta Metal Mater 41:2523-2532, 1993), respectively. The limitation of the indentation strain is at 0.06, 0.03, and 0.01 for combinations of σX − ɛK, σO − ɛA, and σH − ɛM. The stress constraint factor (called the ratio of mean contact pressure to tensile stress) for combinations of σX − ɛK, σO − ɛA, and σH − ɛM is 3.4, 3.4, and 2.6 to obtain the optimized fitting indentation stress–strain curves with the parameter n of the power law of 0.306, 0.248 and 0.173, which reveal the deviation of 43.0%, 15.9%, and 19.2%, respectively, in comparison with that of the tensile flow curve. Considering the best fitting curve by the combination of σO − ɛA, together with the stress constraint factor \(\psi\) of 3.4, the fitting parameters of n and K are 0.248 and 588.56 corresponding to the deviation of 15.9% and 7.7% in terms of these parameters in the tensile flow curve.

Similar content being viewed by others

References

Ahn JH, Kwon D (2001) Derivation of plastic stress–strain relationship from ball indentations: Examination of strain definition and pileup effect. J Mater Res 16:3170–3178

Ammar HR, Haggag FM (2019) Nondestructive evaluation of mechanical properties of nanostructured Al−Cu alloy at room and elevated temperatures. Trans Nonferrous Met Soc China 29:2472–2482

Angker L, Swain MV (2006) Nanoindentation: Application to dental hard tissue investigations. J Mater Res 21:1893–1905

Atkins AG, Tabor D (1965) Plastic indentation in metals with cones. J Mech Phys Solids 13:149–164

Bartier O, Hernot X, Mauvoisin G, Moussa C (2013) Comparison between representative deformations in Vickers indentation and spherical indentation. Mat Tech 101:303

Basu S, Moseson A, Barsoum MW (2006) On the determination of spherical nanoindentation stress–strain curves. J Mater Res 21:2628–2637

Branch NA, Subhash G, Arakere NK, Klecka MA (2010) Material-dependent representative plastic strain for the prediction of indentation hardness. Acta Mater 58:6487–6494

Bucaille JL, Stauss S, Felder E, Michler J (2003) Determination of plastic properties of metals by instrumented indentation using different sharp indenters. Acta Mater 51:1663–1678

Bulychev SI, Alekhin VP, Shorshorov MK, Ternovskii AP, Shnyrev GD (1975) Determination of Young’s modulus according to indentation diagram. Zavod Lab 41:1137–1140

Bulychev SI, Alekhin VP, Shorshorov MK, Ternovskii AP (1976) Mechanical properties of materials studied from kinetic diagrams of load versus depth of impression during microimpression. Strength Mater 8:1084–1089

Cheng YT, Cheng CM (1999a) Can stress-strain relationships be obtained from indentation curves using conical and pyramidal indenters? J Mater Res 14:3493–3496

Cheng YT, Cheng CM (1999b) Scaling relationships in conical indentation of elastic-perfectly plastic solids. Int J Solids Struct 36:1231–1243

Cheng YT, Cheng CM (2004) Scaling, dimensional analysis, and indentation measurements. Mater Sci Eng R 44:91–149

Cheng G, Choi KS, Hu X, Sun X (2016) Determining individual phase properties in a multi-phase Q&P steel using multi-scale indentation tests. Mat Sci Eng A-Struct 652:384–395

Chollacoop N, Dao M, Suresh S (2003) Depth-sensing instrumented indentation with dual sharp indenters. Acta Mater 51:3713–3729

Chung KH, Lee W, Kim JH, Kim C, Park SH, Kwon D, Chung K (2009) Characterization of mechanical properties by indentation tests and FE analysis – validation by application to a weld zone of DP590 steel. Int J Solids Struct 46:344–363

Dao M, Chollacoop N, Van Vliet KJ, Venkatesh TA, Suresh S (2001) Computational modeling of the forward and reverse problems in instrumented sharp indentation. Acta Mater 49:3899–3918

Doerner MF, Nix WD (1986) A method for interpreting the data from depth-sensing indentation instruments. J Mater Res 1:601–609

Field JS, Swain MV (1993) A simple predictive model for spherical indentation. J Mater Res 8:297–306

Field JS, Swain MV (1995) Determining the mechanical properties of small volumes of material from submicrometer spherical indentations. J Mater Res 10:101–112

Fischer-cripps AC (1997) Elastic–plastic behaviour in materials loaded with a spherical indenter. J Mater Res 32:727–736

Fischer-Cripps AC (2000) A review of analysis methods for sub-micron indentation testing. Vacuum 58:569–585

Fitzner A, Palmer J, Gardner B, Thomas M, Preuss M, Fonseca JQ (2019) On the work hardening of titanium: new insights from nanoindentation. J Mater Sci 54:7961–7974

Giannakopoulos AE, Suresh S (1999) Determination of elastoplastic properties by instrumented sharp indentation. Scripta Mater 40:1191–1198

Gouldstone A, Chollacoop N, Dao M, Li J, Minor AM, Shen YL (2007) Indentation across size scales and disciplines: Recent developments in experimentation and modeling. Acta Mater 55:4015–4039

Habbab H, Mellor B, Syngellakis S (2006) Post-yield characterization of metals with significant pile-up through spherical indentations. Acta Mater 54:1965–1973

Haj-Ali R, Kim HK, Koh SW, Saxena A, Tummala R (2008) Nonlinear constitutive models from nanoindentation tests using artificial neural networks. Int J Plasticity 24:371–396

Haušild P, Materna A, Nohava J (2012) On the identification of stress–strain relation by instrumented indentation with spherical indenter. Mater Des 37:373–378

Herbert EG, Pharr GM, Oliver WC, Lucas BN, Hay JL (2001) On the measurement of stress–strain curves by spherical indentation. Thin Solid Films 398–399:331–335

Herbert EG, Oliver W, Pharr G (2006) On the measurement of yield strength by spherical indentation. Philos Mag 86:5521–5539

Hernot X, Moussa C, Bartier O (2014) Study of the concept of representative strain and constraint factor introduced by Vickers indentation. Mech Mater 68:1–14

Hertz H (1896) Miscellaneous paper. MacMillan and co, New York

Hill R, Storakers B, Zdunek AB (1989) A theoretical study of the Brinell hardness test. P R Soc Lond 423:301–330

Iracheta O, Bennett C, Sun W (2016) Characterization of material property variation across an inertia friction welded CrMoV steel component using the inverse analysis of nanoindentation data. Int J Mech Sci 107:253–263

Jang JI, Choi Y, Lee YH, Kwon D, Kim DJ, Kim JT (2003) Nondestructive observation on tensile property change of hydrogen-exposed Cr–Mo–V steel HAZ using an instrumented indentation technique. J Mater Sci Lett 22:499–502

Jayaraman S, Hahn GT, Oliver WC, Rubin CA, Bastias PC (1998) Determination of monotonic stress-strain curve of hard materials from ultra-low-load indentation tests. Int J Solids Struct 35:365–381

Jiang J, Fasth A, Nylén P, Choi WB (2009) Microindentation and inverse analysis to characterize elastic-plastic properties for thermal sprayed Ti2AlC and NiCoCrAlY. J Therm Spray Technol 18:194–200

Johnson KL (1970) The correlation of indentation experiments. J Mech Phys Solids 18:115–126

Kalidindi SR, Pathak S (2008) Determination of the effective zero-point and the extraction of spherical nanoindentation stress–strain curves. Acta Mater 56:3523–3532

Kang S, Kim Y, Kim K, Kim J, Kwon D (2013) Extended expanding cavity model for measurement of flow properties using instrumented spherical indentation. Int J Plasticity 49:1–15

Khan MK, Hainsworth SV, Fitzpatrick ME, Edwards L (2010) A combined experimental and finite element approach for determining mechanical properties of aluminium alloys by nanoindentation. Comput Mater Sci 49:751–760

Kim JY, Lee KW, Lee JS, Kwon D (2006) Determination of tensile properties by instrumented indentation technique: Representative stress and strain approach. Surf Coat Technol 201:4278–4283

Kogut L, Etsion I (2002) Elastic-plastic contact analysis of a sphere and a rigid flat. J Appl Mech 69:657–662

Lee J, Lee C, Kim B (2009) Reverse analysis of nano-indentation using different representative strains and residual indentation profiles. Mater Des 30:3395–3404

Lee JH, Kim T, Lee H (2010) A study on robust indentation techniques to evaluate elastic–plastic properties of metals. Int J Solids Struct 47:647–664

Leitner A, Maier-Kiener V, Kiener D (2016) Extraction of flow behavior and hall–Petch parameters using a nanoindentation multiple sharp tip approach. Adv Eng Mater 19:1600669

Leitner A, Maier-Kiener V, Kiener D (2018) Essential refinements of spherical nanoindentation protocols for the reliable determination of mechanical flow curves. Mater Des 146:69–80

Li P, Ma X, Tong T, Wang Y (2020) Microstructural and mechanical properties β-type Ti-Mo-Nb biomedical alloys with low elastic modulus. J Alloy Compd 815:152412

Lodh A, Pant P, Kumar G, Krishna KVM, Tewari R, Samajdar I (2020) Orientation-dependent solid solution strengthening in zirconium: a nanoindentation study. J Mater Sci 55:4493–4503

Luo W, Kirchlechner C, Li J, Dehm G, Stein F (2020) Composition dependence of hardness and elastic modulus of the cubic and hexagonal NbCo2 Laves phase polytypes studied by nanoindentation. J Mater Res 35:185–195

Mata M, Casals O, Alcalá J (2006) The plastic zone size in indentation experiments: the analogy with the expansion of a spherical cavity. Int J Solids Struct 43:5994–6013

Matthews JR (1980) Indentation hardness and hot pressing. Acta Metall Mater 28:311–318

Mesarovic SD, Fleck NA (1999) Spherical indentation of elastic-plastic solids. P R Soc Lond 455:2707–2728

Meyer E (1908) Untersuchungen über härteprüfung und härte brinell methoden. Z Ver deut Ing 52:645–835

Milman YV, Galanov BA, Chugunova SI (1993) Plasticity characteristic obtained through hardness measurement. Acta Metal Mater 41:2523–2532

Moussa C, Bartier O, Mauvoisin G, Delattre G, Hernot X (2013) Literature review on mechanical characterization of materials using a representative strain in spherical indentation. Mat Tech 101:1–14

Moussa C, Hernot X, Bartier O, Delattre G, Mauvoisin G (2014a) Evaluation of the tensile properties of a material through spherical indentation: definition of an average representative strain and a confidence domain. J Mater Sci 49:592–603

Moussa C, Hernot X, Bartier O, Delattre G, Mauvoisin G (2014b) Identification of the hardening law of materials with spherical indentation using the average representative strain for several penetration depths. Mat Sci Eng A 606:409–416

Mukhopadhyay NK, Paufler P (2006) Micro- and nanoindentation techniques for mechanical characterisation of materials. Int Mater Rev 51:209–245

Muliana A, Steward R, Haj-Ali RM, Saxena A (2002) Artificial neural network and finite element modelling of nanoindentation tests. Metall Mater Trans A 33:1939–1947

Ogasawara N, Chiba N, Chen X (2005a) Limit analysis-based approach to determine the material plastic properties with conical indentation. J Mater Res 21:947–957

Ogasawara N, Chiba N, Chen X (2005b) Representative strain of indentation analysis. J Mater Res 20:2225–2234

Oliver WC, Pharr GM (1992) An improved technique for determining hardness and elastic modulus using load and displacement sensing indentation experiments. J Mater Res 7:1564–1583

Oliver WC, Pharr GM (2004) Measurement of hardness and elastic modulus by instrumented indentation: Advances in understanding and refinements to methodology. J Mater Res 19:3–20

Page TF, Riester L, Hainsworth SV (1998) The plasticity response of 6H SiC and related isostructural materials to nanoindentation: slip vs densification. In: Moody NR, Gerberich WW, Burnham N, Baker SP (eds) Fundamentals of nanoindentation and nanotribology, MRS Proc 521, United States, pp 113–118

Patel DK, Kalidindi SR (2016) Correlation of spherical nanoindentation stress-strain curves to simple compression stress-strain curves for elastic-plastic isotropic materials using finite element models. Acta Mater 112:295–302

Pathak S, Shaffer J, Kalidindi SR (2009) Determination of an effective zero-point and extraction of indentation stress–strain curves without the continuous stiffness measurement signal. Scripta Mater 60:439–442

Richmond O, Morrison H, Devenpeck M (1974) Sphere indentation with application to the Brinell hardness test. Int J Mech Sci 16:75–82

Schuh CA (2006) Nanoindentation studies of materials. Mater Today 9:32–40

Shim S, Jang J, Pharr GM (2008) Extraction of flow properties of single-crystal silicon carbide by nanoindentation and finite-element simulation. Acta Mater 56:3824–3832

Sneddon IN (1965) The relation between load and penetration in the axisymmetric Boussinesq problem for a punch of arbitrary profile. Int J Eng Sci 3:47–57

Sonmez FO, Demir A (2007) Analytical relations between hardness and strain for cold formed parts. J Mater Process Tech 186:163–173

Sun G, Xu F, Li G, Huang X, Li Q (2014) Determination of mechanical properties of the weld line by combining micro-indentation with inverse modeling. Comput Mater Sci 85:347–362

Tabor D (1951) The hardness of metals. Clarendon Press, Oxford

Takakuwa O, Mano Y, Soyama H (2014) Increase in the local yield stress near surface of austenitic stainless steel due to invasion by hydrogen. Int J Hydrogen Energy 39:6095–6103

Taljat B, Zacharia T, Kosel F (1998) New analytical procedure to determine stress-strain curve from spherical indentation data. Int J Solids Struct 35:4411–4426

Tirupataiah Y, Sundararajan G (1991) On the constraint factor associated with the indentation of work-hardening materials with a spherical ball. Metall Trans A 22:2375–2384

**ong Z, Saleh AA, Casillas G, Cui S, Pereloma EV (2020) Phase-specific properties in a low-alloyed TRIP steel investigated using correlative nanoindentation measurements and electron microscopy. J Mater Sci 55:2578–2587

Xu B, Chen X (2010) Determining engineering stress–strain curve directly from the load–depth curve of spherical indentation test. J Mater Res 25:2297–2307

Yetna N’Jock M, Chicot D, Decoopman X, Lesage J, Ndjaka JM, Pertuz A (2013) Mechanical tensile properties by spherical macroindentation using an indentation strain-hardening exponent. Int J Mech Sci 75:257–264

Zhang C, Li F, Wang B (2013) Estimation of the elasto-plastic properties of metallic materials from micro-hardness measurements. J Mater Sci 48:4446–4451

Acknowledgments

The authors would gratefully like to thank the Ministry of Science and Technology for supporting the fund in the project under MOST 109-2221-E-006-131-MY2 and Professor Wang-Long Lee for providing software COMSOL to help finite element simulation.

Funding

This study was funded by Ministry of Science and Technology, Taiwan (MOST 109–2221-E-006–131-MY2).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Huang, FY., Liu, YW. & Kuo, JC. Uncertainties in the representative indentation stress and strain using spherical nanoindentation. Appl Nanosci 11, 895–909 (2021). https://doi.org/10.1007/s13204-020-01646-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13204-020-01646-x