Abstract

The central Sichuan Basin, located in western China, holds great significance in terms of hydrocarbon production, especially in relation to complex carbonate reservoirs, notably the Qixia Formation of the Middle Permian epoch. However, the comprehensive evaluation of this geological formation presents considerable challenges due to complex lithology, limited availability of reservoir property data at various scales, inadequacies in data integration, and the absence of a reliable reservoir ranking system for development decision making. Previous studies primarily relying on conventional data at the reservoir level, such as well logs and geological information, have proven insufficient in accurately characterizing the reservoir. This is especially evident without precise lithological information and detailed knowledge of microscale properties, which are crucial for effective reservoir evaluation. To address these challenges, this study integrates advanced technologies like X-ray diffraction, micro-CT and scanning electron microscope (SEM) techniques in digital drill cutting analysis at the microscale. A novel scoring system has been developed using a prominent component analysis (PCA) approach and an expert scoring system, which incorporates existing conventional well log data and digital cutting analysis. This scoring system has been validated using actual production data, thus establishing a robust evaluation methodology for assessing the exploration potential and optimizing development strategies for carbonate gas reservoirs in the Qixia Formation. The innovative approach, which incorporates parameters at both micro- and macroscales, holds promising potential in facilitating future exploration and development efforts.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

The Sichuan Basin, situated in western China, is a prominent hydrocarbon-producing region renowned for its intricate carbonate reservoirs. Among these reservoirs, the Middle Permian Qixia Formation, a marine carbonate stratum, has recently gathered significant attention for gas exploration in the central part of the Sichuan Basin. This increased interest is primarily driven by the remarkable gas production achieved in the western section of the Sichuan Basin. Moreover, the central Sichuan Basin has also shown promising gas test results, highlighting its considerable exploration and development potential (Hu et al., 2018; Guan et al. 2018; He et al. 2021; Lu et al. 2021; Hou et al. 2017). As a significant carbonate reservoir in the region, the Permian Qixia Formation is recognized as a valuable natural gas resource with high potential. However, evaluating these carbonate reservoirs poses numerous challenges:

(1) Lithologic complexity: The depositional setting of the Qixia Formation is predominantly characterized by a carbonate platform environment, which likely encompasses a range of depths from shallow marine to deeper marine conditions. Consequently, the prevailing lithologies are primarily carbonates, with notable occurrences of limestones and dolomites. However, relying solely on existing conventional well log data poses challenges in accurately assessing the reservoir’s ranking (Cheng et al. 2016; Fu et al. 2016; Li et al. 2019a, b; Ren et al. 2019).

(2) Carbonate heterogeneity: Carbonate reservoirs exhibit complex pore systems comprising matrix, interparticle, vuggy, and fracture porosity. This wide array of reservoir spaces gives rise to significant heterogeneity, which poses challenges in accurately quantifying and predicting the porosity and permeability of the reservoir.

Given the intricate nature of carbonate reservoirs, researchers and industry professionals have been compelled to develop evaluation methodologies to aid in the assessment of these reservoirs. (Babadagli et al., 2004; Hou et al. 2010; Al-Saqran et al. 2012; Deng et al. 2013; Bai et al. 2022; Abel et al., 2014; Al-Owihan et al. 2014; Gibrata et al. 2019; Tadayoni et al. 2020; Aghli et al. 2020; Seddik et al. 2022; Hou et al. 2023; Yan et al. 2023). These methodologies typically integrate multiple parameters to classify and assess the reservoir quality and potential, surpassing the conventional petrophysical analysis tools by incorporating advanced technologies for precise characterization. The utilization of scoring and ranking methodologies in reservoir evaluation has witnessed significant advancements over the years. Amal (2007) introduced a scoring system, amalgamating multiple parameters, to assess well conditions and systematically rank them based on the results. Taking a multifaceted approach, Clark (2009) integrated historical recovery factors, material balance, and decline curve analysis to derive a more informed recovery factor, aiding in developmental decision making. Pioneering in data analytics, Goldstein et al. (2010) developed a computational methodology leveraging the random forest algorithm on extensive datasets. Srimoyee et al. (2013) highlighted the adaptability of ranking systems across varied datasets in the petroleum engineering realms. Employing a data-driven analysis for ranking reservoir, Serkan et al. (2014) optimized operations in the oil and gas sector by analyzing both historical and real-time data. Further enhancing evaluation methods, Keaton (2015) designed a robust rating system that considered both regional and site-specific scales, providing a thorough evaluation of geological model intricacies. Gherabati et al. (2018) fused geological insights with petrophysical analysis to rank and fine-tune predictions of recoverable hydrocarbon volumes. Digging deeper into reservoir attributes, Abuamarah et al. (2021) emphasized core-scale parameters to sharpen reservoir quality assessments. Muther et al. (2022) underscored the role of contemporary optimization technologies and machine learning in refining the planning process for unconventional reservoirs. Advancing the automation further, Mubarak and Koeshidayatullah (2023) employed machine learning techniques, particularly leveraging well log data, to predict reservoir attributes. Li et al. (2023) developed a new score method to evaluate and rank carbonate reservoir using expert scoring and the random forest approach.

The carbonate reservoir is characterized by the complex dual-pore system of fractures and vugs, which leads to significant heterogeneity. Previous studies have encountered difficulties in thoroughly evaluating carbonate reservoirs due to their reliance on macroscale reservoir properties alone. This approach lacks an integrated analysis of multiscale data from various sources, such as focusing solely on well log or rock sample data. Traditional well logs do not provide sufficient information to characterize such reservoirs (Mahiout et al. 2014), while newer logging tools like NMR can only detect a limited volume of rocks. High-resolution borehole images can be influenced by the borehole environment and the reliability of statistical calculations (Hou et al 2010). The lack of microscale information from core samples is often due to the highly fractured and vuggy nature of carbonate formations, which makes drilling challenging and results in significant drilling fluid losses and core recovery failures (Keith et al 2016). Petrophysical measurements from conventional laboratory experiments, such as mercury-air capillary pressure data, are insufficient to reveal the full extent of rock properties affected by carbonate heterogeneity (Zhu et al 2013). This study aims to overcome these limitations by integrating advanced technologies such as X-ray diffraction, micro-CT, and SEM to enhance the precision of microscale data obtained from drill cuttings for evaluating carbonate reservoirs in the specified region. The use of today’s advanced technologies in the oil and gas industry makes it difficult to select the most relevant data for reservoir evaluation, and accurately choosing features for management decision making is also challenging. In this paper, a novel score system has been developed to assess these reservoirs using principal component analysis. It incorporates parameters derived from digital cutting analyses at the microscale while also integrating pre-existing well log data at the macroscale. The purpose of this system is to establish a rapid and precise methodology for evaluating the developmental feasibility of the reservoir by integrating available micro- and macroscale information.

Methods

X-ray diffraction analysis

Introduction

X-ray diffraction stands out as a fast, accurate and efficient non-destructive testing method. It works by analyzing the diffraction spectrum of minerals via X-ray diffraction of mineral crystals. By comparing these spectra, it can determine the percentage content of various minerals. The X-ray diffraction method allows for accurate identification of a rock sample’s mineral composition, refining the accuracy of lithology identification based on mineral content percentages. It can also be used as an important means to pinpoint stratigraphic and trap boundaries. This technology has been widely used in oil and gas fields such as Daqing, Tarim in **njiang, and Bohai in recent years. It has solved many problems in exploration and development and has played a key role in identifying complex lithology such as sandstone, carbonate, igneous rock, stratigraphic interfaces and trap boundaries (Fang 2016; Hu et al. 2020; Li et al. 2017; Ni et al., 2018; Yan et al. 2015; Yu 2018; Yu et al. 2020; Zhang et al. 2021). Recently, it has been used to detect mineral components of drill cuttings to identify lithology in North Sea field, Norway, and accurately distinguished changes in stratigraphic interfaces and successfully identifies sand body boundaries of oil and gas reservoirs.

Application

Mineral percentages were determined utilizing DX-27mini Benchtop X-ray diffractometer through X-ray diffraction (XRD) analysis. To prepare the samples, drill cutting samples were finely ground using a grinding dish until the resulting powder could pass through a 200-mesh sieve, ensuring a homogeneous sample. The finely ground sample was then carefully placed in the groove of a glass slide to create a flat and level surface for analysis.

For the X-ray diffraction analysis, the scanning parameters were set as follows: a starting angle of 5° and an ending angle of 65°, providing a comprehensive angular range for accurate identification of mineral phases. The measurement time for each data point was set to 0.5 s, balancing between acquisition speed and data quality. To ensure sufficient data resolution, a step width angle of 0.02° was employed, enabling precise measurement of peak positions. The X-ray diffractometer was operated at a tube voltage of 40 kV and a tube current of 25 mA, optimizing the X-ray beam intensity for reliable and precise determination of mineral percentages.

Micro-CT and SEM experiments

Introduction

Computed tomography (CT) technology, initially developed in the medical field during the early 1970s, brought about a revolutionary approach to visualizing internal structures of objects without the need for physical dissection. The adaptation of CT scanning for rock sample evaluation represents a significant advancement in both geosciences and the petroleum sector. Specifically tailored CT equipment offers a non-destructive method for visualizing the microstructural intricacies, analyzing composition, and assessing porosity of rock samples in great detail. This technology enables comprehensive evaluations of reservoir quality and hydrocarbon storage potential by facilitating the identification of fine fractures, vugs, and complex pore structures. The reconstructed digital cutting faithfully and comprehensively depicts the characteristics of the rock’s pore structure. Furthermore, this method allows for numerical simulation calculations and experimental investigations (Geng et al. 2014; Peng 2022; Qu et al. 2014; Sheng et al. 2019; Zhao et al. 2021). This state-of-the-art technology aids in transitioning from microscopic rock research to impactful applications that significantly enhance oil and gas recovery (Long et al. 2019; Zhang et al. 2022; Sun et al. 2021; Yao et al. 2022).

Scanning electron microscopy (SEM) is a powerful imaging technique used in scientific research for the characterization and analysis of solid materials at the micro- and nanoscale. It operates by scanning a finely focused electron beam across the surface of a sample, generating signals that provide information about the sample’s topography, elemental composition, and other material properties (Lemmens et al. 2011; Cudjoe et al 2019). The electron beam interacts with the sample, causing various interactions such as secondary electron emissions, backscattered electrons, and characteristic X-ray emissions. These interactions are detected and converted into high-resolution images or compositional maps, revealing fine details and structural features of the sample with high magnification and spatial resolution (Landry et al. 2020).

Application

In this study, we employed the state-of-the-art PoroScan 3000 CT equipment offering top-of-the-line capabilities for precise imaging and analysis of porous materials. The PoroScan 3000 CT equipment has an impressive scan resolution of up to 0.5 μm, enabling us to capture the intricate details of the materials with high precision and accuracy. The X-ray source voltage range of 180 kV and a maximum output power of 25W provided a wide range of energy for X-ray imaging. Additionally, the flat panel detector, with an imaging area of 254 mm × 317 mm and a pixel matrix of 2560 × 2048, combined with the optically coupled detector with a pixel matrix of 4096 × 4096, and lenses at 4 × , 10 × , and 20 × magnifications allowed us to obtain high-quality 2D and 3D images of the porous samples from multiple perspectives.

Furthermore, we utilized the TESCAN MIRA3 XMH in this study for high-performance imaging and analysis of samples at the nanoscale level. The TESCAN MIRA3 XMH is a recent-generation scanning electron microscope that provides a range of features and capabilities. This top-of-the-line microscope is designed to deliver precise imaging and analysis of various types of samples, including porous materials. We used this advanced technology to explore and analyze the porosity and pore distribution of the samples at the nanoscale level.

Digital cutting analysis

The rock samples underwent scanning at a resolution of 1.5 μm to generate a three-dimensional grayscale model. The commonly employed non-local means filtering technique was utilized for denoising. This algorithm effectively smooths and averages the pixel values around a target pixel, employing a weighted average of the surrounding pixels. This ensures that the filtered image maintains clarity without sacrificing details. Following that, the watershed algorithm was utilized to perform a threshold segmentation on the three-dimensional grayscale data. This process enabled the separation of distinct regions within the data, leading to the creation of a binarized three-dimensional model representing the rock samples. This model served as a foundation for subsequent calculations of petrophysical properties. The micro-porosity parameter was subsequently statistically calculated based on the binarized three-dimensional data obtained from scanning using a maximum sphere model (Alpak et al. 2019; Liu et al. 2022). The porosity in this study was determined by combining the micro-porosity derived from micro-CT with the nano-porosity obtained from SEM analysis.

The permeability of a digital cutting sample can be determined through numerical simulation. This process entails initializing the physical field and implementing boundary processing using the three-dimensional structure model of the rock samples from the CT. The mirror boundary condition is employed as the boundary processing method for the Lattice Boltzmann method (Dai et al. 2019). By employing this approach, a simulation area and multiple mirror areas with identical configurations are obtained. Within the simulation area, fluid flow is driven by a body force. The distribution function within this simulation area is then calculated. Based on this body force and distribution function, the absolute permeability of the rock sample is determined.

PCA and score system

Introduction

Principal component analysis (PCA) is a widely used method in machine learning and data analysis. It serves as a dimensionality reduction and data visualization technique that can effectively reduce large datasets by transforming a set of variables into a smaller subset that retains most of the original information (Peng 2022). The concept of PCA originated from the work of Karl Pearson in 1901, where he sought to identify the major and minor axes of an ellipse. Later, in 1930, Harold Hotelling independently developed the technique and named it PCA. It aims to identify the “principal components” of the data, which are essentially the axes that capture the maximum variation in the data. While the principal components themselves lack a direct physical interpretation, it is possible to ascertain the key physical parameters influencing each component by analyzing the weights of the original variables associated with them. The reduced dataset consists of the measured parameters derived from identifying the original physical parameters that contribute significantly to the top principal components. By examining the loadings or coefficients associated with each principal component, we can identify the original features with the greatest magnitude in the linear combinations that define these components.

Application

In the domain of reservoir evaluation, the application of principal component analysis (PCA) entails following a systematic procedure:

-

1)

Data Collection: collect relevant data pertaining to the reservoir, including parameters such as porosity, permeability, lithology, and other pertinent factors.

-

2)

Data Preprocessing: normalize or standardize the data to ensure uniform scaling of each variable. This prevents biases resulting from variations in the scale of individual parameters.

-

3)

Application: apply PCA to the preprocessed data, generating principal components that are linear combinations of the original variables.

-

4)

Interpretation: typically, the initial principal components capture a significant portion of the data’s variability. Analyze the weights of the original variables associated with these components to understand the most influential parameters.

-

5)

Visualization: visualize clusters or trends in reservoir properties by plotting the data using the first two or three principal components.

-

6)

Utilization: leverage the reduced dimensionality of the data post-PCA for further analyses, such as clustering, regression, or classification. This facilitates the identification of important patterns or relationships crucial for reservoir evaluation.

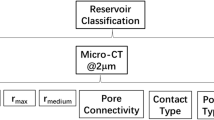

The scoring system is devised by employing PCA-based dimensional reduction analysis, which integrates control factors derived from a diverse set of 14 input parameters. These input parameters encompass various aspects such as micron-scale porosity, pore type, neutron logging (CNL), average pore throat radius, median pore throat radius, micron permeability, dolomite content, calcite content, quartz content, clay contents, gamma ray logging (GR), density logging (DEN), resistivity logging, and acoustic logging (AC). Through the utilization of PCA analysis, our scoring system condenses these 14 input parameters into a reduced set of parameters, thereby enhancing efficiency and effectiveness in evaluating reservoir potential. The weight of each principal control factor is determined. Normalization of the points for each control factor is performed by dividing them by the maximum value and then multiplying by their respective weight.

The cumulative score of all normalized factors, calculated using Eq. (1), represents the ranking of the reservoir. A scoring threshold is established with the aid of production data correlations and insights from local reservoir experts.

where fi is the variable importance from PCA analysis, and pi is the score of the control factor from the experts.

Results and discussion

Sample selection

The objective of this study is to perform experimental investigations using rock samples obtained from cores and drill cuttings, with the aim of addressing the inaccuracies and limitations associated with lithology and petrophysical properties. The samples were specifically selected from wells within the carbonate strata of the Qixia Formation in the Gaoshiti-Moxi area, situated in the central Sichuan Basin (Fig. 1). Given the complex nature of lithology and petrophysical properties in this region, a sampling scheme has been devised to ensure the representative collection of both reservoir and non-reservoir characteristics. First, X-ray diffraction testing was employed on successive drill cuttings from each well. This was compared with mineral content results and well log lithology interpretation to find the correct depth interval. The sample range was then narrowed down to reservoir/non-reservoir, based on gas indication from drilling data and production data. To determine mineral composition and identify lithology, a total of 14 drill cuttings were subjected to X-ray diffraction analysis. Additionally, micro-CT and SEM were employed for the analysis of digital cutting properties.

Mineral contents and lithology

Following the X-ray diffraction testing conducted on the drill cutting samples, the mineral composition and content percentages were determined (Fang 2016). The findings indicate that the Qixia Formation in the study area primarily consists of calcite and dolomite minerals, with the combined percentage of these two minerals generally exceeding 90%. Furthermore, the majority of samples exhibit a higher calcite content compared to dolomite. The lithology of the Qixia Formation in the Gaoshiti-Moxi area is predominantly comprised of limestone, followed by slightly dolomitic limestone and dolomitic limestone, with dolomite present in minimal quantities.

Microscale pore structure

Fourteen drill cutting samples were carefully selected within the study area to undergo micro-CT scanning and SEM analysis. Subsequently, digital reconstruction and simulations were conducted to analyze the microscopic characteristics of pores and petrophysical parameters as shown in Table 1. Figure 2 presents the findings related to the pore structure characteristics at the micron-scale from SEM. It is observed that samples Gaoshi 001 X32-4234m and Moxi 31X1-4465m predominantly consist of pure dolomite with large angular pores. The results of dolomitic limestone samples (Gaoshi 001-H33-4248m, Gaoshi 18-4278m, Moxi 131-4485m) reveal the presence of dark spots and small internal pores. Two samples, Gaoshi 001-X45-4164m and Gaoshi 18-4278m, exhibit fractures. In particular, sample Gaoshi 001-X45-4164m displays white calcareous lumps of varying sizes. Micro-pores are predominantly observed in these samples.

Microscale pore structure of drill cuttings from SEM: a Fracture, limestone, well GS001-X45, 4164m; b Large dissolved angular pores, dolomite, well GS001-X32, 4234m; c Dissolved pores, slightly dolomitic limestone, GS001-H33, 4248m; d Fracture, dolomitic limestone, GS18, 4278m; e Large dissolved angular pores, dolomite, MX31X1, 4465m; f Dissolved pores, dolomitic limestone, MX131, 4485m; g Tight matrix, limestone, well MX108, 4662m; h Tight matrix and filled fractures, limestone, well MX108, 4670m; i Tight matrix and filled fractures, limestone, MX123, 4332m; j Tight matrix, limestone, MX123, 4340m; k Tight matrix, limestone, GS001-H33, 4272m; l Fractures, limestone, GS001-H33, 4280m; m Tight matrix, limestone, GS102, 4050m; n Tight matrix, limestone, GS102, 4058m

The remaining samples are composed of dense pure limestones characterized by extremely low porosity. Some samples, such as those obtained from Moxi 108-4670m, Moxi 123-4332m, and Gaoshi 001-H33-4280m, exhibit micro-fractures (Fig. 2). Most fractures are partially filled with minerals, and dissolved pores are infrequently present. The proportion of micrometer-sized pores is relatively low, as indicated in Table 1. Furthermore, fractures are observed in some samples, such as Gaoshi 001-H33-4280m. The pore throat distribution curves demonstrate multiple peaks, indicating significant rock heterogeneity.

All drill cutting samples primarily consist of carbonates with a notably high matrix density. The pore types range from matrix to fracture matrix, while the porosity distribution ranges from 0.42% to 1.31%, predominantly comprising of micrometer-sized pores. The permeability from the digital cuttings ranges from 0.01 to 0.11mD, as outlined in Table 1.

Moreover, the analysis of the pore throat distribution curve from the digital cutting uncovered a bimodal or multi-modal nature, indicating the presence of reservoir heterogeneity. The porosity is predominantly derived from micron pores, with a supplementary contribution from nanoscale pores toward the overall porosity (shown in Fig. 3).

Results from score system

The collection of evaluation factors from Qixia Formation reservoirs in the Gaoshit-Moxi area involved collating data from both the current study and previous information. These factors encompassed multiscale porosity, permeability, average pore throat radius, median pore throat radius, mineral content (such as calcite and dolomite), fracture opening, logging data (including gamma ray, neutron, density, and resistivity), lithology, reservoir space type, and other relevant information. The collected data underwent processing to address missing values, utilizing observations and similarities within this study to complete the data sets.

Subsequently, PCA was conducted to examine the relationships between different characteristic factors, reduce dimensions to mitigate overfitting, and analyze the primary controlling factors of the reservoir following data dimensionality reduction. Table 2 presents the results of the PCA analysis. The first seven principal components were retained based on the “elbow point” from eigenvalue. The most effective variable has been interpreted based on the contribution for each principal component. The main controlling factors, ranked in order of importance, fi, are micron-scale porosity, neutron logging (CNL), average pore throat radius, micron permeability, dolomite content, density logging (DEN), and acoustic logging (AC) (as depicted in Fig. 4). The resulting rankings align with the opinions of local experts who possess specialized knowledge and understanding of the area. According to the local experts, the controlling factor in the changing lithologies and depositional environments of this area is frequently attributed to porosity at the micron-scale. To determine the porosity of the reservoir, neutron logging (CNL) and density logging (DEN) are significant factors. Average pore throat radius and micron permeability are key determinants of reservoir productivity. Furthermore, dolomite content has the potential to impact reservoir productivity by influencing its capacity to hold and produce hydrocarbons. Acoustic logging (AC) can be utilized to estimate compressional and shear velocities of rocks, which serve as important indicators of rock quality and brittleness. These findings serve as a reliable foundation for rapid reservoir evaluation.

The score, pi, for each corresponding parameters is then evaluated through the local experts in this field, which is shown in Table 3. The expert scoring system is employed for the assessment of input parameters in order to derive a comprehensive score for the gas reservoir index. Experts utilize their knowledge and understanding of the reservoirs to determine the ranges of key factors and assign corresponding scores to them. These factors play a crucial role in the evaluation process and contribute to the overall assessment of the gas reservoir. The scores 60, 80, and 100 indicate the ranking of each parameter from poor to good and excellent.

Following Eq. (1), the score values were calculated for each individual well as shown in Table 4. The reservoirs were subsequently ranked in descending order based on their scores, with higher-scoring reservoirs prioritized for development. This ranking system, reliant on scores, serves as a dependable foundation for optimizing reservoir development strategies.

Method validation

Experts familiar with the carbonate reservoirs in this region affirm the accuracy and effectiveness of the employed methodology in accurately assessing the quality and production potential of carbonate gas reservoirs in the Sichuan Basin. All the well listed in the paper have been checked with production data, for instance, in the study area, well GS001-X32, with a score of 98, has demonstrated a substantial gas flow and proven productivity. Similarly, well MX31X1, scoring 94, has also yielded excellent production outcomes. MX 131 with a score of 91 has proven production data, and MX108-b with a score of 87 shows no gas indication.

As illustrated in Fig. 5, the scores acquired from the assessment of 14 wells aptly demonstrate the clear demarcation between reservoir and non-reservoir wells based on their respective gas production. Red wells indicate reservoirs, while blue wells correspond to non-reservoirs. By thoroughly analyzing the data presented in Fig. 5, a threshold score of 90 can be established to effectively discriminate between reservoir and non-reservoir wells. This score serves as a crucial parameter in accurately characterizing the production potential of the wells, thereby enabling targeted decision making during hydrocarbon exploration and production endeavors. Figure 6 presents the correlation between the score and the production values for the fourteen wells, thereby affirming the efficacy and robustness of the developed scoring system. This visual depiction serves as tangible evidence of the system’s ability to accurately evaluate and quantify the productive capacity of the wells. By examining the relationship between the assigned scores and the corresponding production levels, valuable insights can be gained, allowing for informed decision making and strategic planning in the field of hydrocarbon exploration and production. The scoring system can be further updated by adding new data in the future.

Conclusions

This study introduces an innovative scoring system that integrates microscale data, obtained through advanced techniques such as X-ray diffraction, micro-CT, and SEM, with macroscale data derived from well logging. The system utilizes principal component analysis (PCA) and incorporates expert knowledge to validate its performance using actual production data. The key findings of this study are as follows:

-

1.

The scientific methodology employed in this study considers various influential factors, including micron-scale porosity, neutron logging (CNL), average pore throat radius, micron permeability, dolomite content, density logging (DEN), and acoustic logging (AC). These parameters are integrated using the proposed scoring system to evaluate the reservoir potential and facilitate effective reservoir development strategies.

-

2.

By combining microscale and macroscale data, this study provides a more holistic and precise assessment of carbonate gas reservoirs in the central Sichuan Basin. The insights gained contribute to a better understanding of reservoir behavior and can assist in optimizing production strategies and field development.

It is important to acknowledge certain limitations and identify future research areas. The availability and quality of data derived from X-ray diffraction, micro-CT, and SEM analyses may have limitations. Variations in sample collection, preparation, and analysis techniques can introduce uncertainties and impact the accuracy of reservoir evaluation. Additionally, this study is based on data from only fourteen reservoirs, thus the model would benefit from further validation and updates with more extensive data. The practical applications and enhanced reservoir performance can be explored by assessing the effectiveness of the score system in optimizing production strategies, well placement, and field development. Furthermore, future research will extend the application of this method to unconventional shale gas reservoirs in the Sichuan Basin for broader interest and applications.

Abbreviations

- AC:

-

Borehole Compensated Acoustic Log

- CNL:

-

Compensated Neutron Log

- CT:

-

Computed Tomography

- DEN:

-

Density Log

- GR:

-

Gamma Ray

- PCA:

-

Principal Component Analysis

- SEM:

-

Scanning Electron Microscopy

References

Abel C, Nelson F (2014) Petrophysical evaluation of a carbonate reservoir in Campos Basin - Southeastern Brazil. 2714–2718. https://doi.org/10.1190/segam2014-0302.1

Abuamarah BA, Nabawy BS (2021) A proposed classification for the reservoir quality assessment of hydrocarbon-bearing sandstone and carbonate reservoirs: a correlative study based on different assessment petrophysical procedures. J Nat Gas Sci Eng 88:103807

Aghli G, Moussavi-Harami R, Mohammadian R (2020) Reservoir heterogeneity and fracture parameter determination using electrical image logs and petrophysical data (a case study, carbonate Asmari formation, Zagros Basin, SW Iran). Pet Sci 17:51–69

Al-Owihan H, Al-Wadi M, Thakur S, Behbehani S, Al-Jabari N, Dernaika M, and Koronfol S (2014) Advanced rock characterization by dual energy CT imaging: a novel method in complex reservoir evaluation. Paper presented at the international petroleum technology conference, Doha, Qatar. https://doi.org/10.2523/IPTC-17625-MS

Alpak FO, Zacharoudiou I, Berg S et al (2019) Direct simulation of pore-scale two-phase visco-capillary flow on large digital rock images using a phase-field lattice Boltzmann method on general-purpose graphics processing units. Comput Geosci 23:849–880

Al-Saqran F, Padhy GS, Abdul-Latif A, Al-Anezi K, Thakuria A, Vasquez R (2012) Integrated carbonate formation evaluation for heterogeneous carbonate reservoirs: a case study from minagish oolite reservoir. Paper presented at the Abu Dhabi International Petroleum Conference and Exhibition, Abu Dhabi, UAE, November. https://doi.org/10.2118/162391-MS

Amal AH (2007) New Scoring System for Evaluating Well Integrity. Paper presented at the SPWLA Middle East Regional Symposium, Abu Dhabi, UAE. Paper Number: SPWLA-MERS-2007-JJ

Babadagli T, Al-Salmi S (2004) A review of permeability-prediction methods for carbonate reservoirs using well-log data. SPE Res Eval & Eng 7:75–88. https://doi.org/10.2118/87824-PA

Bai Y, Tan M, Cao H, Tang J, Liang Z (2022) Intelligent classification of carbonate reservoir quality using multisource geophysical logging and seismic data. IEEE Trans Geosci Remote Sens 60:1–12

Cheng L, Wang K, Feng M et al (2016) True or false reservoir characteristics and well-logging recognition for the permian, Sichuan Basin. Nat Gas Technol Econ 10(4):10–14

Clark AJ (2009) Determination of recovery factor in the bakken formation, Mountrail County, ND. Paper presented at the SPE Annual technical conference and exhibition, New Orleans, Louisiana. https://doi.org/10.2118/133719-STU

Cudjoe S, Liu S, Barati R , Hasiuk F, Goldstein R, Tsau JS , Nicoud B, Bradford K, Baldwin A, David M (2019) Pore-Scale Characterization of eagle ford outcrop and reservoir cores with SEM/BSE, EDS, FIB-SEM, and Lattice Boltzmann Simulation. Paper presented at the SPE Annual technical conference and exhibition, Calgary, Alberta, Canada. https://doi.org/10.2118/195805-MS

Dai Z, Li H, Tang F, Luo D, Wang Y, Yan Z (2019) A new method of digital core construction and analysis for unconsolidated sandstone. Paper presented at the SPE annual technical conference and exhibition, Calgary, Alberta, Canada. https://doi.org/10.2118/196200-MS

Deng S, Wang Y, Hu Y et al (2013) Integrated petrophysical log characterization for tight carbonate reservoir effectiveness: a case study from the longgang area, Sichuan Basin. China Pet Sci 10:336–346

Fang X (2016) Mud logging technology of X-ray diffraction whole rock mineral analysis. Mud Logging Eng 27(1):14–18

Fu L, Shen Y, Cao G et al (2016) Application of XRD diffraction technique of lithological identification in Junggar basin. Henan Sci Technol 13:84–86

Geng C, Yang Y, Gao Y (2014) Optimization of image processing method based on rock CT images of different resolutions. Sci Technol Eng 14(02):1–4

Gherabati SA, Hammes U, Male F, Browning J (2018) Assessment of hydrocarbon in place and recovery factors in the eagle ford shale play. SPE Res Eval Eng 21:291–306. https://doi.org/10.2118/189982-PA

Gibrata MA, Ghedan SG, Rouis L, Yanfidra D (2019) Advanced and integrated petrophysical evaluation for reservoir characterization of complex carbonate reservoir: case study. Paper presented at the SPE gas & oil technology showcase and conference, Dubai, UAE. https://doi.org/10.2118/198636-MS

Goldstein BA, Hubbard AE, Cutler A et al (2010) An application of random forests to a genome-wide association dataset: methodological considerations & new findings. BMC Genet 11:49

Guan X, Chen S, Su W et al (2018) Carbonate reservoir characteristics and main controlling factors of middle Perminan Qixia formation in NW Sichuan basin. Lithol Reserv 30(02):67–76

He P, Xu W, Zhang L et al (2021) Characteristics and genetic mechanism of Qixia Formation dolomite in Moxi-Gaoshiti area, central Sichuan Basin. Acta Sedimentol Sin 39(06):1532–1545

Hou G, Zhou J, Gu M et al (2017) Lithofacies paleogeography and exploration realms of middle Permian Qixia formation and Maokou formation Sichuan Basin. Marfgine Origin Petrol Geol 22(01):25–31

Hou J, Zhao L, Zhao W, Feng Z, Wang X, Zeng X (2023) Evaluation of pore-throat structures of carbonate reservoirs based on petrophysical facies division. Front Earth Sci 11:1164751

Hou H, Yun H, Yun X (2010) An integrated approach on carbonate reservoir evaluation by combining borehole image and NMR Logs: a case study in ordovician carbonate, east China. Paper presented at the SPE EUROPEC/EAGE Annual conference and exhibition, Barcelona, Spain. https://doi.org/10.2118/131580-MS

Hu A, Pan L, Hao Y (2018) Origin, characteristics and distribution of dolostone reservoir in Qixia formation and Maohou formation, Sichuan basin China. Marine Origin Petrol Geol 23(2):39–52

Hu Y, Li Z, Guo M et al (2020) Application of X-ray diffraction logging technology in lithology identification of Bohai M structure. Mud Logging Eng 31(03):130–136

Keaton JR (2015) A suggested geologic model complexity rating system. engineering geology for society and territory-volume 6: applied geology for major engineering projects. Springer International Publishing, pp 363–366

Keith CI, Safari A, Aik KL, Thanasekaran M, Mohamed F (2016) Coring parameter optimisation: the secret to long carbonate cores. Paper presented at the offshore technology conference Asia, Kuala Lumpur, Malaysia. https://doi.org/10.4043/26712-MS

Landry CJ, Hart B S, Maša P (2020) Comparison of wireline log and SEM image-based measurements of porosity in overburden shales. Paper presented at the SPE/AAPG/SEG unconventional resources technology conference, Virtual. https://doi.org/10.15530/urtec-2020-3141

Lemmens HJ, Butcher AR, PWSK. B (2011) FIB/SEM and SEM/EDX: a new dawn for the SEM in the core lab? Petrophysics 52: 452–456. Paper Number: SPWLA-2011-v52n6a4

Li J, Sun H, Hou Q (2017) Study of XRD lithology fast identification method. China Petrochem 10:61–62

Li H, Zhu X, Gu Y et al (2019a) Reservoir characteristics and control factors of Qixia formation in the Longnvsi-Guang’an area. Nat Gas Technol Econ 13(03):7–13

Li H, Pan Z, Chen Y et al (2023) A new score system using data-driven approach to rank carbonate gas reservoirs in Sichuan Basin. J Petrol Explor Prod Technol 13:1315–1327

Li M, Liu H, Liang F et al (2019) Prediction of seismic reflection characteristics and distribution of thin layered dolomite reservoir of Qixia Formation in Longnusi Araea[C]. 31th Natural gas academic annual conference. Hefei: institute of petroleum and gas professional committee of China, 319–330

Liu Y, Wang S, Zheng R, Li H (2022) Quantitative characterization of tight rock microstructure of digital core. Geofluids. https://doi.org/10.1155/2022/3554563

Long W, Wang G, Zan C et al (2019) Digital cutting application in offshore exploration. Ocean Eng Equip Technol 6(S1):272–275

Lu F, Tan X, Wang L et al (2021) Characteristics and controlling factors of dolomite reservoirs within shoal controlled karst in the middle permian Qixia formation central Sichuan basin. Acta Sedimentol Sin 39(02):456–469

Mahiout S, Clerke E A, Belowi A, Qubaisi K, Ammar Q (2014) Complex gas bearing carbonate reservoir evaluation: a case study from Saudi Arabia. Paper presented at the SPWLA 55th Annual logging symposium, Abu Dhabi, United Arab Emirates. Paper Number: SPWLA-2014-RRRR

Mubarak Y, Koeshidayatullah A (2023) Hierarchical automated machine learning (AutoML) for advanced unconventional reservoir characterization. Sci Rep 13:13812

Muther T, Qureshi HA, Syed FI et al (2022) Unconventional hydrocarbon resources: geological statistics, petrophysical characterization, and field development strategies. J Petrol Explor Prod Technol 12:1463–1488

Ni P, Chen W (2018) Application of X-ray diffraction to whole-rock logging in Bohai Oilfiled. Mar Geol Front 34(05):56–60

Peng C (2022) Multi-resolution storage of digital core and analysis of connected area. Sci Technol Eng 22(33):14608–14616

Qu L, Sun W, Du H et al (2014) Characterization technique of pore structure by 3D digital core based on CT scanning and its application: an example from Sangonghe formation of 116 well field in mobei oilfield. Geoscience 28(01):190–196

Ren C, Zhao X, Chen W et al (2019) Geophysical characteristics of Qixia formation in southwestern Sichuan Basin. Sci Technol Eng 19(34):80–85

Seddik I A, Singh M, Al W et al (2022) Integration of extra deep azimuthal resisitivity application with formation evaluation technologies reduces uncertainties and enchances reservoir navigation in the first extended reach well in a carbonate reservoir of a mature field: a case history from Abu Dhabi Onshore. Paper presented at the international petroleum technology conference, Riyadh, Saudi Arabia. https://doi.org/10.2523/IPTC-22637-MS

Serkan D, Kaan D, Tayfun T, Mamta A, Ding J (2014) A workflow for intelligent data-driven analytics software development in oil and gas industry. Paper presented at the SPE Annual technical conference and exhibition, Amsterdam, The Netherlands. https://doi.org/10.2118/170859-MS

Sheng J, Yang X, Li G et al (2019) Application of multiscale X-CT imaging digital core technique on observing micro-pore structure of carbonate reservoirs. Geosicence 33(3):653–661

Srimoyee B, Marko M, Jeffrey Y, Dwight F, Jon O, Singh A (2013) Causal analysis and data mining of well stimulation data using classification and regression tree with enhancements. Paper presented at the SPE Annual technical conference and exhibition, New Orleans, Louisiana, USA. https://doi.org/10.2118/166472-MS

Sun H, Belhaj H, Bera A (2021) New insight of correlation between digital rock analysis and petrographic study for rock type classification within carbonate reservoir transition zone. Arabian J Geoseci 14(367):1–13

Tadayoni M, Khalilbeyg M, Bin JR (2020) A new approach to heterogeneity analysis in a highly complex carbonate reservoir by using borehole image and conventional log data. J Petrol Explor Prod Technol 10:2613–2629

Yan J, Pu X, Zhou L et al (2015) Naming method of gine-grained sedimentary rocks on basis of X-ray diffraction data. China Petrol Explor 20(01):48–54

Yan P, Luo L, Liu D, Chang J, Chen J (2023) New Reservoir quality evaluation technique for fractured carbonates. In: Lin, J. (eds) Proceedings of the 2022 International Petroleum and Petrochemical Technology Conference. IPPTC 2022. Springer, Singapore

Yao S, Cheng H, **ong Z et al (2022) Method characterizing shale oil reservoirs in Jimsar based on quantitative digital analysis of cuttings. Oil Drill Prod Technol 44(01):117–122

Yu W, Zhang R, Miao X et al (2020) Application of XRD mineralogical analysis techique in Yangshuiwu buried hill exploration. Mud Logging Eng 31(01):35–41

Yu H (2018) Study of X-ray diffraction technology in carbonate lithology identification in Gucheng area. 30(5): 65-66

Zhang Y, Zhang Y, Hou Y et al (2021) Application of X-ray diffraction analysis technique in special lithology identification of Shulu Sag. Sino-Global Energy 26(S1):78–82

Zhang Q, Liu X, Shi W et al (2022) Analysis of carbonate rocks microstructure features based on micro CT and scanning electron microscopy. Sci Technol Eng 22(34):15043–15051

Zhao J, Pan J, Hu Y et al (2021) Digital rock physics-based studies on effect of pore types on elastic properties of carbonate reservoir Part 1: imaging processing and elastic modelling. Chin J Geophys 64(02):656–669

Zhu G, Wang X, Rui G (2013) Comprehensive formation evaluation of HF carbonate reservoir by integrating the static and dynamic parameters. Paper presented at the SPE Asia Pacific oil and gas conference and exhibition, Jakarta, Indonesia, October 2013. https://doi.org/10.2118/165896-MS

Funding

This work was supported by the Program for Guangdong Introducing Innovative and Entrepreneurial Teams (No. 2017ZT07G264); Shenzhen Peacock Plan (No. KQTD2017033114582189) and The Shenzhen Science and Technology Innovation Committee (JCYJ20170817152743178).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

On behalf of all the co-authors, the corresponding author states that there is no conflict of interest.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Xu, H., Wang, G., Xu, W. et al. A novel score system to evaluate carbonate reservoir combining microscale and macroscale parameters. J Petrol Explor Prod Technol 14, 1101–1112 (2024). https://doi.org/10.1007/s13202-024-01755-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13202-024-01755-1